Heat dissipating method for sewing machine with direct-drive motor

A heat dissipation method and sewing machine technology, which is applied to sewing machine components, sewing equipment, electromechanical devices, etc., can solve the problems that cannot be ruled out, such as the temperature of the koke sewing machine and the temperature increase of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

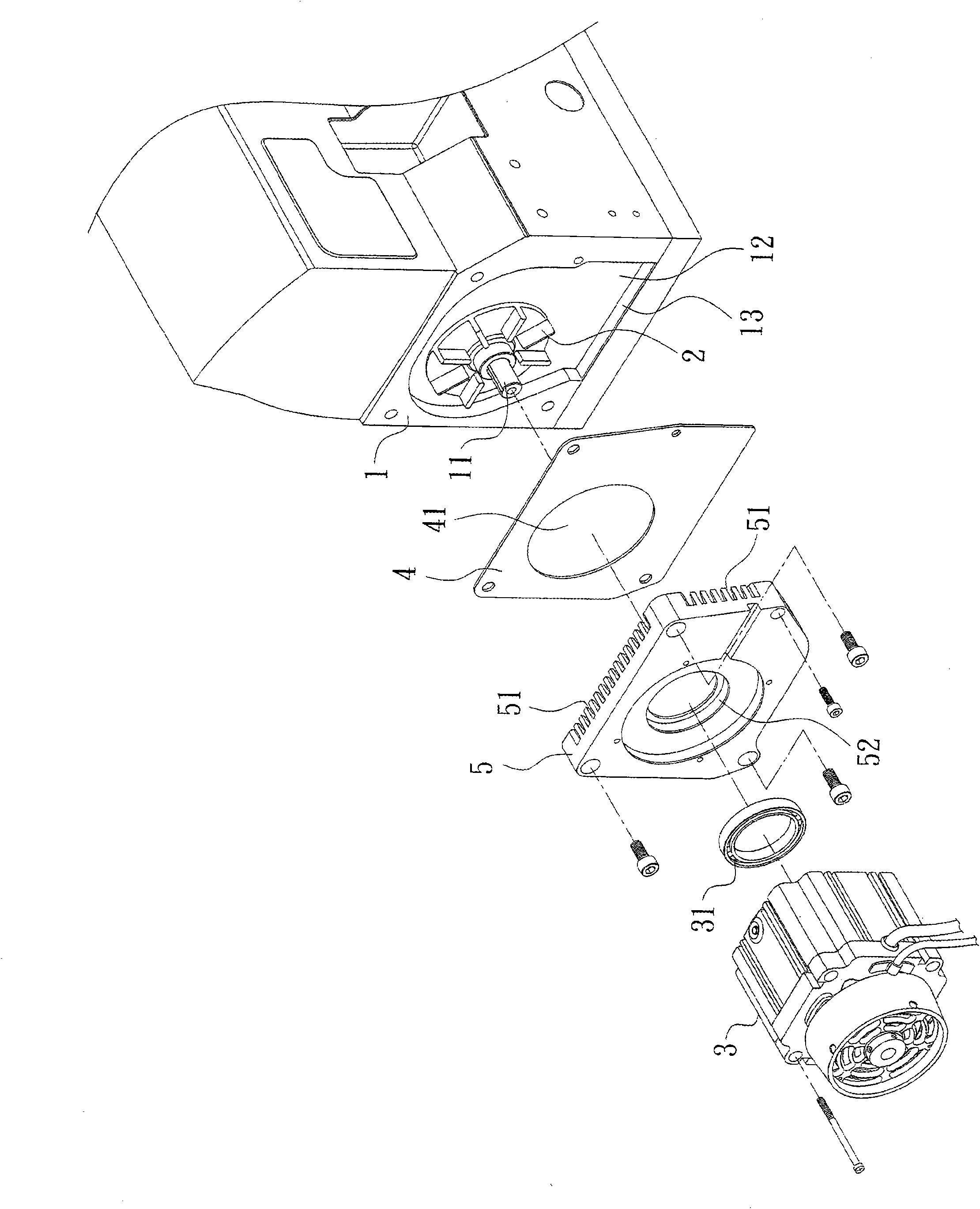

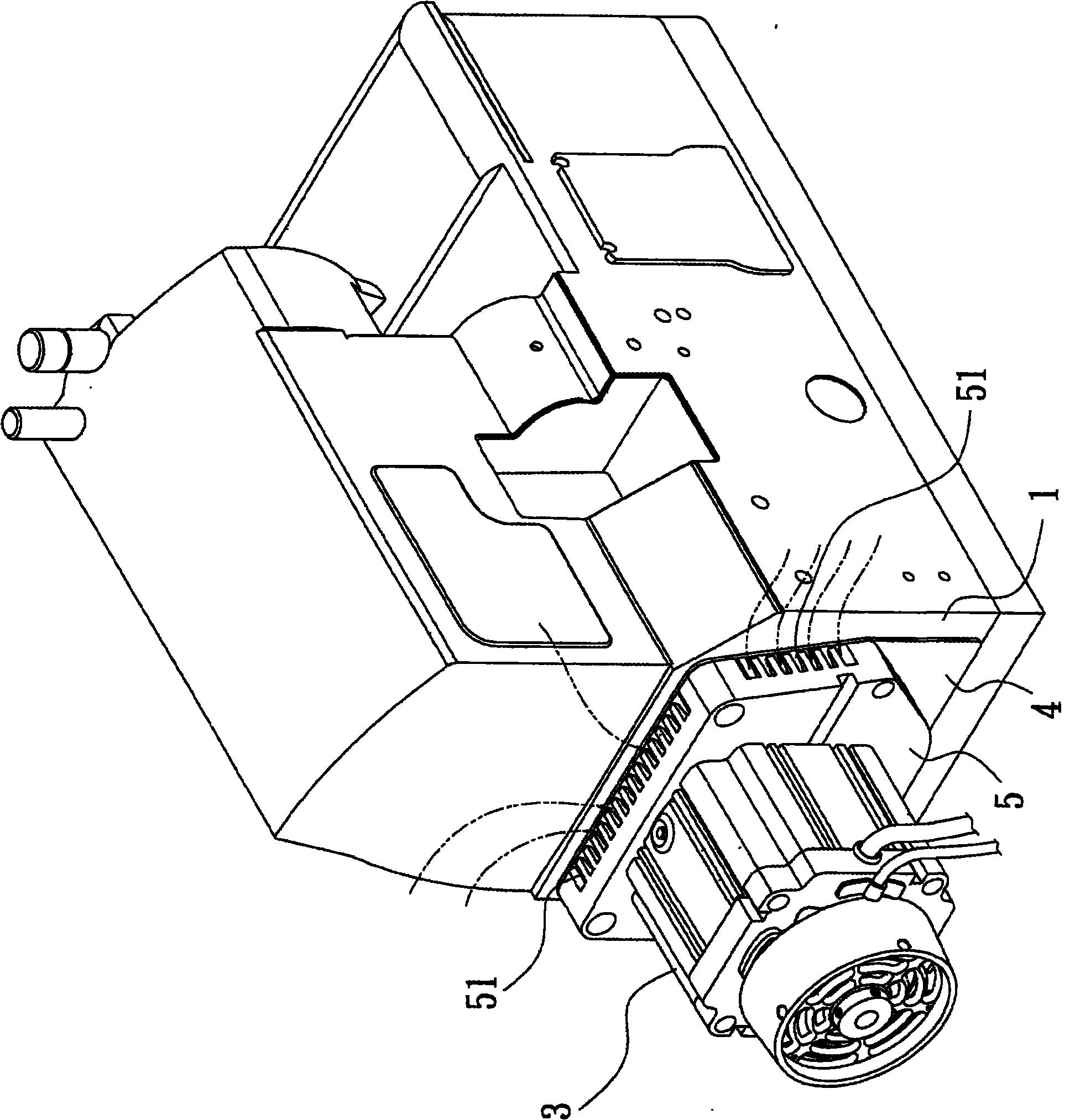

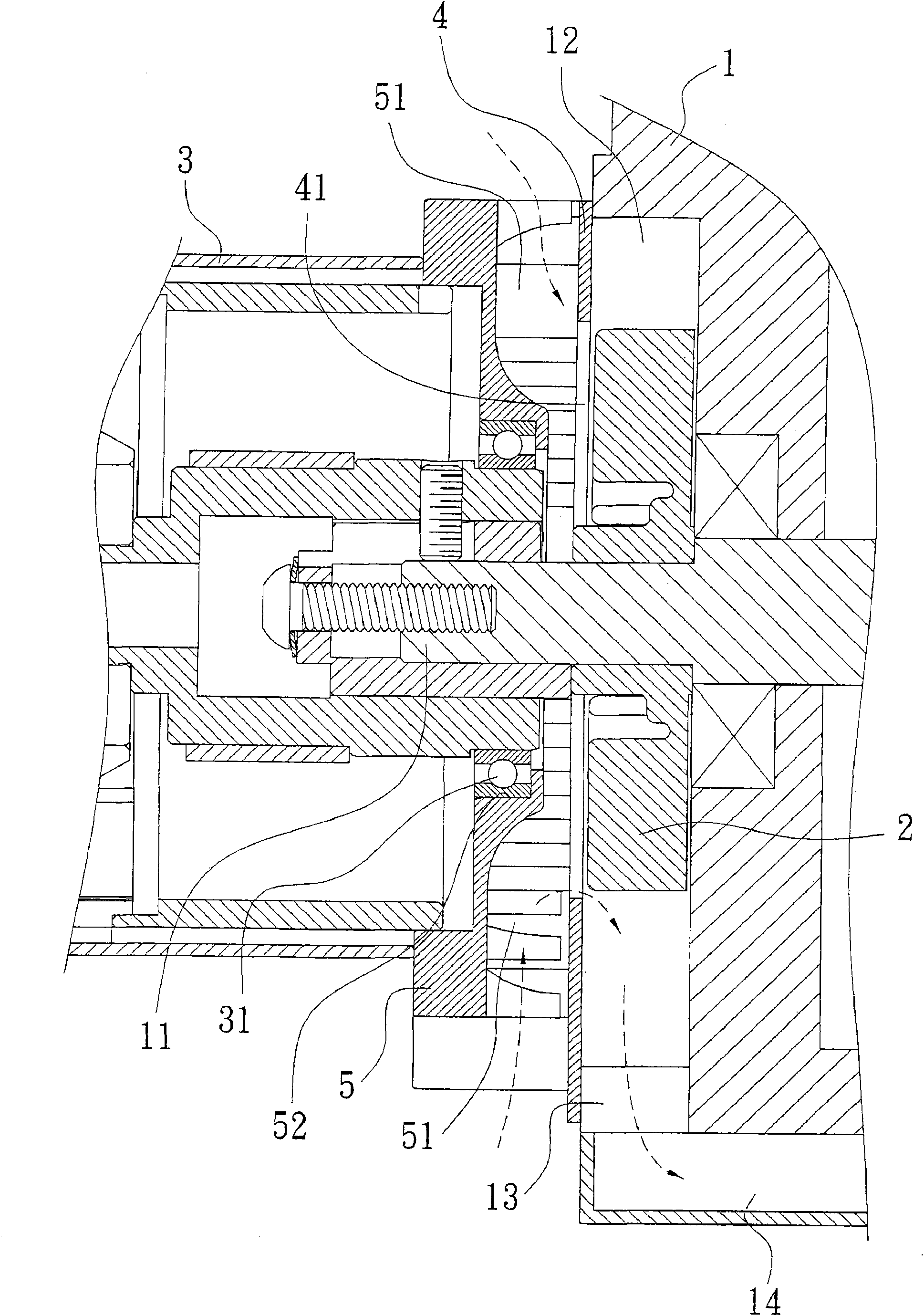

[0026] In order to make the technical content of the present invention, the purpose of the invention and the effects it can achieve can be disclosed more completely and clearly, the following will be described in detail in conjunction with the accompanying drawings:

[0027] First, see Figure 1 ~ Figure 3 The three-dimensional decomposition and cross-sectional schematic diagram of the heat dissipation method of a sewing machine with a direct-drive motor shown in the present invention are mainly provided with an air guide groove 12 at the end of the power input spindle 11 of the sewing machine head part 1, and the air guide groove 12 A channel 13 is provided below to connect to the oil pan 14, and a fan 2 is correspondingly arranged on the main shaft 11, and the end of the main shaft 11 is correspondingly combined with a direct drive motor 3, wherein:

[0028] A partition 4 is correspondingly assembled on the end face of the machine head part 1, and the center of the partition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com