Patents

Literature

32results about How to "Solve the problem of uneven cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

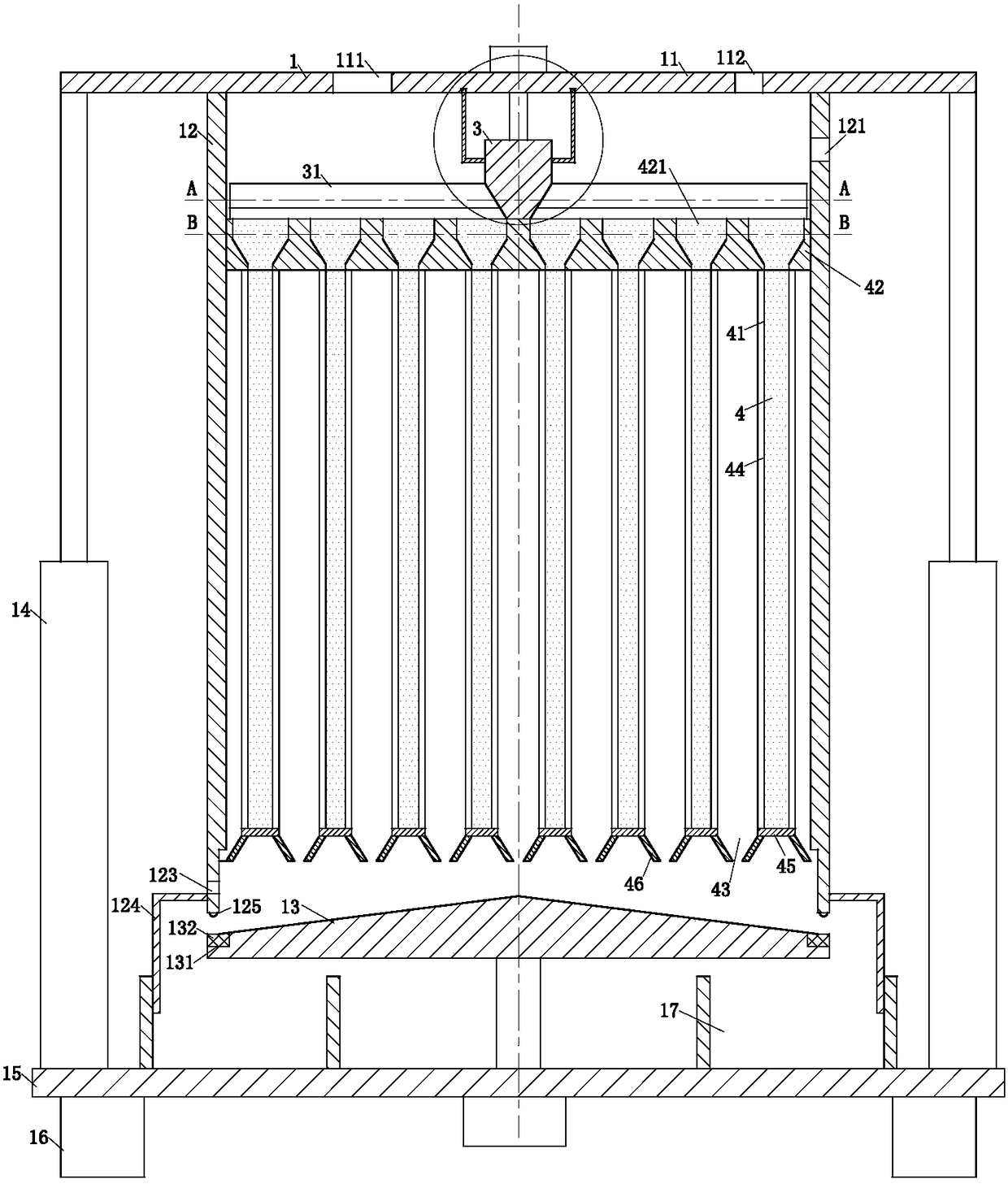

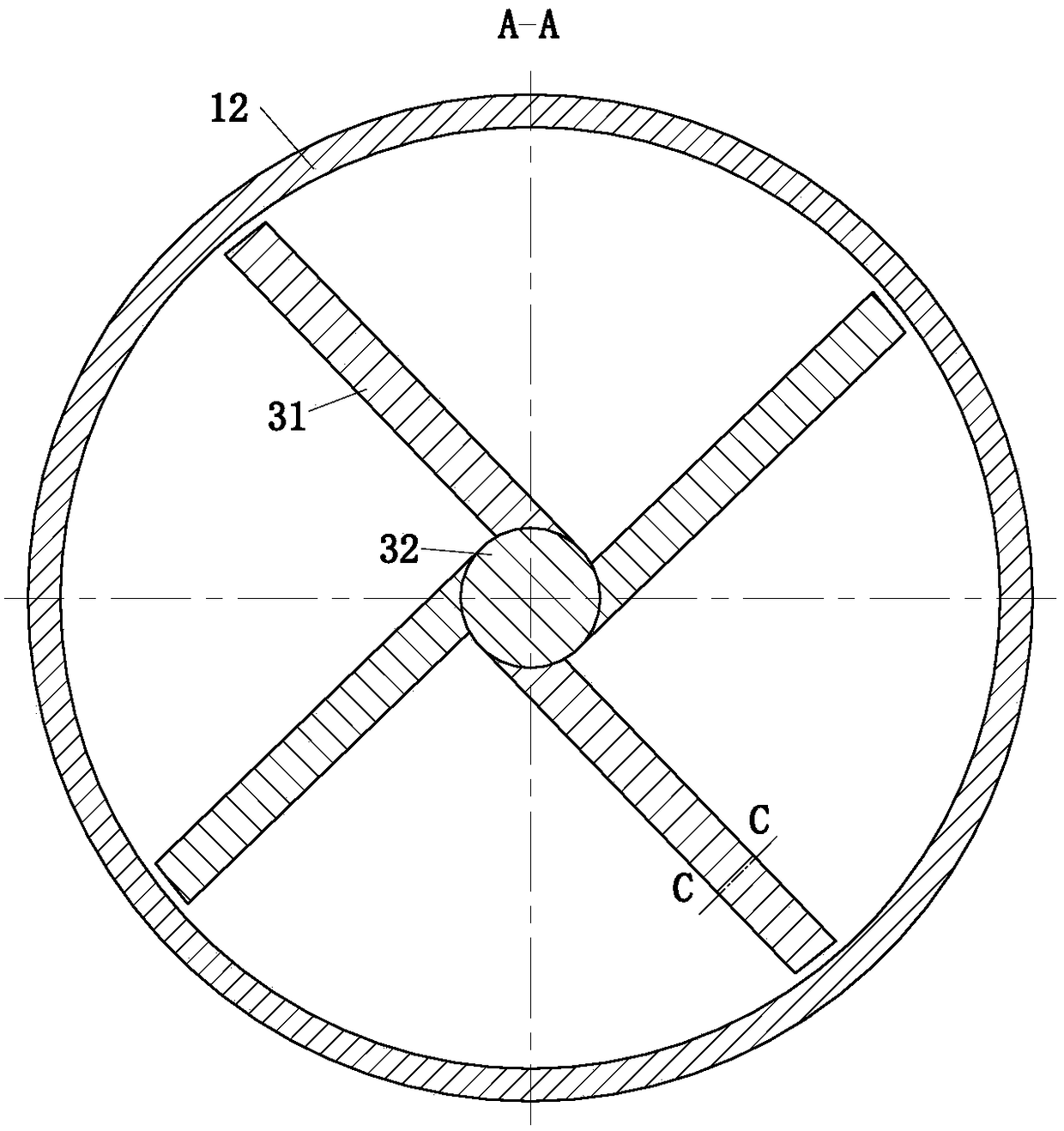

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

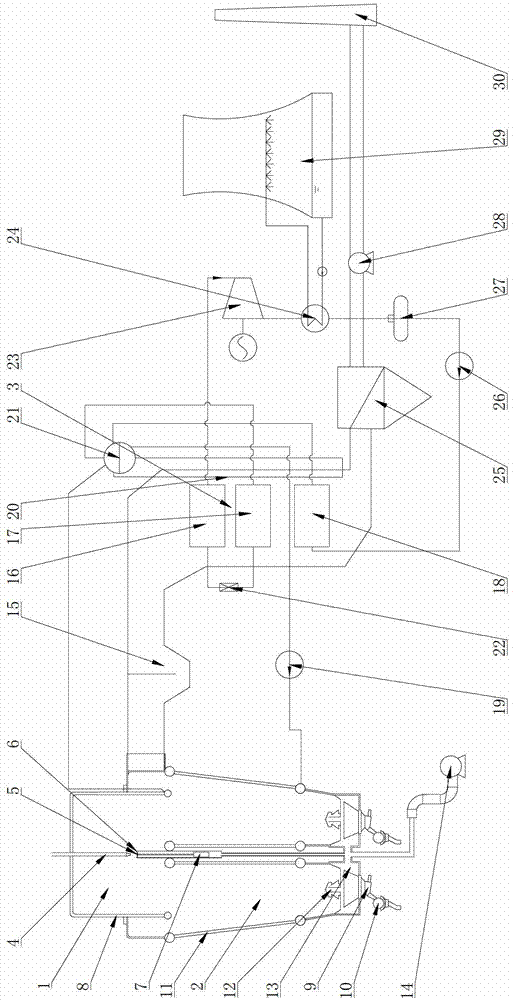

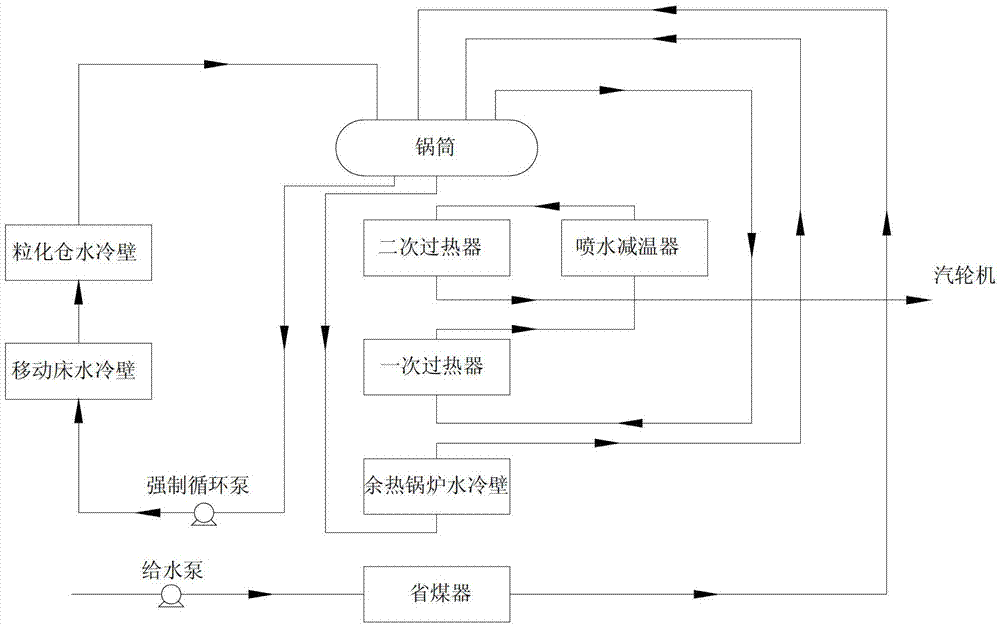

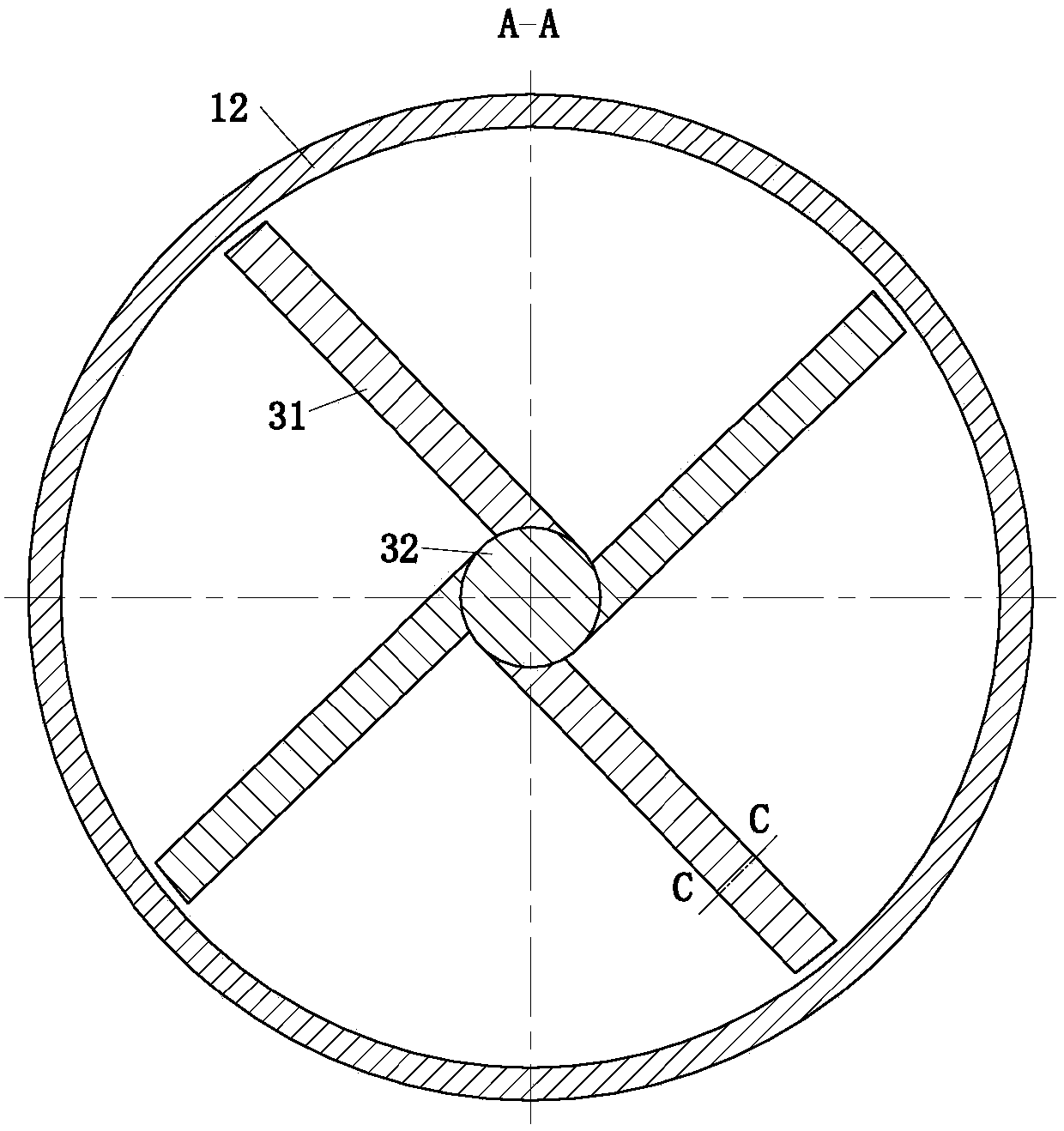

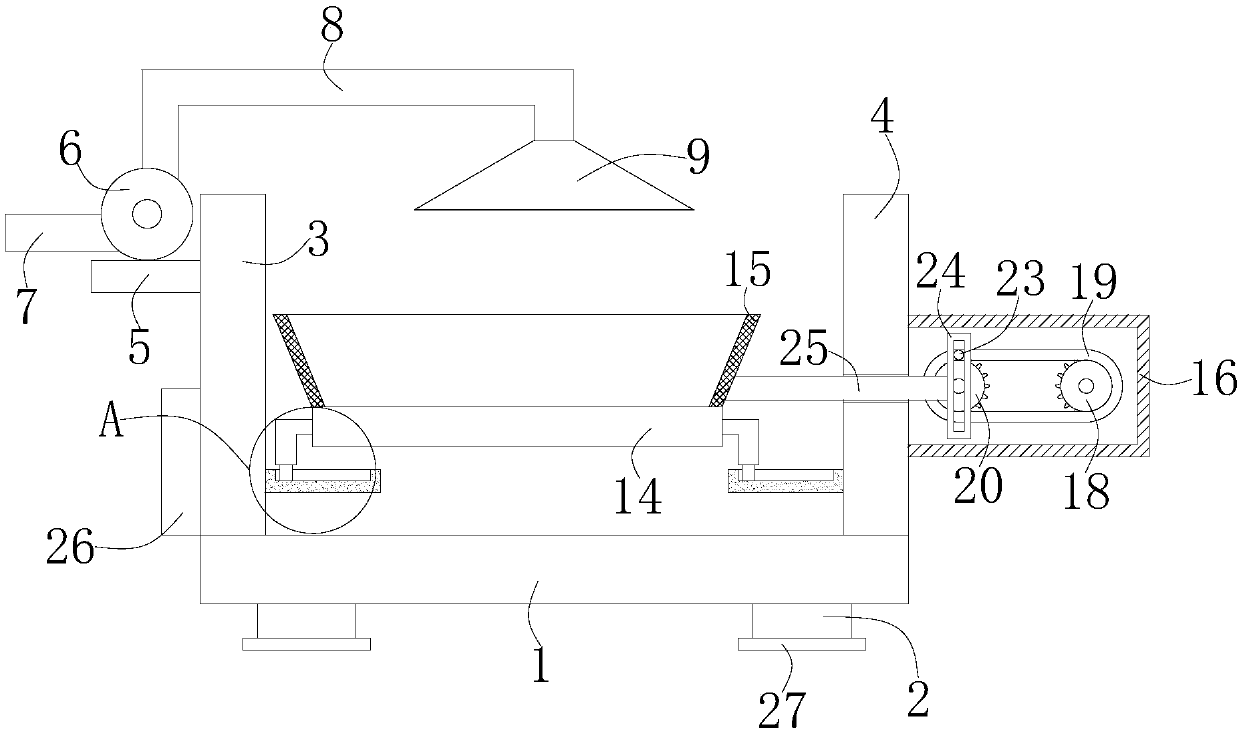

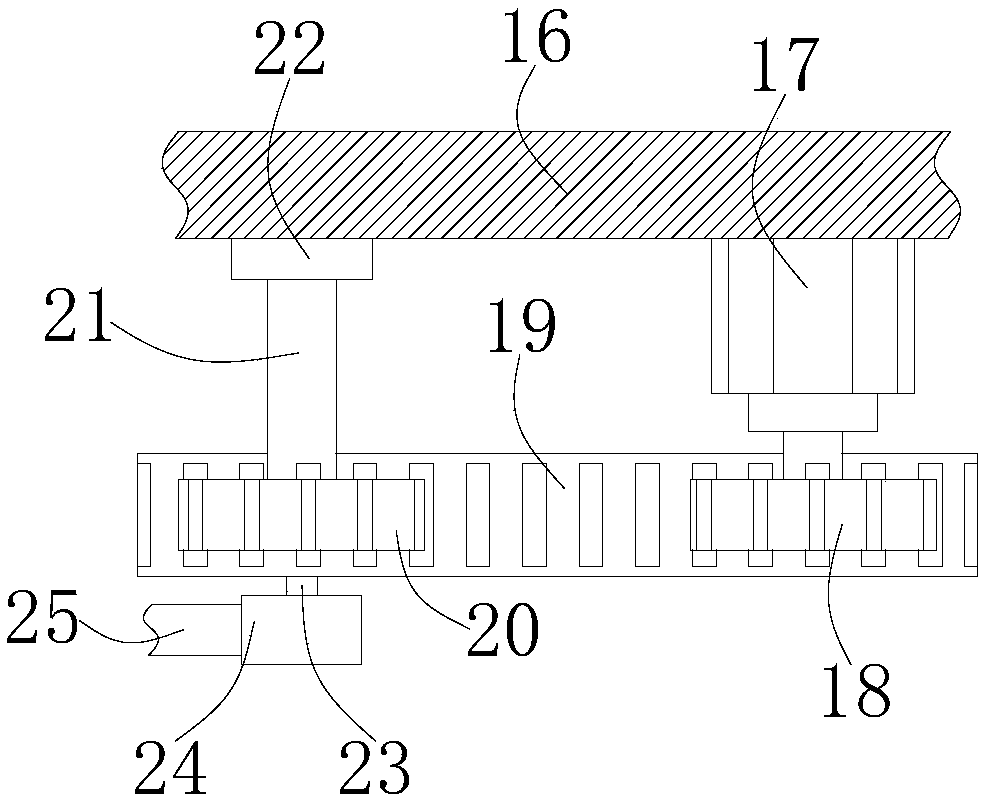

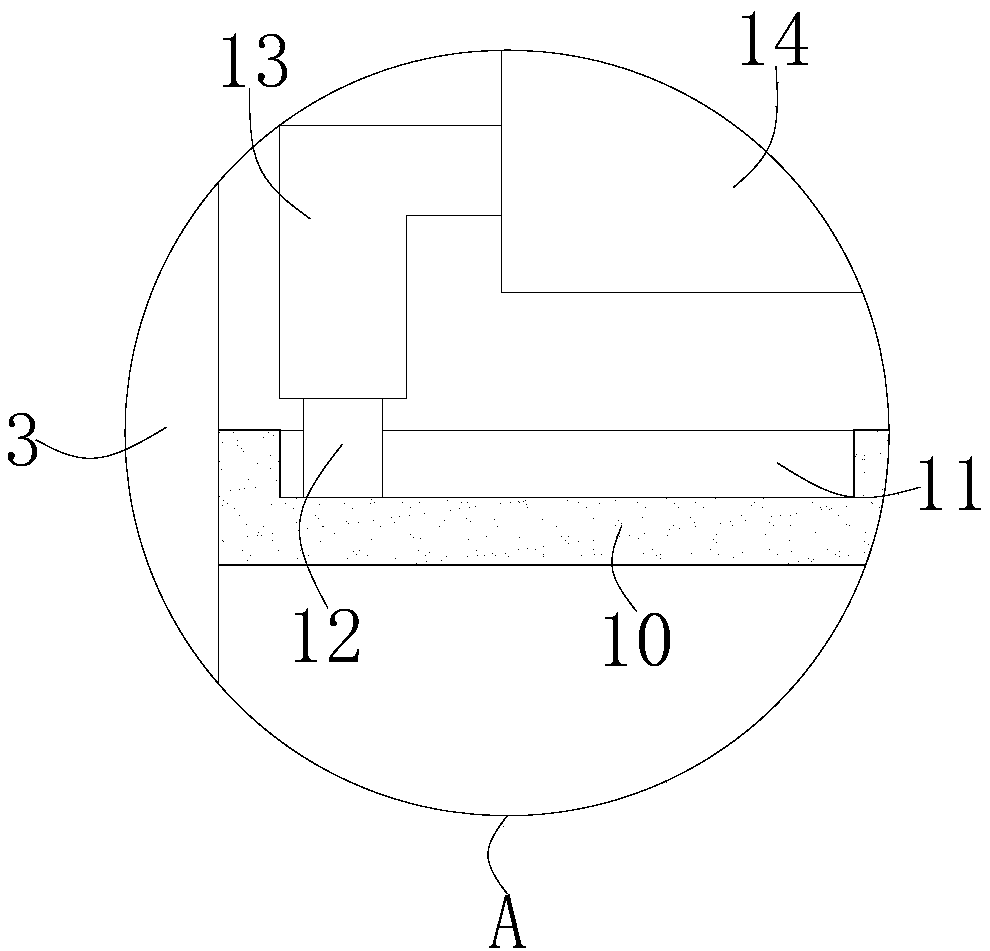

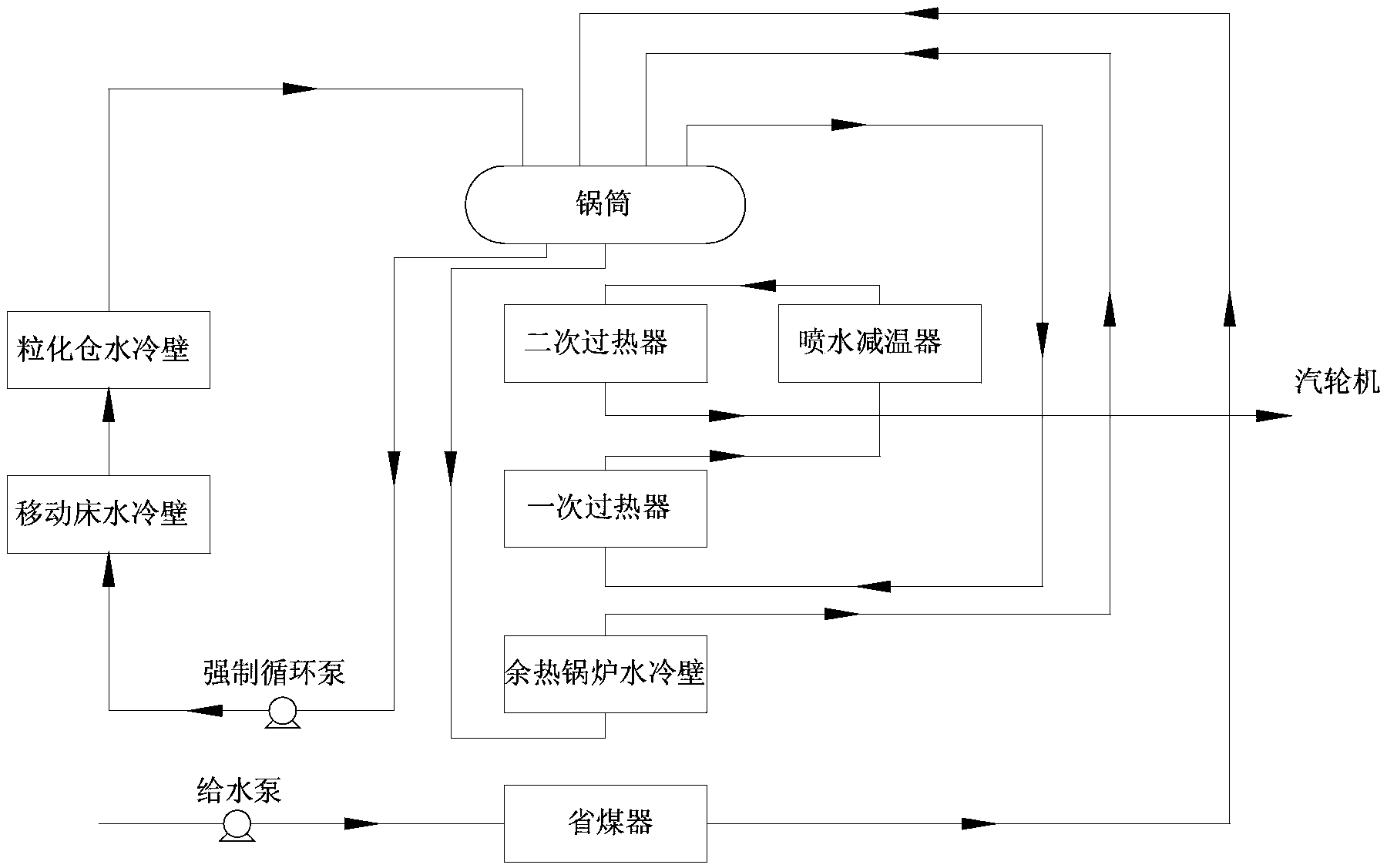

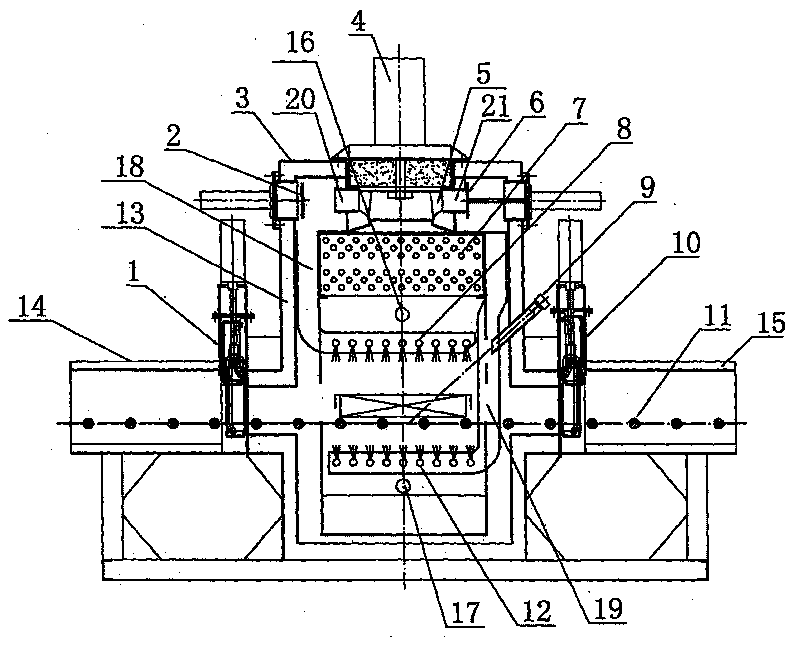

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

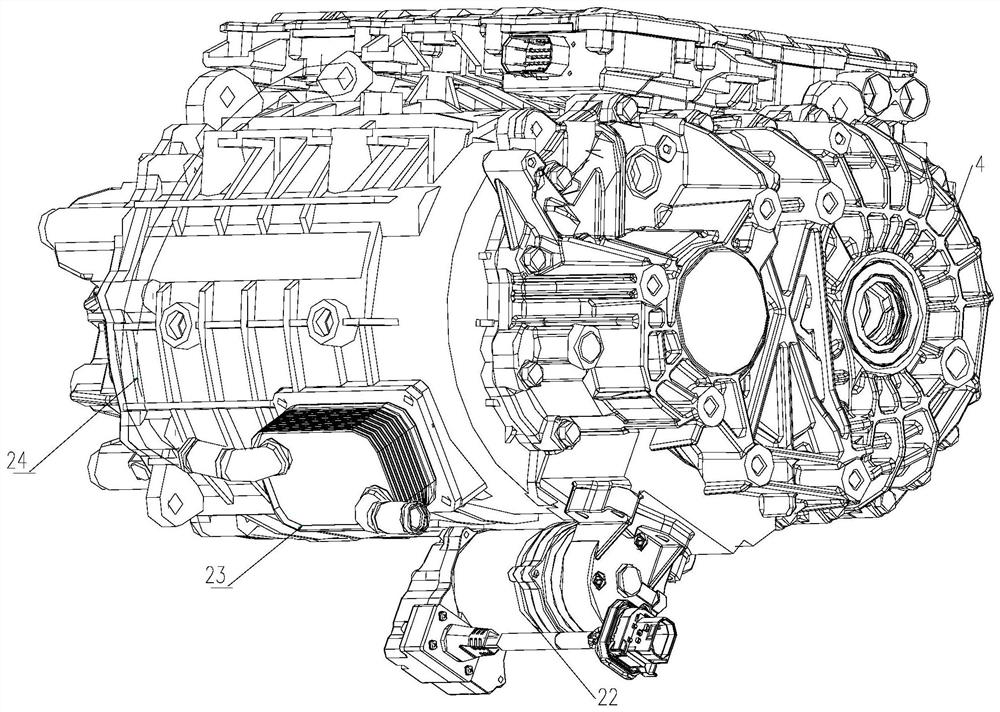

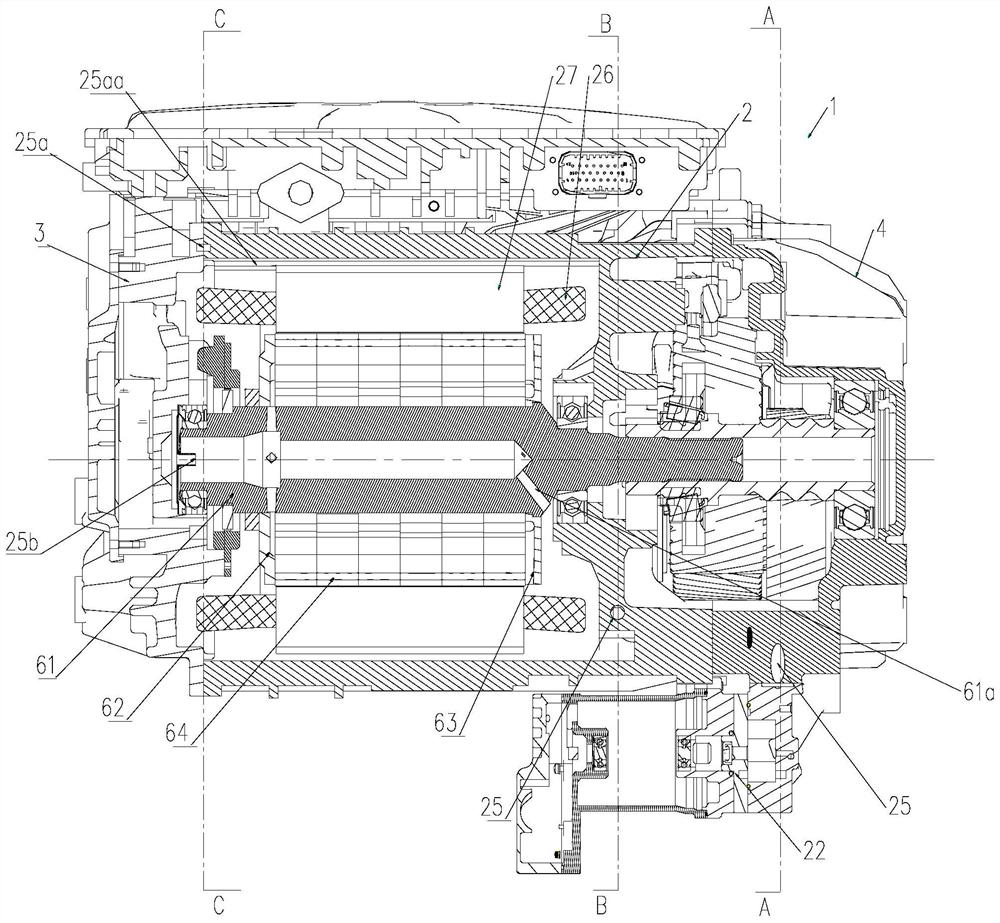

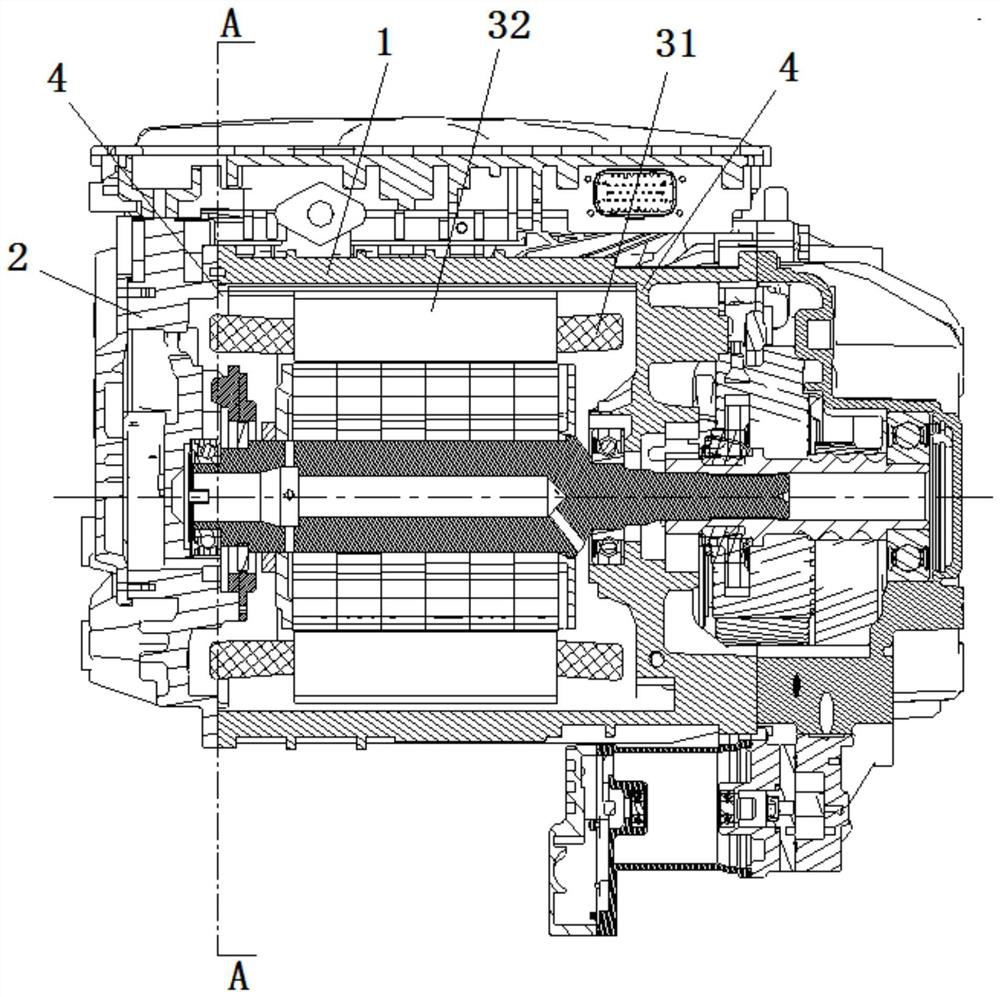

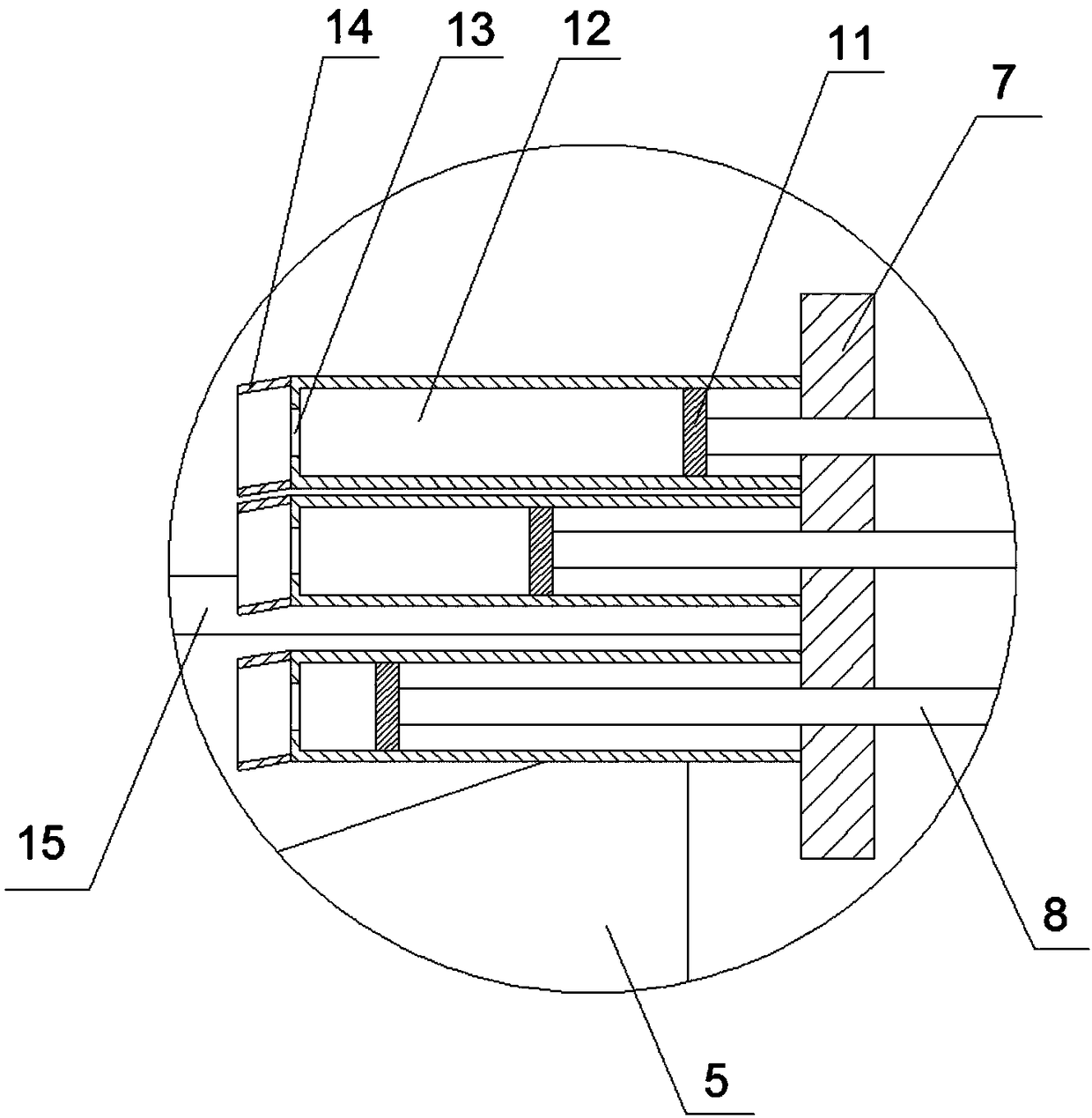

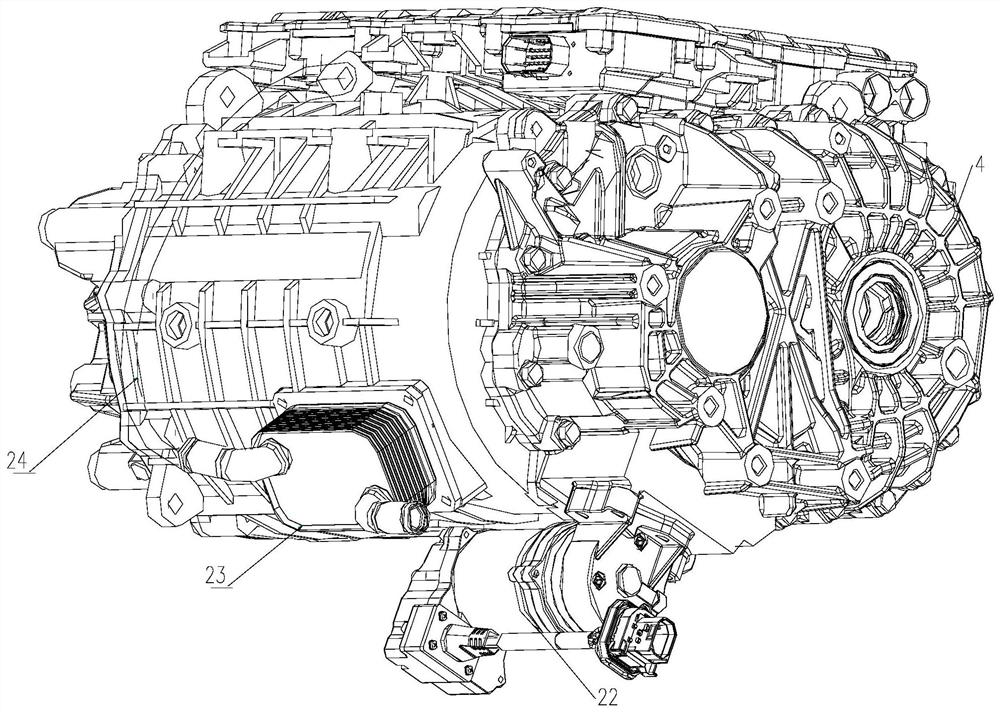

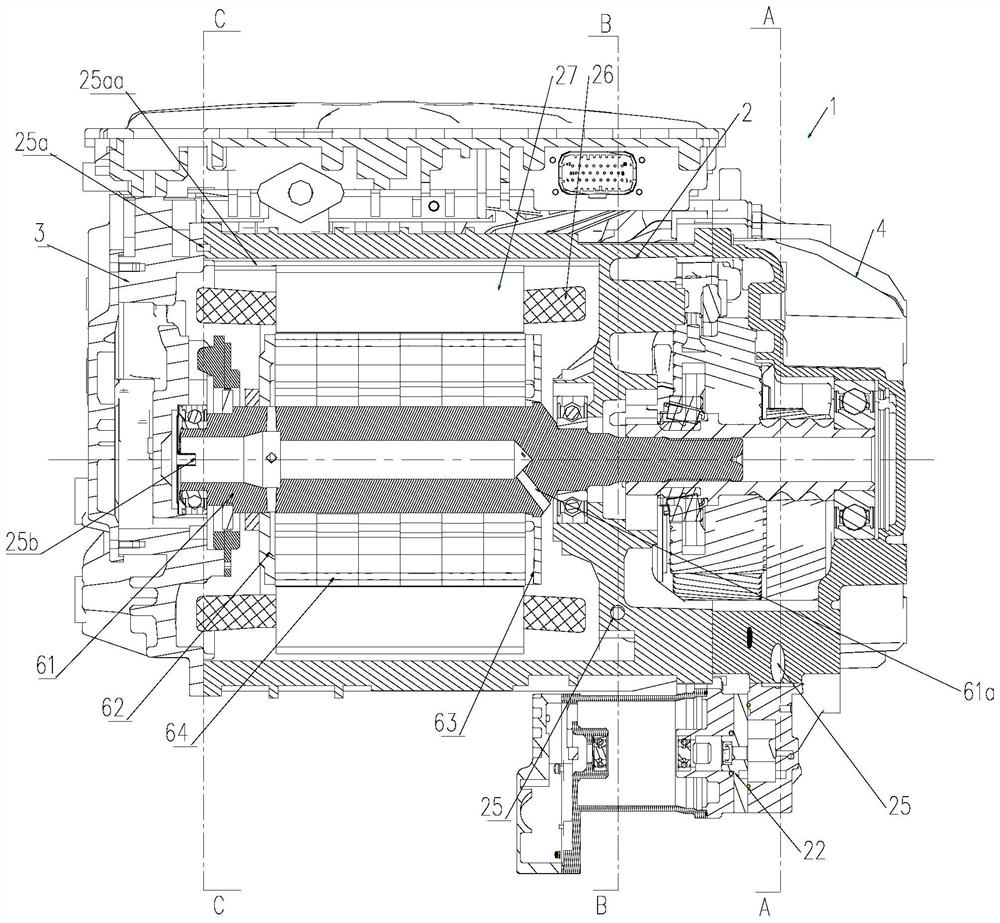

Three-in-one oil cooling electric driving structure

ActiveCN112421889AReduce the risk of oil spillsGuaranteed cooling effectMagnetic circuit rotating partsElectric machinesElectric machineReduction drive

The invention discloses a three-in-one oil cooling electric drive structure which comprises a speed reducer-to-motor rear end oil cooling structure integrated with an electric drive shell, a rotor cooling structure and a stator cooling structure. The speed reducer-to-motor rear end oil cooling structure conveys cooling oil in a speed reducer shell into a main oil way of the motor shell, the main oil way is divided into a first oil way and a second oil way on a rear end cover, the first oil way is communicated with the stator cooling structure, and the second oil way is communicated with the rotor cooling structure. The stator cooling structure is used for introducing cooling oil into the upper part of the electric drive, and directionally cooling the stator through an oil spraying hole ina stator oil distribution channel in the motor shell; the rotor cooling structure is used for rotating and throwing cooling oil through a rotor to achieve cooling. A circulating oil way is connected through the structural design of the shell, the oil way is shunted on the shell, cooling of the stator and the rotor is guaranteed, an additional oil distributing structure and an additional copper pipe are not needed, the integration degree of oil cooling electric drive is improved, the cost is reduced, and the risk of oil leakage of an oil pipe is reduced.

Owner:HEFEI JUYI POWER SYST CO LTD

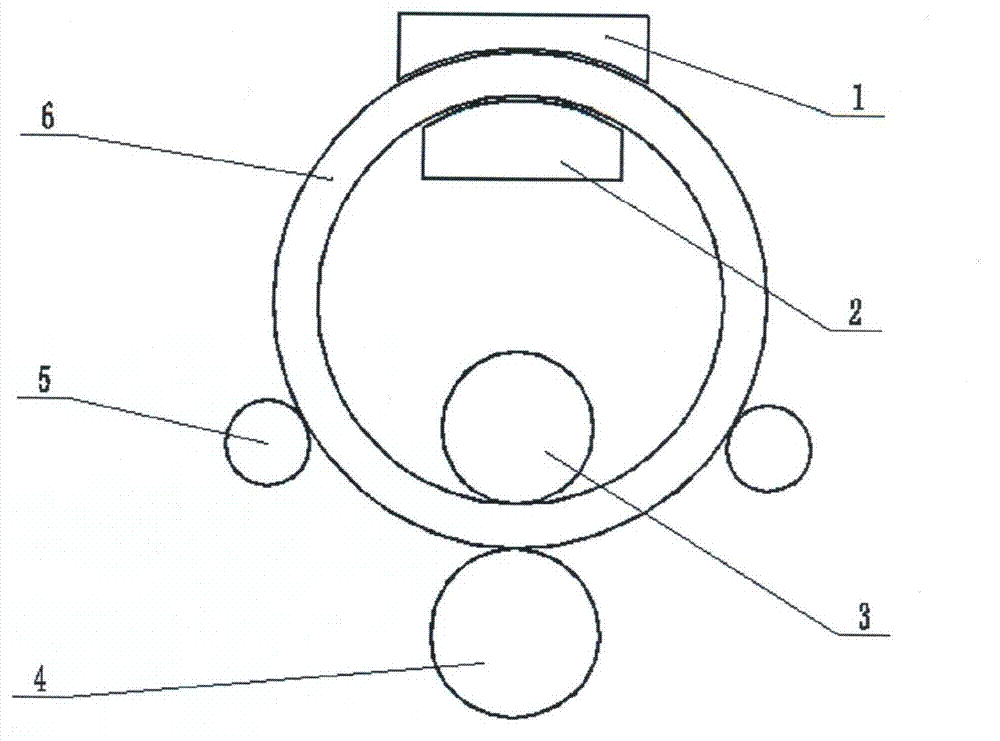

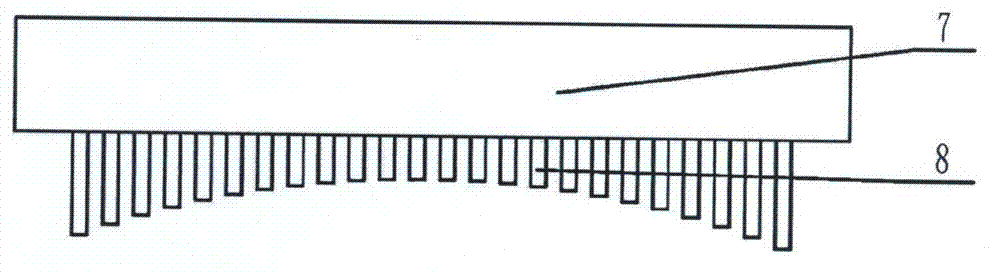

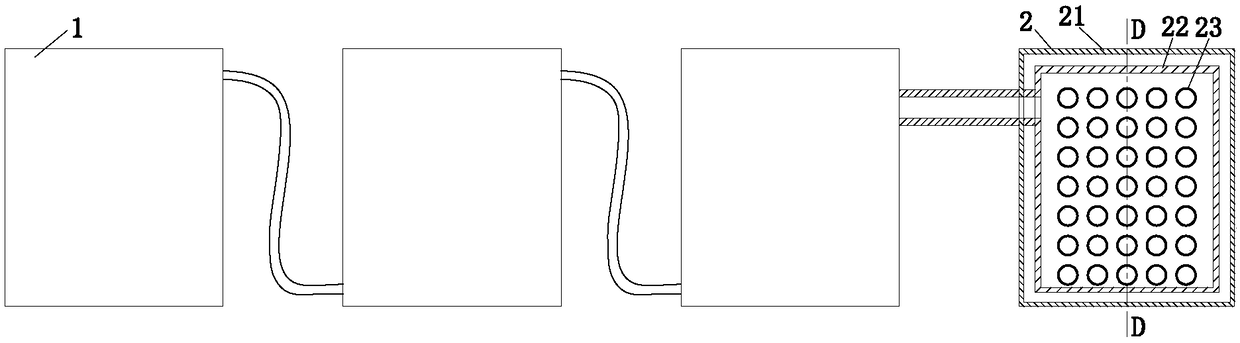

Hot rolling spray cooling method for large cylinder

ActiveCN102847732ASolve the problem of uneven coolingIncrease the direct contact areaWork treatment devicesMetal rolling arrangementsEngineeringFlow ratio

