An Alcohol Distillation Device Convenient for Loading and Unloading Grains

A distillation device and alcohol technology, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of increasing production costs, reducing the efficiency of wine production, and unable to automatically load and unload fermented grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

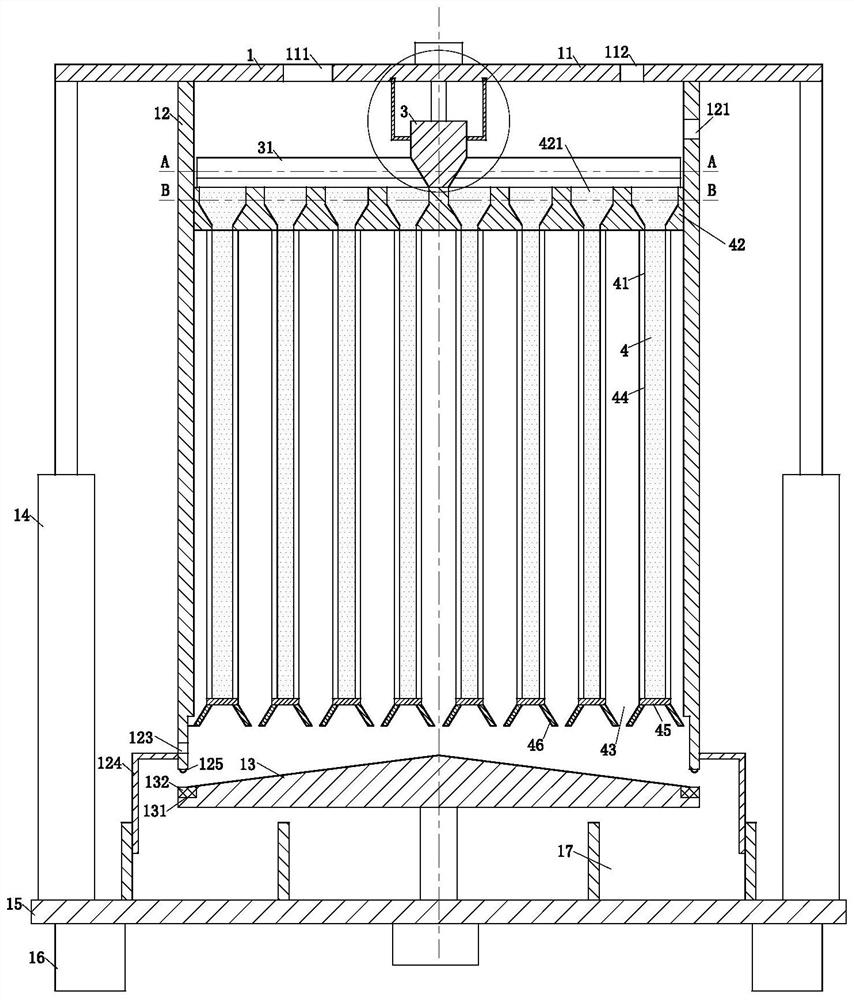

[0032] As an embodiment of the present invention, the upper surface of the No. 1 lower bottom plate 13 is conical, which is convenient for the fermented grains to slide from the upper surface of the No. 1 lower bottom plate 13 into the recovery box 17; and the upper surface of the No. 1 lower bottom plate 13 An annular groove 131 is provided at the edge; a rubber ring 132 is installed in the annular groove 131; an annular protrusion 125 is arranged at the bottom of the No. 1 side plate 12; the annular protrusion 125 passes through Cooperate with the rubber ring 132 to seal the No. 1 side plate 12 and the No. 1 lower bottom plate 13 .

[0033] As an embodiment of the present invention, it is characterized in that: the recovery box 17 is circular; the lower end of the No. 1 side plate 12 is equipped with a material retaining cover 124, the material retaining cover 124 is cylindrical, and the material retaining cover 124 is used for conveying the bad unstrained spirits in the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com