Brazing steel cooling system and cooling method thereof

A cooling system, brazing steel technology, applied in furnaces, charge control, lighting and heating equipment, etc., can solve problems such as performance degradation of brazing steel, reduce water consumption, accurately control the size of water flow, and solve the effects of uneven cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

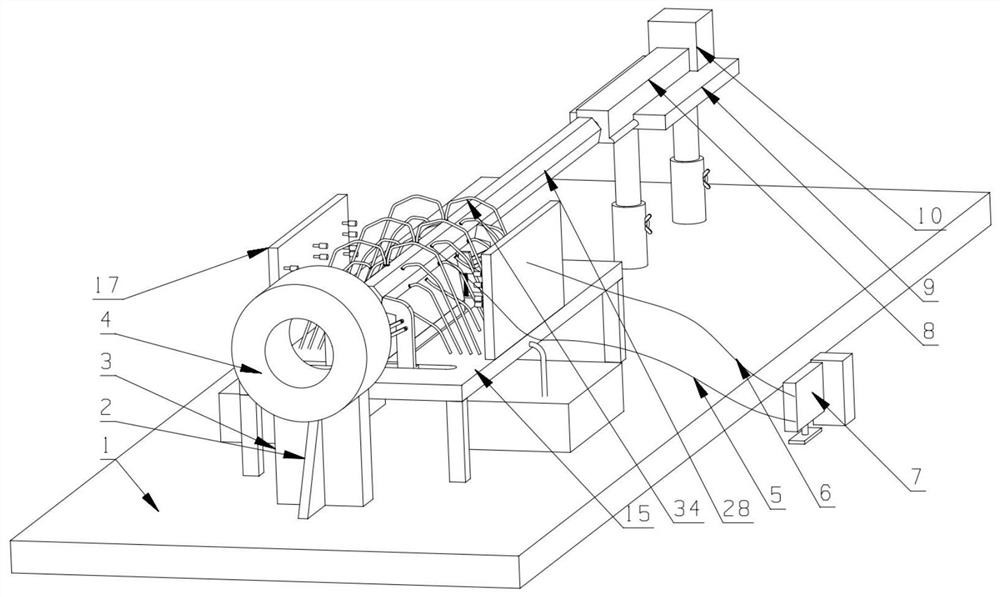

[0039] Such as figure 1 Shown is the schematic diagram of the brazing steel cooling system of the present invention. The brazing steel cooling system of the present invention includes a base, a workbench, an air cooling device, a propulsion device, a positioning device, a temperature measuring device, a cooling device and a feedback device.

[0040] The air-cooling device includes an air-cooled drier 4 arranged on the first end of the base 1, and the air-cooled drier 4 is fixed on the base 1 near the outlet of the brazing steel 28 after cooling by means of the support plate 3 and the rib plate 2 fixed thereto. end.

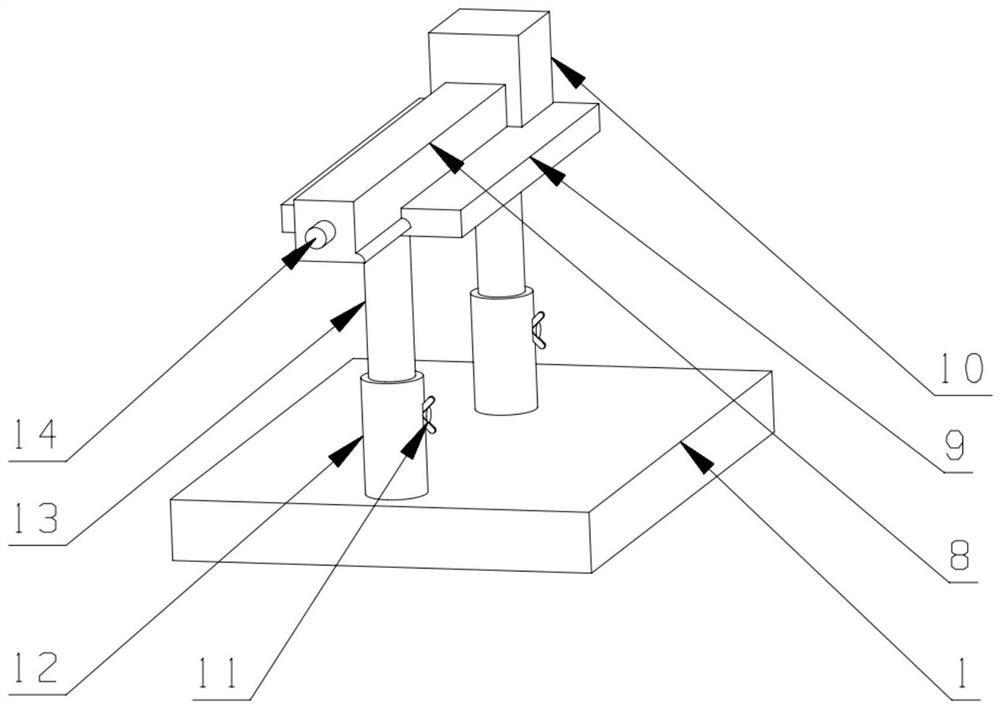

[0041] Such as figure 2 Shown is the three-dimensional schematic diagram of the propulsion device of this embodiment, the guide rail 9 is installed on the base 1 through the shrinkable tube 12 and the telescopic column 13, the propulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com