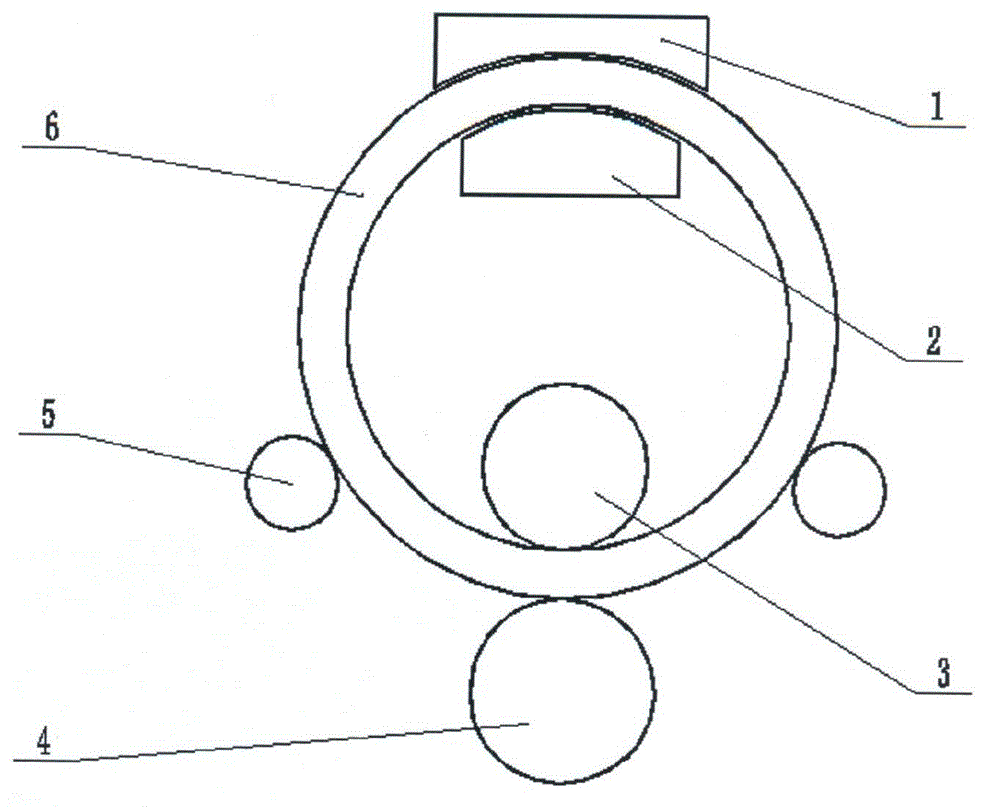

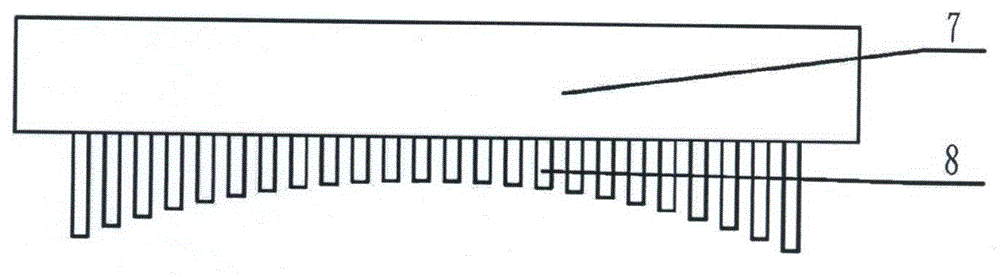

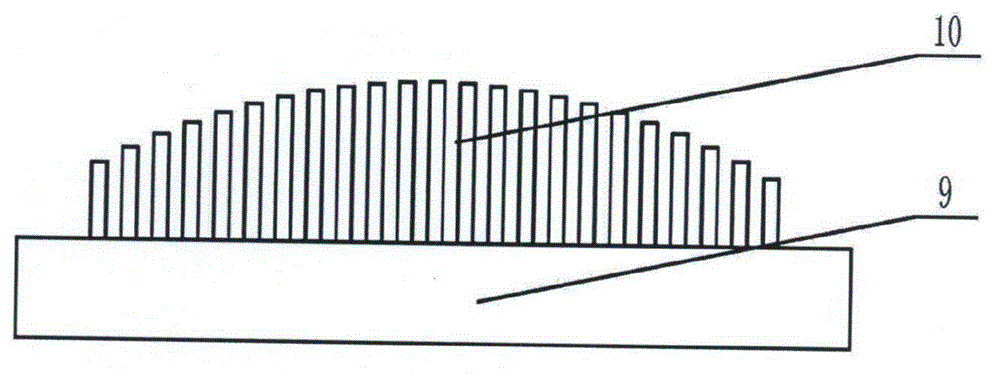

The invention relates to a hot rolling spray cooling method for a large cylinder, which is characterized in that an upper spray device and a lower spray device are manufactured; after a large cylinder is rolled, the cylinder is clamped by an upper roller and a lower roller, so that the cylinder is rotated by the driving of frictional force; additionally, the lower spray device extends into the cylinder, and the upper spray device is arranged outside the cylinder; the length of cooling water pipes on the upper spray device and the lower spray device is regulated, so that a connecting line of all of the cooling water pipes on each spray device near the wall end of the cylinder forms a semicircle shape which is concentric with the cylinder; and additionally, the quantity ratio of the cooling water pipes on an upper spray collecting plate and a lower spray collecting plate of the upper spray device and the lower spray device and the flow ratio of cooling water are regulated, so as to cool the inner and outer surfaces of the large cylinder at the same cooling speed after rolling. The hot rolling spray cooling method has the advantages that the problem of uneven cooling of the traditional cylinder heat treatment is solved, the cooling efficiency is increased, the coefficient of heat transfer of the surface of the cylinder is increased on the initial stage of cooling, and the surface quality of the cylinder is greatly increased.

Owner:YANSHAN UNIV

Quenching device

ActiveCN110241296ASolve the problem of uneven coolingFurnace typesHeat treatment furnacesWater sprayQuenching

The invention discloses a quenching device. A quenching water tank 2 comprises a bottom water spraying pipeline, a side water spraying pipeline and a water return pipeline, wherein the bottom water spraying pipeline is arranged on one side of the bottom of the quenching water tank 2; the side water spraying pipeline is arranged on the inner side wall, far away from the bottom water spraying pipeline, of the quenching water tank 2; a plurality of nozzles are arranged on the bottom water spraying pipeline and the side water spraying pipeline; and a heat exchanger is arranged on the water return pipeline. Through the plurality of nozzles on the bottom water spraying pipeline and the side water spraying pipeline are correspondingly sprayed to the bottom and the side surface of a quenching part, and the quenching part can be cooled uniformly due to the fact that the water temperature of the bottom of the quenching part is consistent with the water temperature of the side surface of the quenching part.

