Oil cooling stator structure

An oil-cooled stator and cold stator technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, cooling/ventilation device, etc., can solve the problem of uneven cooling of the stator, and achieve the purpose of solving uneven cooling. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

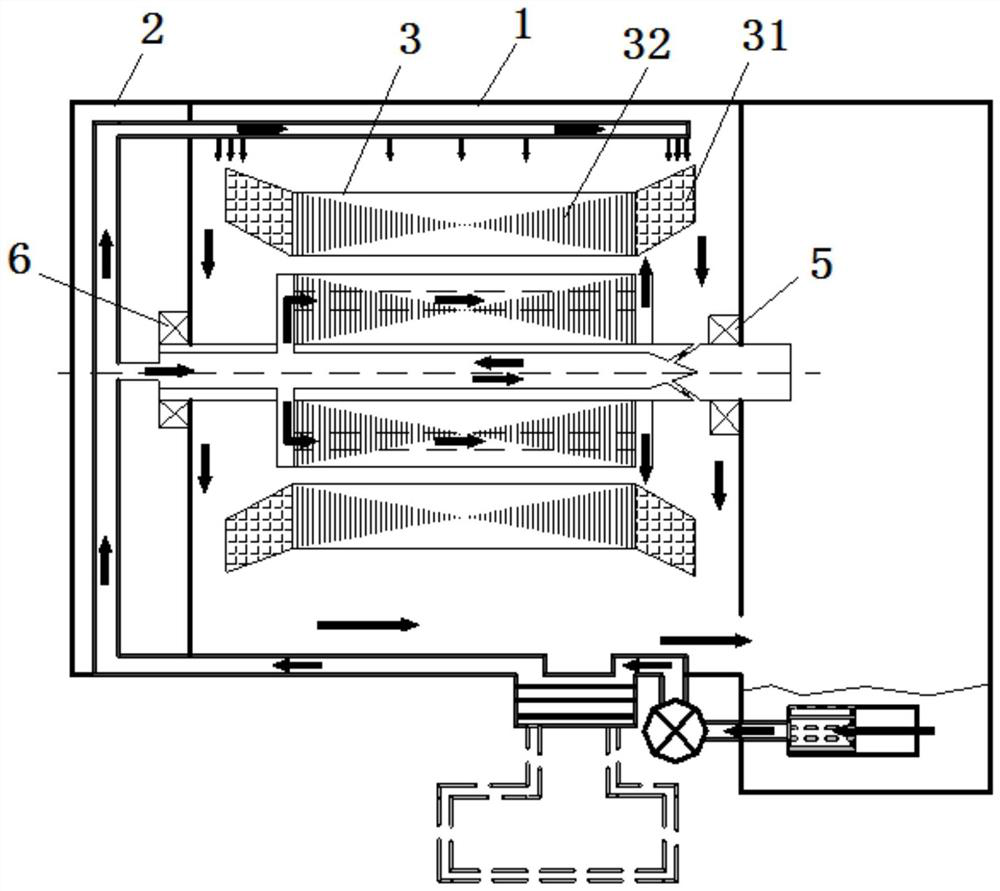

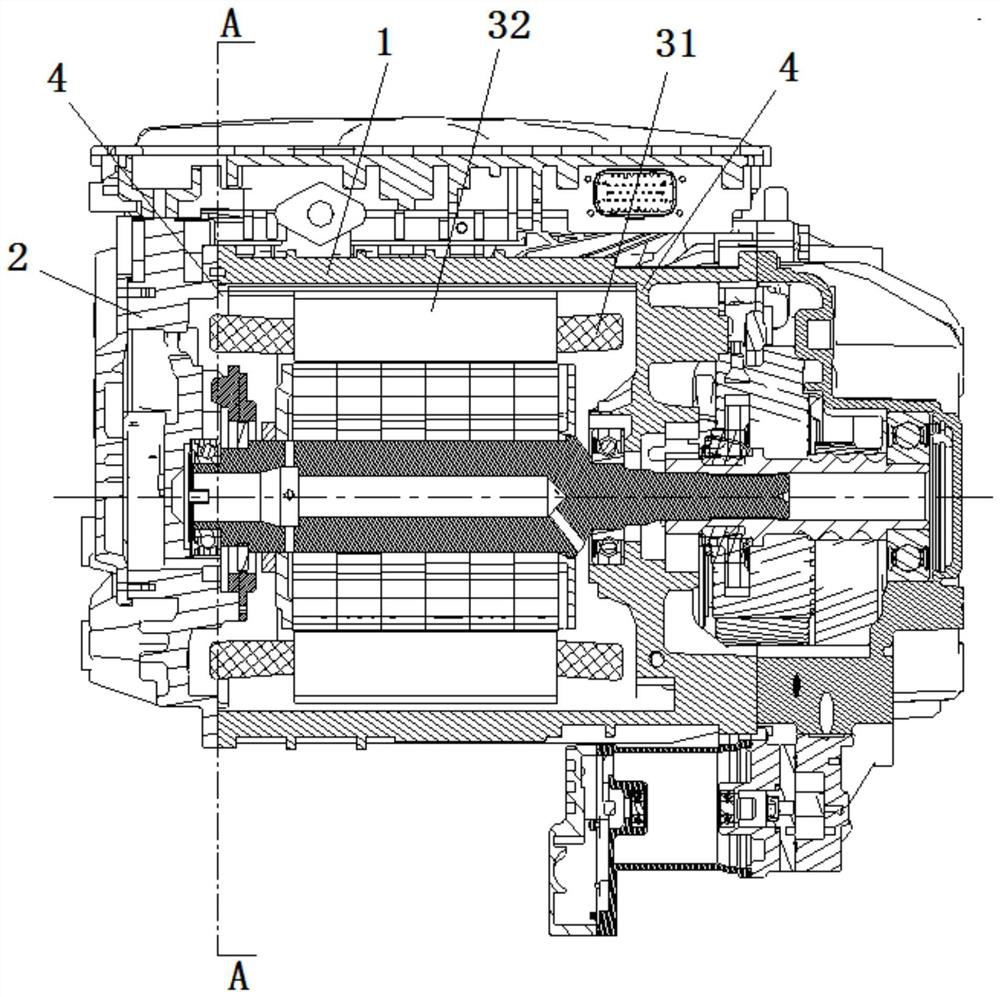

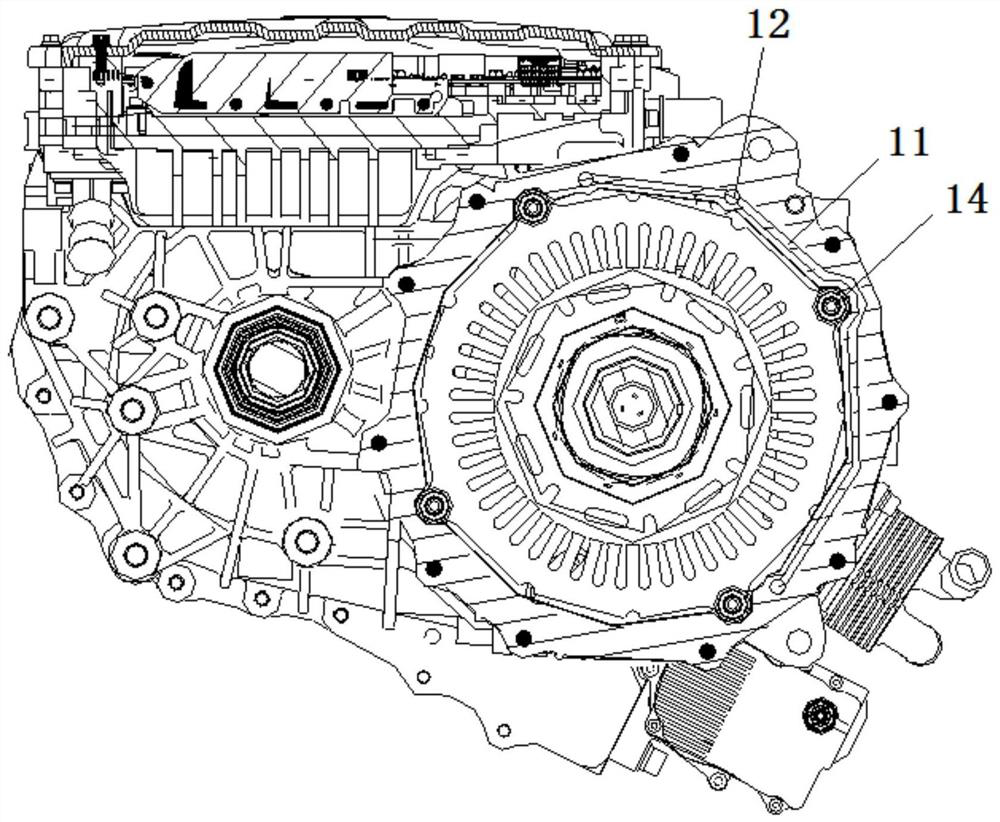

[0023] Embodiment: This application provides an oil-cooled stator structure, combined with reference Figure 1 to Figure 5 , the oil-cooled stator structure includes: a motor housing 1 , a rear end cover 2 , and a stator 3 . The stator 3 includes a stator end wire case 31 and a stator core 32 .

[0024] combined reference Figure 1 to Figure 3 , the end of the rear end cover 2 and the motor housing 1 is provided with a circumferential oil groove 11, the cooling oil enters the oil groove 11 from the rear end cover 2 of the electric drive, and is introduced into the upper part of the electric drive along the oil groove 11; the motor casing The outer circumference of the body 1 is provided with an axial stator oil channel 12 close to the top, and the stator oil channel 12 communicates with the oil groove 11; the stator oil channel 12 is provided with an oil spray hole 13 corresponding to the cooling part, and the cooling oil flows from the The oil pouring hole 13 drops down to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com