Barrel type alcohol distillation system

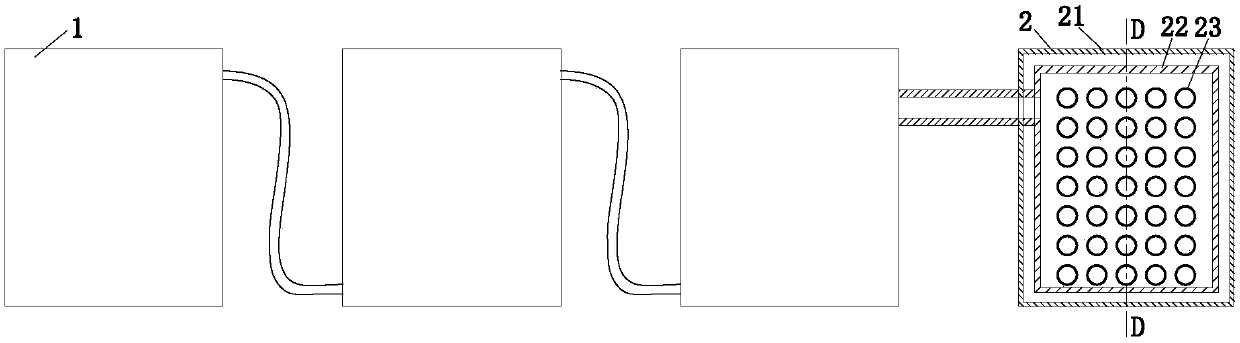

A distillation system and alcohol technology, which is applied in the field of barrel-type alcohol distillation systems, can solve the problems of not setting up a rapid cooling device, reducing the efficiency of wine production, and using restrictions, and achieve the effects of improving cooling efficiency, uniform cooling and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