Owner:CHINA ACADEMY OF MACHINERY SCIENCE & TECHNOLOGY +1

Permanent magnet motor, refrigeration compressor and air conditioning unit

ActiveCN104377852ASolve the problem of uneven coolingIncrease the heat transfer ratioCompressorMagnetic circuit rotating partsRefrigeration compressorPermanent magnet motor

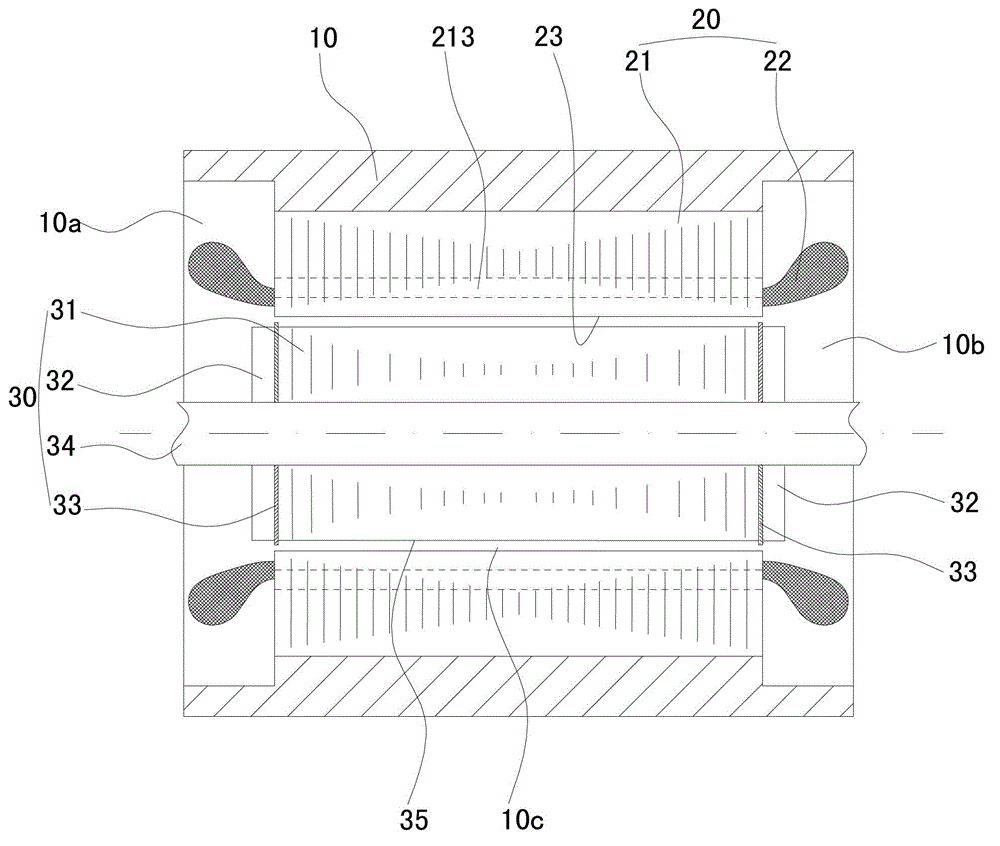

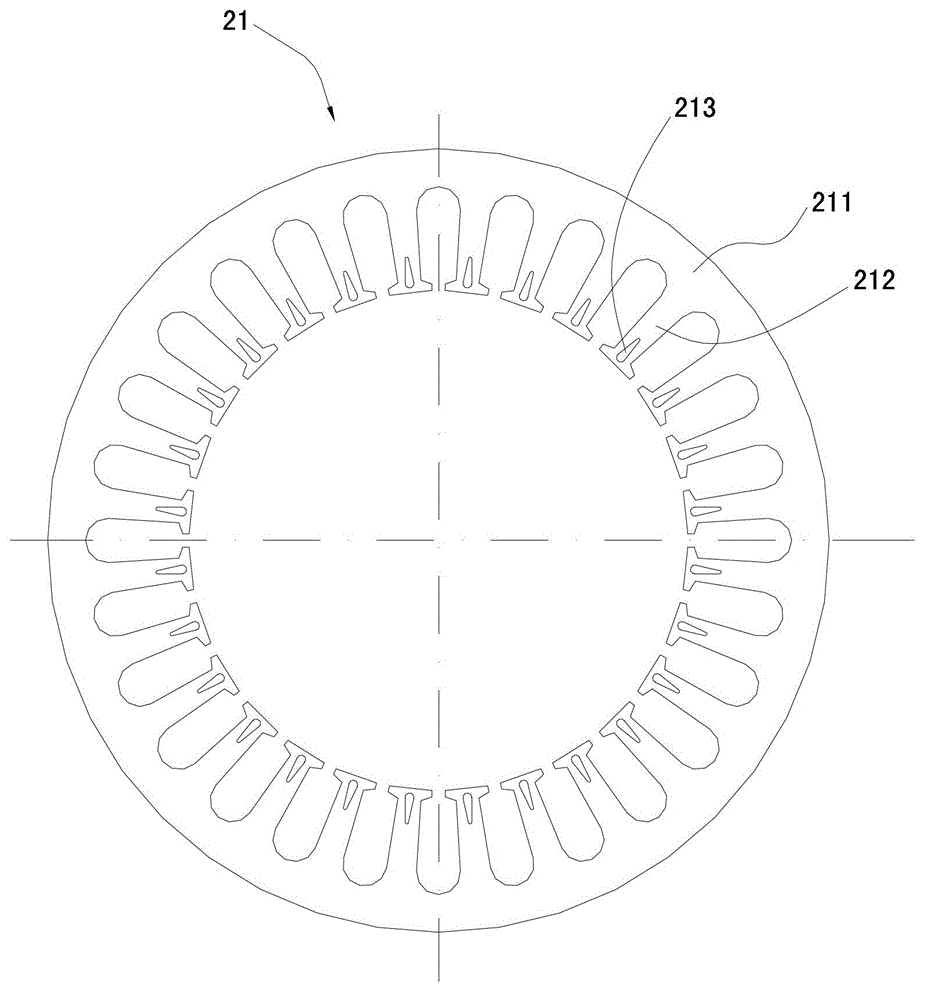

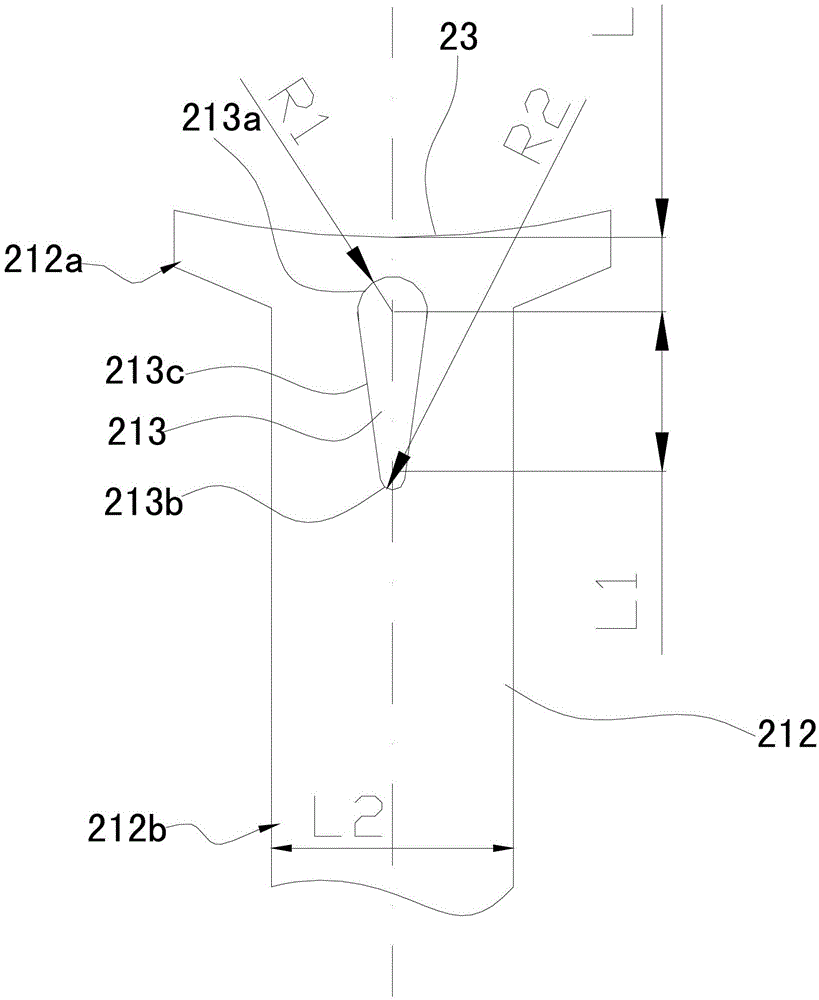

A permanent magnet motor, a refrigeration compressor, and an air conditioning unit. A stator (20) and a rotor (30) are mounted in a housing (10) of the permanent magnet motor. An inner cavity of the housing (10) is partitioned to form a first inner cavity (10a) and a second inner cavity (10b). An axial ventilation hole (213) communicated with the first inner cavity (10a) and the second inner cavity (10b) is disposed on a tooth portion (212) of a stator core (21) of the stator (20), and the axial ventilation hole (213) is a taper hole extended along a height direction of the tooth portion (212). The width of one end, close to the head (212a) of the tooth portion, of the axial ventilation hole (213) is greater than the width of one end, close to the root (212b) of the tooth portion, of the axial ventilation hole (213). The taper hole can enable a fluid to fully exchange heat at the tooth portion (212) that generates heat most intensively, and can further enable residual paint in an immersion-painting process to be centralized to a narrow end of the ventilation hole under the action of surface tension, so that a wide end keeps clear.

Owner:GREE ELECTRIC APPLIANCE INC OF ZHUHAI

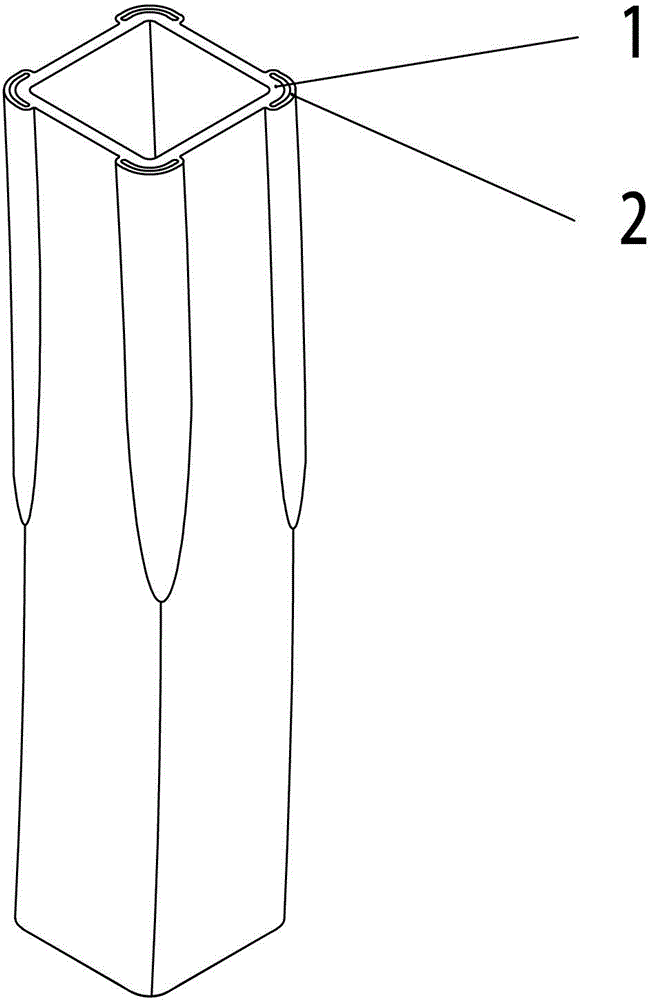

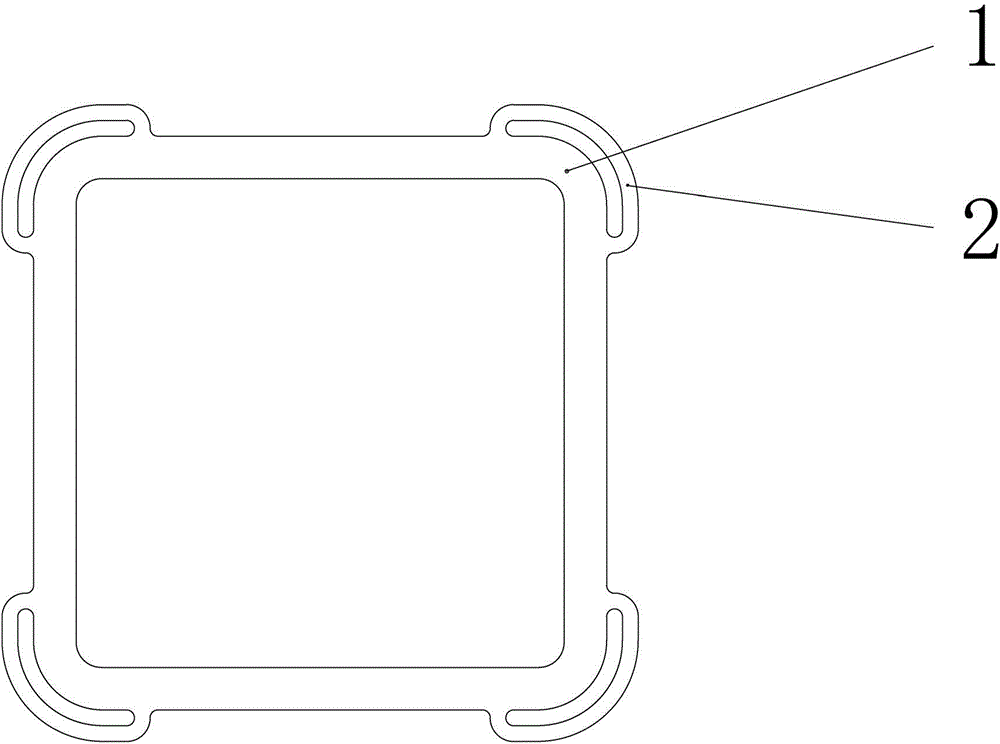

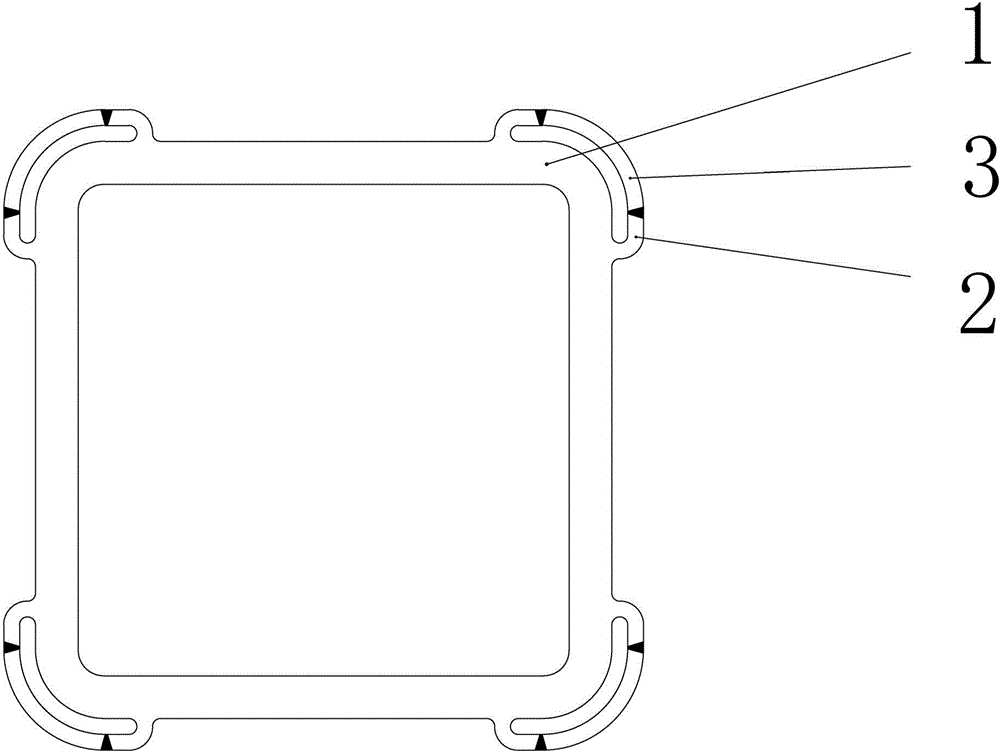

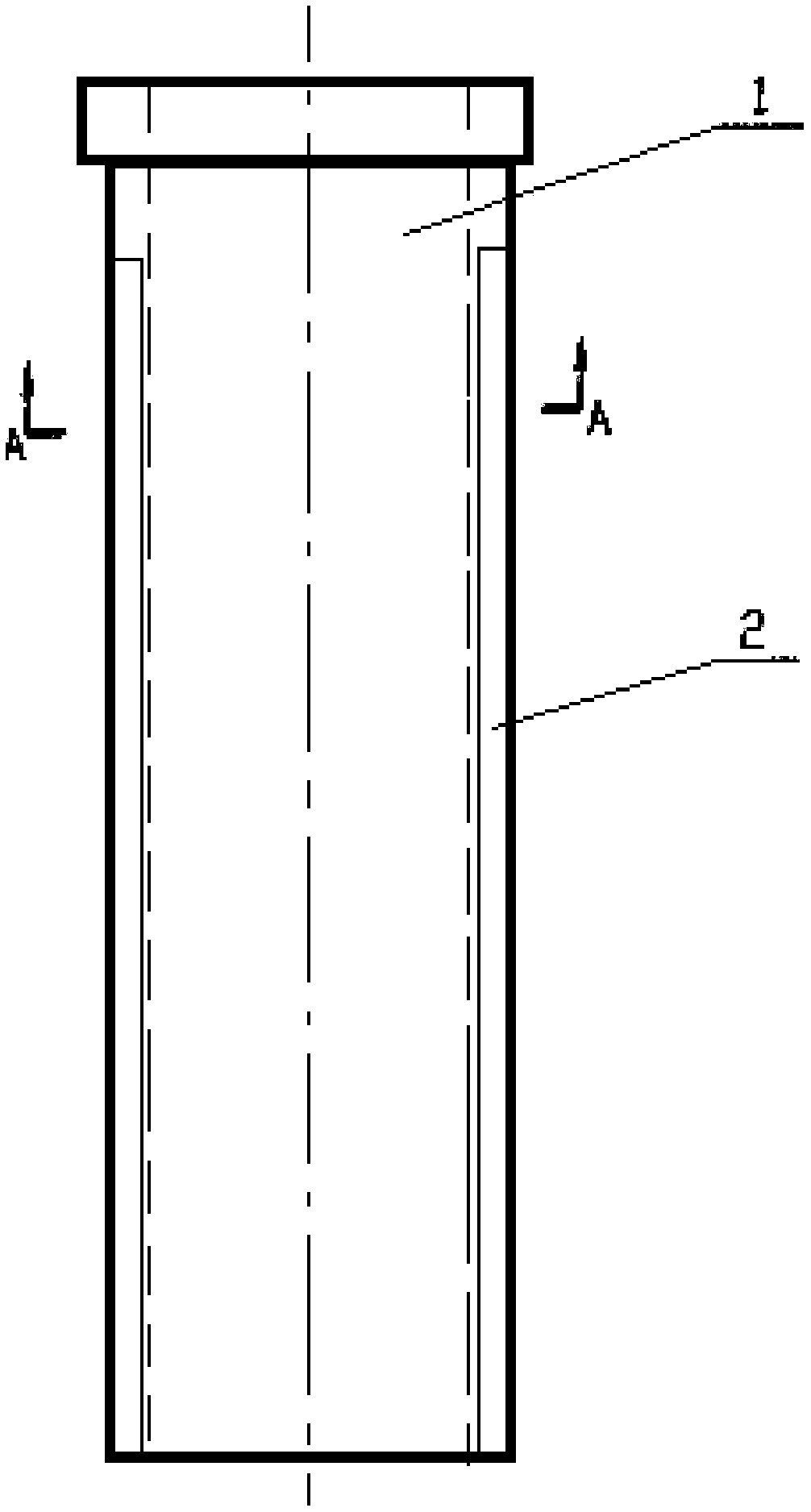

Even-cooling crystallizer copper tube and manufacturing method thereof

PendingCN104624990ASolve uneven coolingIntuitive effectProcess efficiency improvementPhysicsEngineering

An even-cooling crystallizer copper tube for continuous casting is characterized in that an outer-layer corner tube walls (2) are arranged outside corresponding corner tube walls (1) of the crystallizer copper tube, an interlayer is formed between each outer-layer corner tube wall (2) and the corresponding corner tube wall (1) so as to reduce cooling intensity of corners of the copper tube, and the corners and edges of the copper tube can be evenly cooled. The even-cooling crystallizer copper tube is concise in structure, the problem that the corners of the copper tube are unevenly cooled is directly solved, corner cracking tendency of the casting blank is lowered, ingot pulling speed of a continuous casting machine is increased, tolerance lever of continuous casting technology is relaxed, and equipment investment of the continuous casting machine is reduced. A tubular blank tube is directly manufactured by a liquid die forging method, the wall thickness of the corners of the blank tube is larger than that of the edges, conditions are created for construction of a corner structure of the even-cooling crystallizer copper tube, and manufacturing cost of the crystallizer copper tube is lowered by the liquid die forging technology.

Owner:周嘉平

Food cold storage system

ActiveCN108518906AImprove connectivityImprove stabilityLighting and heating apparatusDomestic refrigeratorsCooling effectEngineering

The invention relates to the field of food processing, and discloses a food cold storage system. The food cold storage system is mainly composed of a cold storage chamber, a first conveying belt, a second conveying belt, cold storage boxes and a wedge-shaped block. A groove is formed in the bottom of a storage cavity. The wedge-shaped block is in sliding connection in the groove and is located between the first conveying belt and the second conveying belt. A pushing mechanism is arranged in a circulation cavity. The multiple cold storage boxes are placed on the first conveying belt, multiple cold storage grooves are formed in the upper portions of the cold storage boxes, and a cooling cavity is arranged on the lower portion of each cold storage box, one sides of the cooling cavities communicate with multiple communicating pipes, and a sub-body of a quick joint is mounted on each communicating pipe. Multiple main bodies of the quick joints are arranged on the other sides of the coolingcavities. A wedge-shaped bottom with dual wedge faces is arranged at the bottom of each cold storage box, and the wedge-shaped bottoms cooperate with the wedge-shaped block. By means of the scheme, all portions of foods can be cooled, the food cooling effect is enhanced, and then the fold cold storage quality is enhanced.

Owner:重庆市长寿区可又可食品有限公司

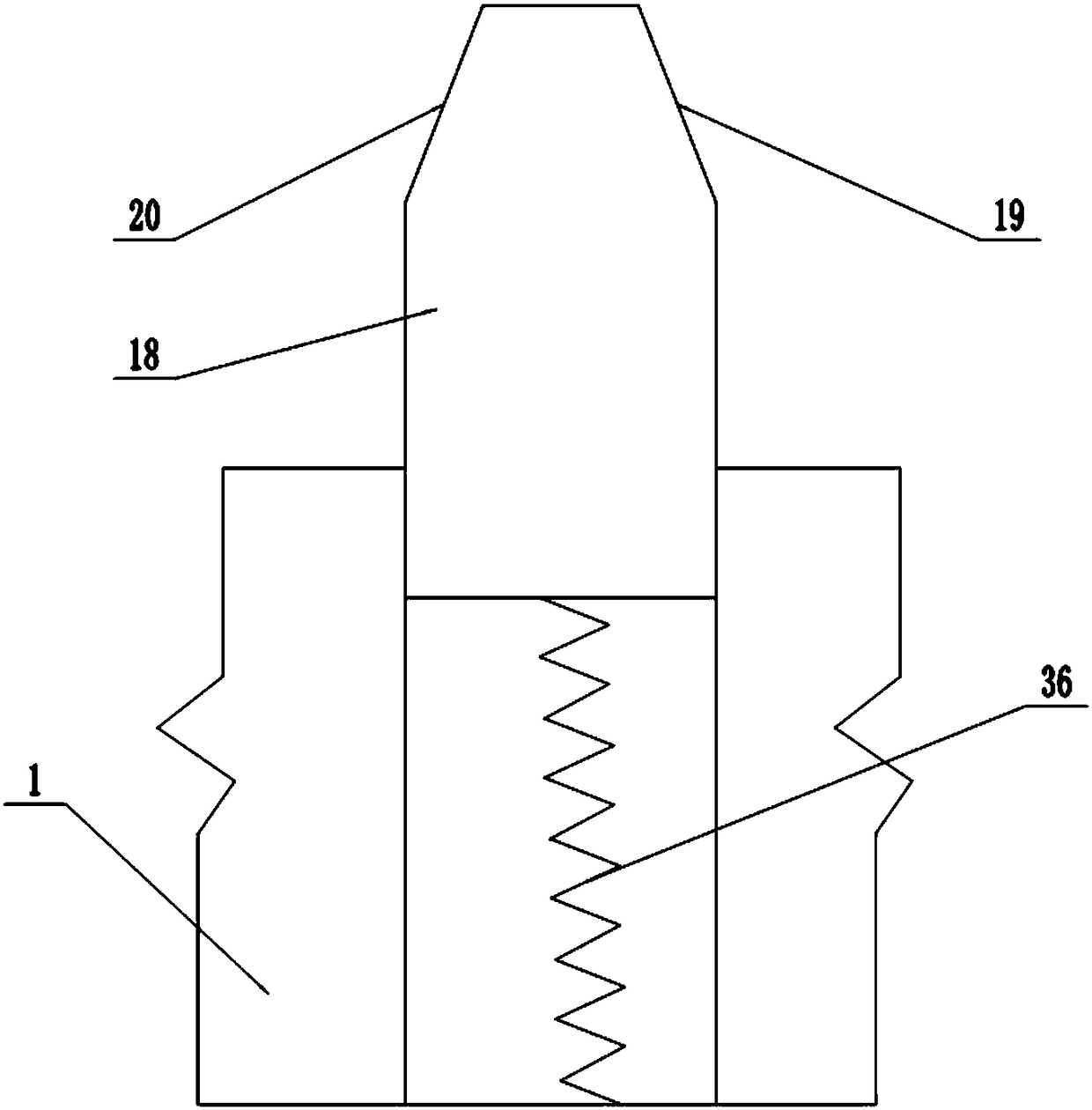

Alcohol distillation device convenient for loading and unloading fermented grains

The invention belongs to the field of wine making equipment and particularly relates to an alcohol distillation device convenient for loading and unloading fermented grains. The alcohol distillation device comprises three distillation devices and a collection tank, wherein the three distillation devices are connected in series; an extrusion unit is used for extruding the fermented grains into thedistillation devices; a distillation cylinder is fixed on the inner surface of a side plate I through a mounting plate I; when the distillation devices are used for distilling the fermented grains, aninterlayer I is filled with steam, the humidity in the fermented grains in the distillation cylinder is increased, an upper base plate I and the side plate I are driven to move in the vertical direction through the stretching and shrinking of a pressure bar, and a first base plate I is driven to rotate by a motor through a rotating shaft and is cooperated with a baffling cover so as to convey thefermented grains back to a recycling box; and an air inlet is used for conveying air to a distillation unit, so as to discharge the fermented grains from the distillation unit. The alcohol distillation device is mainly used for automatically loading and unloading the fermented grains, the alcohol distillation efficiency can be improved, and the production cost can be lowered.

