Even-cooling crystallizer copper tube and manufacturing method thereof

A mold copper tube and tube wall technology is applied in the field of uniform cooling of the mold copper tube, which can solve the problems of reducing the cooling strength of the corner of the mold copper tube, no popularization and application, poor steel grade adaptability, etc., and achieves a reduction in process tolerance. The effect of reducing the production cost and improving the cooling intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] Example 1.

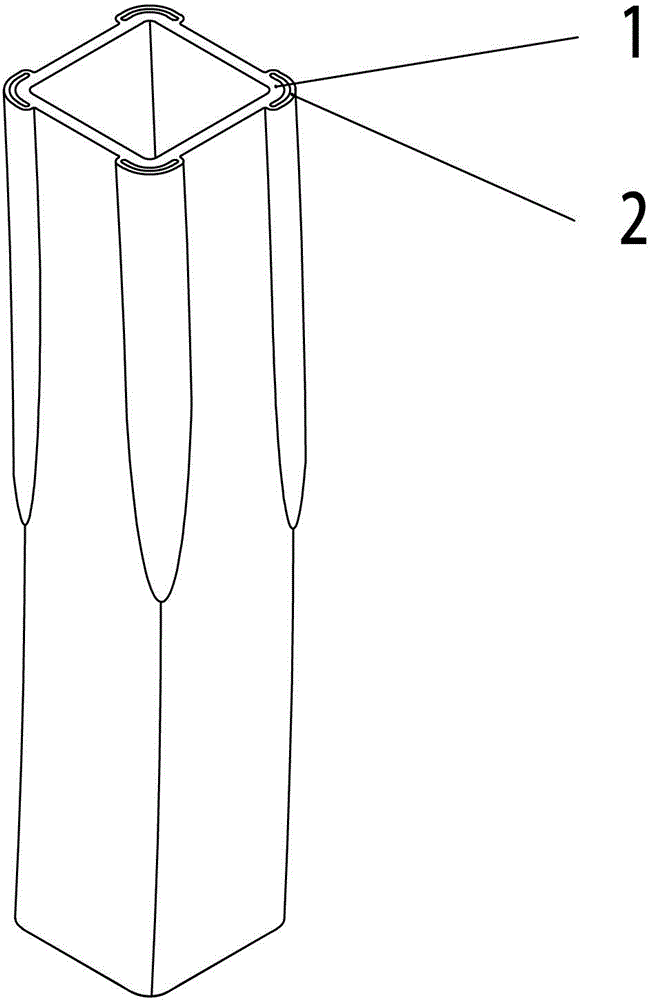

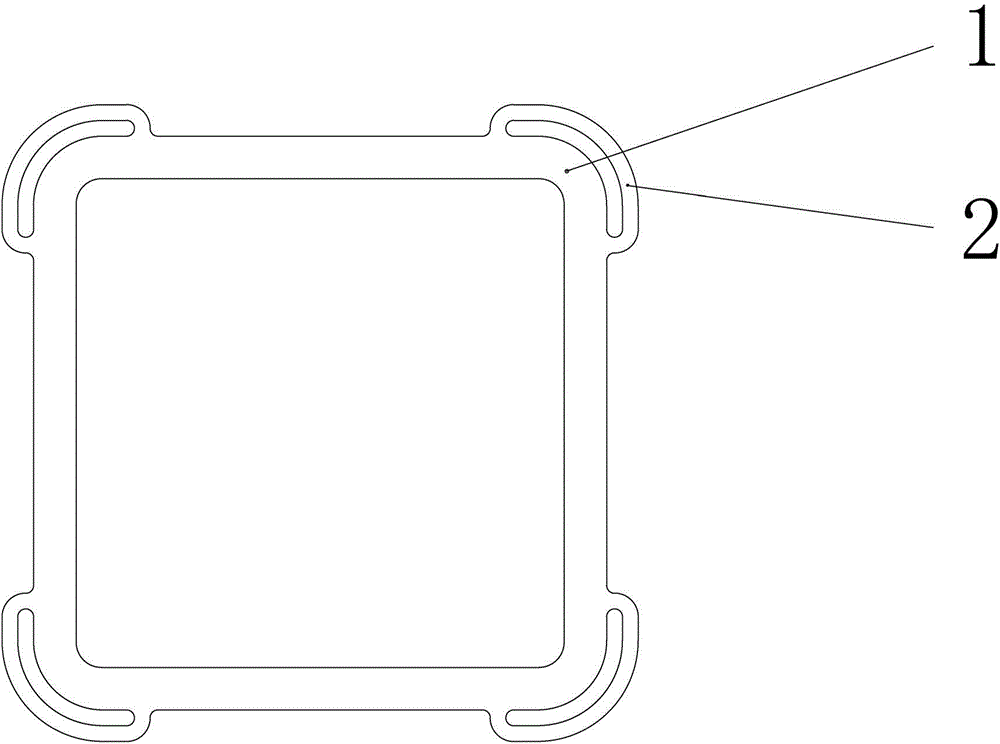

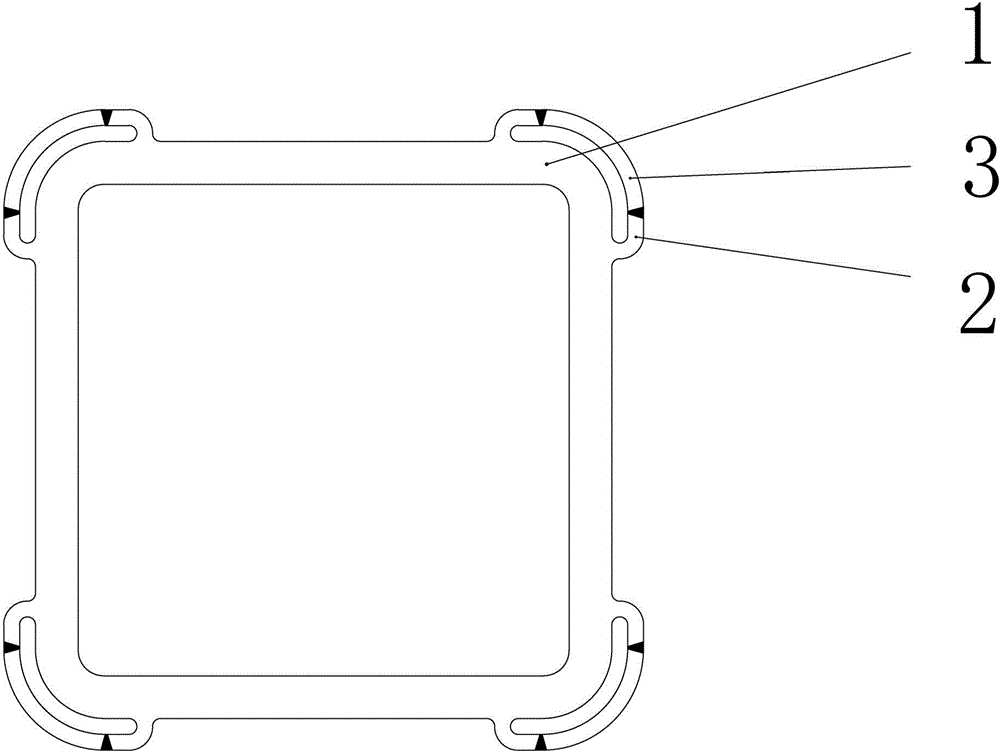

[0036] Figure 1 and figure 2 The uniformly cooled crystallizer copper tube of the present invention has a corner outer tube wall 2 outside the corner tube wall 1, and the edge of the corner outer tube wall 2 is connected with the corner tube wall 1. The length covered by the outer tube wall 2 at the corner is the upper half of the mold copper tube, and the width is 25mm from the top of the mold copper tube corner to both sides, and gradually decreases from top to bottom.

[0037] The outer surface of the copper tube of the crystallizer is provided with corrugations perpendicular to the axial direction of the copper tube, except for 30mm on both sides of the top of the corner of the copper tube.

[0038] Manufacturing method: the blank tube is manufactured by thinning and stretching, mechanical processing and other technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com