Round-head keyhole sartorius

A sewing machine and buttonhole technology, which is applied to sewing machine components, needle holders for sewing machines, sewing equipment, etc., can solve the problems of wear and sintering of sliding parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

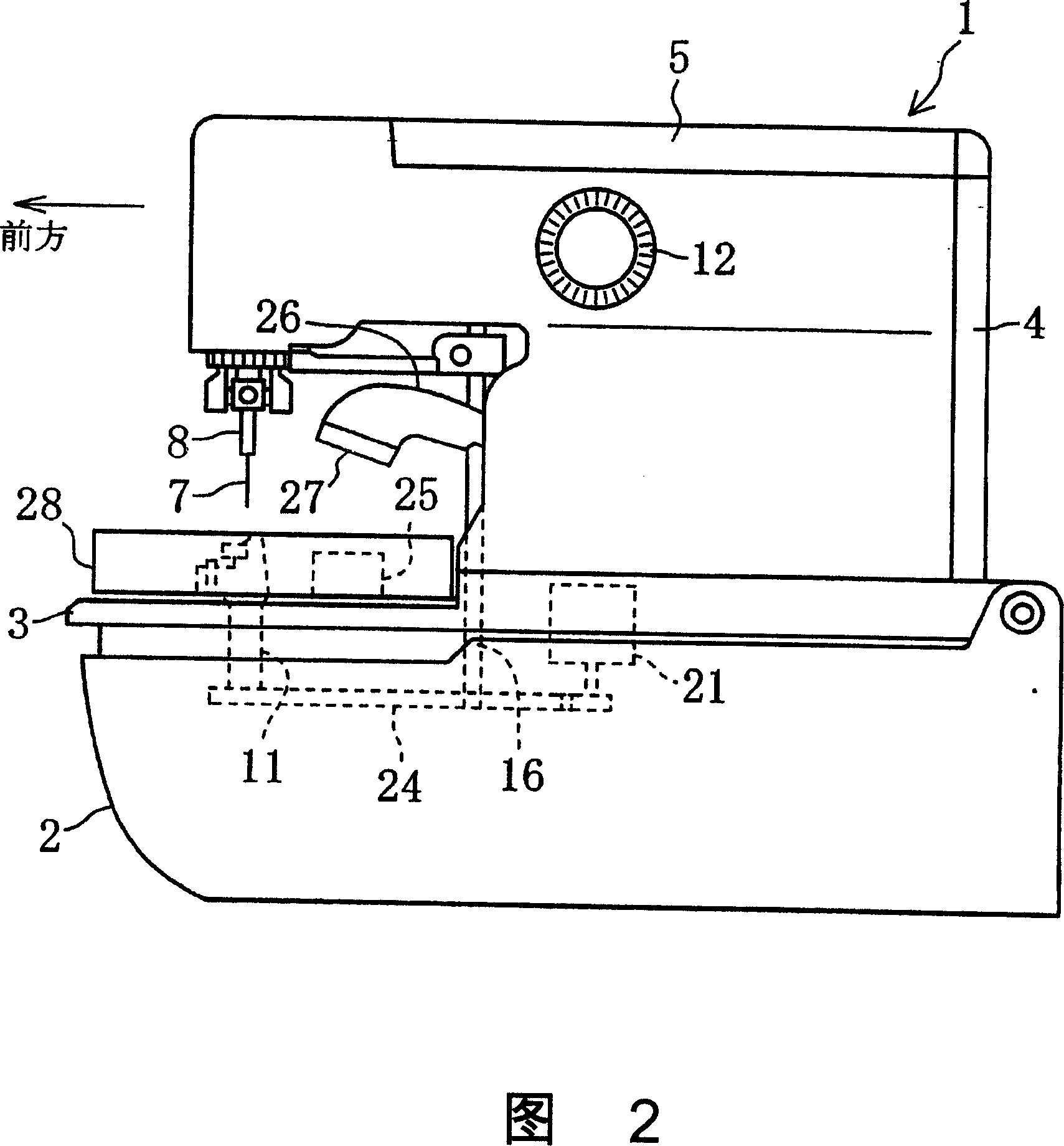

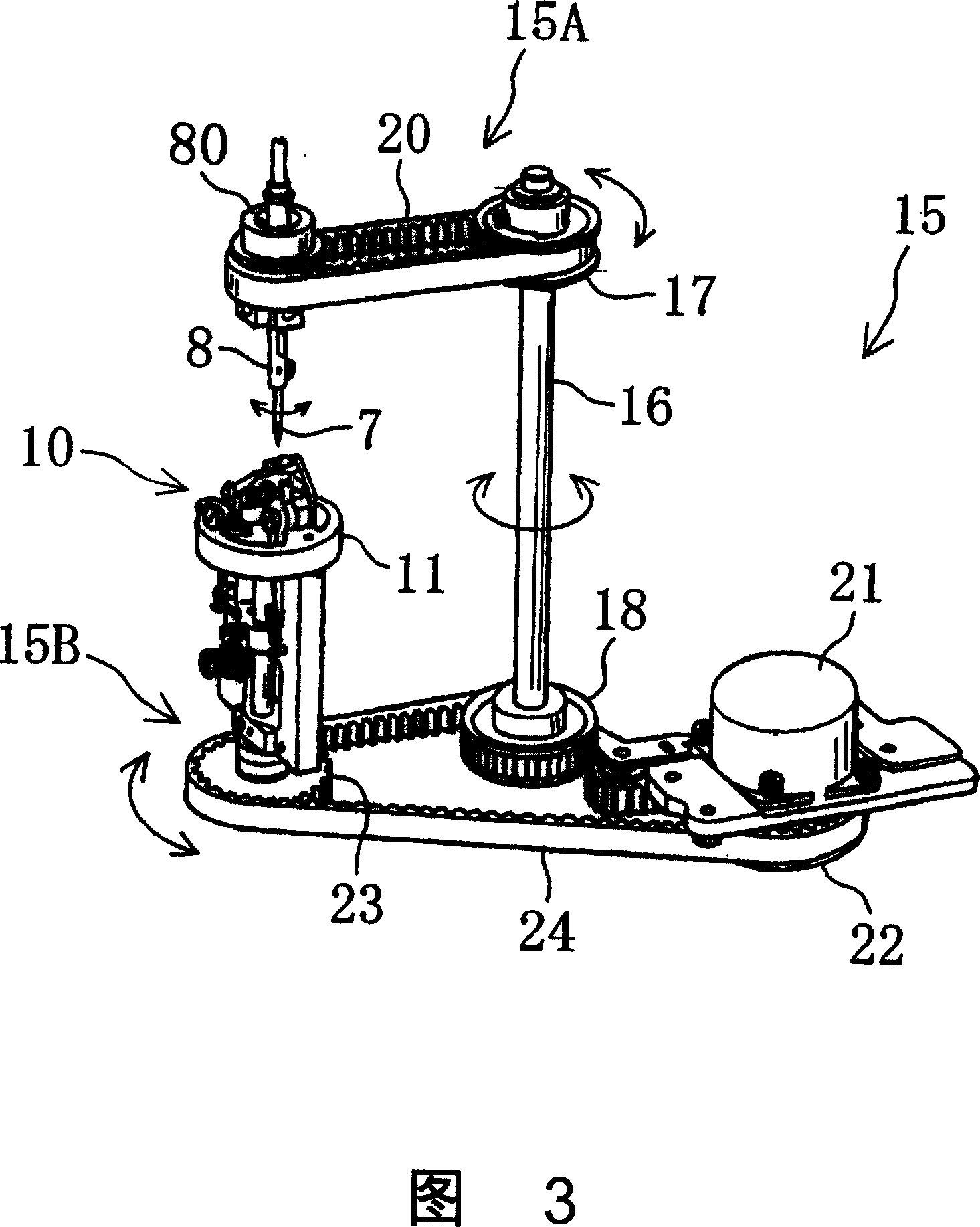

[0026] In order to explain this invention in detail, it demonstrates referring drawings.