Owner:杭州同福永酿酒有限公司

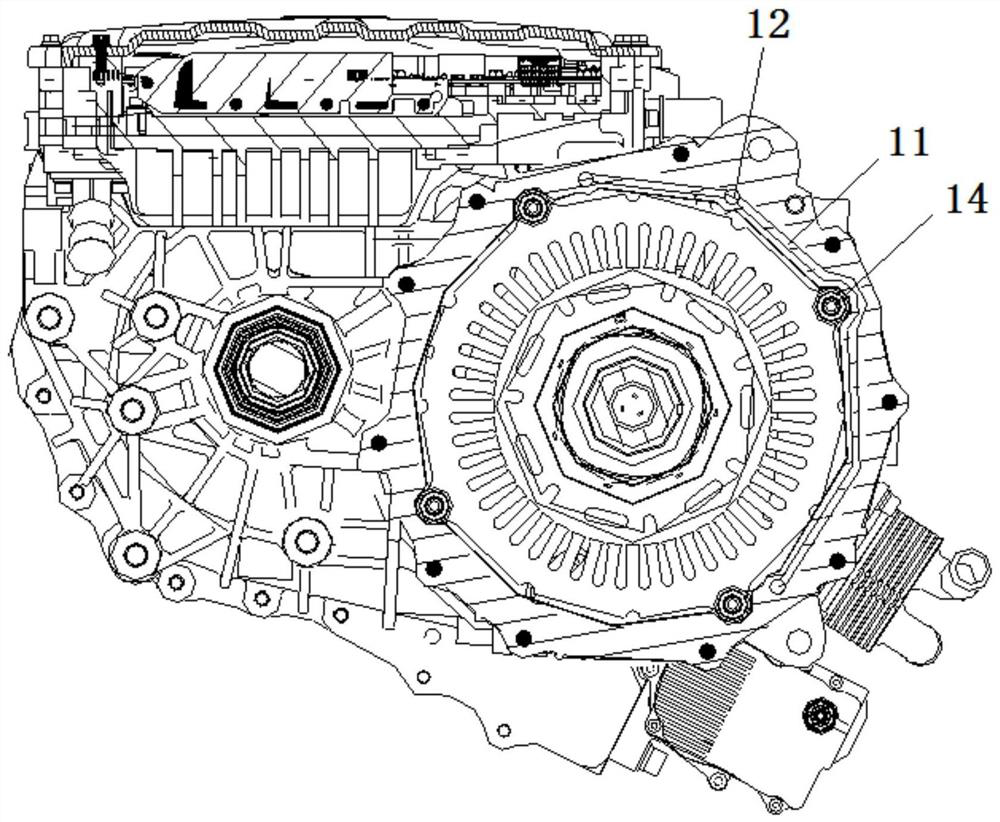

Oil cooling stator structure

InactiveCN112701854ASolve the problem of uneven coolingEnables directional coolingMagnetic circuit stationary partsCooling/ventillation arrangementThermodynamicsElectric machine

The invention discloses an oil cooling stator structure which is characterized by comprising a motor shell, a rear end cover and a stator; the stator comprises a stator end coil and a stator iron core; circumferential oil grooves are formed in the rear end cover and the end of the motor shell; and cooling oil enters the oil grooves from the rear end cover of an electric driver and is led into the upper portion of the electric driver along the oil grooves; an axial stator oil distribution channel is arranged close to the upper portion of the outer circumference of the motor shell; the stator oil distribution channel is communicated with the oil grooves; oil spraying holes corresponding to cooling parts are formed in the stator oil distribution channel, and the cooling oil falls down from the oil spraying holes to directionally cool the stator end coil and the stator iron core. The oil liquid of the rear end cover of the electric driver is introduced into the stator oil distribution channel above the electric driver; and the oil spraying holes corresponding to the cooling parts are used for realizing directional cooling of the stator end coil and the stator iron core, so that the problem of non-uniform cooling of the stator is solved.

Owner:HEFEI JUYI POWER SYST CO LTD

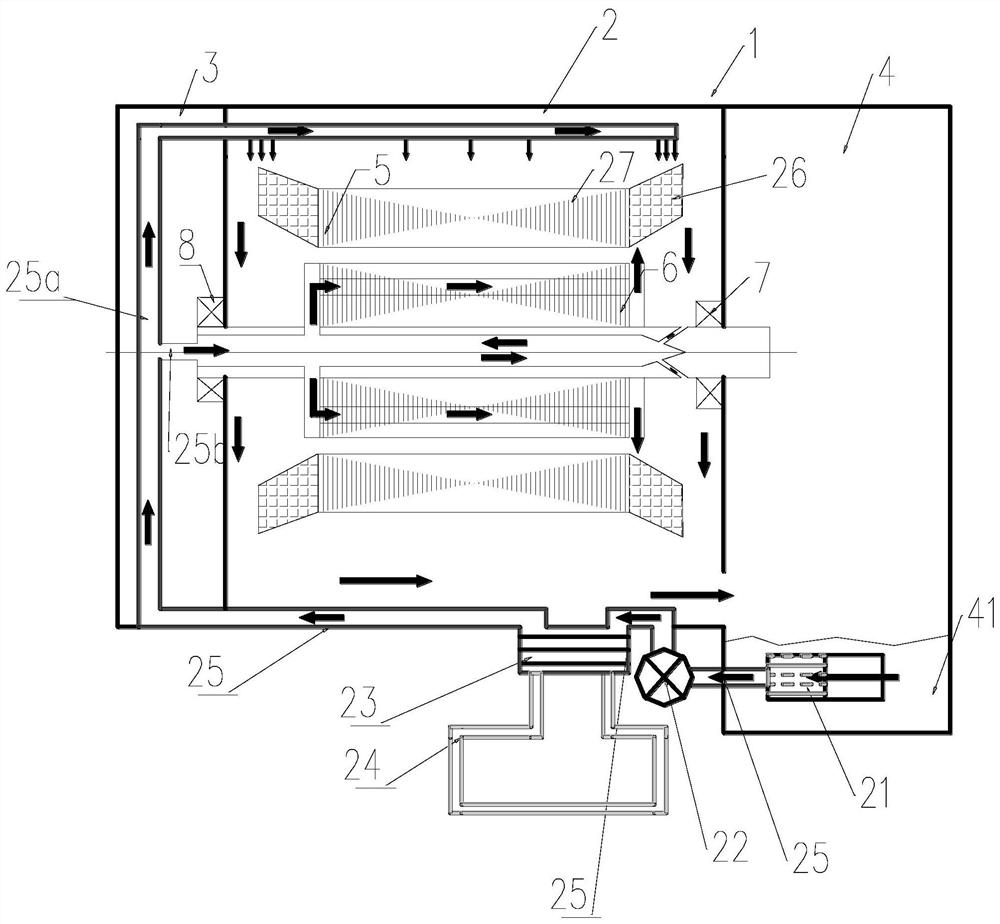

Sealing rapid cooling chamber

The invention relates to a sealed fast cooling chamber which mainly comprises a fast cooling chamber shell, a front door of the fast cooling chamber, a back door of the fast cooling chamber, a fan and fan blades. The fast cooling chamber shell, the front door of the fast cooling chamber and the back door of the fast cooling chamber form a sealed body, an upper blow-off nozzle and a lower blow-off nozzle which can be controllably opened and closed are arranged inside the inner cavity of the fast cooling chamber shell, the upper blow-off nozzle and the lower blow-off nozzle are oppositely arranged; the fan is arranged on the fast cooling chamber shell, an air inlet pipe is arranged under the air inlet of the fan blades, a cold-heat exchanger is arranged between the air inlet of the fan blades and the air inlet pipe, and air circulation is formed between the air inlet pipe and the air outlet pipe; the air outlet of the fan blades is respectively communicated with an upper air outlet pipe and a lower air outlet pipe, the upper blow-off nozzle is communicated with the upper air outlet pipe by an upper blow-off pipe, and the lower blow-off nozzle is communicated with the lower air outlet pipe by a lower blow-off pipe. The sealed fast cooling chamber has the advantages of providing a protective atmosphere fast cooling chamber with a novel sealed structure, solving the problem of uneven cooling, ensuring stable and reliable quality of the bright isothermal normalizing, and realizing the purposes of saving materials and reducing energy consumption.

Owner:HANGZHOU JINZHOU TECH CO INC

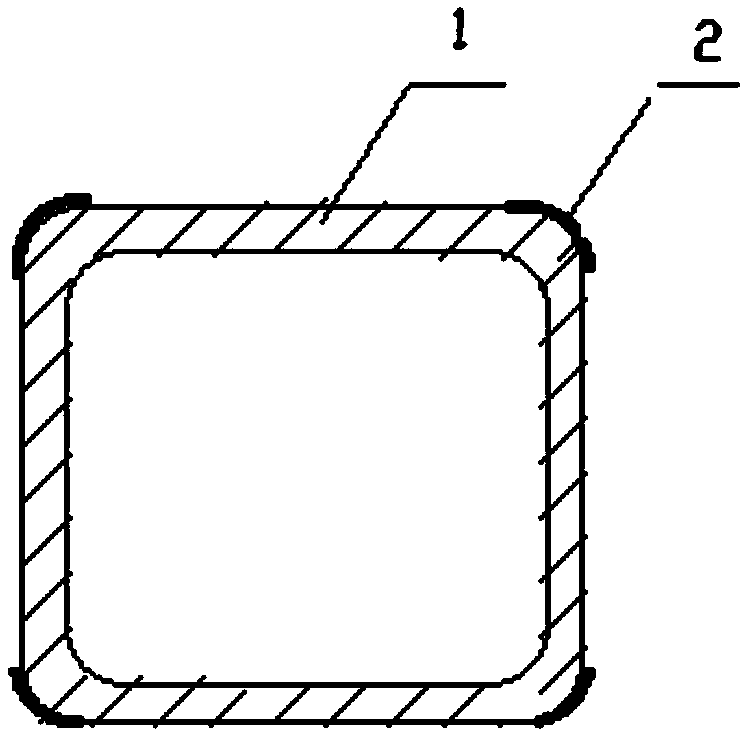

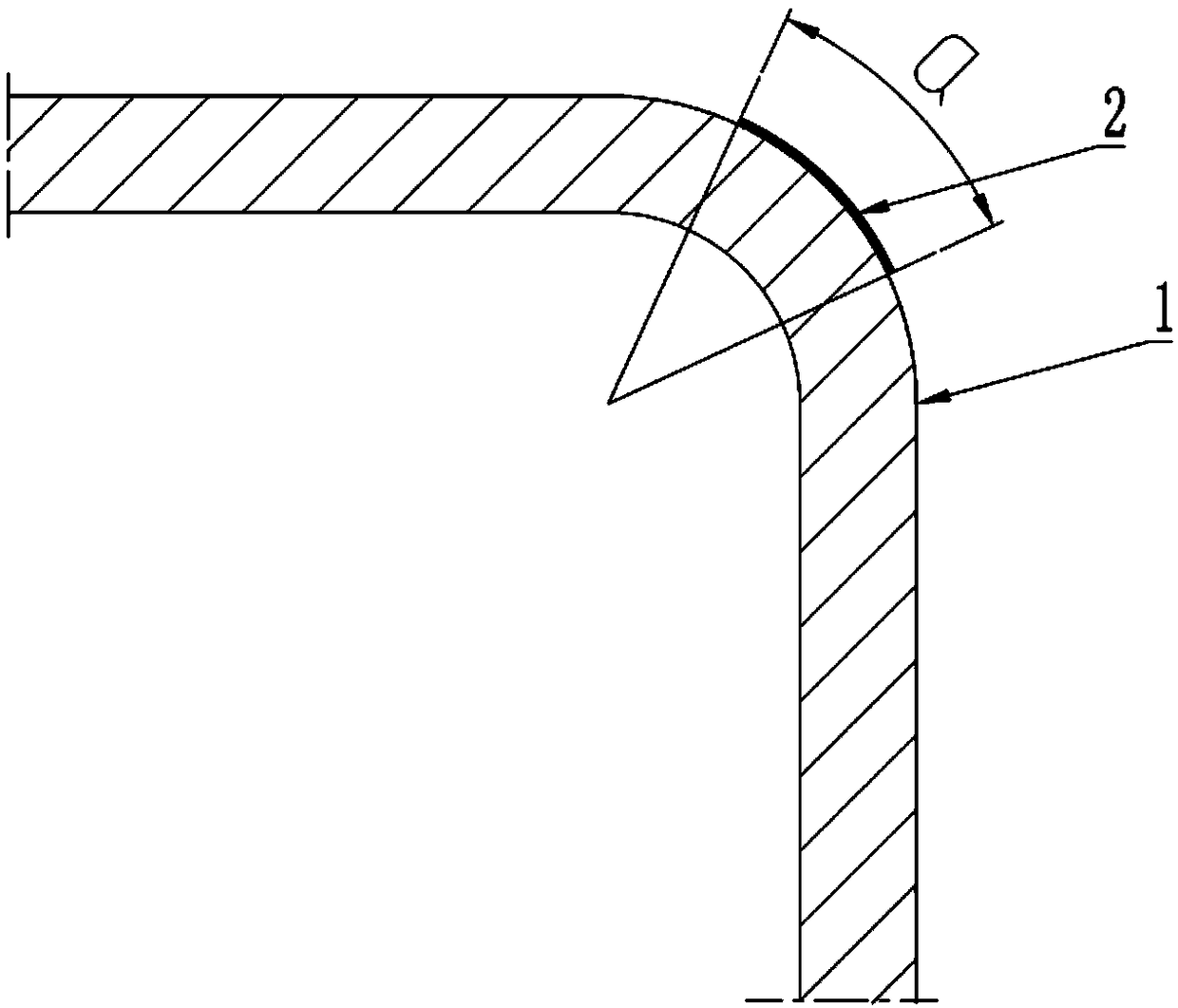

Crystallizer copper pipe with uniform cooling function

ActiveCN108941486ASolve the problem of uneven coolingImprove overcoolingSand blastingThermal insulation

The invention designs a crystallizer copper pipe with a uniform cooling function. A layer of 5920-SN sealant with a set thickness is bonded in a set size range of the outer surface of a corner part ofthe crystallizer copper pipe to serve as a high-temperature-resistant thermal insulation coating, and the portion, bonded with the high-temperature-resistant thermal insulating coating, of the cornerpart of the copper pipe is subjected to pre-texturing treatment through sand blasting or laser; the thickness of the high-temperature-resistant thermal insulating coating is set to be 0.04 mm to 0.2mm, the width of the high-temperature-resistant thermal insulating coating bonded to the corner part of the crystallizer copper pipe is not larger than the arc length of a transition arc of the outersurface of the corner part, and the width is not smaller than 1 / 4 of the arc length of the transition arc, and the heat conductivity coefficient of the thermal insulation coating ranges from 0.02 to 0.1 w / k.m, and when the thermal insulation coating ranges from 260 DEG C to 300 DEG C, the time of working with fundamental strength higher than 1.5 MPa is longer than 500 hours. The crystallizer copper pipe solves the problem of uneven cooling of the crystallizer copper pipe, the phenomenon of supercooling of the corner part of a casting blank is improved, and particularly, it is guaranteed that the thermal insulation coating can be firmly adhered to the corner part of the crystallizer copper pipe, so that the use effect is not influenced, the implementation is easy, the reliability is high, and the crystallizer copper pipe is beneficial to popularization and use.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

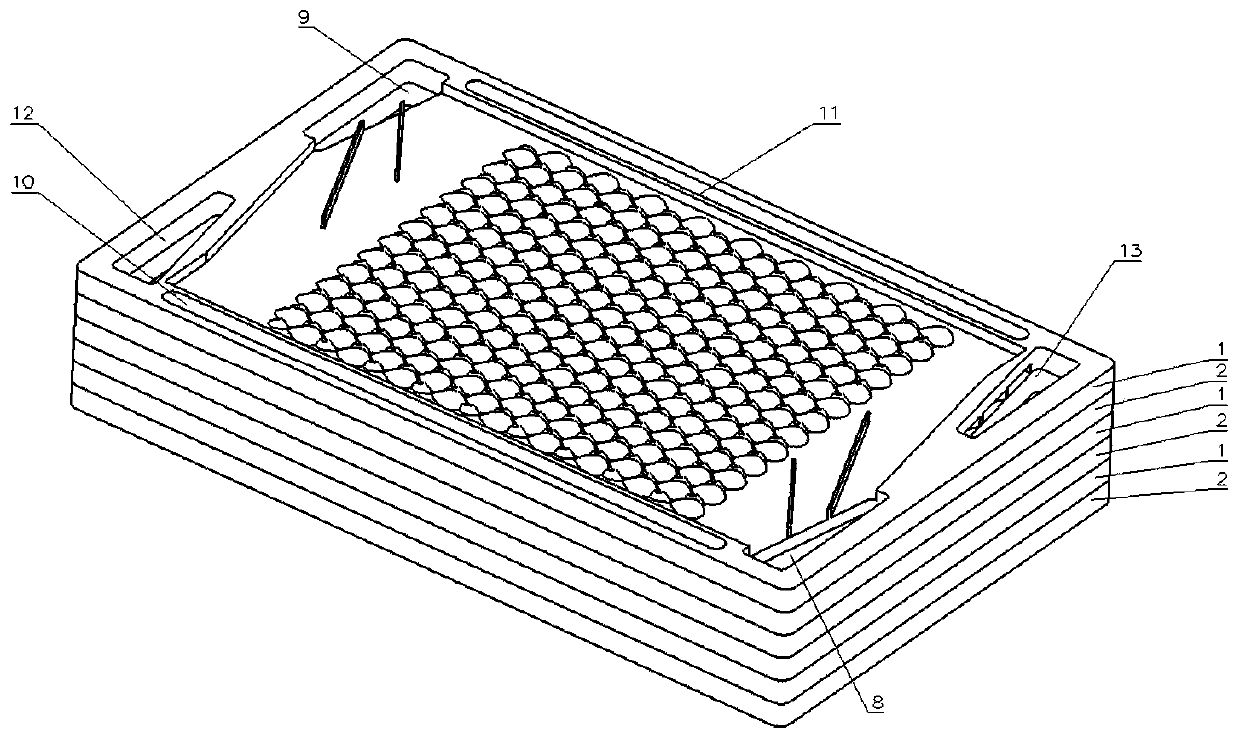

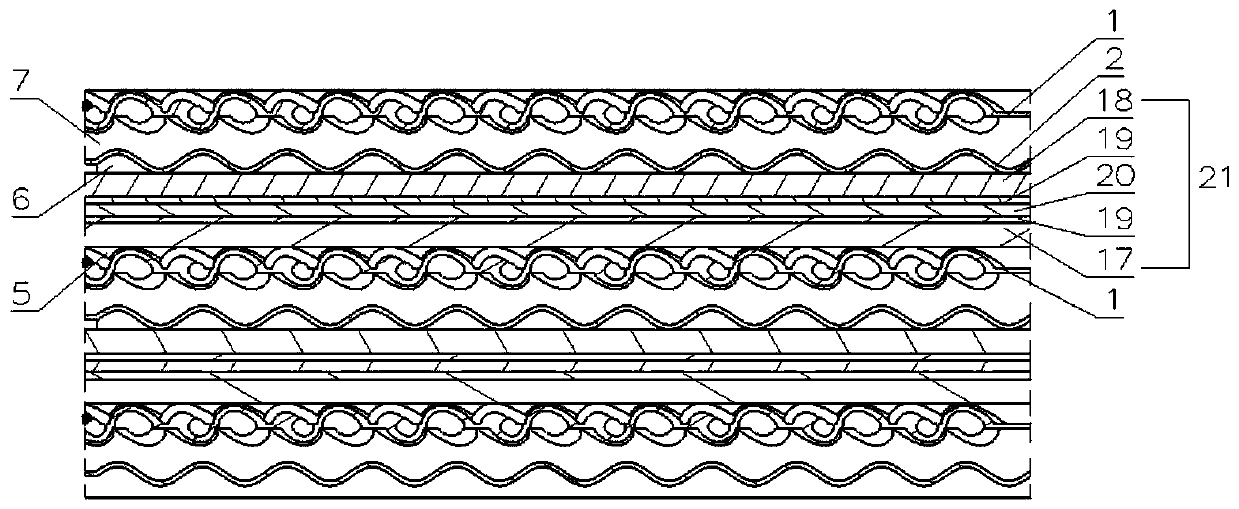

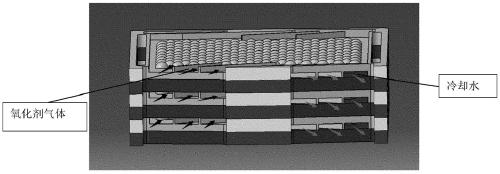

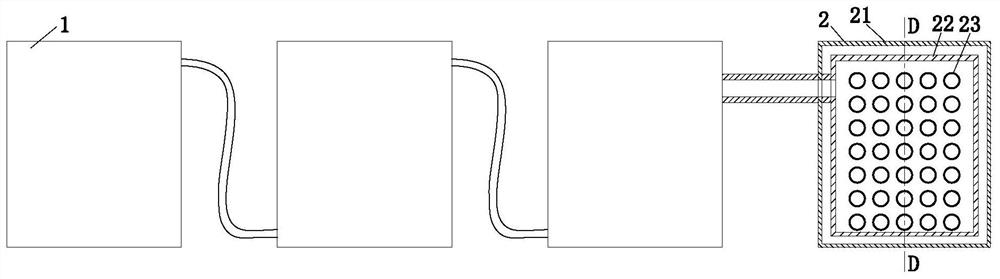

Single fuel cell, fuel cell stack and working mode

ActiveCN111540925ASolve the problem of blocking the flow channel of the first plateImprove cooling effectCollectors/separatorsFuel cellsNew energy

The invention discloses a single fuel cell, a fuel cell stack and a working mode. The invention belongs to the technical field of new energy automobile fuel cells. The single fuel cell is characterized by comprising a second plate, a membrane electrode group and a first plate, the membrane electrode group is arranged between the second plate and the first plate; the upper side of the first plate is provided with a semi-water-drop-shaped protrusion protruding upwards and a semi-water-drop-shaped recess recessed downwards. The lower side of the first plate is provided with a semi-water-drop-shaped protrusion protruding downwards and a semi-water-drop-shaped recess recessed upwards. By adopting the single fuel cell, the fuel cell stack and the working mode, the stability of the fuel cell canbe effectively improved.

