Single fuel cell, fuel cell stack and working mode

A fuel cell stack and fuel cell technology, applied in the direction of fuel cells, fuel cell components, circuits, etc., can solve the problems of cooling the fuel cell temperature, uniform cooling of the first plate temperature, blocking the flow channel, etc., and increase the contact area. Large, uniform cooling effect, the effect of avoiding gas blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

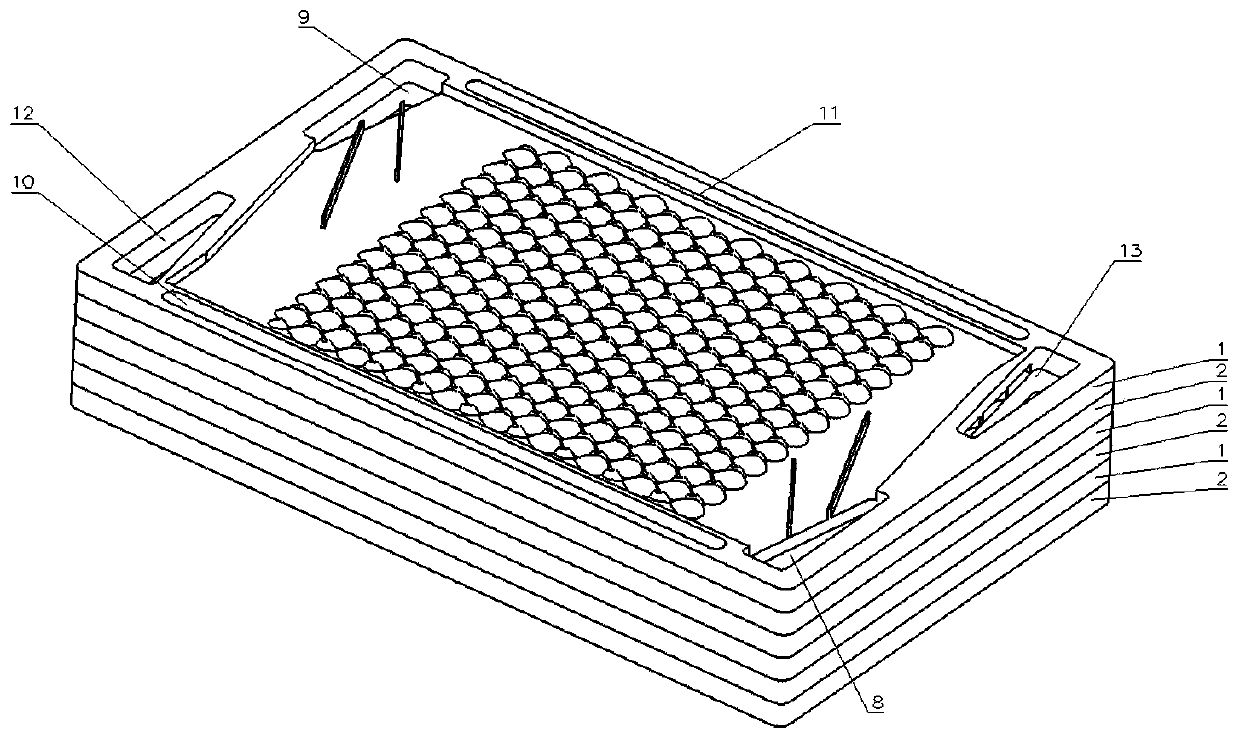

[0067] Embodiment 1, a fuel cell stack, which is formed by stacking current collectors and membrane electrode groups (ie: current collectors-membrane electrode groups-current collectors-membrane electrode groups-current collectors), and the fuel cell The ends of the stack are end plates;

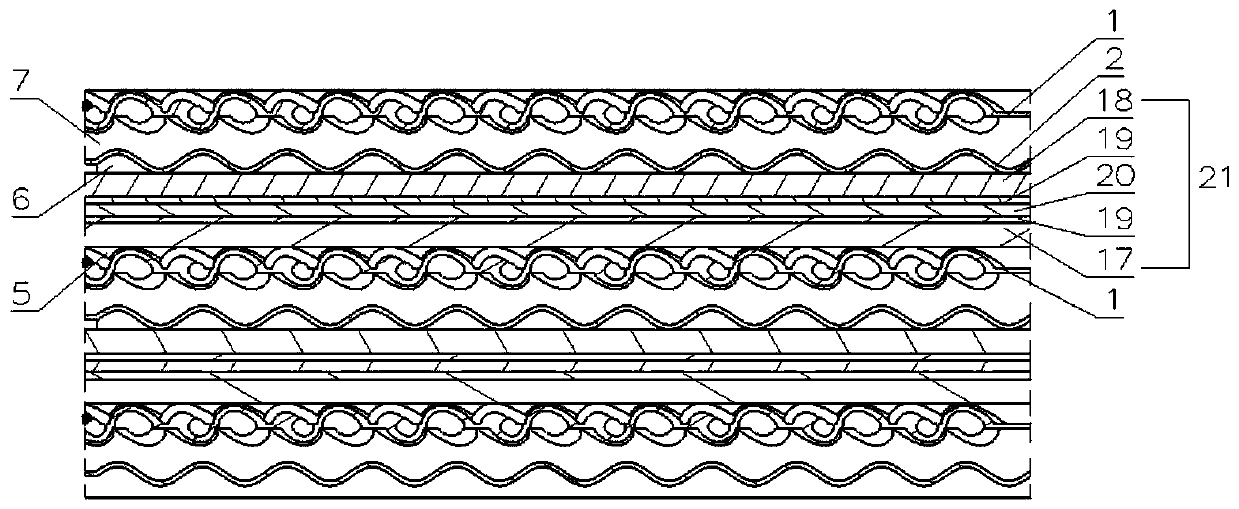

[0068] Such as figure 2 As shown, the collector plate includes: a first plate 1 located at the upper part and a second plate 2 located at the lower part; the first plate 1 and the second plate 2 are arranged in parallel (both are rectangular metal plates), and the first plate 1 The lower surface of the middle part and the upper surface of the middle part of the second plate 2 are provided with a cooling water flow cavity 7;

[0069] The membrane electrode group includes from top to bottom: hydrogen diffusion layer 18, catalytic layer 19, proton exchange membrane 20, catalytic layer 19, air diffusion layer 17;

[0070] The upper surface of the first plate 1 of the collector plate faces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com