Permanent magnet motor, refrigeration compressor and air conditioning unit

一种制冷压缩机、永磁电机的技术,应用在压缩机、制冷机、制冷组件等方向,能够解决永磁电机冷却不均等问题,达到解决冷却不均问题、稳定控制电机温度、提高换热比的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

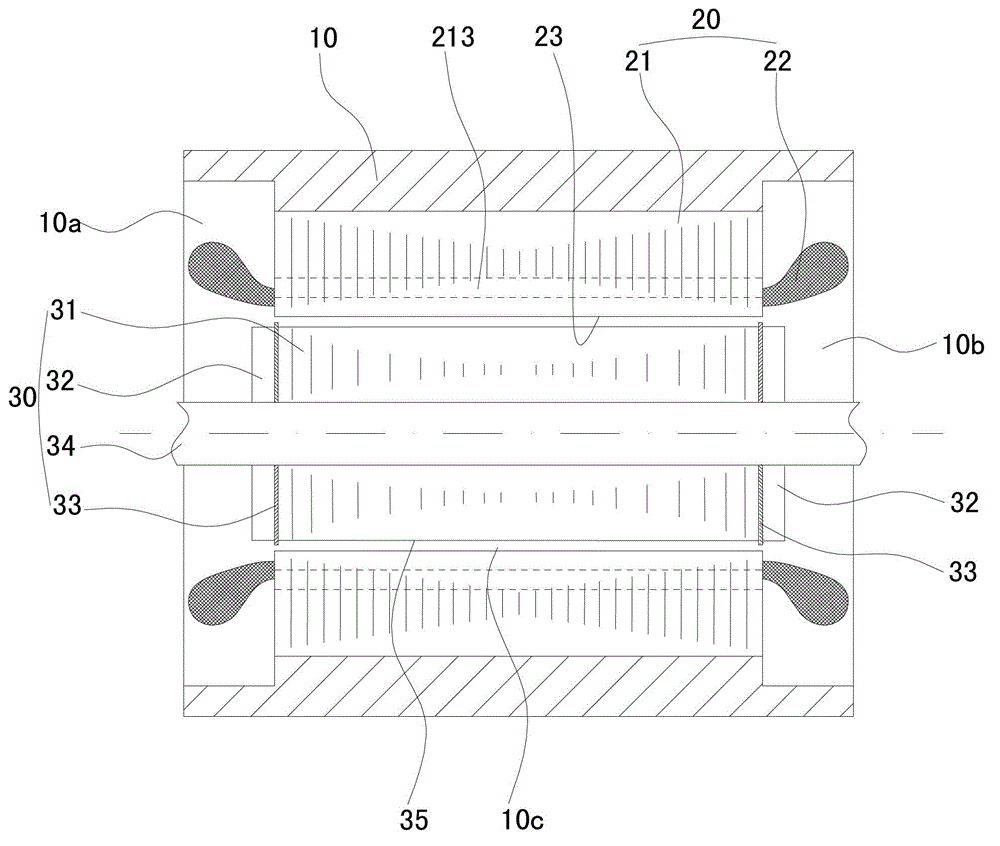

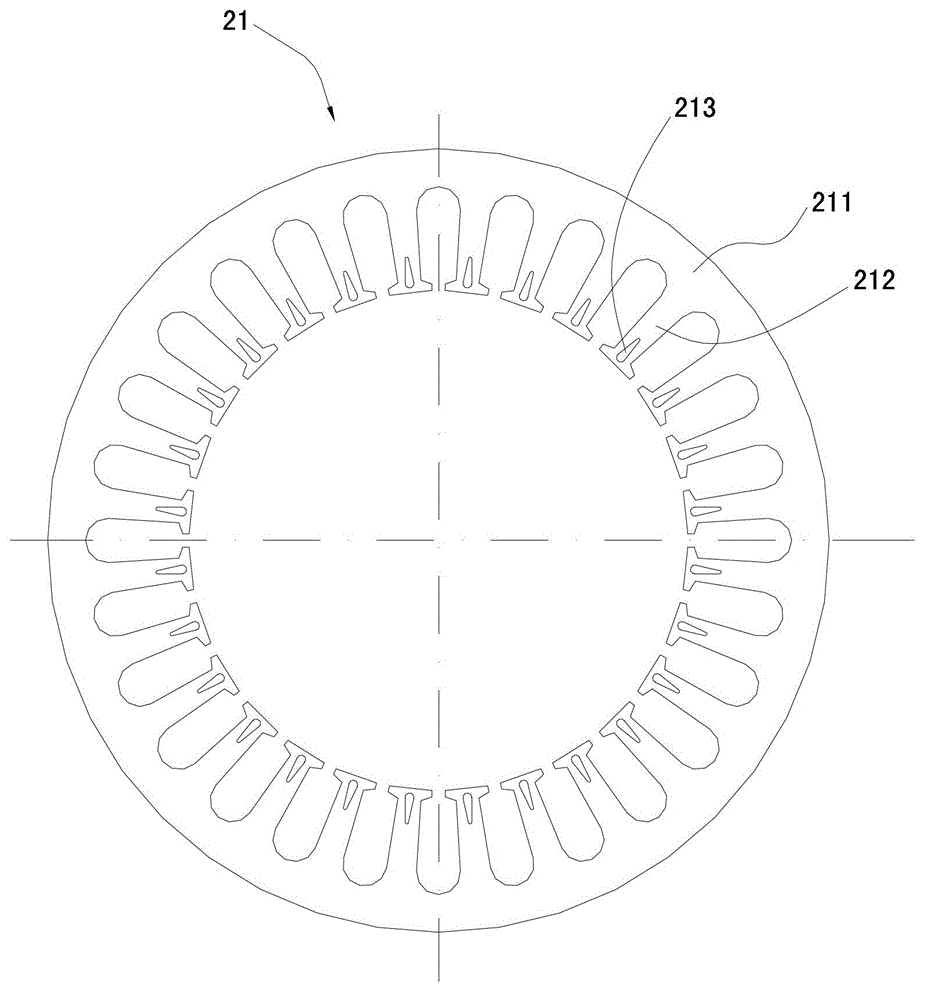

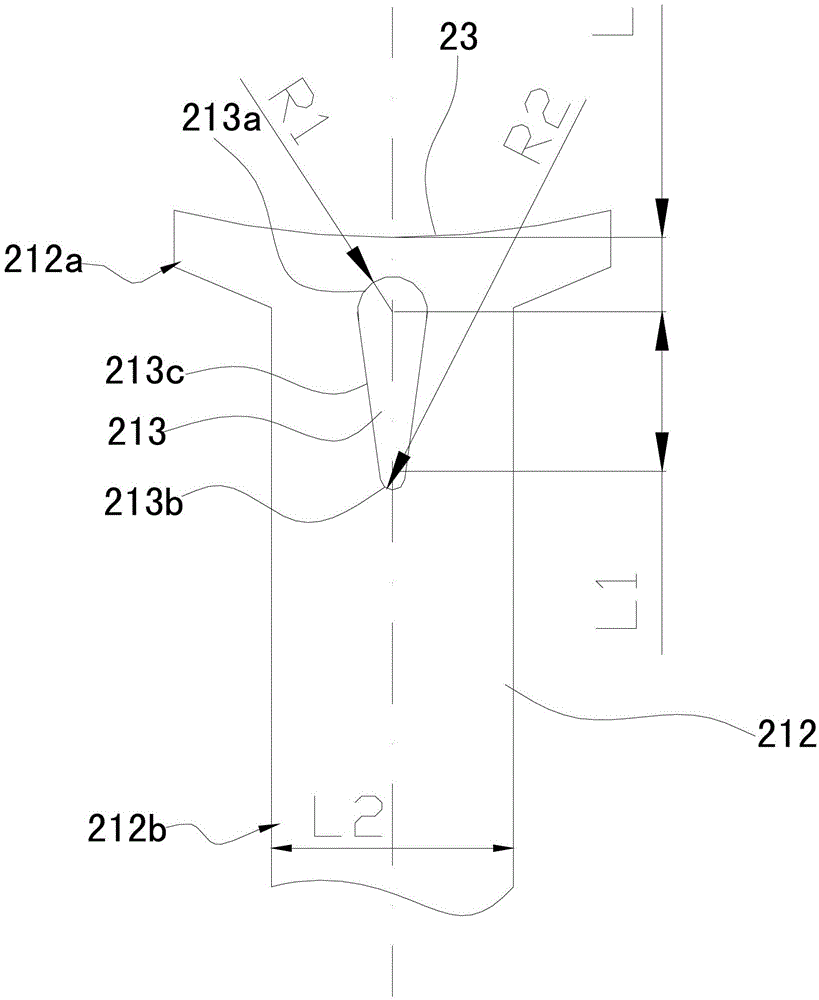

[0026] In one embodiment of the present invention, a permanent magnet motor is provided, such as figure 1 As shown, the permanent magnet motor includes a casing 10 , a stator 20 and a rotor 30 , the stator 20 is fixedly installed in the casing 10 , and the stator includes a stator core 21 and a coil winding 22 . The rotor 30 is installed inside the stator core 21, and the stator 20 and the rotor 30 divide the inner chamber of the housing 10 into a first inner chamber 10a on the left side and a second inner chamber on the right side. 10b, and an air gap 10c is formed between the inner circular surface 23 of the stator and the outer circular surface 35 of the rotor. The rotor 30 includes a rotating shaft 34 , a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com