Quenching device

A technology of quenching device and conveying roller, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problem of uneven cooling of quenched parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

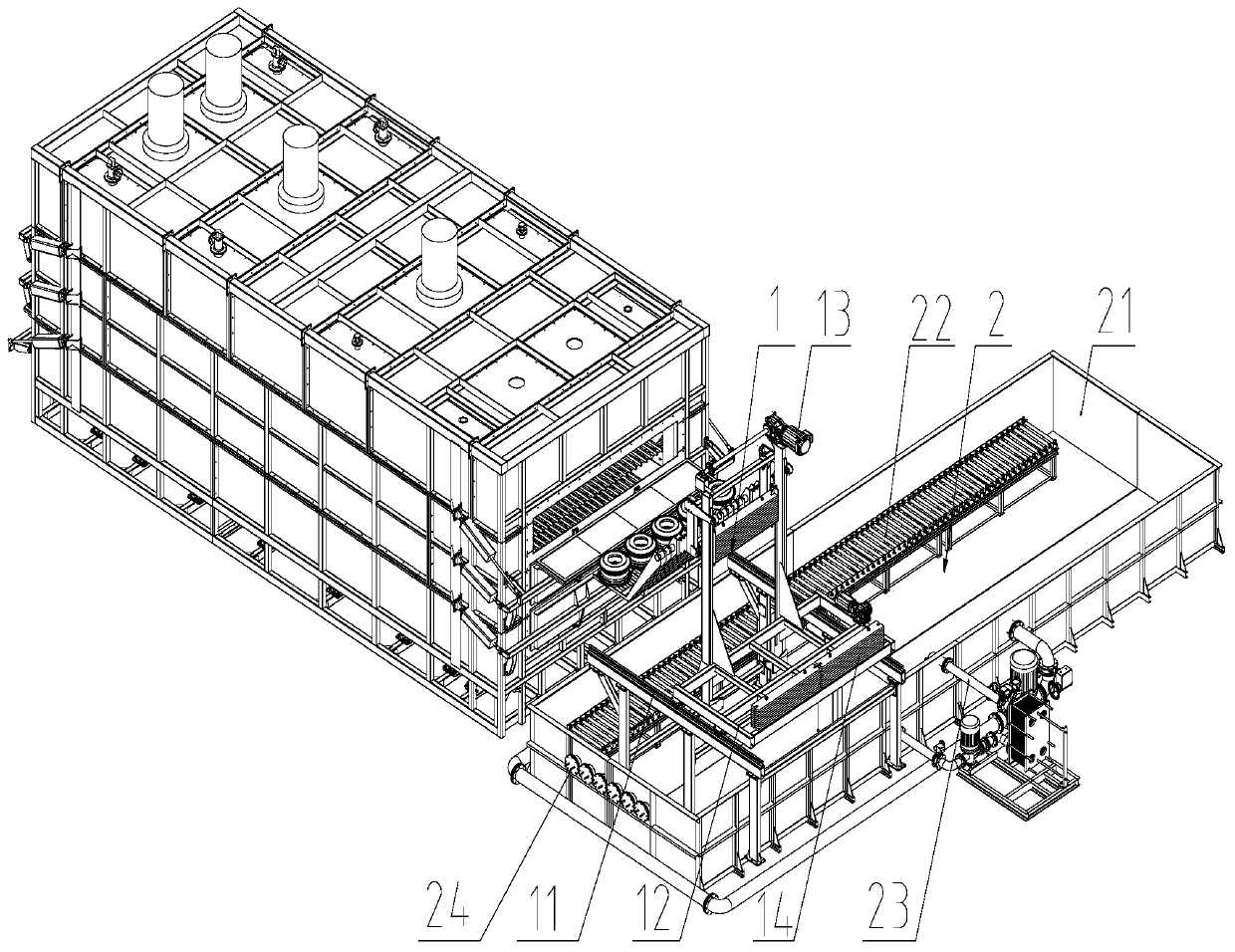

[0051] Such as figure 1 Shown is a quenching device for rapid and uniform automatic quenching of aluminum alloy wheels, which includes a reclaimer 1 and a quenching water tank 2 placed under the reclaimer 1 .