Owner:擎能动力科技(苏州)有限公司

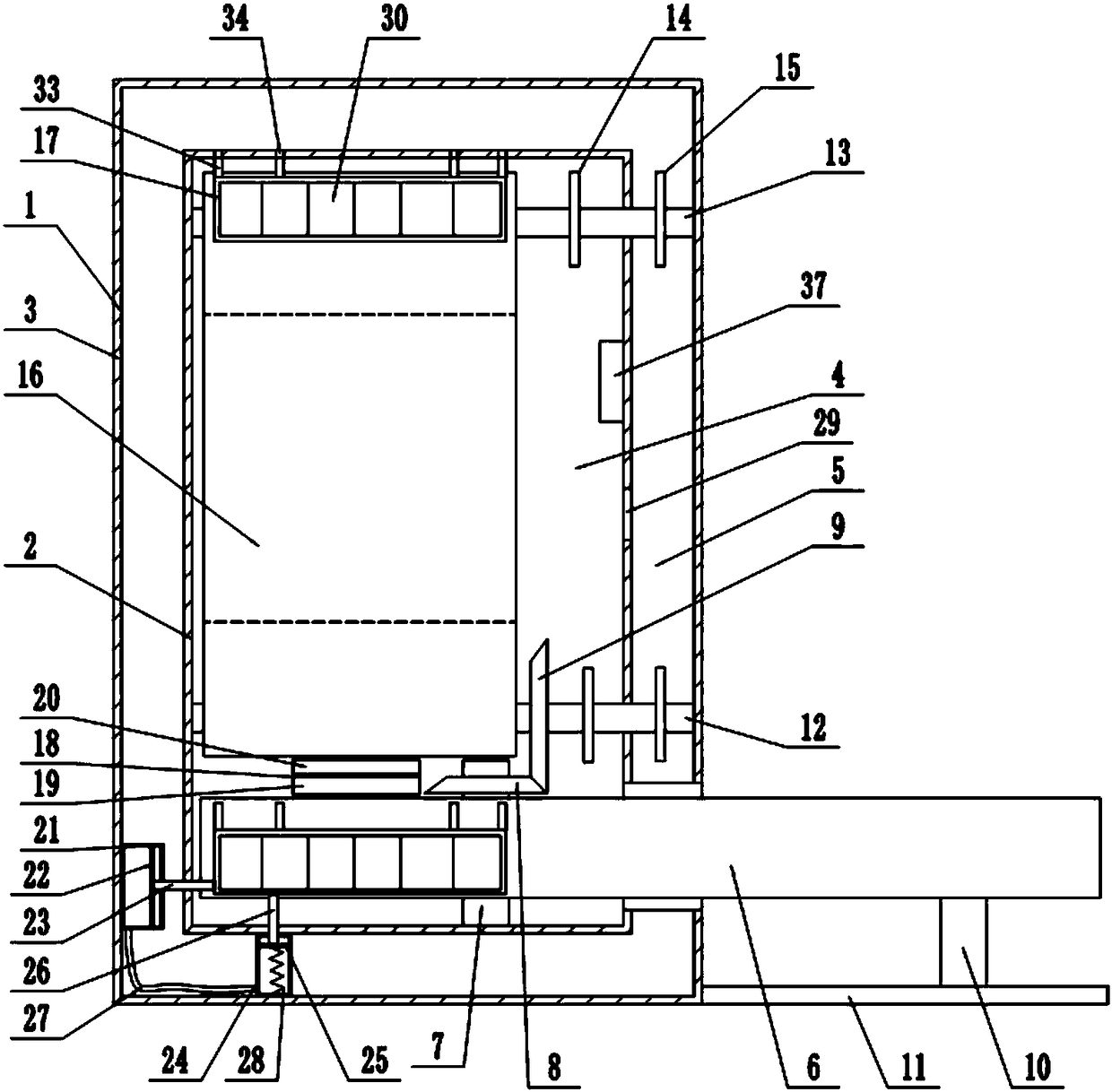

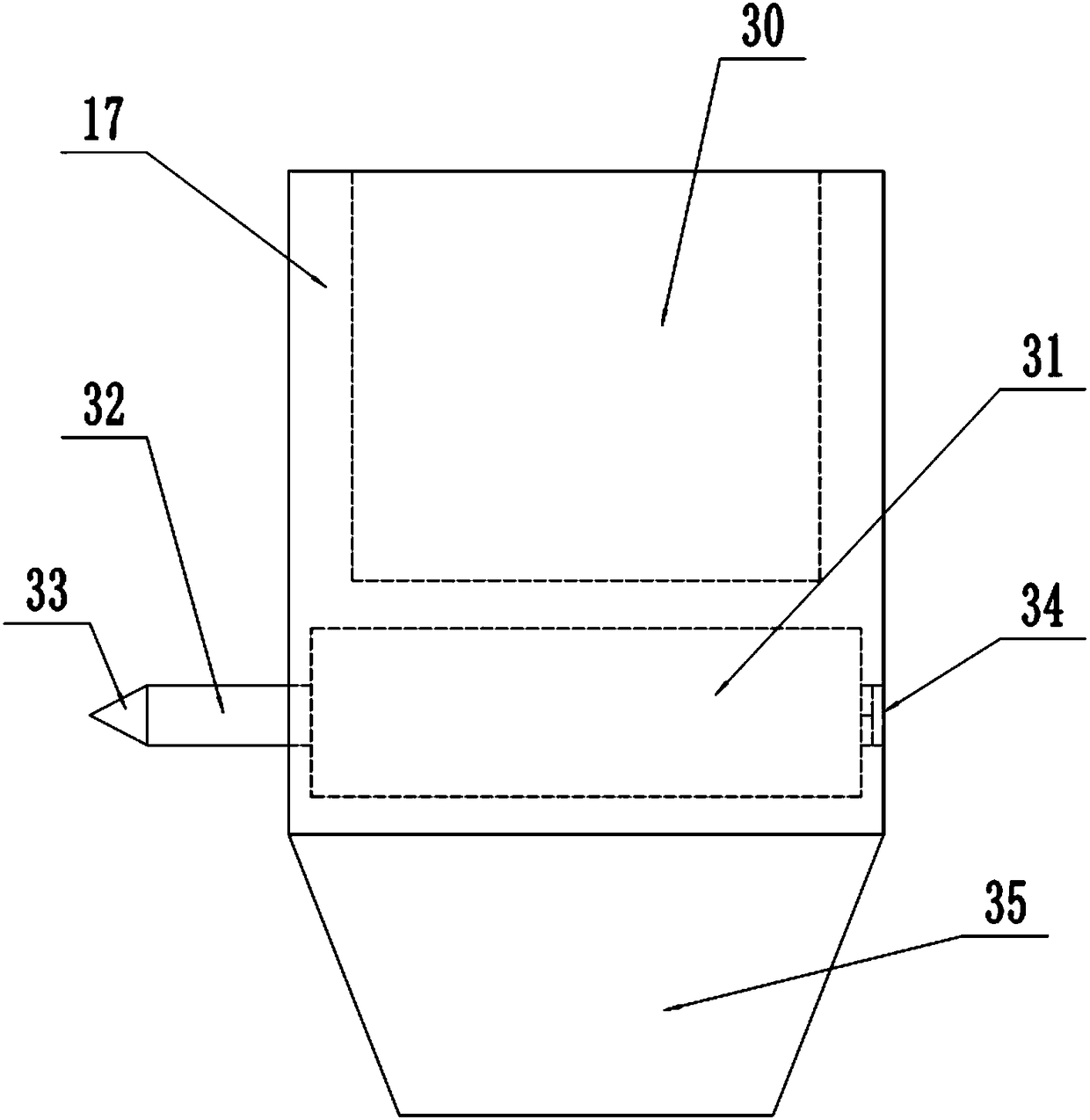

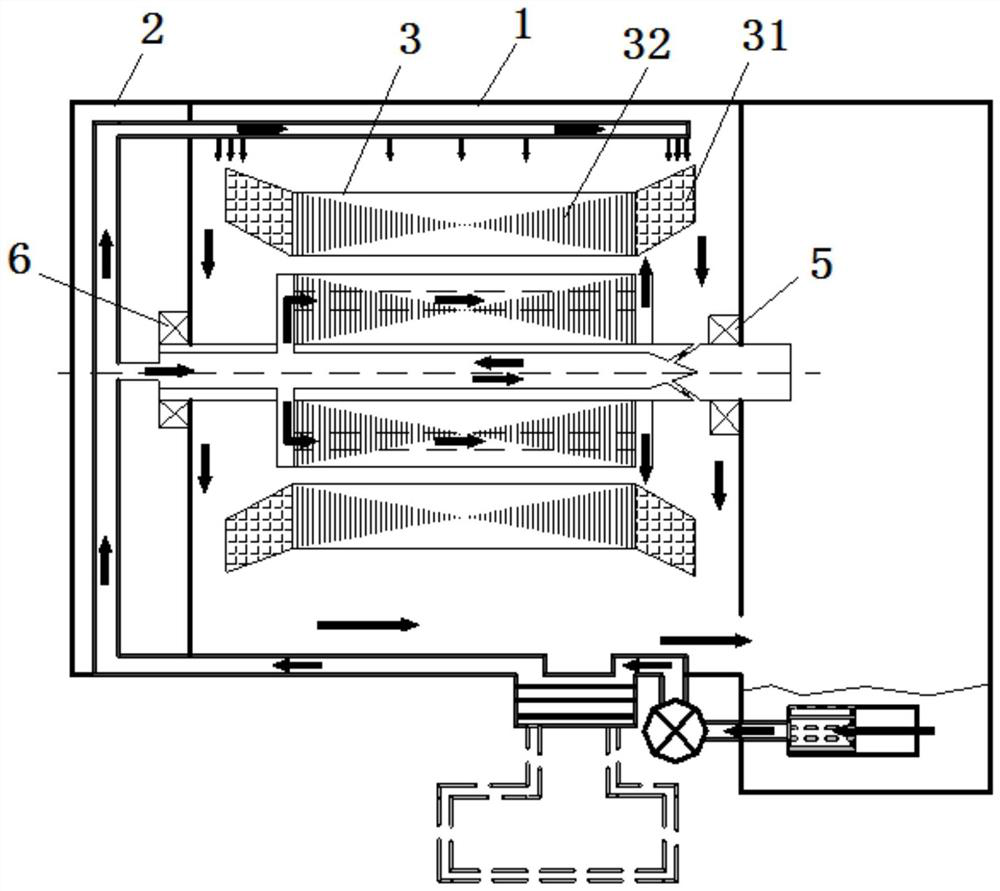

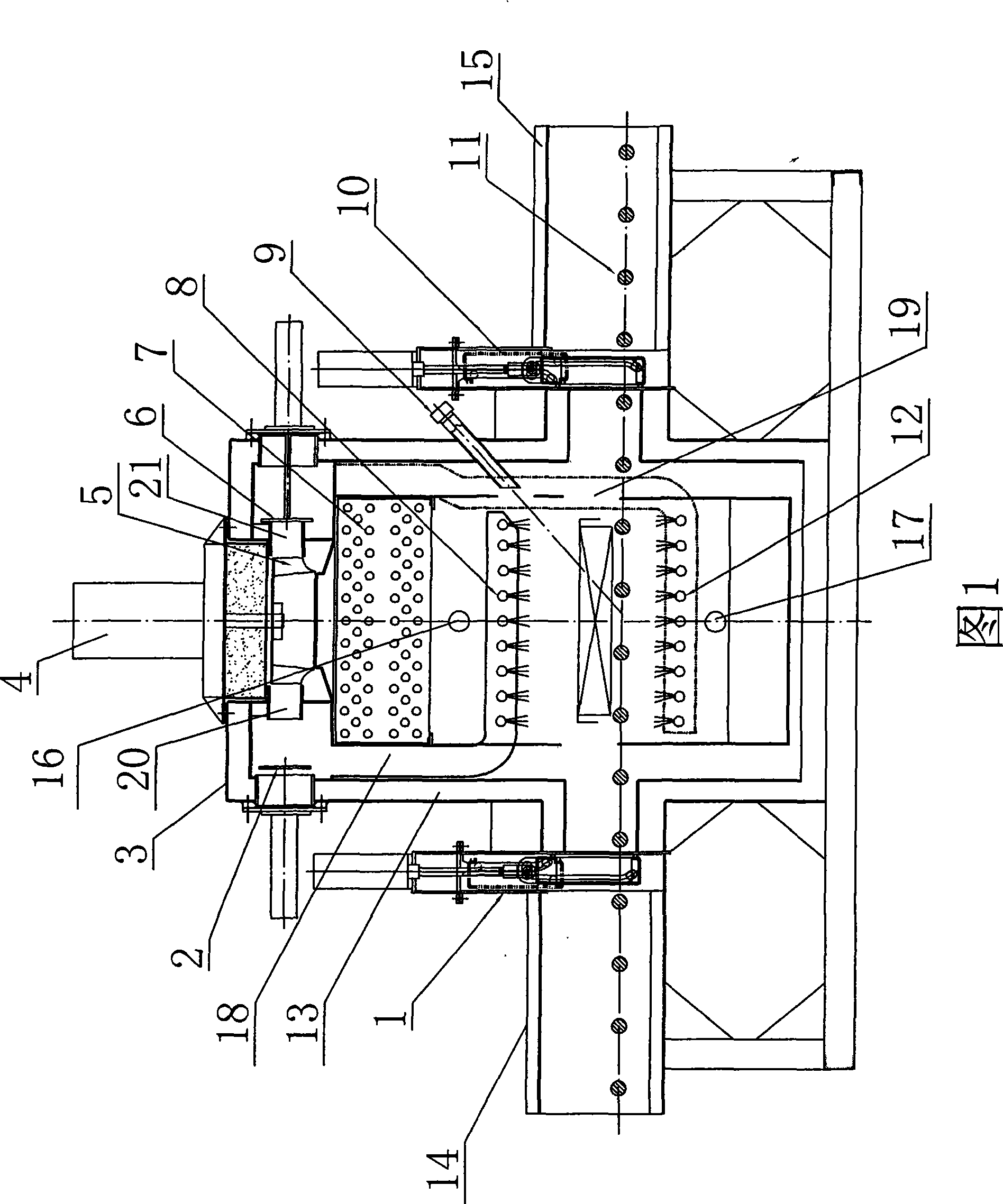

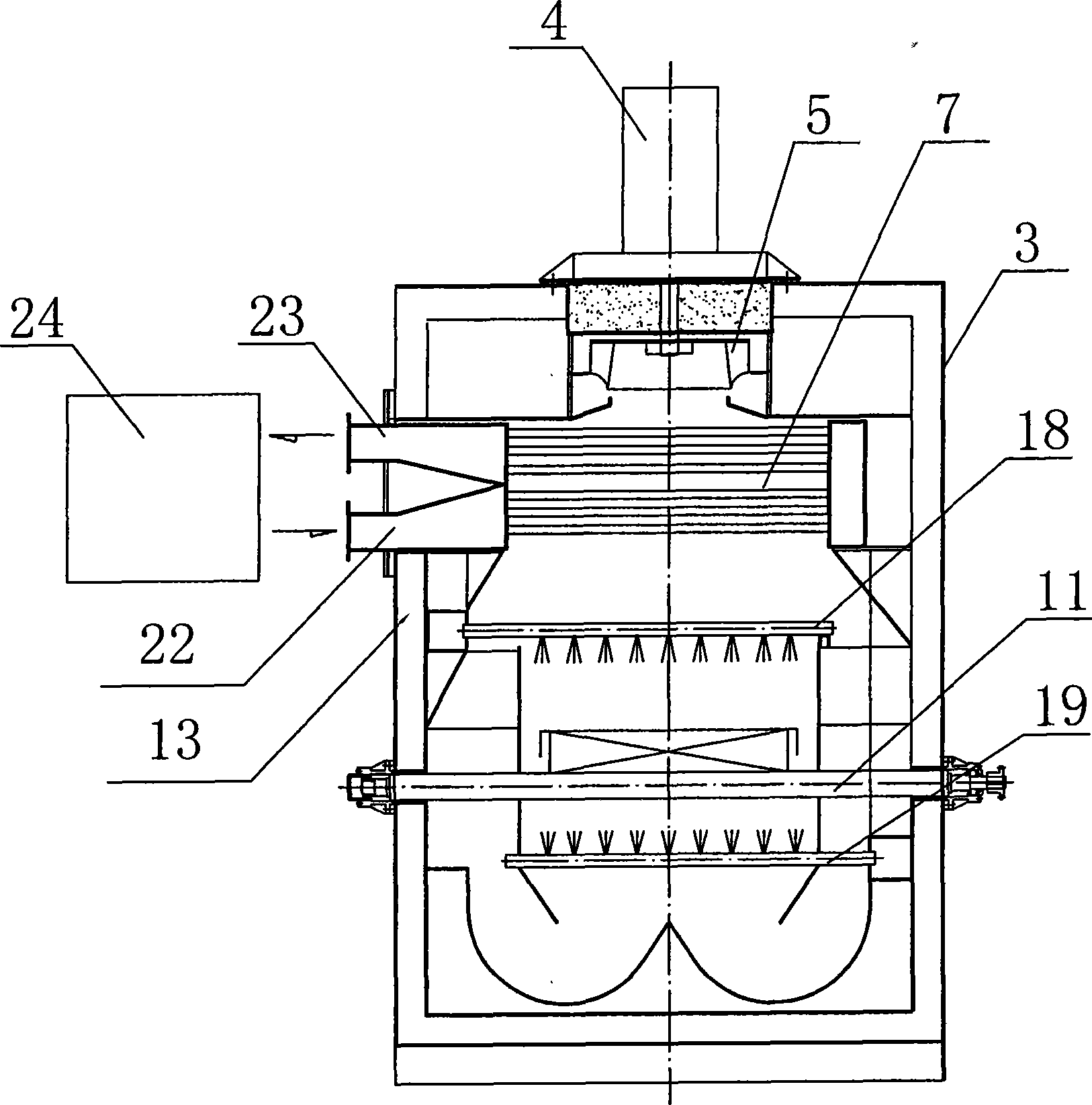

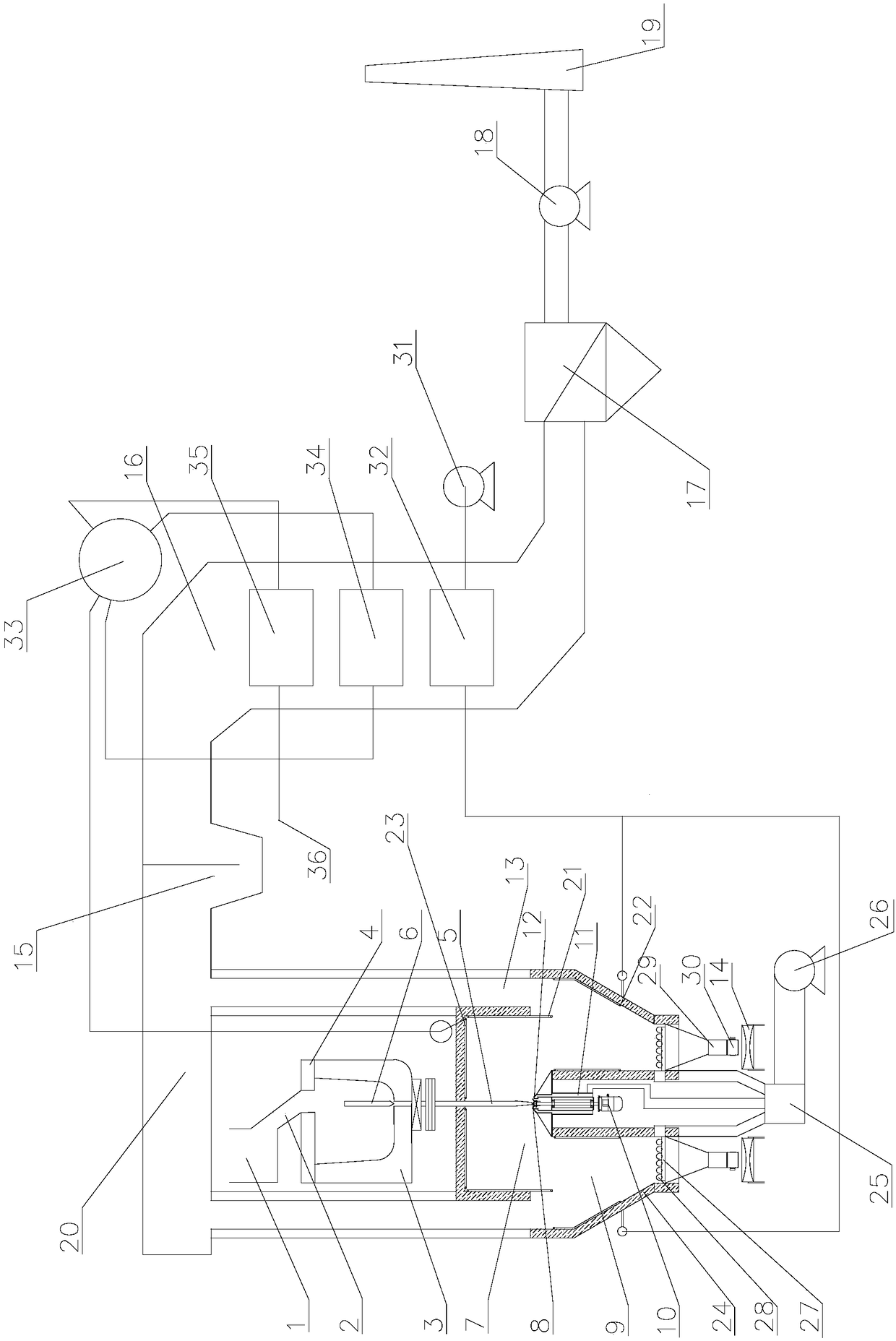

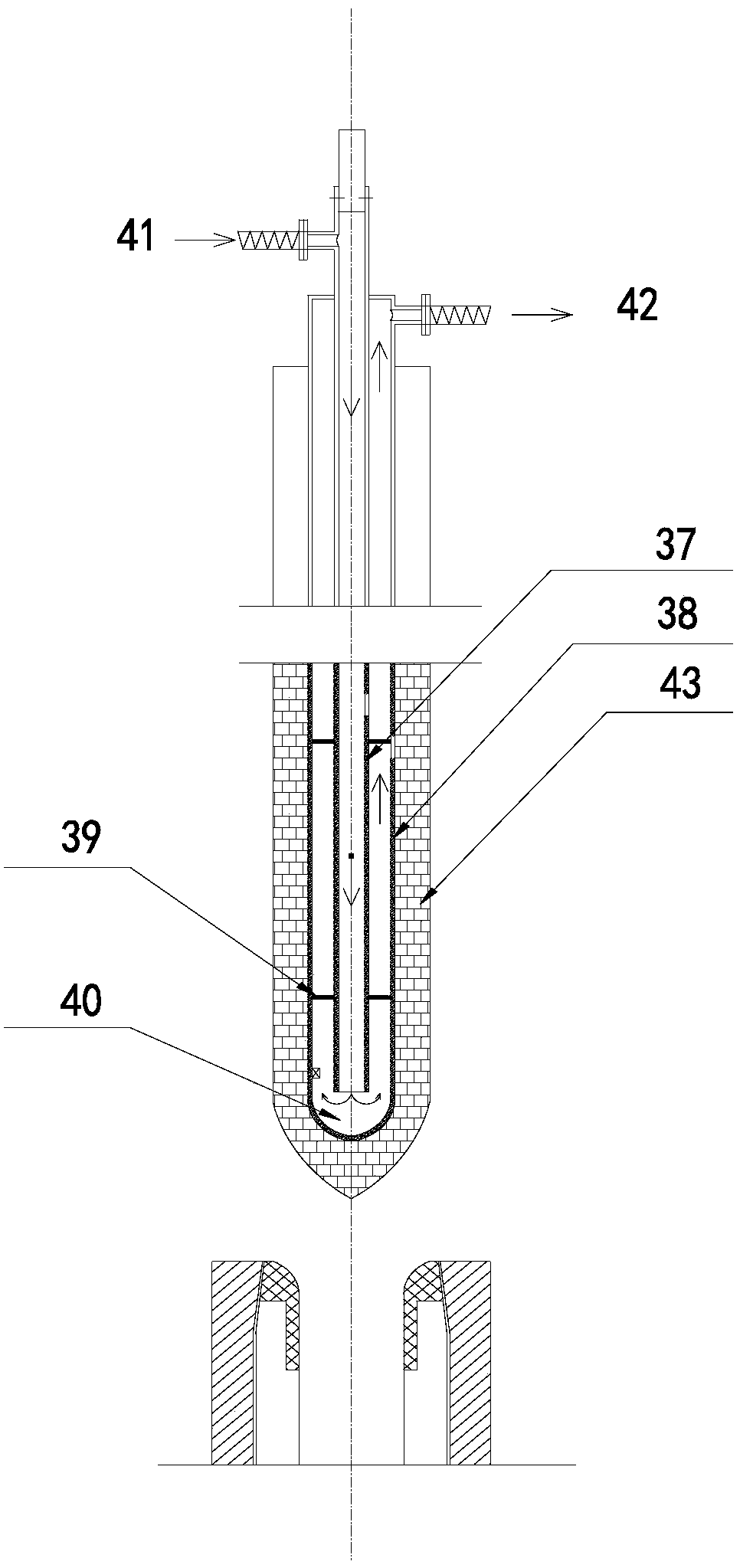

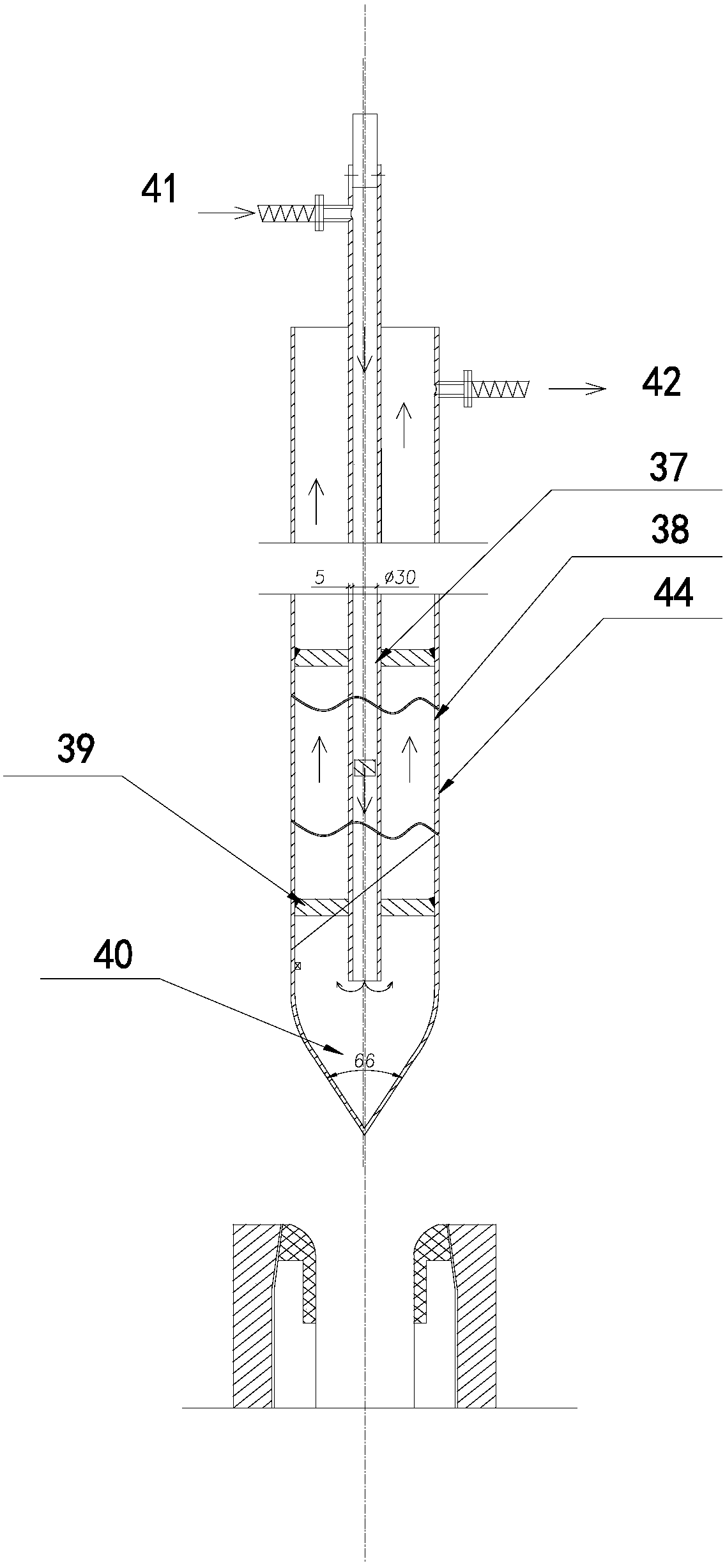

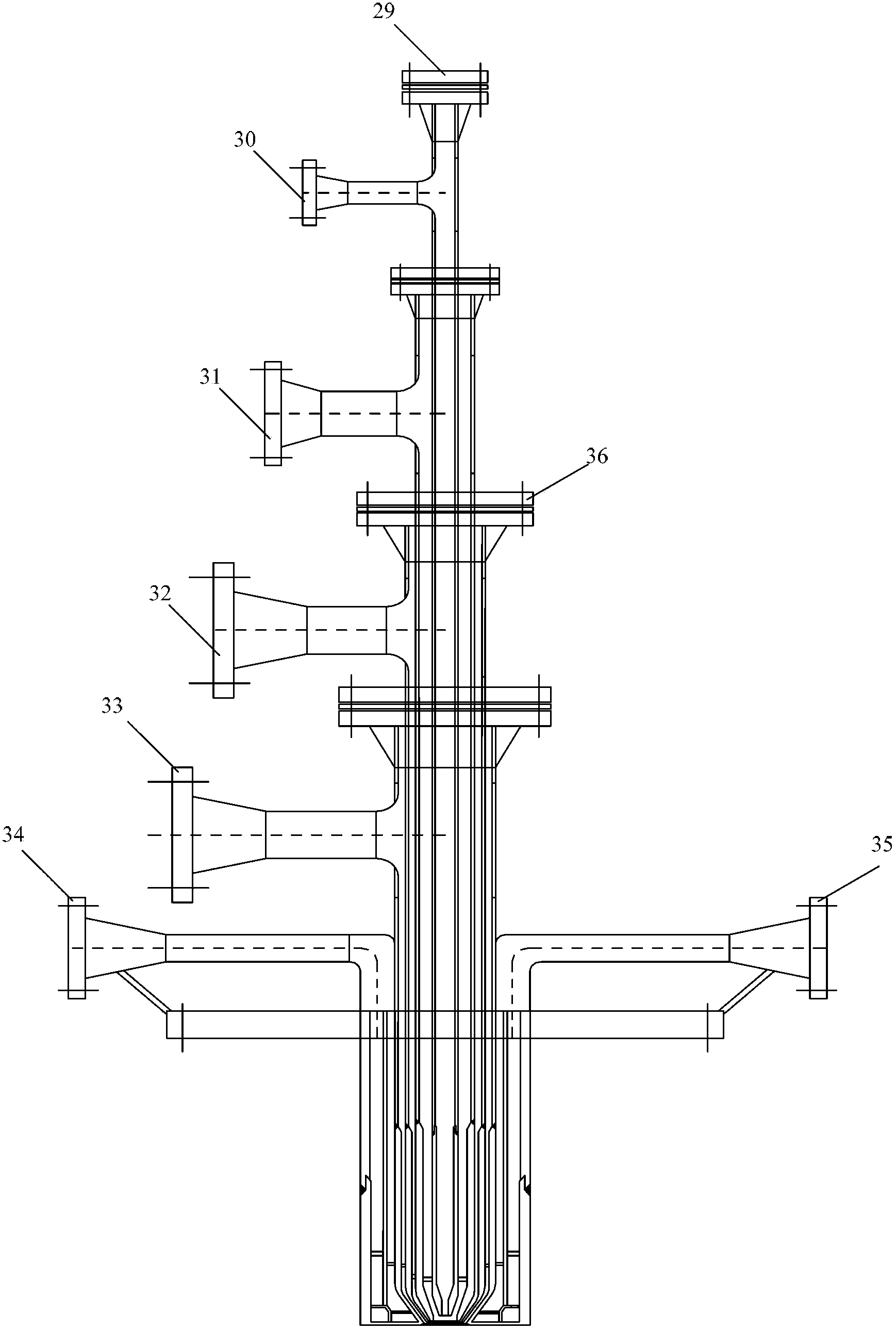

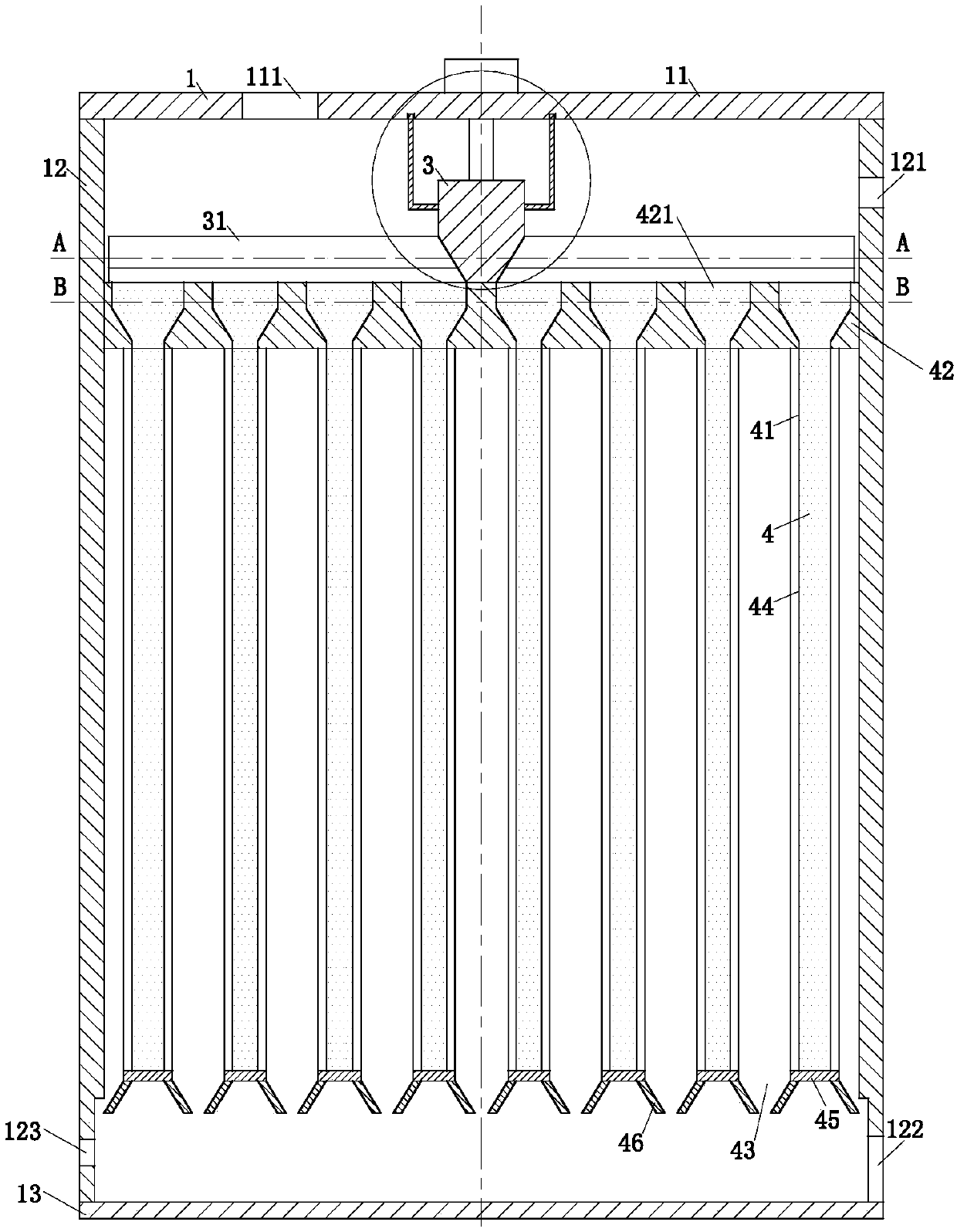

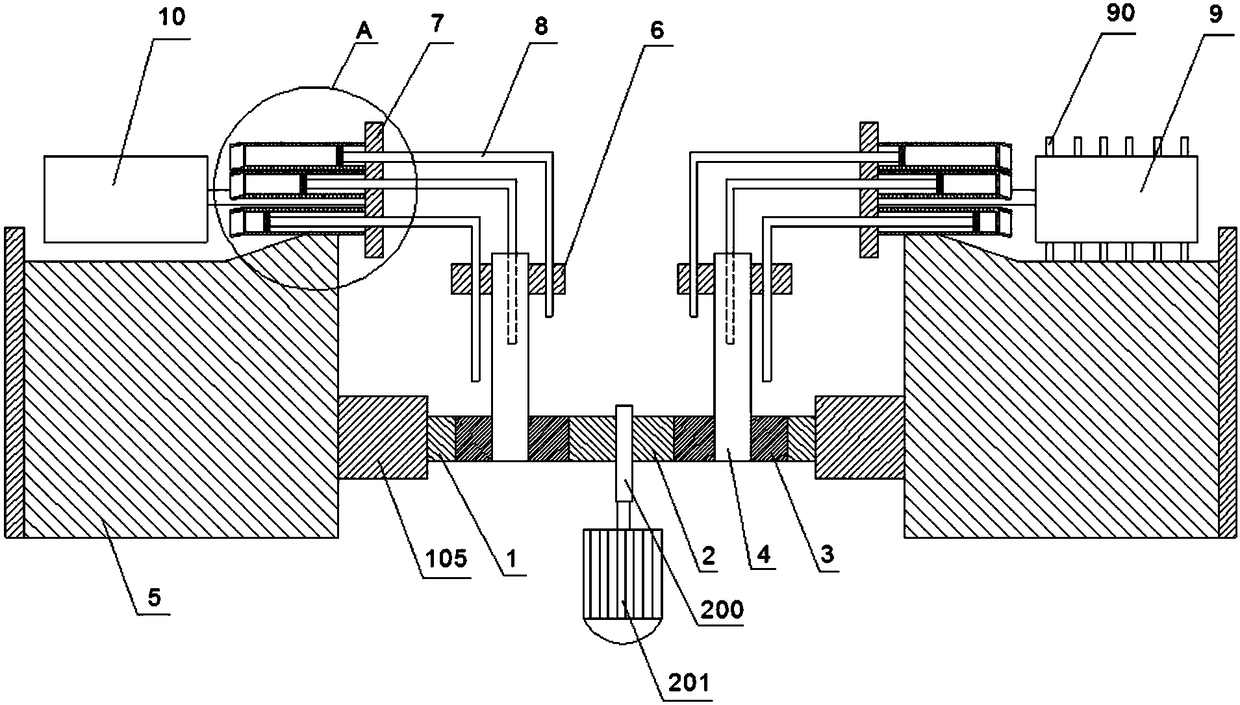

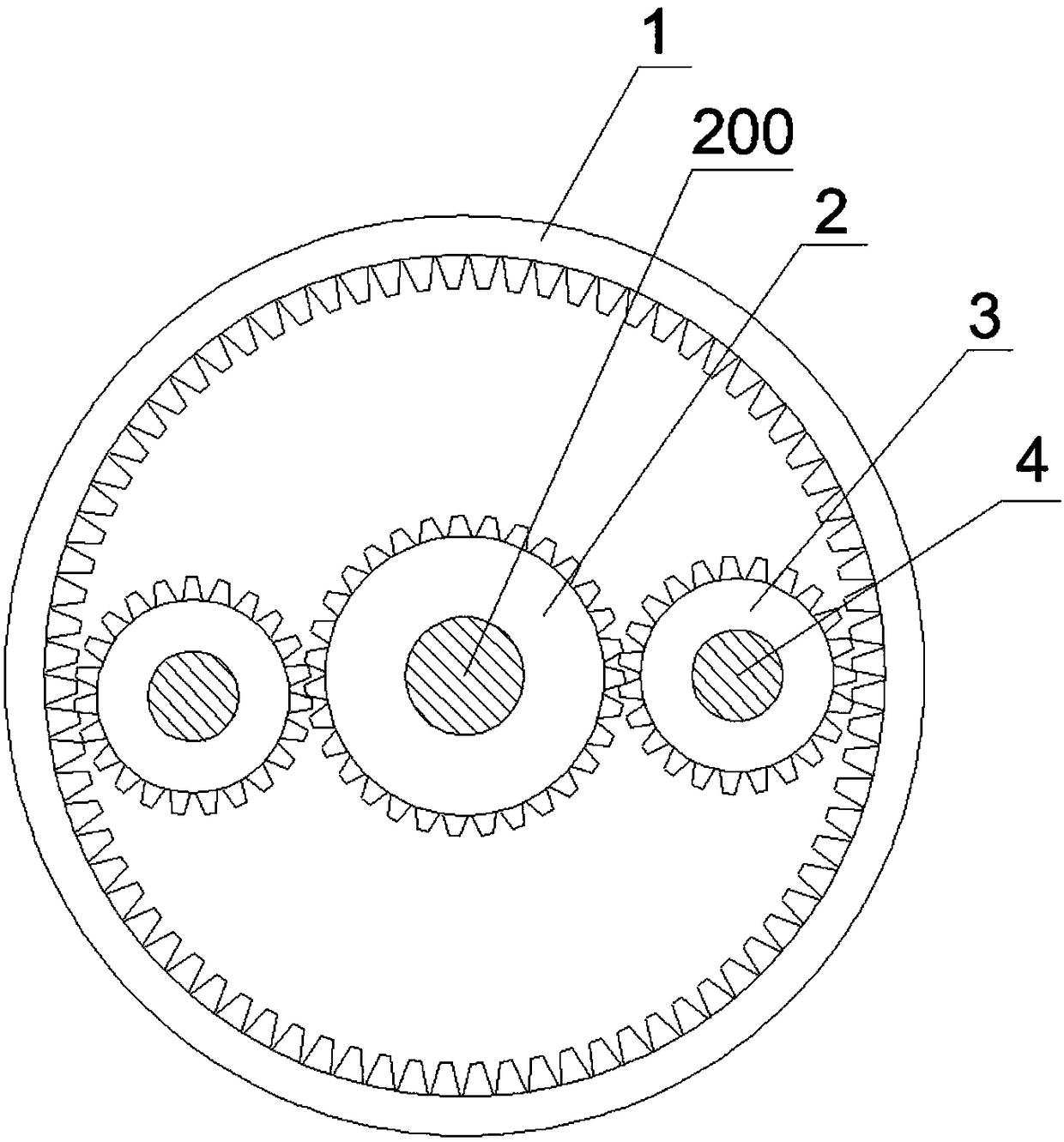

