Hot rolling spray cooling method for large cylinder

A technology of spray cooling and large cylinder, which is applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., and can solve problems such as uneven cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] Method 1: By adopting the spray cooling method proposed by the present invention, the spray cooling after rolling of the large-scale barrel section is simulated. After adopting this method, the uniformity of temperature distribution on the inner and outer surfaces of the cylinder section is analyzed.

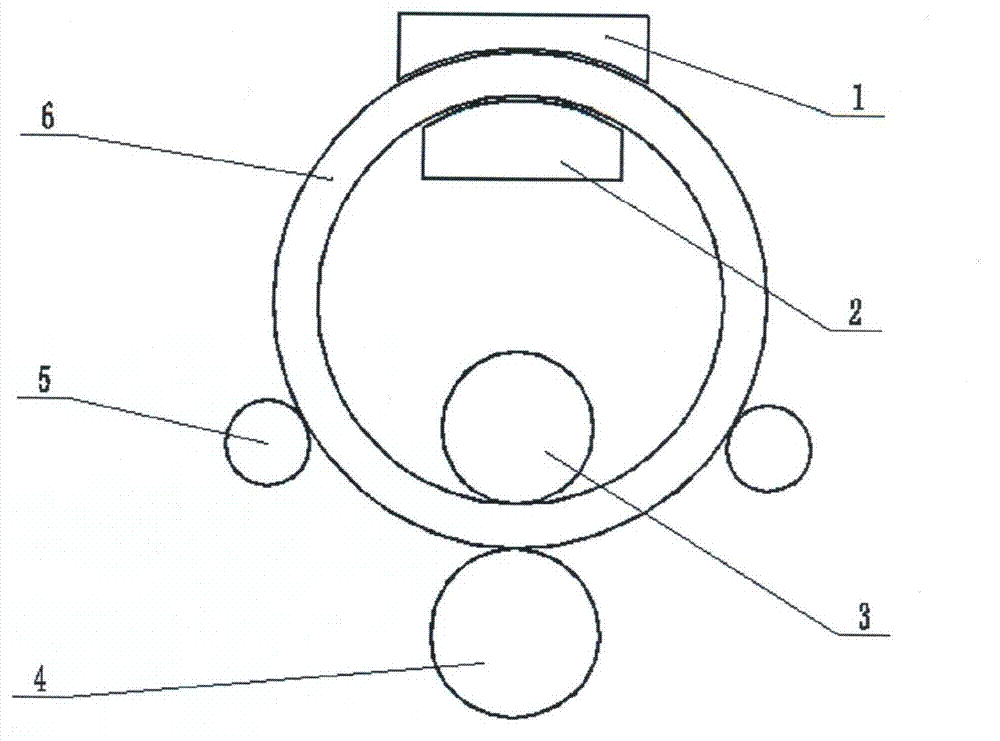

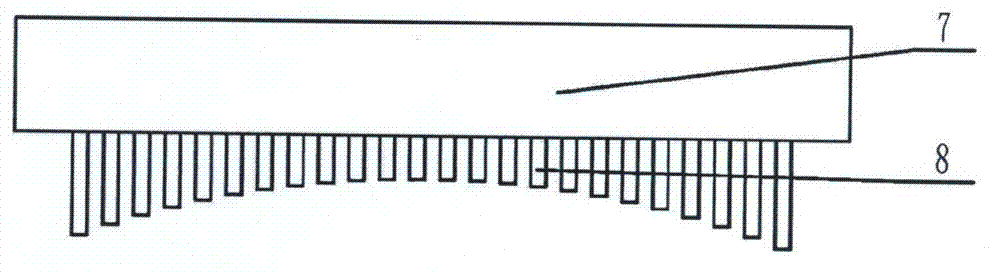

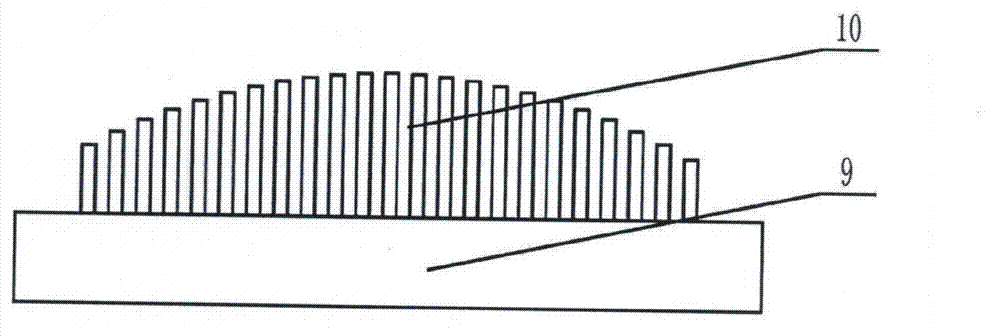

[0058] Specifications of the barrel section used: outer diameter: d 1 =5830mm, inner diameter: d 2 =4796mm, width: 2680mm; the speed of the upper and lower rolls is 0.3rad / s. The basic properties of the material: yield limit: 58MPa; elastic modulus: 90000MPa; Poisson's ratio: 0.3; the rest of the density, specific heat, etc. are functions of temperature. Through the calculation, it can be known that the rotation speed of the barrel joint is 0.1rad / s, and its initial temperature is set at 900°C. Adjust the height of the cooling water pipe so that the arc at the end is concentric with the barrel section and the distance is 50mm. At the same time, the angle between the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com