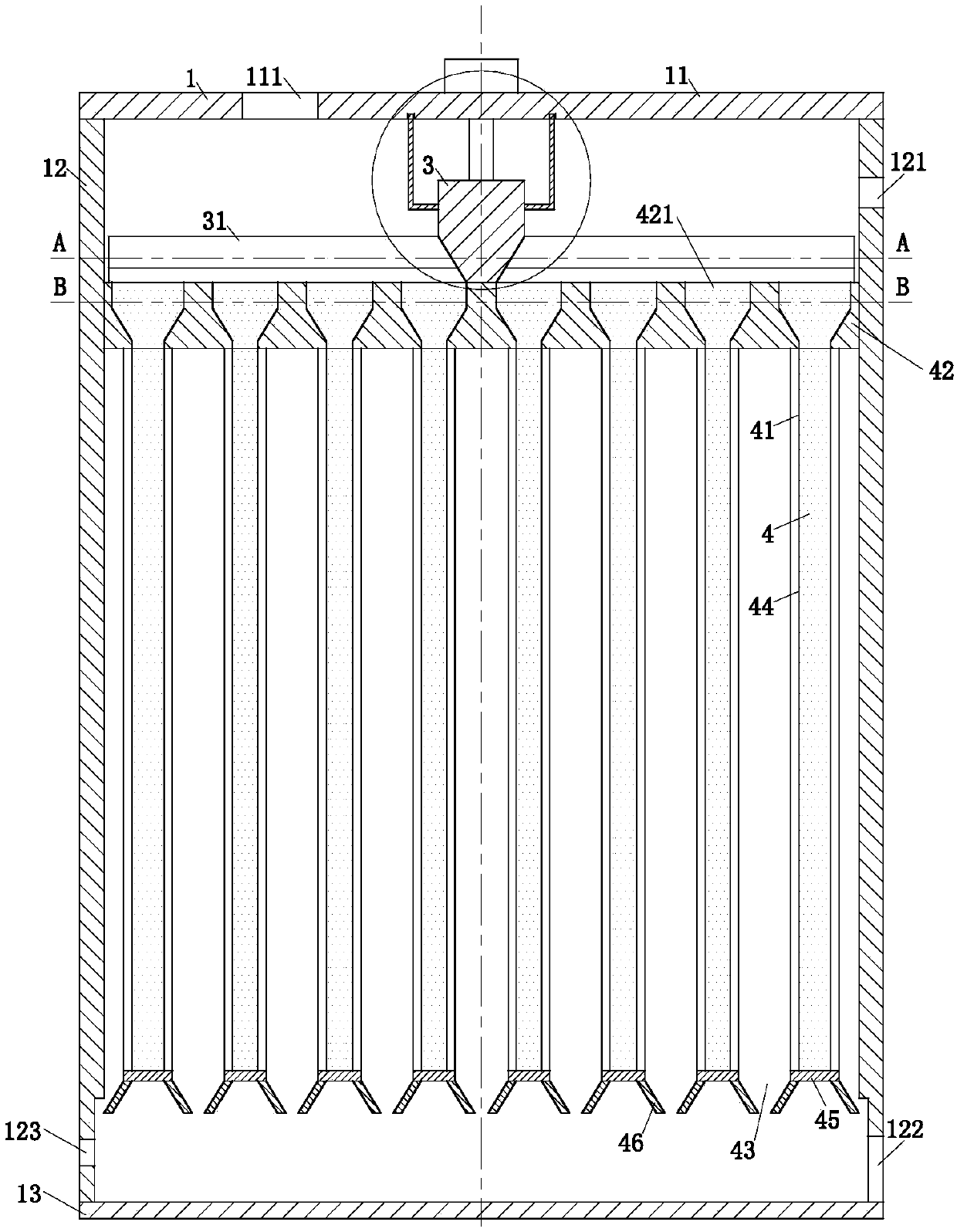

[0030] As an embodiment of the present invention, the No. 1 mounting plate 42 is provided with a plurality of No. 3 through holes 421; connected to the storage port. The unstrained spirits fall to the upper surface of the No. 1 installation plate 42 through the feed port 111, and the extrusion device rotates and squeezes the unstrained grains on the No. 1 installation plate 42 to make the grains enter the distillation cylinder 41 through the No. 3 through hole 421 When the steam distills the bad unstrained spirits in the distillation cylinder 41, the bad unstrained spirits can only enter the No. 3 through hole 421 through the inside of the circular cylinder 44, so that the steam can distill the bad unstrained spirits in the distillation cylinder 41.

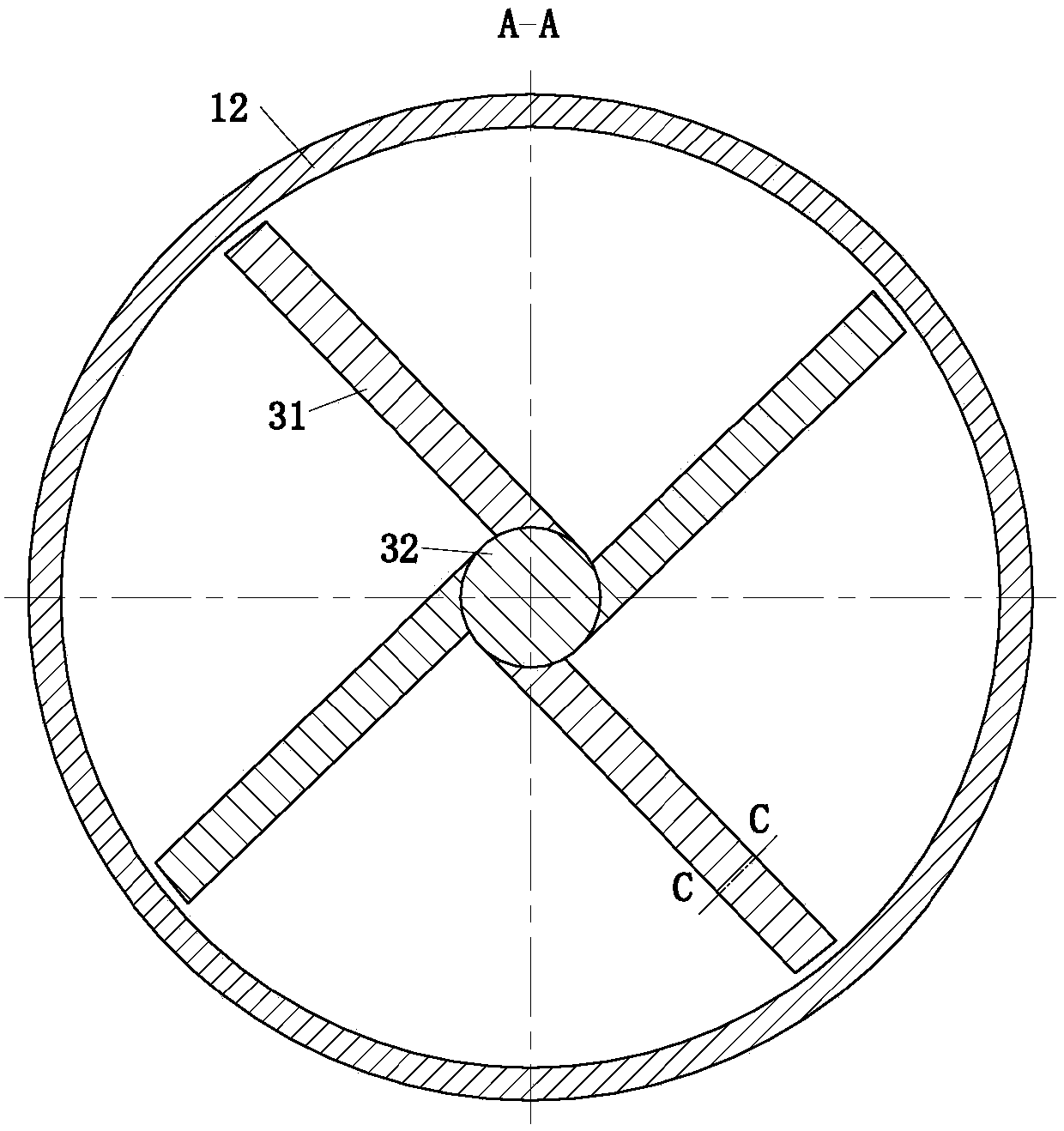

[0031] As an embodiment of the present invention, the extruding unit 3 includes an extruding rod 31, a connecting block 32 and a closed cylinder 33; the extruding rod 31 is used to extrude the grains into the distillation cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com