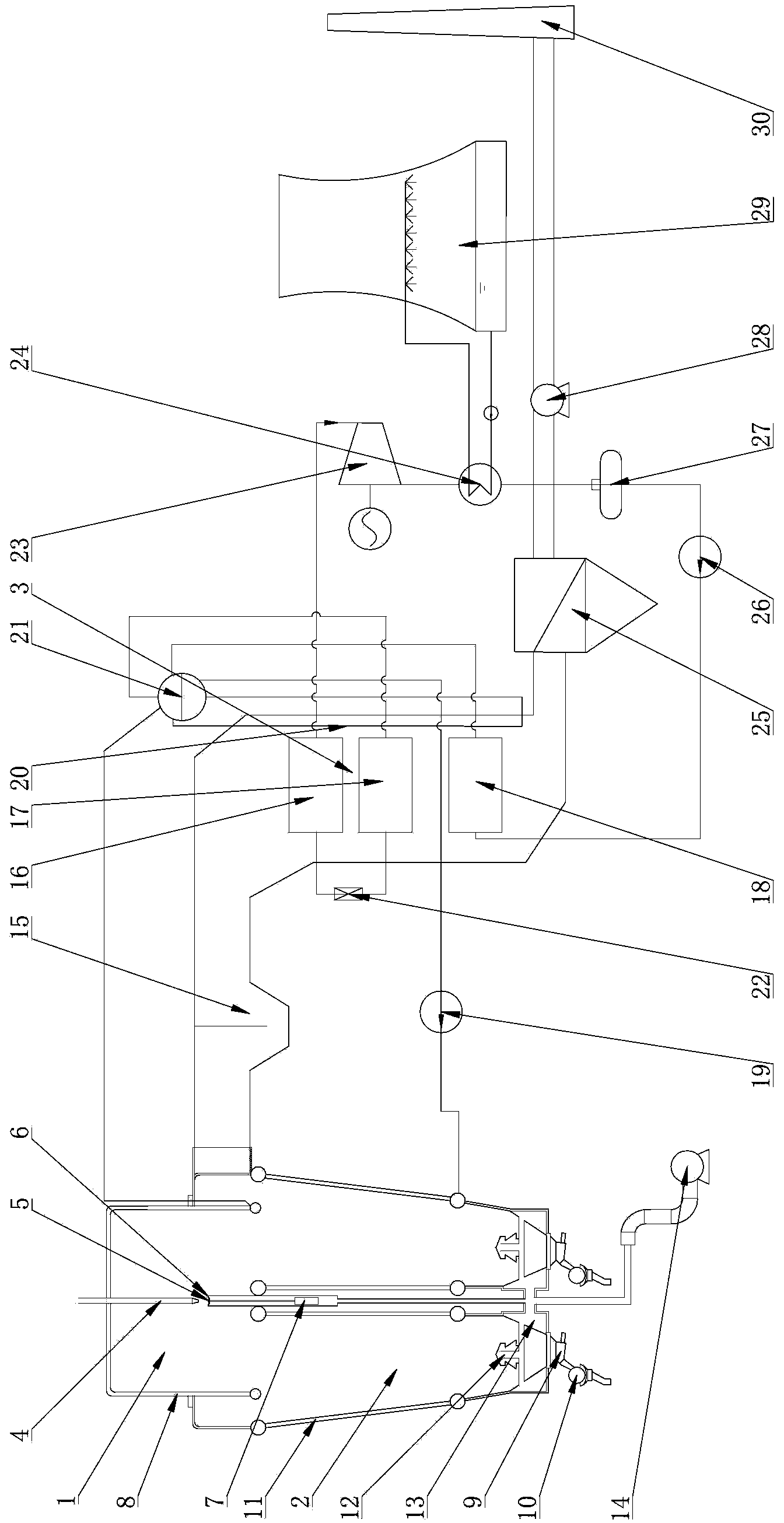

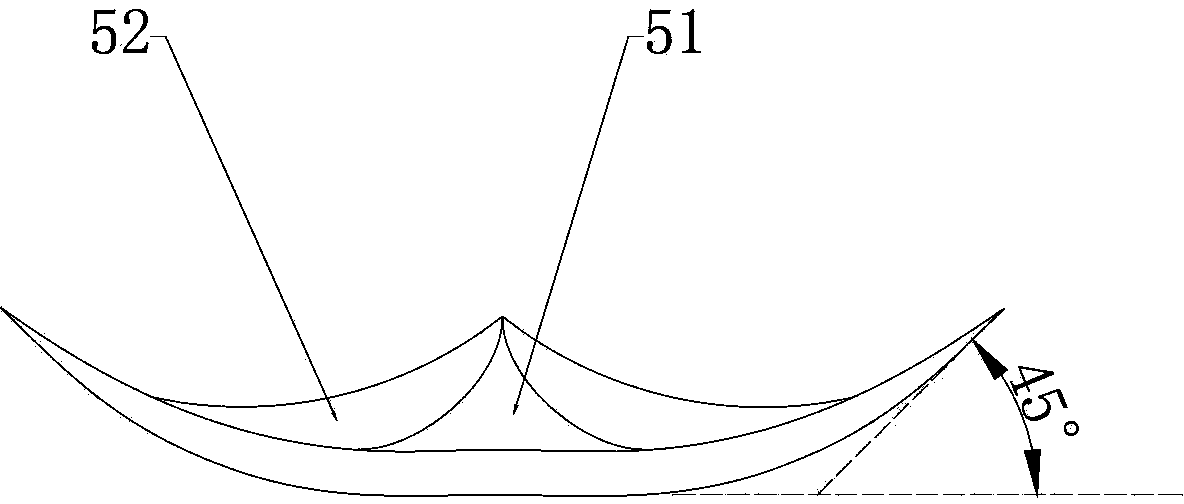

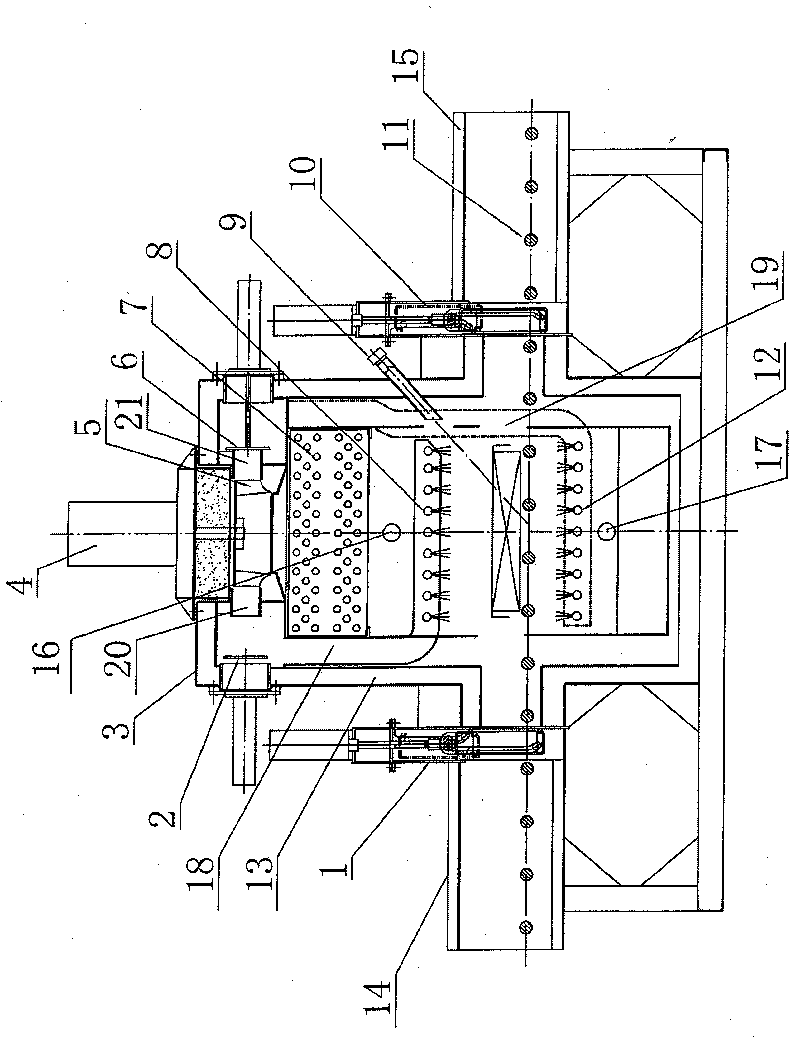

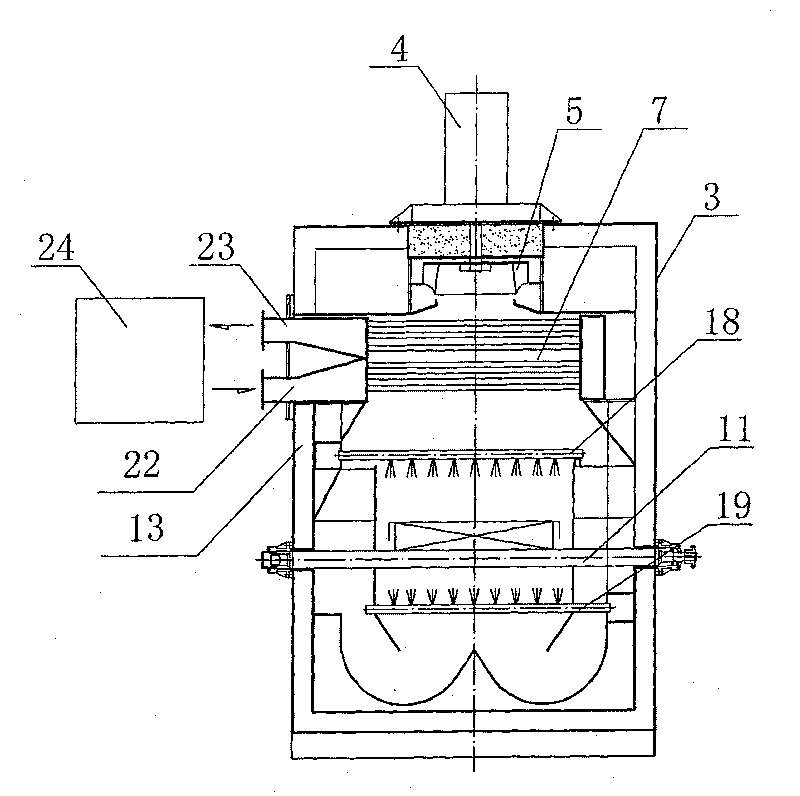

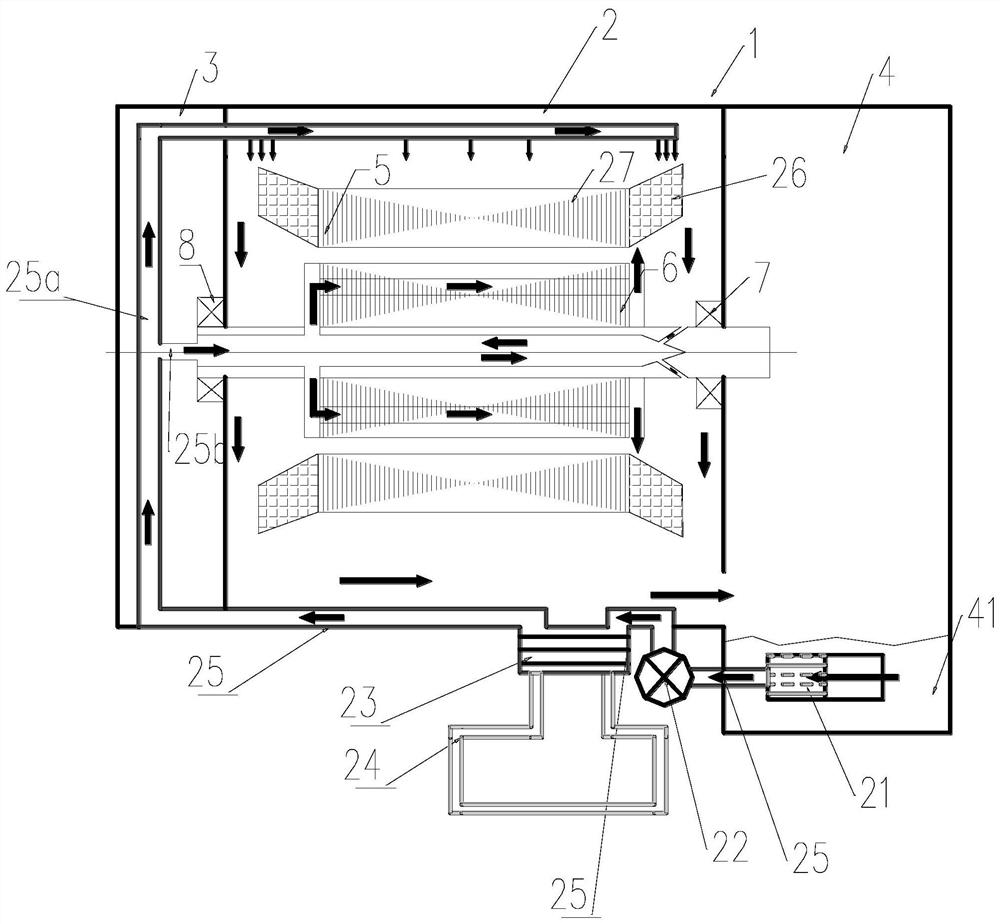

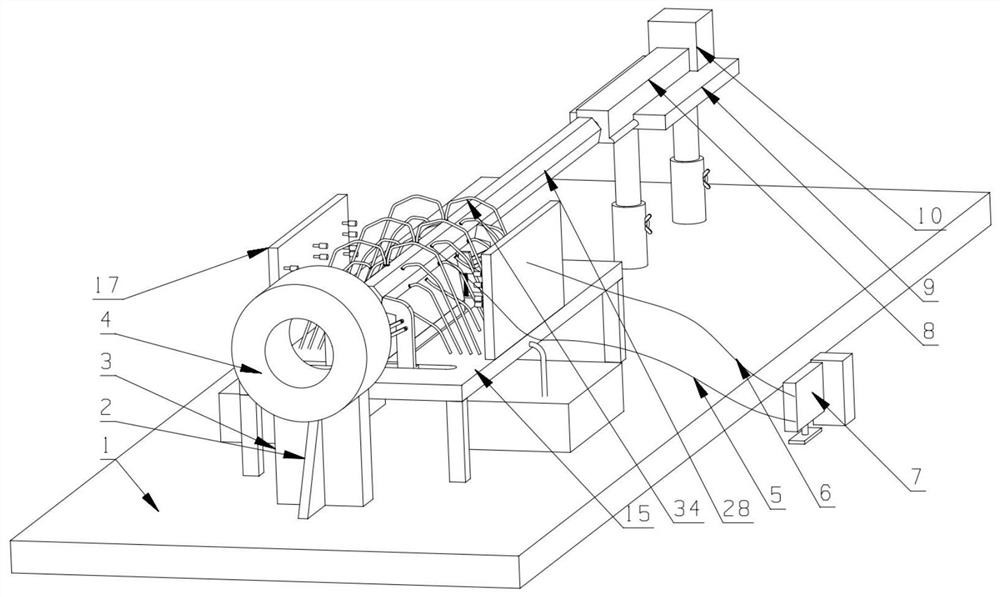

A waste heat recovery system and method for dry centrifugal granulation of high-temperature liquid slag

ActiveCN105603135BSolve the problem of continuous running out of synchronizationSafe and stable operationIncreasing energy efficiencyRecycling and recovery technologiesLiquid slagDelivery system

