Maintenance method of controlled cooling after rolling flow regulating valve

A technology of flow control valve and adjustment method, applied in valve details, valve device, temperature control and other directions, can solve the problems of flow control valve adjustment accuracy deviation, etc., to improve the quality of steel plates and avoid abnormal valve action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

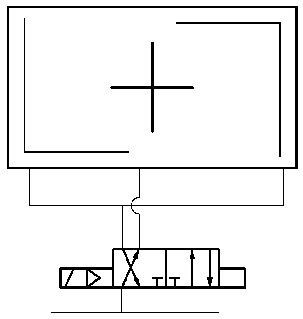

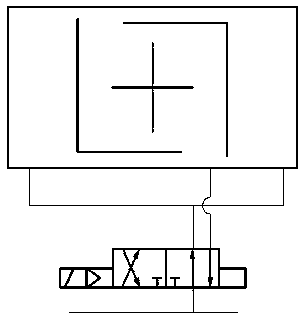

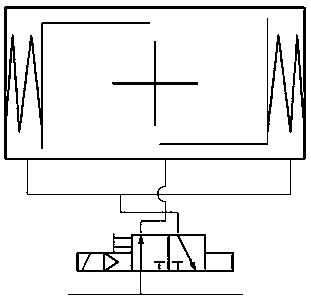

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the examples.

[0034] The invention discloses a method for maintaining a cooling control flow regulating valve after rolling, which includes the following steps:

[0035] S1. Formulate the adjustment method of the valve cylinder actuator of the flow control valve, so as to meet the stroke requirements of the valve during the adjustment action process;

[0036] S2. Set the corresponding speed adjustment method of the valve to meet the efficiency of the valve in the adjustment process, and avoid the phenomenon that the flow has not been adjusted and stabilized when the steel plate reaches the cooling control system due to the slow or long time of valve adjustment;

[0037] S3. Formulate a flexible test method for valves, so as to determine the specific faults of the valve;

[0038] S4. Formulate valve fault maintenance methods, master the composition and structure of valve parts, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com