Three-in-one oil cooling electric driving structure

An electric drive, three-in-one technology, applied in the field of three-in-one oil-cooled electric drive structure, can solve the problems of large oil leakage risk, complicated production process and assembly process, and increased material cost, so as to reduce the risk of oil leakage, The effect of solving uneven cooling and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

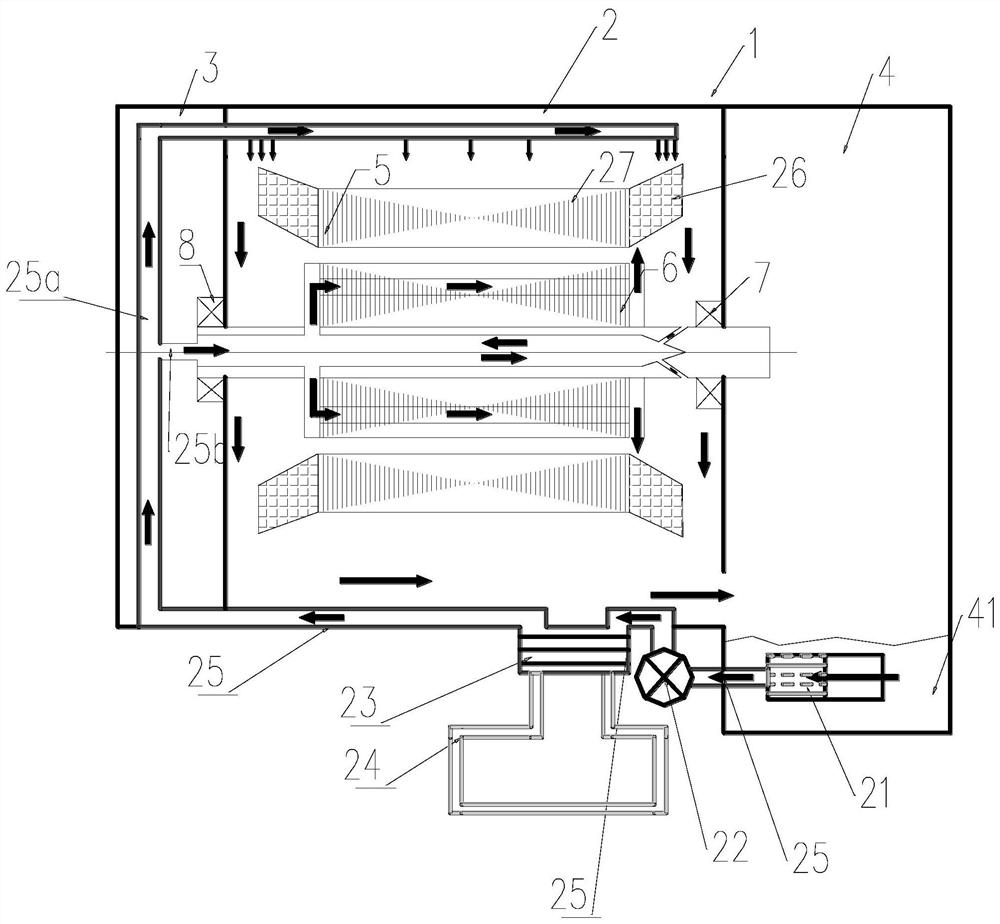

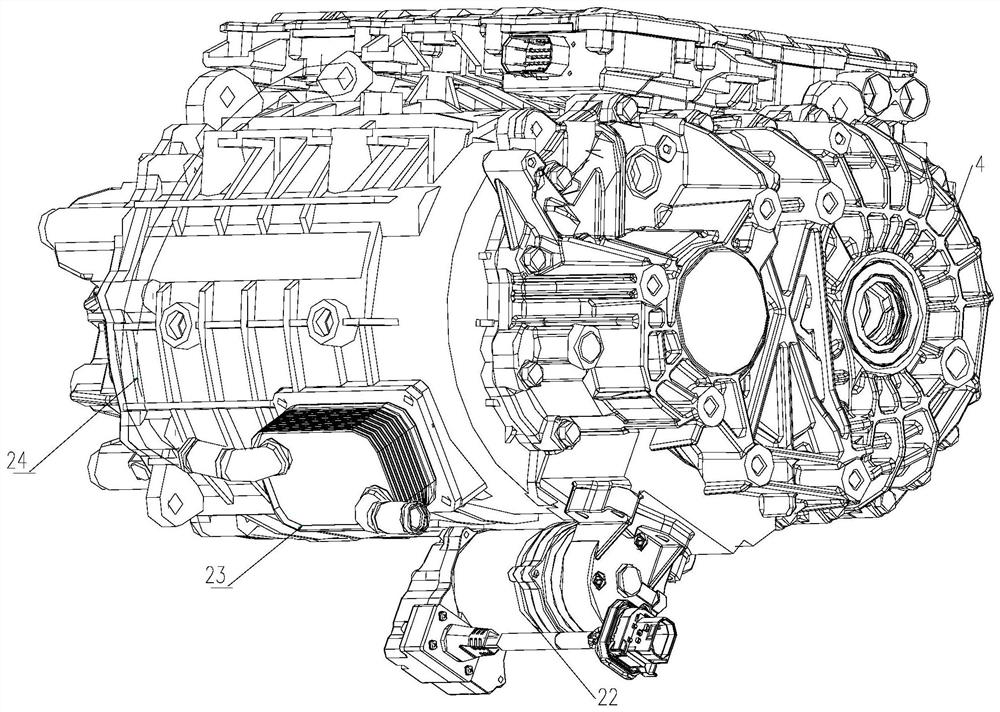

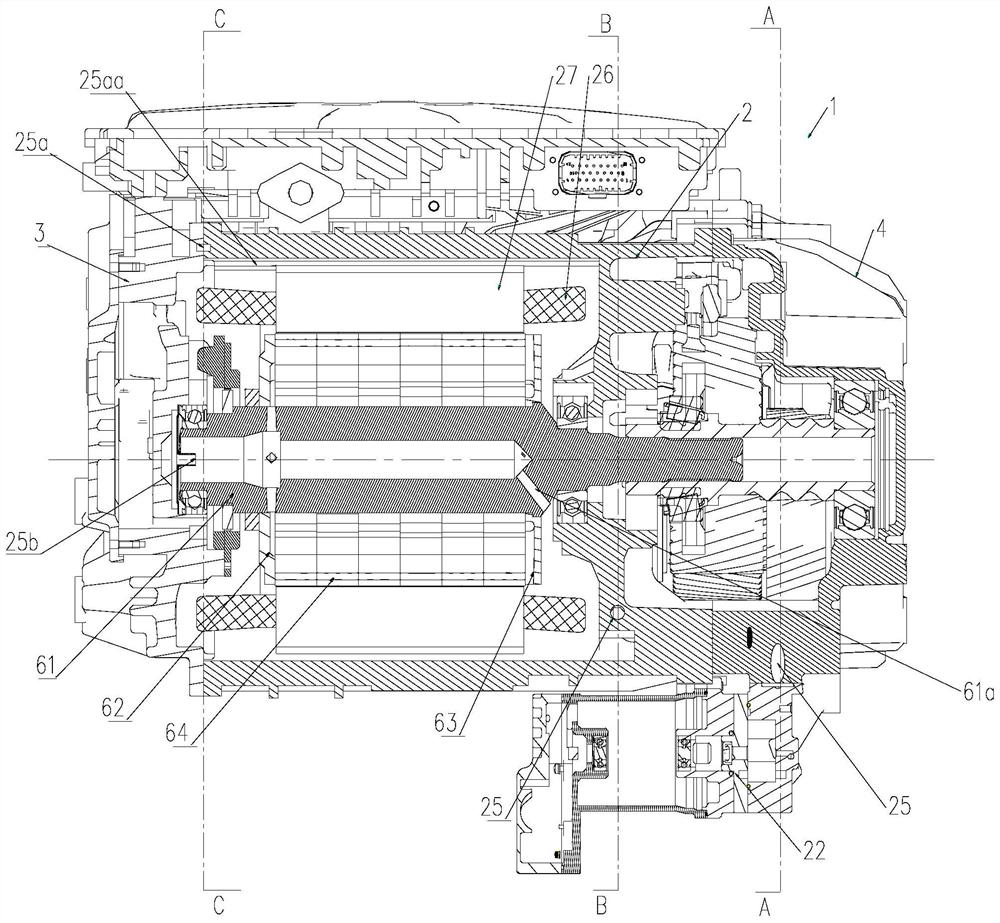

[0043] Embodiment: This application provides a three-in-one oil-cooled electric drive structure, which mainly uses the lubricating oil of the reducer itself. After filtering through the filter, the oil pump provides power, and after cooling, it enters the electric drive. Among them, the oil circuit is cooled Finally, the rear end cover is divided into two paths, one path enters the rotor to cool the rotor and bearings, and the other path enters the housing to cool the stator, and finally the oil drops to the lower part of the motor due to power, and flows back to the reducer to complete the entire cooling cycle. combined reference Figure 1 to Figure 13 , the three-in-one oil-cooled electric drive structure 1 includes: an oil-cooled structure from the reducer integrated with the electric drive housing to the rear end of the motor, a rotor cooling structure, and a stator cooling structure. The electric drive housing includes a motor housing 2, a rear end cover 3, and a reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com