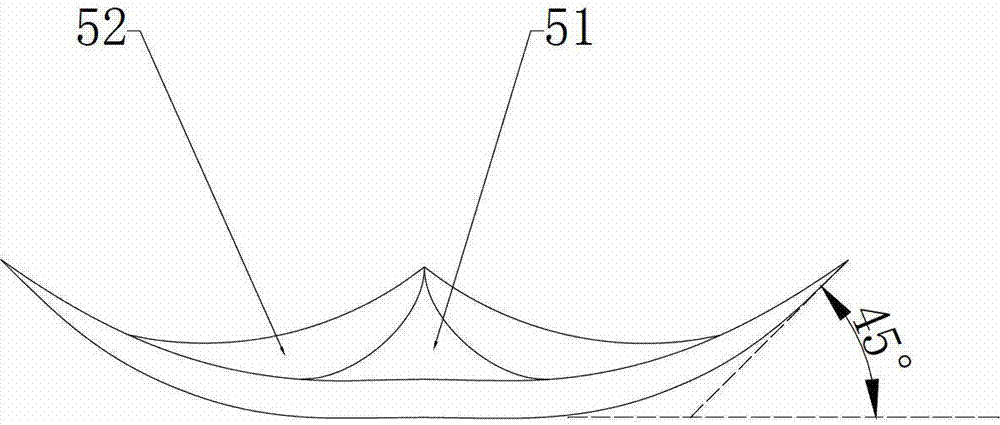

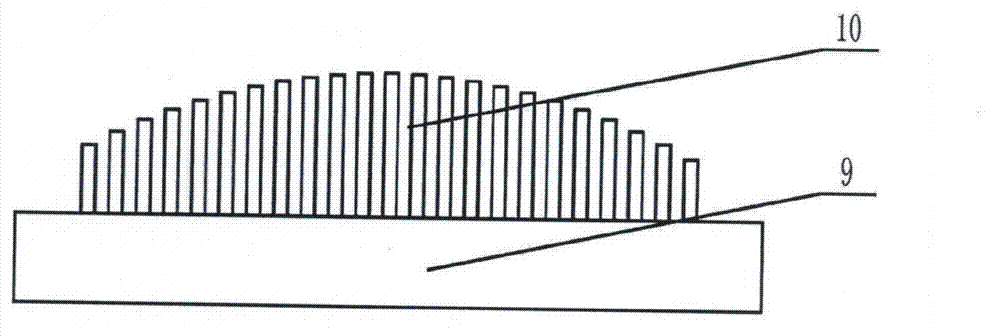

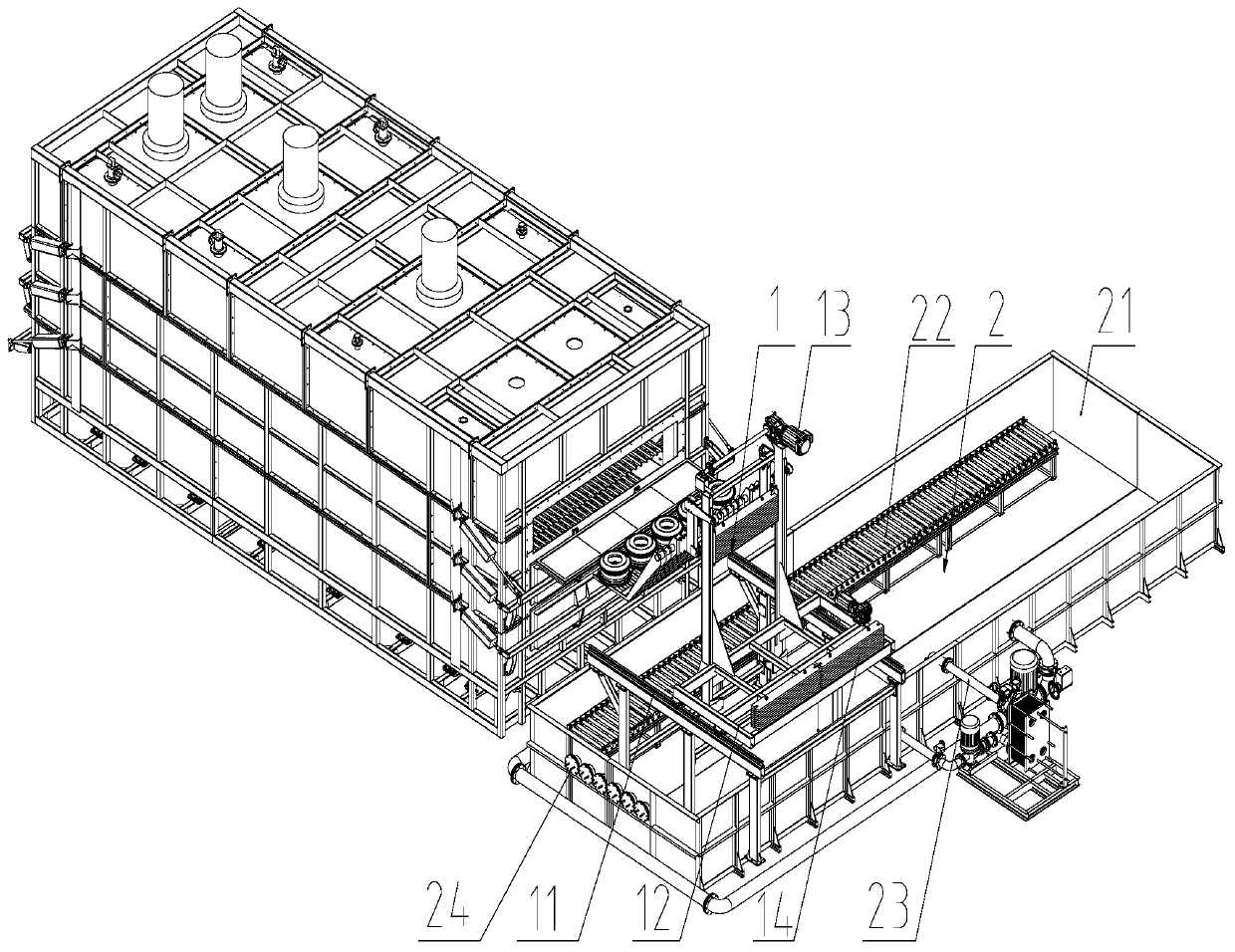

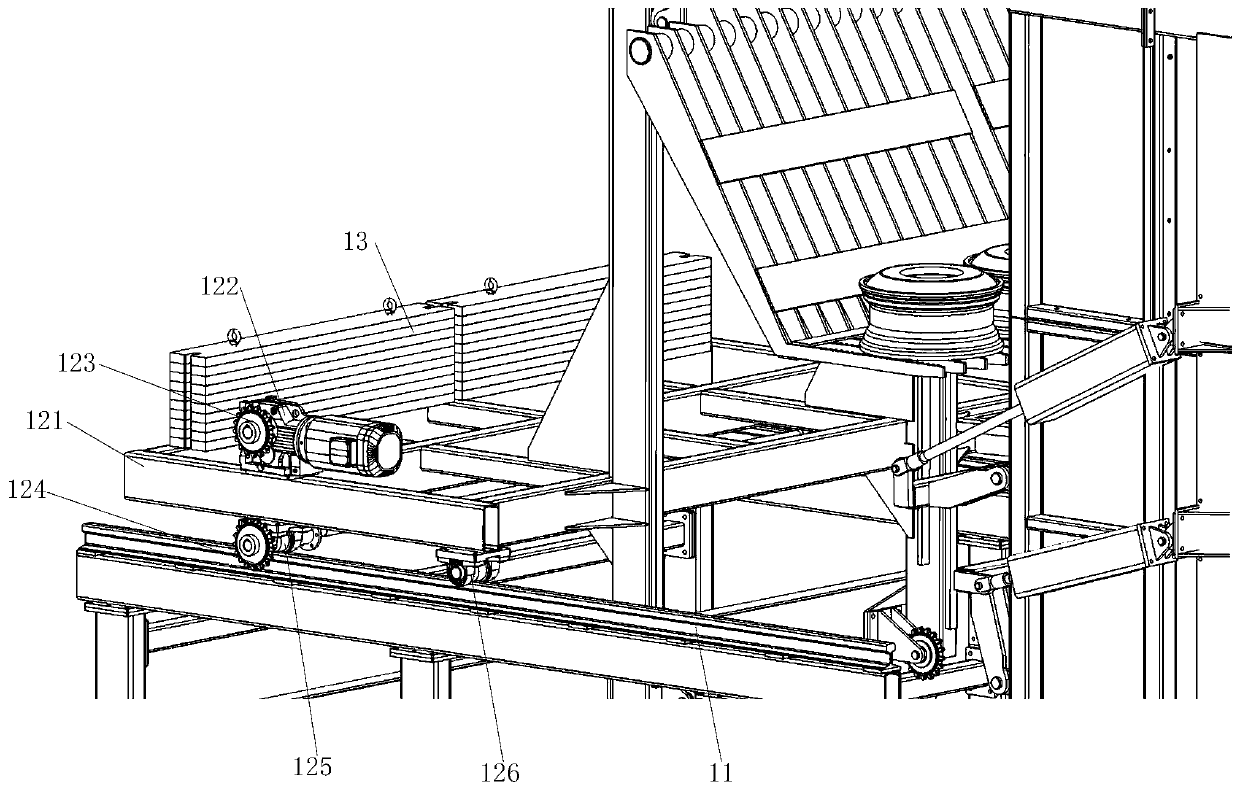

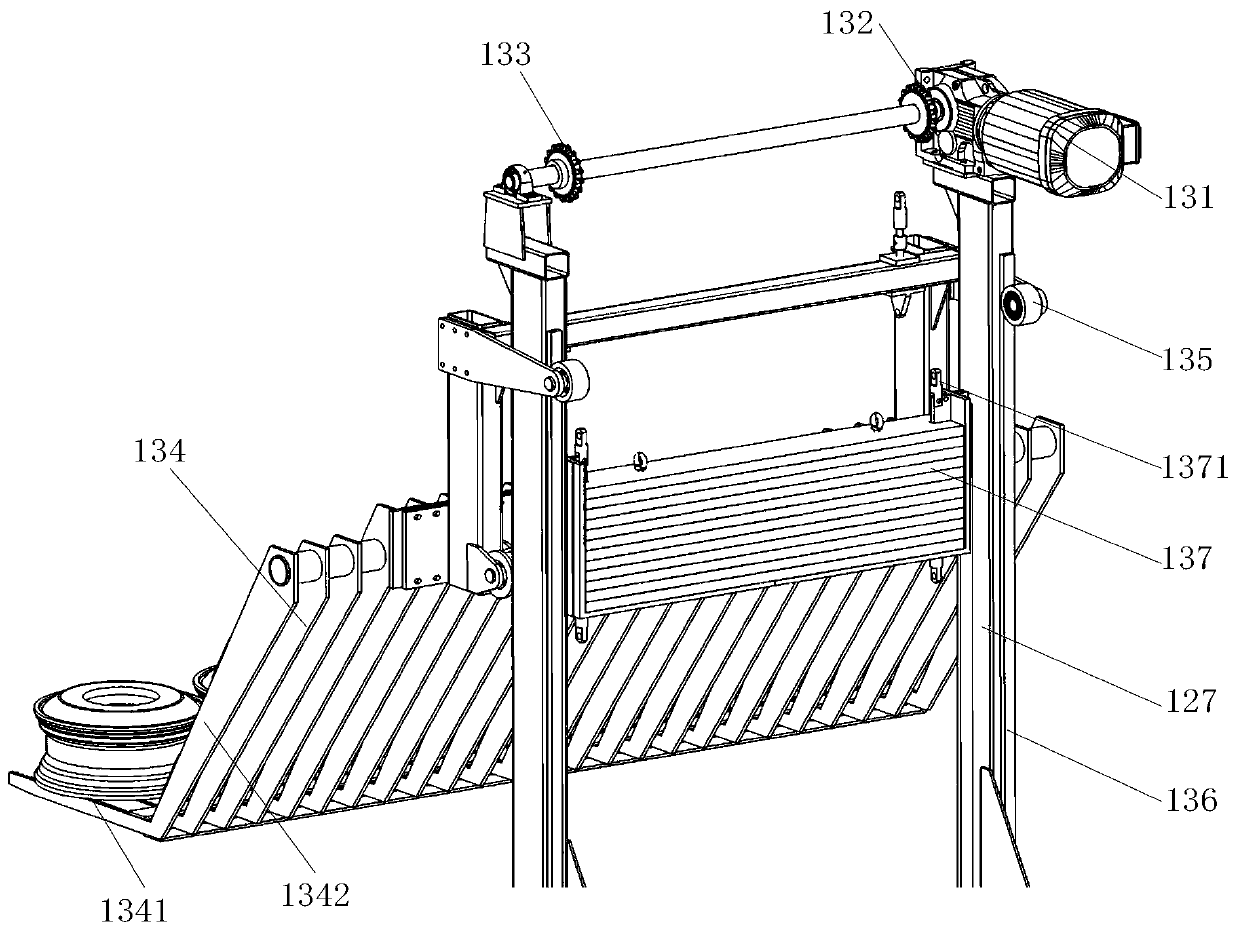

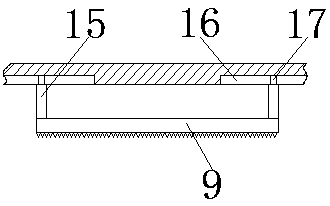

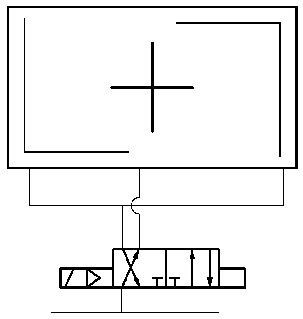

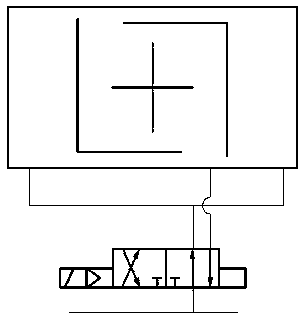

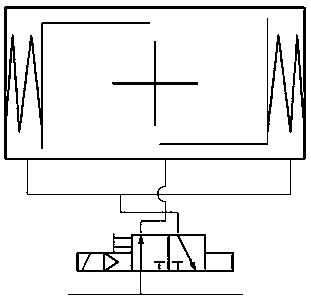

A system and a method for the dry centrifugal granulation of high temperature liquid slag and exhaust heat recovery. The system comprises a liquid slag drainage system, a liquid slag buffering system, a liquid slag granulation and heat exchange system, a slag particle conveying system and an exhaust heat recovery system; the liquid slag drainage system comprises a slag groove (1), a baffle and a slag outlet (2); the liquid slag buffering system is composed of one or more independent slag containers, the slag container comprising structures such as a bag body (3), a bag cover (4), a slag pipe (5), and a stopper rod (6); the liquid slag granulation and heat exchange system is composed of one or more independent granulation and heat exchange systems which are arranged side by side in one or multiple rows, each granulation and heat exchange system being composed of a granulation bin (7), a centrifugal granulator (8), a movable bed (9) and a slag discharge device; the slag particle conveying system comprises a temperature-resistant conveyor belt (14) and a buffering material bin; the exhaust heat recovery system comprises a primary dust collector (15), an exhaust heat boiler (16), a secondary dust collector (17), an exhaust draught fan (18) and a chimney (19) which are connected in sequence.

Owner:XI AN JIAOTONG UNIV +1

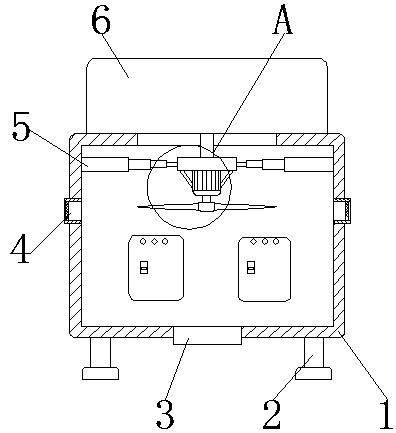

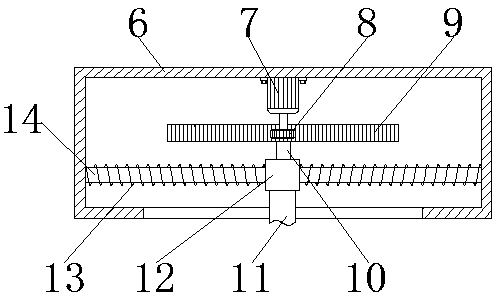

Cooling device for box-type substation

InactiveCN108539637ASolve the problem of uneven coolingCool evenlySubstation/switching arrangement cooling/ventilationSoftware engineeringCooling effect

The present invention discloses a cooling device for a box-type substation. The device comprises a box body, the top portion of the box body is fixedly connected with a cabinet, the top portion of theinner wall of the cabinet is fixedly connected with a positive and negative motor, the output end of the positive and negative motor is fixedly connected with a gear, the back side of the gear is engaged with a toothed plate, the bottom portion of the toothed plate is fixedly connected with a fixed rod, the bottom portion of the fixed rod is fixedly connected with a sliding sleeve, and the innercavity of the sliding sleeve is sleeved with a sliding rod. Through cooperative usage of a cooling port, an air inlet, a cabinet, the positive and negative cabinet, the gear, the toothed plate, the fixed rod, a pull rod, the sliding sleeve, a spring, the sliding rod, a support plate, a motor, a connection block and a fan blade, the problem is solved that a current cooling device for a box-type substation is not uniform in cooling when the cooling device is used, the cooling device for a box-type substation is good in cooling effect, and can perform uniform cooling of elements in the box-type substation so as to facilitate usage of users and improve the practicability of the cooling device for the box-type substation.

Owner:河南许智电力科技有限公司

Maintenance method of controlled cooling after rolling flow regulating valve

ActiveCN111006064AEasy maintenanceAvoid movement anomaliesOperating means/releasing devices for valvesTemperature control deviceProcess engineeringIndustrial engineering

The invention relates to a maintenance method of a controlled cooling after rolling flow regulating valve. The maintenance method is characterized in that two programs and three valve flexibly testingmethods are set to judge that the valve has the problem of unstable flow regulation, and a breakdown maintenance method is adopted to thoroughly solve the problem of control flow fluctuation of the flow regulating valve. By applying the method, the problem of uneven cooling of a steel plate due to the fact that the water amount regulation precision fluctuation is large when the steel plate passesthrough a cold control region, the stable operation of a controlled cooling after rolling system is ensured, the operation reliability of the flow regulating valve is improved, the method is convenient and effective, the high-precision use of the flow regulating valve is recovered in a short time in a relatively low cost, the plate type control capability of the steel plate production is improved, and the practicability is high.

Owner:HANDAN IRON & STEEL GROUP +1

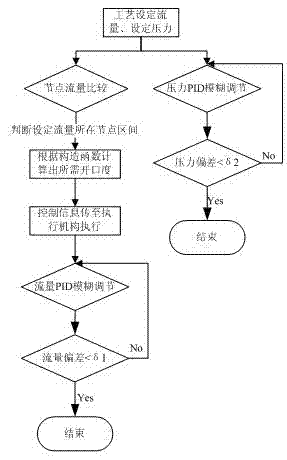

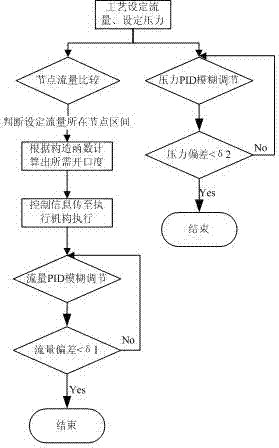

Method for setting flow of hot rolling cooling system

InactiveCN102513375AImprove hit rateImprove performance uniformityTemperature control deviceEngineeringStrip steel

The invention discloses a method for setting flow of a rolling cooling system, wherein the method comprises the following steps: 1) determining direct proportional function of medium flow and collector opening degree needed by the process of each cooling collector, medium flow=k*collector opening degree +b, wherein k and B are constants capable of being determined according to the medium flow needed by the process and the property of performing mechanism; 2) calculating the collector opening degree by the function determined in the step 1) according to a predetermined flow value, and transmitting the control parameter needed by the collector opening degree to an executing mechanism to execute; and 3) carrying out fuzzy adjustment for the medium flow by flow PID (process identification) in order to keep the actual medium flow at the predetermined flow, and carrying out fuzzy adjustment to the pressure of a shunt collector by pressure PID during the whole process. The method of the invention improves the hit rate and property evenness of the band steel by the high precision control of the medium flow of the collector of the cooling zone, solves the problem that the head of the band steel is cooled unevenly during the cooling process, achieves the precision control of temperature of the head and whole roll in a rolling direction, and effectively improves the yield of the band steel.

Owner:NORTHEASTERN UNIV

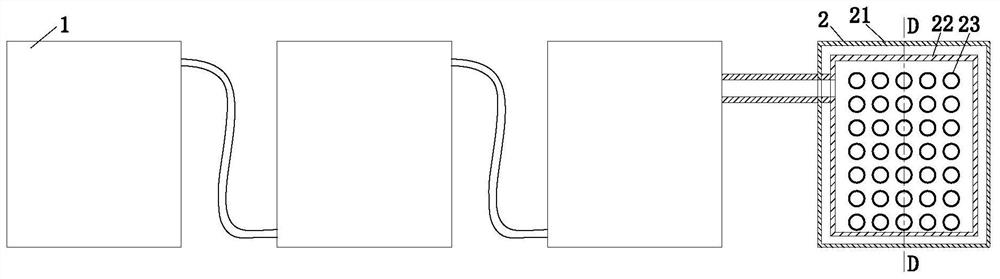

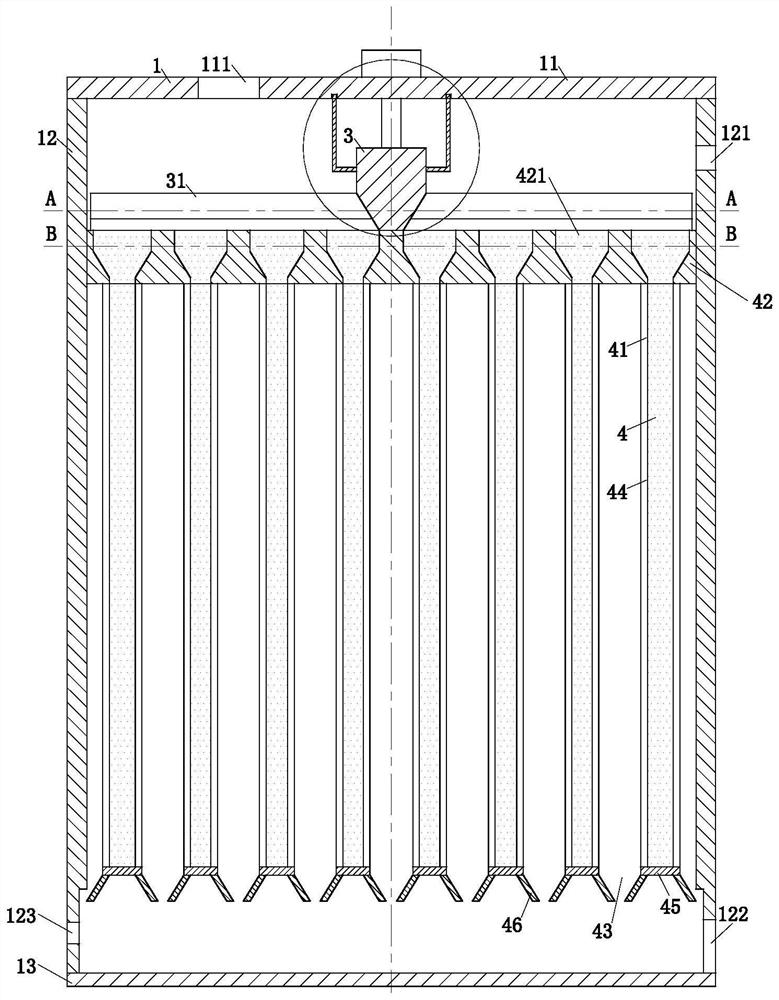

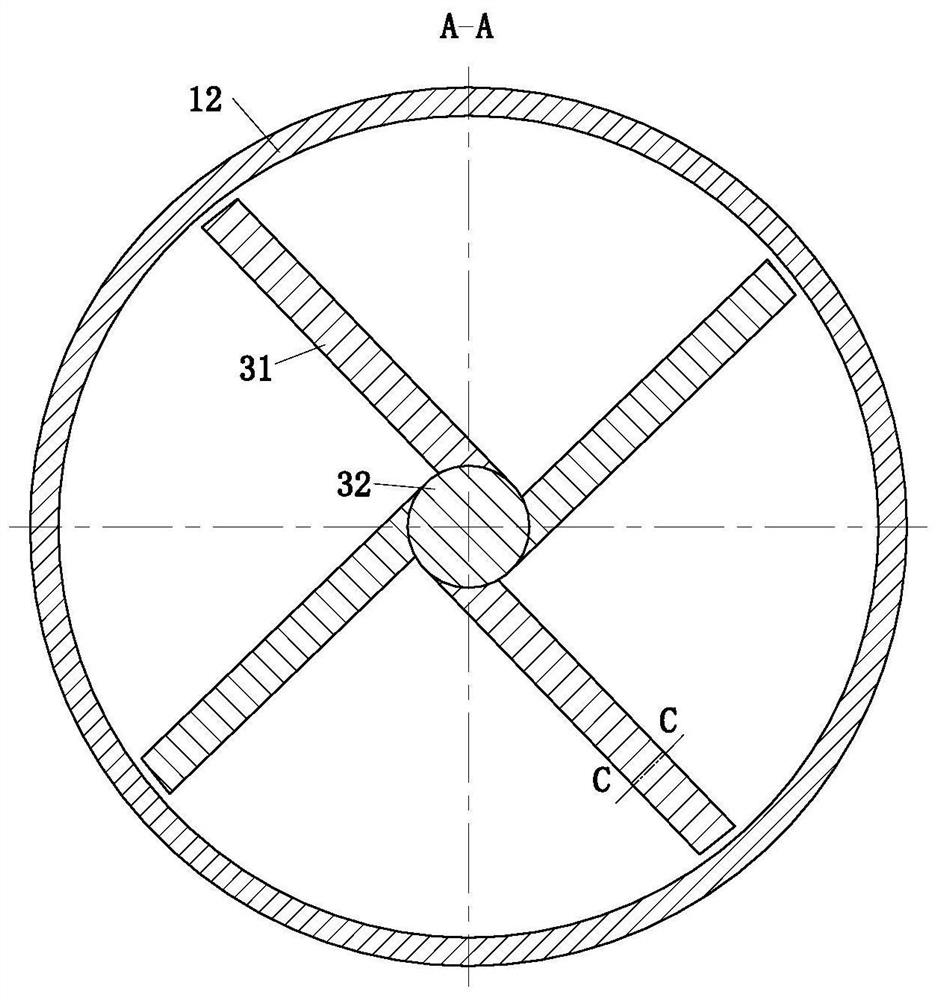

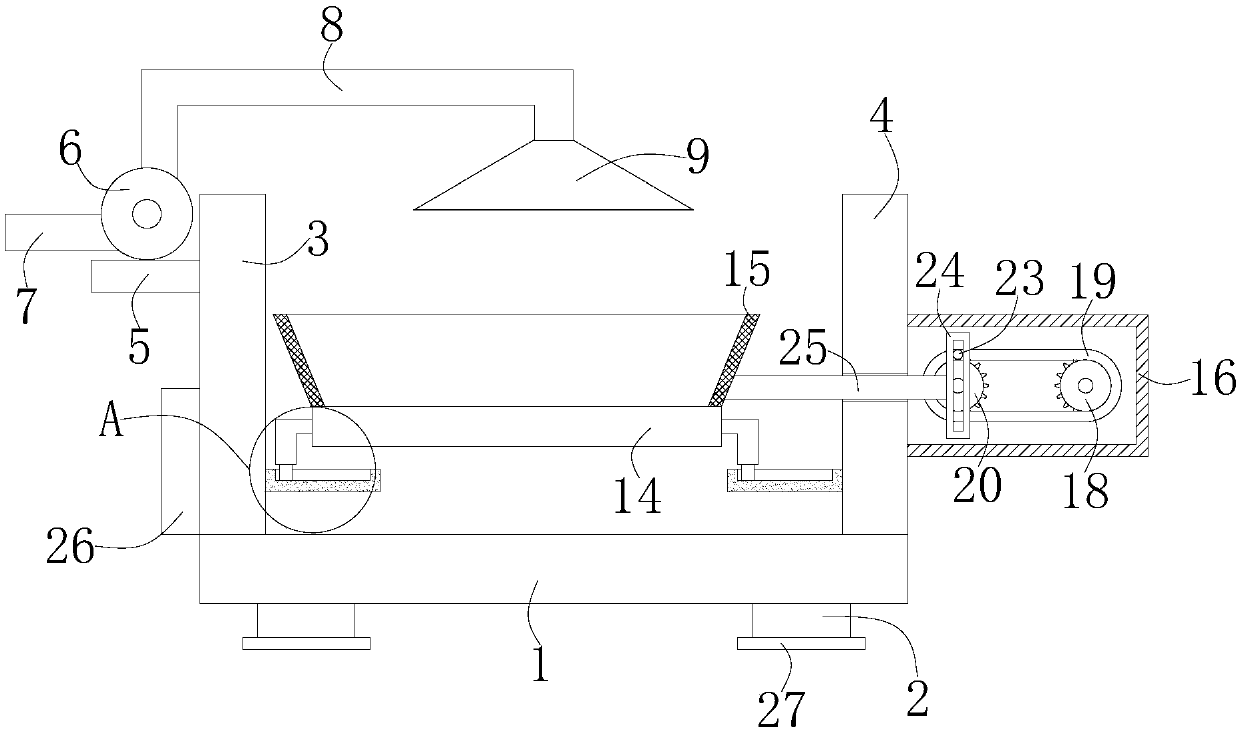

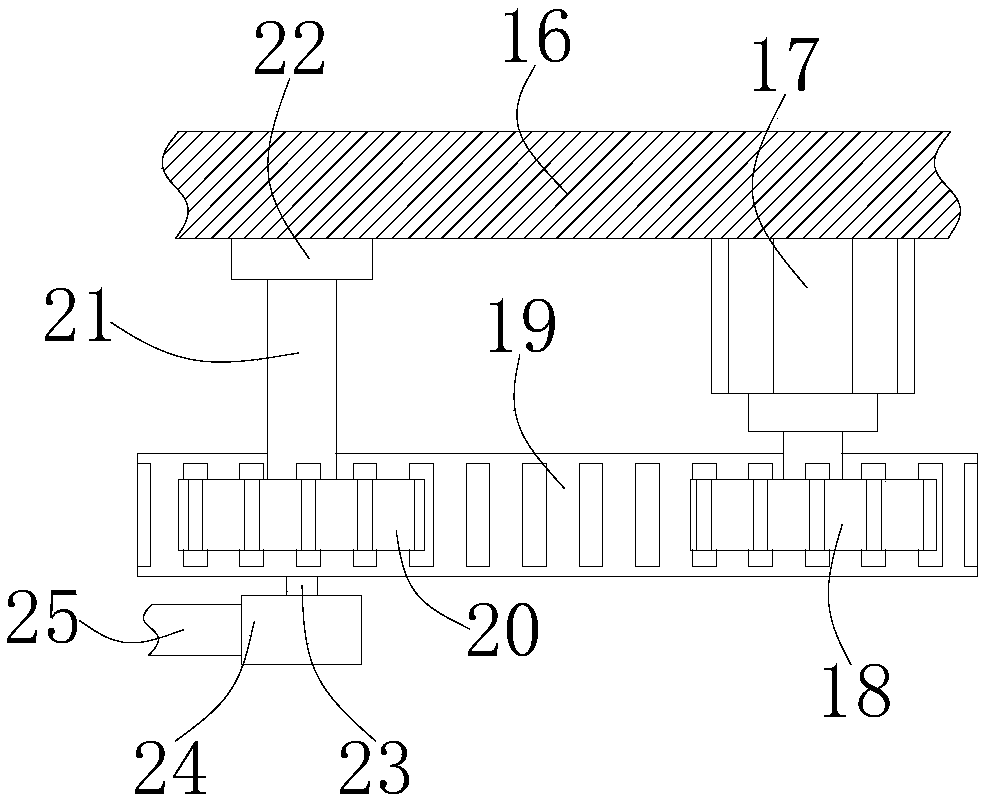

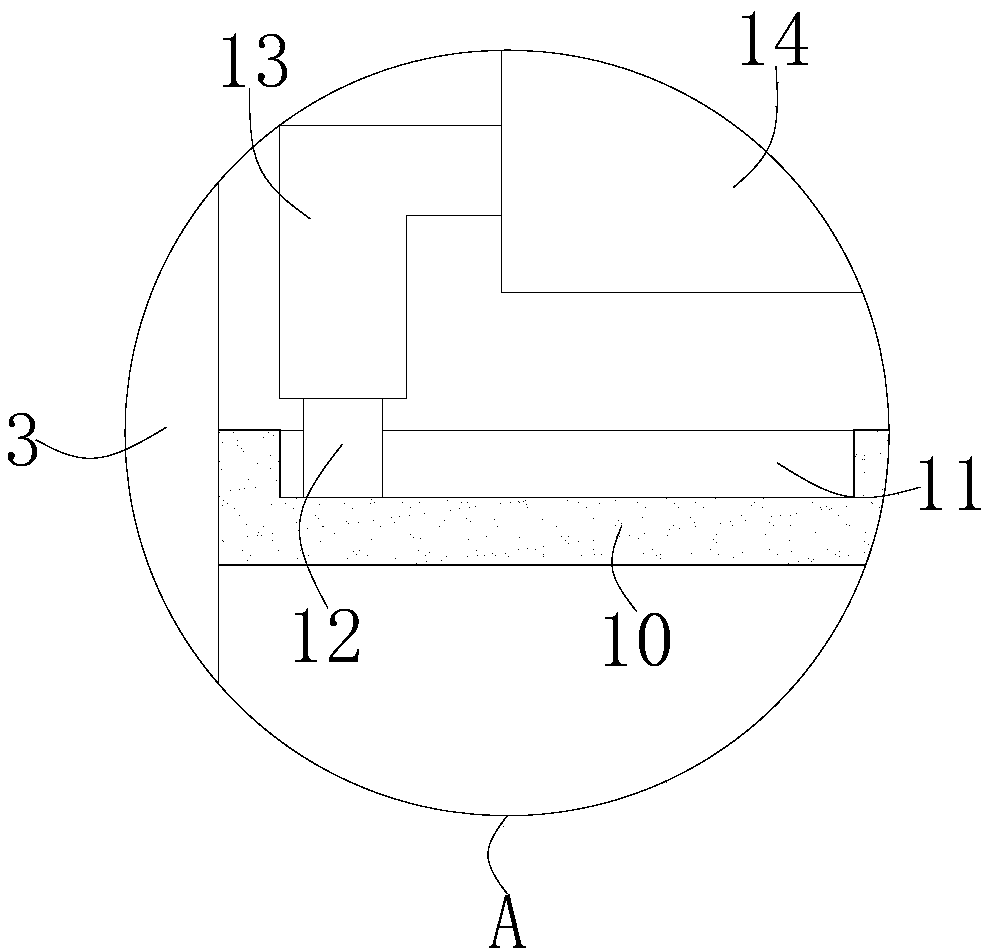

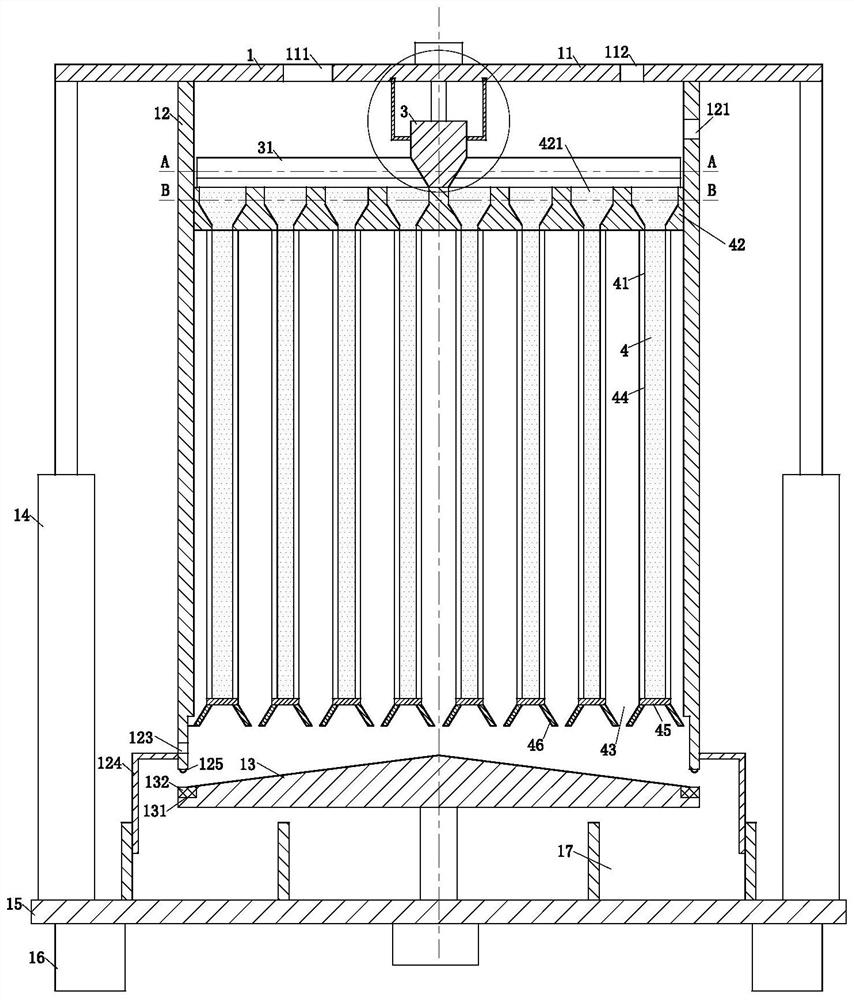

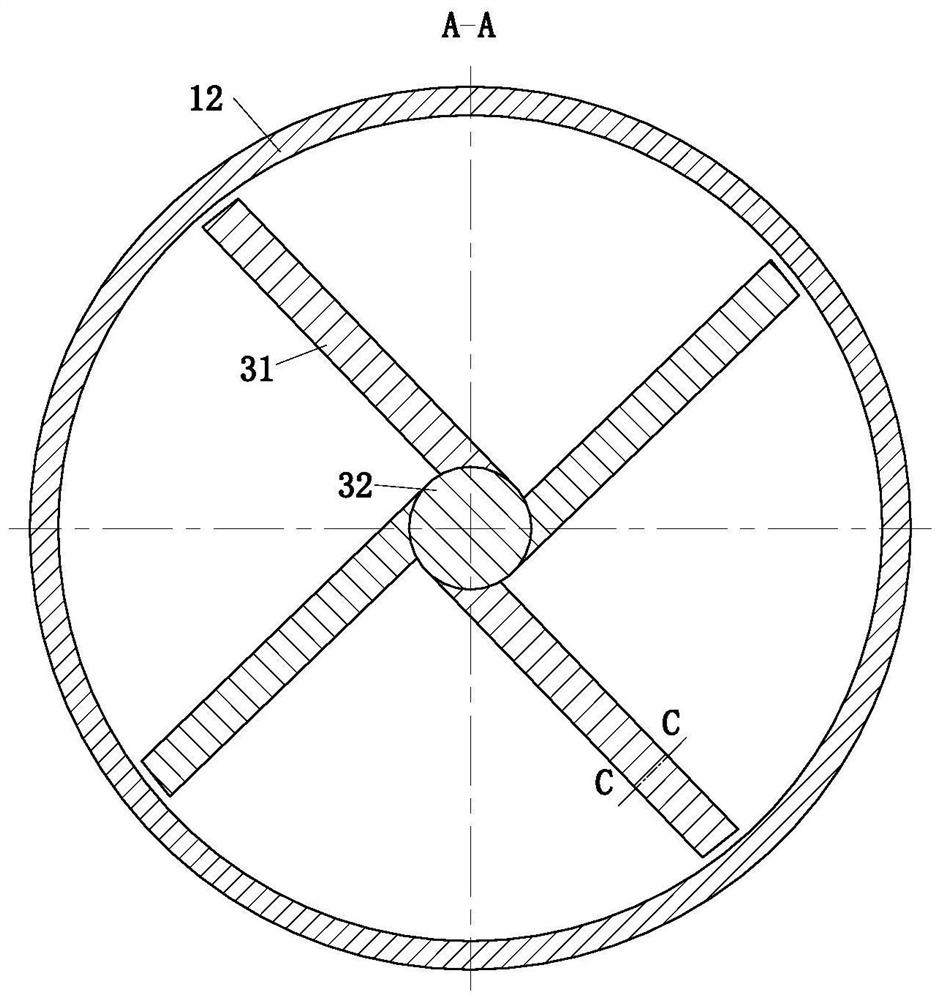

A cylinder type alcohol distillation system

ActiveCN107937227BImprove dissolution efficiencyIncrease humidityAlcoholic beverage preparationAlcoholProcess engineering

The invention belongs to the field of wine brewing equipment, and in particular relates to a barrel type alcohol distillation system. The barrel type alcohol distillation system comprises distillationdevices and a collection box, wherein three distillation devices are arranged; the three distillation devices are connected through a serial connection manner; the collection box is used for collecting alcohol steam distilled by the distillation devices; each distillation device is of a round barrel shape; each distillation device is internally provided with an extruding unit and a distillation unit in sequence from top to bottom; each extruding unit is used for extruding fermented grains into the corresponding distillation unit; each distillation unit comprises a plurality of distillation barrels; the distillation barrels are fixed on the inner surface of a No. 1 side plate through a No. 1 mounting plate; a No. 1 interlayer is formed between the distillation barrels of each distillationunit; when the distillation devices are used for distilling the fermented grains, the No. 1 interlayer is fully filled with steam, and the humidity of the fermented grains in the distillation barrelsis increased, so that the dissolving efficiency of alcohol in the fermented grains is improved; the barrel type alcohol distillation system is mainly used for fermenting the solid-state fermented grains and distilling the alcohol; the alcohol distillation efficiency can be improved, and the production cost is reduced.