[0052] Reclaimer 1

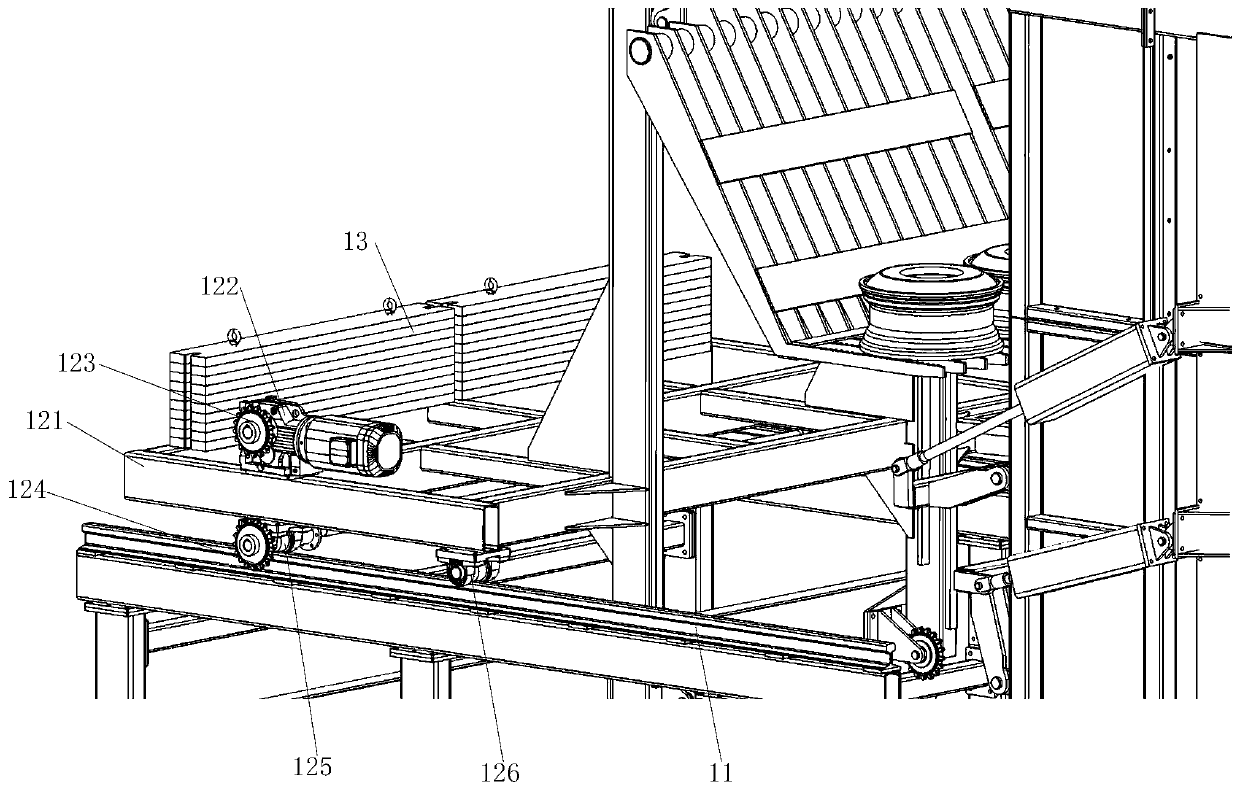

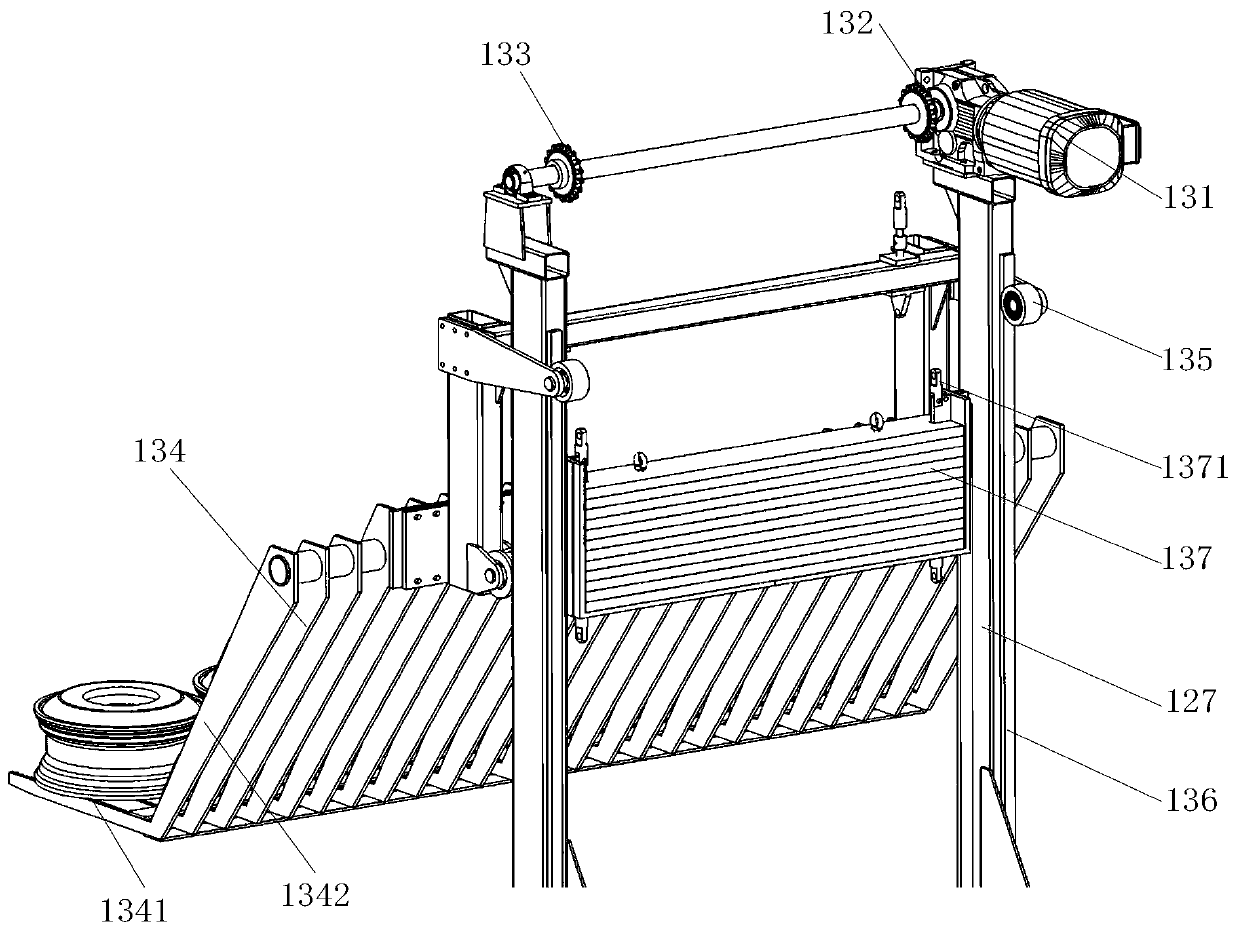

[0053] Such as Figures 1 to 3 As shown, the reclaimer 1 includes a pair of horizontal guide rails 11 arranged in parallel, a dolly 12 that is arranged on the pair of horizontal guide rails 11 and walks horizontally along the guide rail, and a reclaiming lifting assembly 13 that is arranged on the dolly 12; The tail end of 12 is provided with the counterweight 14 of balance center of gravity.

[0054] Dolly 12 comprises vehicle frame 121, is arranged on the driving motor 122 on the vehicle frame 121 side, is installed on the first sprocket wheel 123 on the first driving motor 122 output shafts, is fixed on the car that is arranged on the bottom of the first driving motor 122. The first roller 125 and the second roller 126 that are coaxially arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com