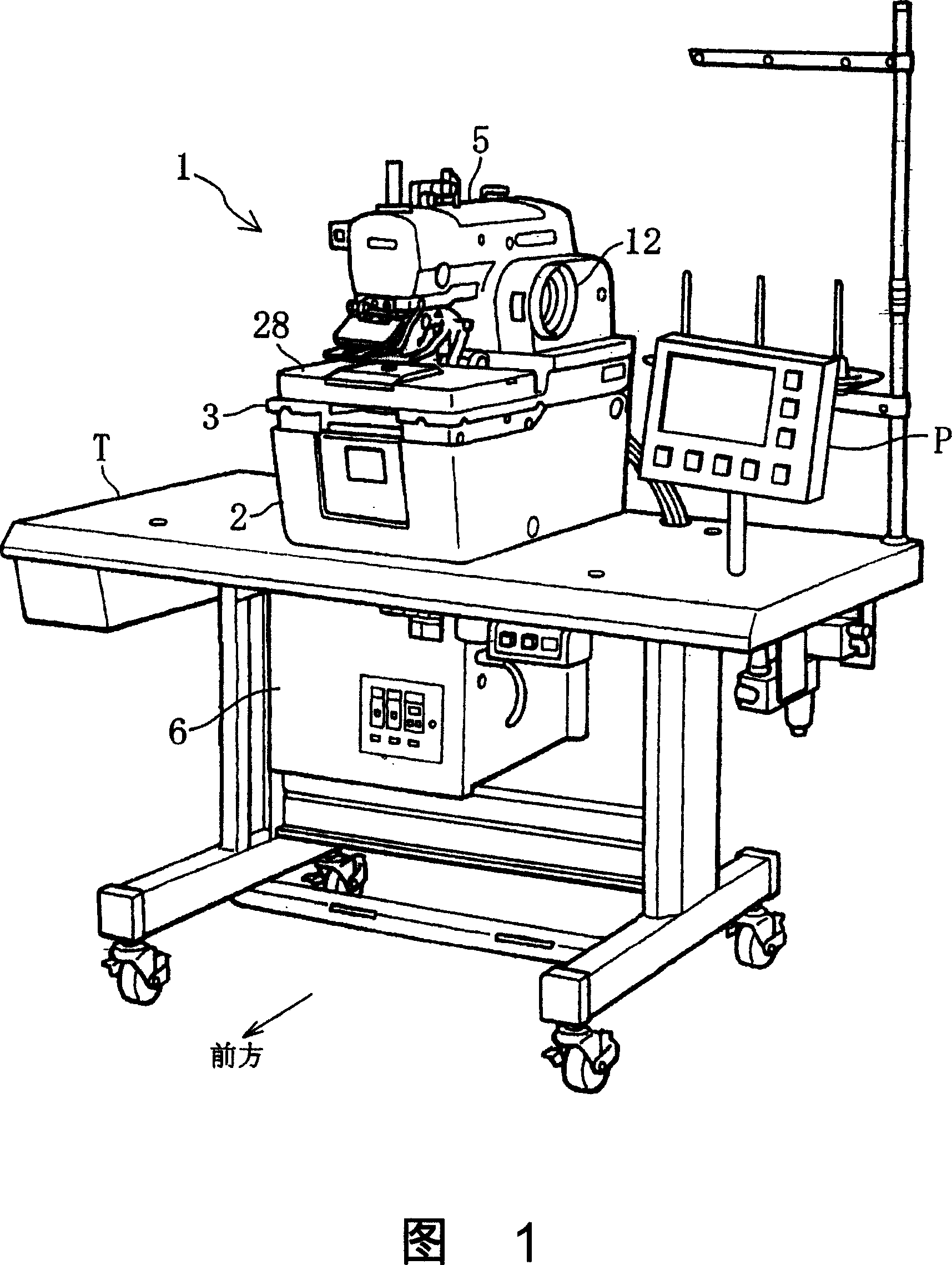

[0027] As shown in Fig. 1 and Fig. 2, the eyelet buttonhole sewing machine 1 is a sewing machine for sewing eyelet eyelet stitches, comprising: a substantially rectangular box-shaped machine base 2; a bottom plate 3 carried on the machine base 2; A pillar portion 4 erected from the rear portion of the bottom plate portion 3 ; a case portion 5 extending forward from an upper portion of the pillar portion 4 , and the like. The buttonhole sewing machine 1 is carried and fixed on the sewing machine table T.

[0028] On the upper side of the sewing machine table T, there is provided an operation panel P etc. for instructing various operations such as selecting one from a variety of eyelet buttonhole stitches, and on the lower side of the sewing machine table T, a A control device 6 composed of a microcomputer for controlling the action of each mechanism.

[0029] A hollow (tubular) needle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com