Owner:浮来春集团股份有限公司

A cooling device for biomass granulation processing

ActiveCN107631643BCool evenlySolve the problem of uneven coolingDirect contact heat exchangersHeat exchange apparatusCooling effectSlide plate

The invention discloses a cooling device for biomass pelletizing processing. The cooling device comprises a base, wherein the two sides of the bottom of the base are fixedly connected with fixed blocks; the left side of the top of the base is fixedly connected with a first stand column; the right side of the top of the base is fixedly connected with a second stand column; the top of the left sideof the first stand column is fixedly connected with a bearing table; and the top of the bearing table is fixedly connected with an exhaust fan. According to the cooling device disclosed by the invention, the bearing table, the exhaust fan, an exhaust tube, an air outlet tube, an air outlet cover, a slide plate, a slide slot, a slide block, a connecting block, a placing table, a ring-shaped baffleplate, a housing, a motor, a drive gear, a chain, a driven gear, a rotary shaft, a bearing base, a slide post, a movable frame, a movable rod and a controller are matched with one another, so that theuniform cooling effect is achieved, the biomass particles are uniformly cooled by the cooling device, and production efficiency of the cooling device is improved, and therefore, practicability of thecooling device is improved.

Owner:NANJING JIAYA FINE CHEM IND

A maintenance method for cooling control flow regulating valve after rolling

ActiveCN111006064BSolve the problem of uneven coolingSolve hidden troublesOperating means/releasing devices for valvesTemperature control deviceControl systemProcess engineering

The invention relates to a maintenance method for a post-rolling cooling control flow regulating valve. Through two program settings and three flexible test methods for the valve, it is determined that the valve has the problem of unstable regulation flow, and a fault maintenance method completely solves the problem of flow regulation. The valve controls flow fluctuation problems. Through the application of this method, the problem of uneven cooling of the steel plate caused by large fluctuations in the accuracy of water adjustment when the steel plate passes through the cooling control area is completely solved, ensuring the stable operation of the cooling control system after rolling, and improving the operation reliability of the flow control valve; the method is convenient Effective, within a relatively low cost, the high-precision use of the flow regulating valve can be restored in a short period of time, and the ability to control the plate shape of the produced steel plate is improved, and the practicability is strong.

Owner:HANDAN IRON & STEEL GROUP +1

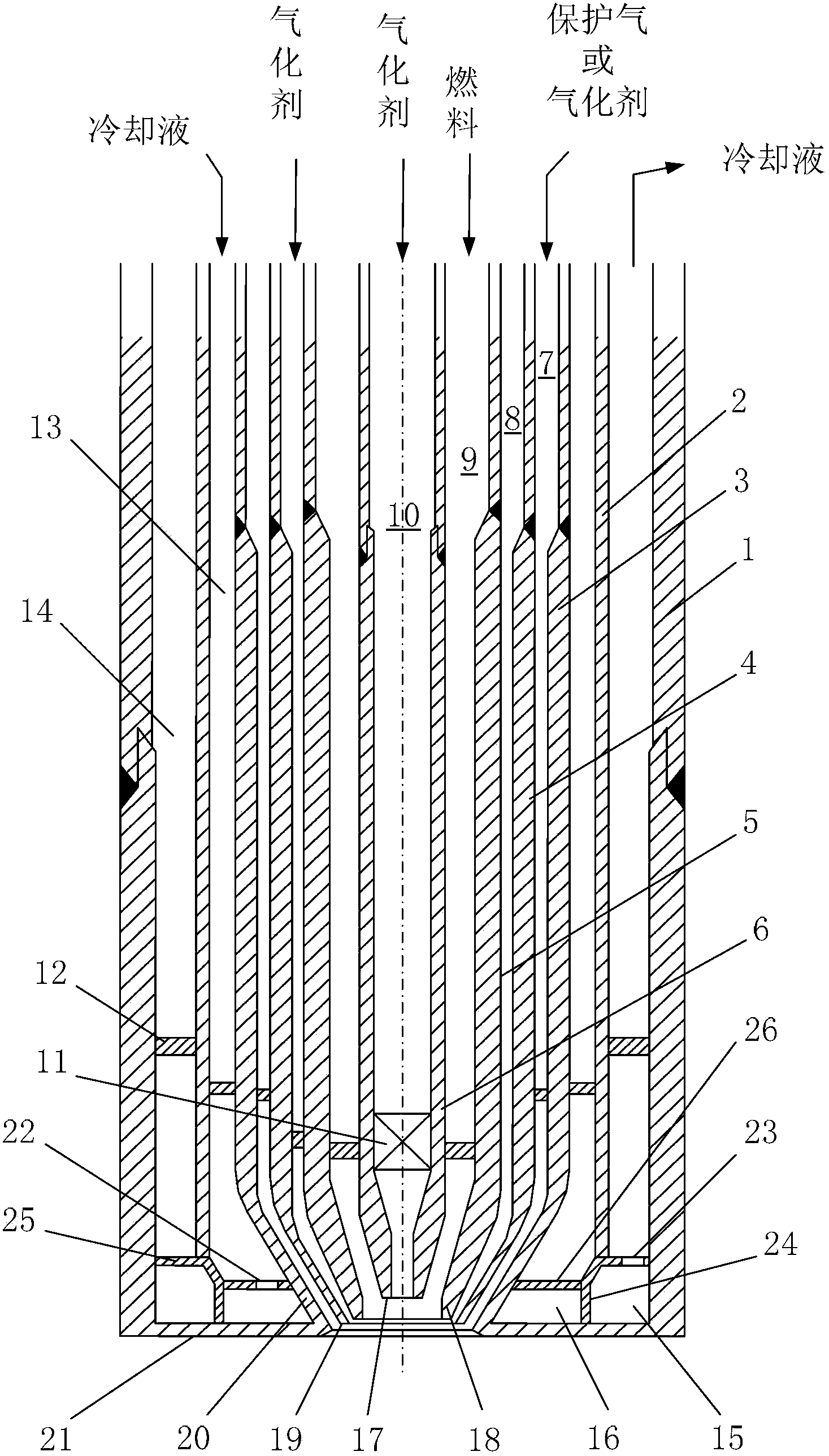

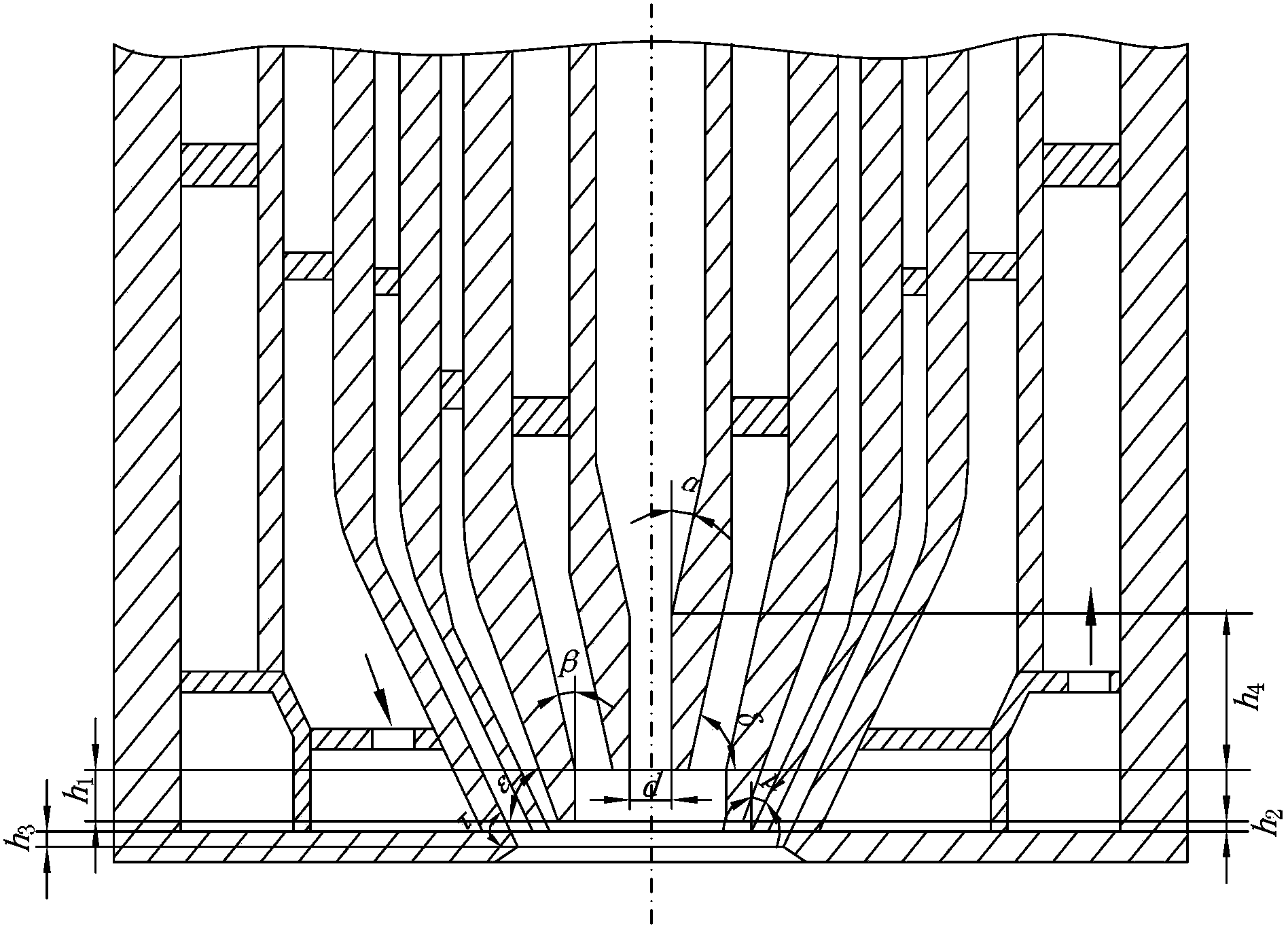

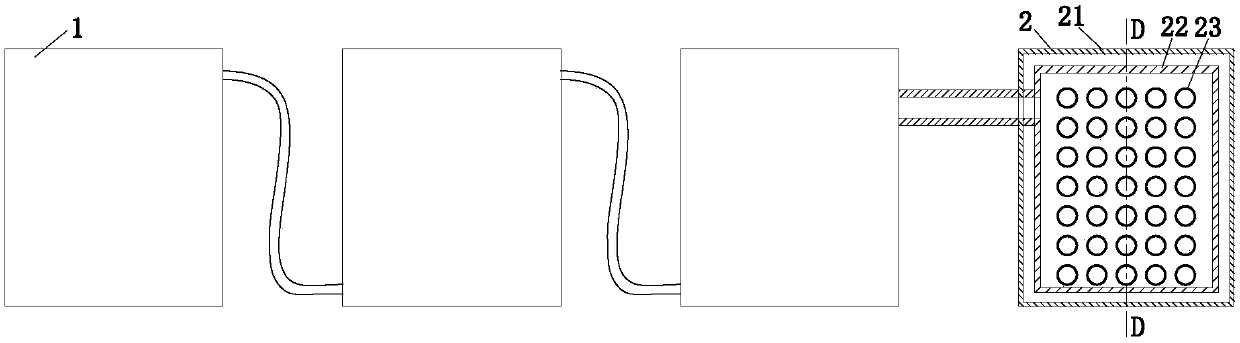

Load-controllable multichannel liquid fuel gasification burner

The invention discloses a load-controllable multichannel liquid fuel gasification burner, which comprises a burner central spray pipe, a first burner outer ring spray pipe, a second burner outer ring spray pipe, a third burner outer ring spray pipe, a burner central sprayer, a first burner outer ring sprayer, a second burner outer ring sprayer, a third burner outer ring sprayer, a swirler and a burner cooling system, wherein the burner central spray pipe, the first burner outer ring spray pipe, the second burner outer ring spray pipe and the third burner outer ring spray pipe are coaxial. According to the load-controllable multichannel liquid fuel gasification burner disclosed by the invention, the rotation of airflow in a central channel is enhanced by adopting a multichannel structural design through arranging the swirler in a central channel spray pipe, thus, the overall atomization performance of the burner is improved. By adopting the multichannel design, on one hand, the atomization of the airflow to liquid fuel can be enhanced, and on the other hand, the regulation on the flow of a gasification agent and the flow of the liquid fuel can be enhanced, thus, the load of the gasification burner is effectively regulated. The liquid fuel burner is cooled by adopting a jacket-type cooling mode. Compared with a coiled pipe-type cooling effect of a traditional industrially applied liquid fuel gasification burner, the jacket-type cooling effect is obviously enhanced.

Owner:SHANGHAI BOILER WORKS

Barrel type alcohol distillation system

ActiveCN107937227AImprove dissolution efficiencyIncrease humidityAlcoholic beverage preparationAlcoholDistillation

The invention belongs to the field of wine brewing equipment, and in particular relates to a barrel type alcohol distillation system. The barrel type alcohol distillation system comprises distillationdevices and a collection box, wherein three distillation devices are arranged; the three distillation devices are connected through a serial connection manner; the collection box is used for collecting alcohol steam distilled by the distillation devices; each distillation device is of a round barrel shape; each distillation device is internally provided with an extruding unit and a distillation unit in sequence from top to bottom; each extruding unit is used for extruding fermented grains into the corresponding distillation unit; each distillation unit comprises a plurality of distillation barrels; the distillation barrels are fixed on the inner surface of a No. 1 side plate through a No. 1 mounting plate; a No. 1 interlayer is formed between the distillation barrels of each distillationunit; when the distillation devices are used for distilling the fermented grains, the No. 1 interlayer is fully filled with steam, and the humidity of the fermented grains in the distillation barrelsis increased, so that the dissolving efficiency of alcohol in the fermented grains is improved; the barrel type alcohol distillation system is mainly used for fermenting the solid-state fermented grains and distilling the alcohol; the alcohol distillation efficiency can be improved, and the production cost is reduced.

Owner:浮来春集团股份有限公司

Cooling device for biomass pelletizing processing

ActiveCN107631643ACool evenlySolve the problem of uneven coolingDirect contact heat exchangersHeat exchange apparatusSoftware engineeringSlide plate

The invention discloses a cooling device for biomass pelletizing processing. The cooling device comprises a base, wherein the two sides of the bottom of the base are fixedly connected with fixed blocks; the left side of the top of the base is fixedly connected with a first stand column; the right side of the top of the base is fixedly connected with a second stand column; the top of the left sideof the first stand column is fixedly connected with a bearing table; and the top of the bearing table is fixedly connected with an exhaust fan. According to the cooling device disclosed by the invention, the bearing table, the exhaust fan, an exhaust tube, an air outlet tube, an air outlet cover, a slide plate, a slide slot, a slide block, a connecting block, a placing table, a ring-shaped baffleplate, a housing, a motor, a drive gear, a chain, a driven gear, a rotary shaft, a bearing base, a slide post, a movable frame, a movable rod and a controller are matched with one another, so that theuniform cooling effect is achieved, the biomass particles are uniformly cooled by the cooling device, and production efficiency of the cooling device is improved, and therefore, practicability of thecooling device is improved.

Owner:NANJING JIAYA FINE CHEM IND

Processing device for producing soy sauce flavor type baijiu

InactiveCN108384691ASolve superficial problemsSolve temperature problemsAlcoholic beverage preparationPulp and paper industryPiston

The invention belongs to the field of baijiu production and processing, and particularly discloses a processing device for producing soy sauce flavor type baijiu. The processing device comprises a rack, the rack is provided with a cooling mechanism, the cooling mechanism comprises an inner gear ring and a driving gear, the inner gear ring is fixedly sleeved with a cooling disc, two middle gears are meshed with the part between the driving gear and the inner gear ring, supporting columns are fixedly connected into gear holes of both middle gears and are both fixedly sleeved with transverse turntables, first through holes are formed in both transverse turntables in the circumferential direction, vertical turntables are arranged at the outer sides of both transverse turntables and are provided with second through holes, L-shaped connecting parts are connected between both the first through holes and the second through holes, piston cavities are fixed to the vertical turntables, pistons are slidably connected into the piston cavities, transverse supporting rods are fixed to rotation centers of both vertical turntables, and leveling rollers and turning rollers fixedly sleeve the transverse supporting rods respectively. The processing device for producing the soy sauce flavor type baijiu can solve the problem that currently, after distilled grain is cooled, the temperature differenceon the surface and the bottom of the distilled grain is large.

Owner:贵州酣客君丰酒业有限公司

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969BEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

Sealing rapid cooling chamber

The invention relates to a sealed fast cooling chamber which mainly comprises a fast cooling chamber shell, a front door of the fast cooling chamber, a back door of the fast cooling chamber, a fan andfan blades. The fast cooling chamber shell, the front door of the fast cooling chamber and the back door of the fast cooling chamber form a sealed body, an upper blow-off nozzle and a lower blow-offnozzle which can be controllably opened and closed are arranged inside the inner cavity of the fast cooling chamber shell, the upper blow-off nozzle and the lower blow-off nozzle are oppositely arranged; the fan is arranged on the fast cooling chamber shell, an air inlet pipe is arranged under the air inlet of the fan blades, a cold-heat exchanger is arranged between the air inlet of the fan blades and the air inlet pipe, and air circulation is formed between the air inlet pipe and the air outlet pipe; the air outlet of the fan blades is respectively communicated with an upper air outlet pipeand a lower air outlet pipe, the upper blow-off nozzle is communicated with the upper air outlet pipe by an upper blow-off pipe, and the lower blow-off nozzle is communicated with the lower air outletpipe by a lower blow-off pipe. The sealed fast cooling chamber has the advantages of providing a protective atmosphere fast cooling chamber with a novel sealed structure, solving the problem of uneven cooling, ensuring stable and reliable quality of the bright isothermal normalizing, and realizing the purposes of saving materials and reducing energy consumption.

Owner:HANGZHOU JINZHOU TECH CO INC

A three-in-one oil-cooled electric drive structure

ActiveCN112421889BReduce the risk of oil spillsGuaranteed cooling effectMagnetic circuit rotating partsElectric machinesElectric machineReduction drive

The invention discloses a three-in-one oil-cooled electric drive structure. The cooling oil in the reducer casing is transported to the main oil circuit of the motor casing. The main oil circuit is divided into a first oil circuit and a second oil circuit at the rear end cover. The first oil circuit is connected to the stator cooling structure, and the second oil circuit is connected to the stator cooling structure. The oil circuit communicates with the rotor cooling structure; the stator cooling structure is used to introduce cooling oil into the upper part of the electric drive, and the stator is directionally cooled through the oil spray holes in the stator oil passage on the motor housing; the rotor cooling structure is used to pass the rotor The cooling oil is rotated and the oil is thrown to achieve cooling. The circulating oil circuit is connected by the structural design of the casing itself, and the oil circuit is divided on the casing to ensure the cooling of the stator and rotor, without the need for additional oil separation structure and copper pipes, which improves the integration of oil-cooled electric drive. , reduce the cost and reduce the risk of oil leakage from the oil pipe.

Owner:HEFEI JUYI POWER SYST CO LTD

Hot rolling spray cooling method for large cylinder

ActiveCN102847732BSolve the problem of uneven coolingIncrease the direct contact areaWork treatment devicesMetal rolling arrangementsFlow ratioSpray cooling

Owner:YANSHAN UNIV

An Alcohol Distillation Device Convenient for Loading and Unloading Grains

ActiveCN108239588BEasy dischargeAutomatic deliveryAlcoholic beverage preparationBiotechnologyEngineering

Owner:杭州同福永酿酒有限公司

Method for improving quenching uniformity of inner-spraying and outer-sprinkling quenching system

InactiveCN110629008AImprove uniformity and stabilityImprove pass rateFurnace typesHeat treatment process controlLength propertyQuenching

The invention discloses a method for improving the quenching uniformity of an inner-spraying and outer-sprinkling quenching system and relates to the technical field of thermal treatment of seamless tubes. The main point of the method lies in that a water replenishing device is designed in the quenching system, part of cooling water which is hindered by a compacting device is replenished, different water replenishing processes are adopted according to the property requirements of steel tubes with different specifications and different steel grades, thus the uniformity of the quenching effect is improved, the problem that the overall-length property of the steel tubes is non-uniform is solved, the qualified rate of the steel tubes is improved, and the characteristics that the system is simple, operation is convenient and fast, and the effects are good are achieved.

Owner:DALIPAL PIPE

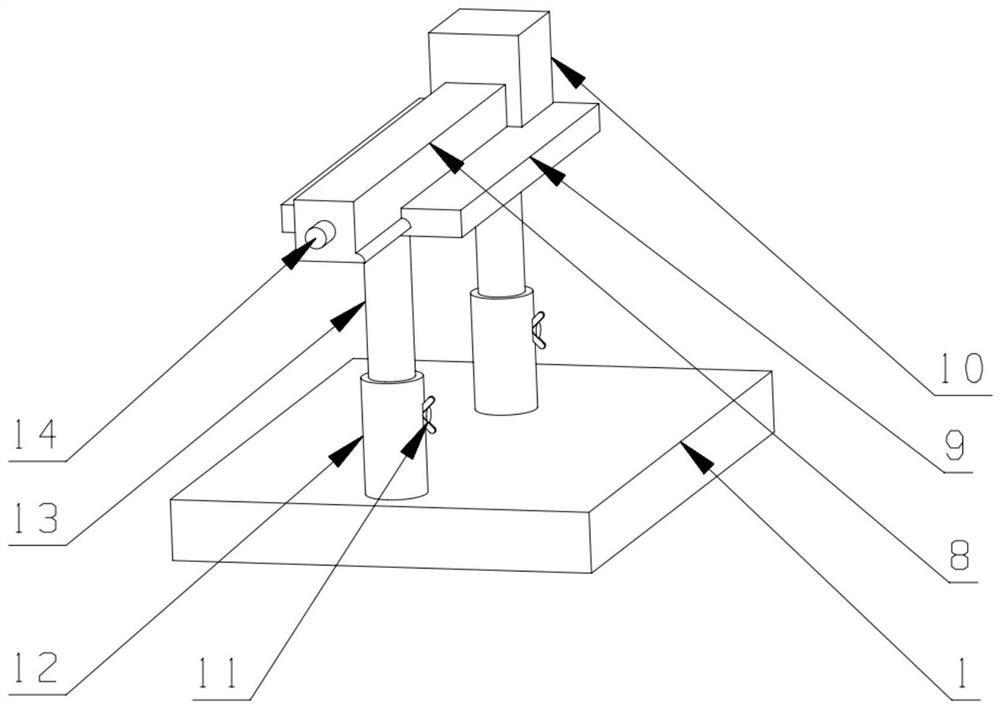

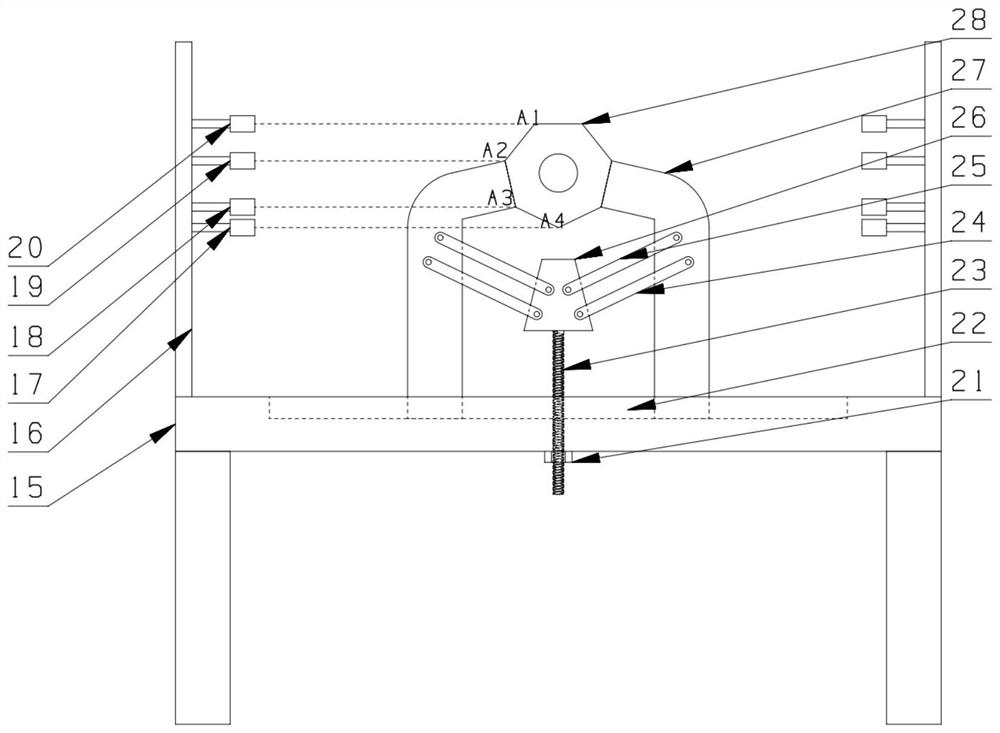

Brazing steel cooling system and cooling method thereof

ActiveCN111426205BSolve the problem of uneven coolingPrecise water controlCharge manipulationHandling discharged materialTemperingWater flow

The invention discloses a drill steel cooling system which comprises a base, a worktable, an air cooling device, a propelling device, a positioning device, a temperature measuring device, a cooling device and a feedback device, wherein the temperatures of four joints A1, A2, A3 and A4 are regulated and controlled by the feedback device; three feedback devices are arranged in the axial direction toensure that the actual cooling temperature of the shaft is controllable. Temperatures at pints of corner angles are controlled precisely by means of a feedback system, so that the problem that the corner angles of the polygonal drill steel are not cooled uniformly is solved. The invention further discloses a cooling method of the drill steel. The feedback system of the method acts to the four joints A1, A2, A3 and A4 separately to control the size of a water flow precisely, so that the water is controlled precisely and the water consumption is reduced. In order to prevent a condition that theactual cooling temperature of the drill steel cannot reach the control temperature as the temperature of the surface of the drill steel raises again due to self-tempering of the drill steel, three feedback systems are uniformly distributed along the axial direction o the drill steel, so that the actual cooling temperature of the steel drill is controllable.

Owner:北渤智能科技秦皇岛有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com