Commercial vehicle hub bearing lubricating grease and preparation method thereof

A technology for bearing lubrication and wheels, which is applied in the direction of lubricating compositions, petroleum industry, thickeners, etc., can solve the problems of not containing compound polyurea thickeners, etc., to reduce the risk of fat rejection, reduce consistency changes, and improve shear stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

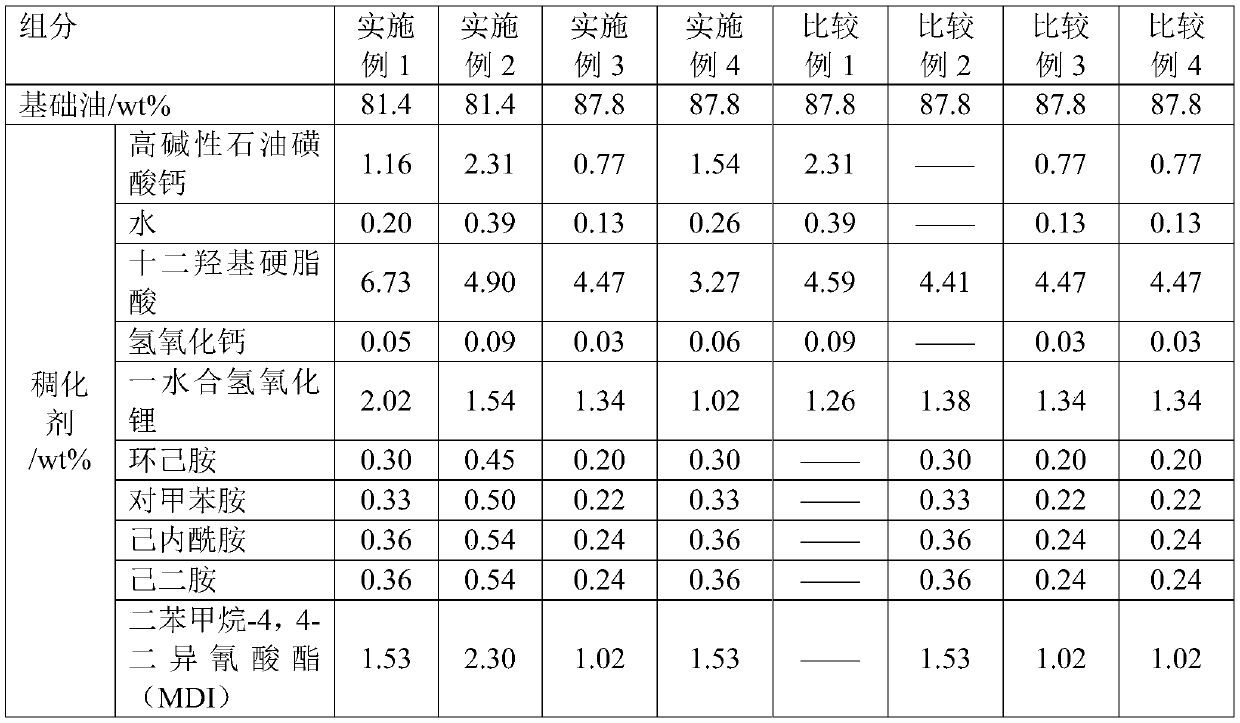

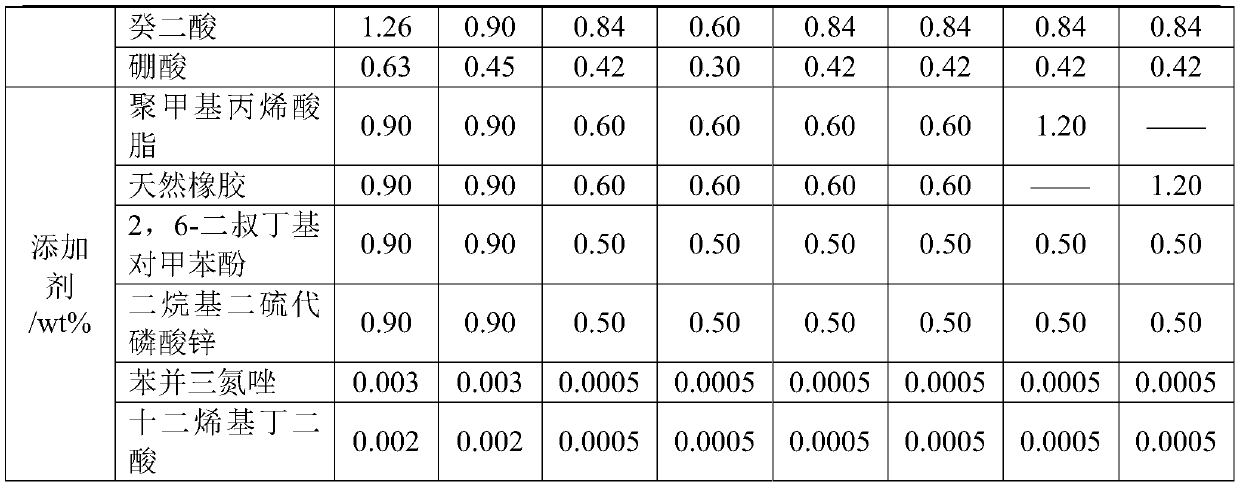

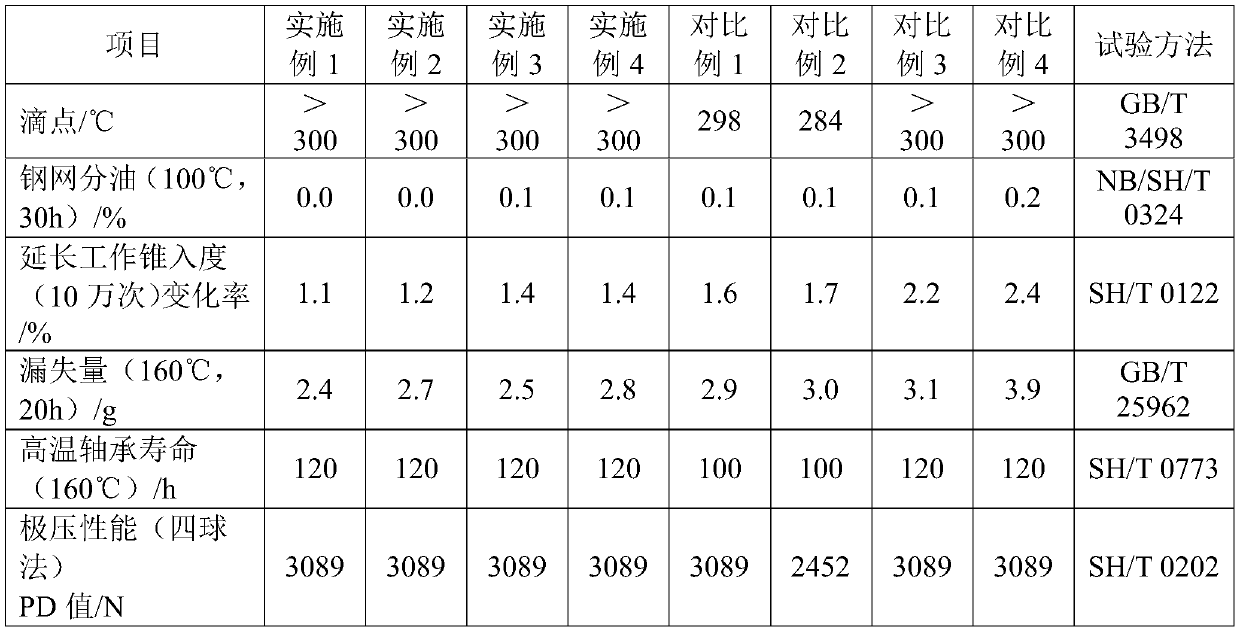

Embodiment 1

[0044] A commercial vehicle hub bearing lubricating grease, comprising the following raw material components in parts by weight: 81.4% of base oil, 15% of composite thickener, 1.8% of composite adhesive, 0.9% of antioxidant, and 0.9% of extreme pressure and antiwear agent %, antirust agent 0.005%, wherein, composite polyurea thickener: composite calcium sulfonate thickener: composite lithium thickener=2:1:7.

[0045] The preparation method comprises the following steps:

[0046] 1) Add 1.16wt% overbased calcium petroleum sulfonate and 0.20wt% water into the reaction kettle, stir, heat up to 90-100°C, and stir at constant temperature for 35 minutes;

[0047] 2) Add 0.10wt% lauryl hydroxystearic acid and 0.05wt% calcium hydroxide (dilute with 3 times water to form a suspension when used), heat up to 140-150°C, and stir at constant temperature for 35 minutes;

[0048] 3) Cool to 90-100°C, add 30wt% base oil and 6.62wt% lauryl hydroxystearic acid, and stir at constant temperature...

Embodiment 2

[0059] A commercial vehicle hub bearing lubricating grease, comprising the following raw material components in parts by weight: 81.4% of base oil, 15% of composite thickener, 1.8% of composite adhesive, 0.9% of antioxidant, and 0.9% of extreme pressure and antiwear agent %, antirust agent 0.005%, wherein, composite polyurea thickener: composite calcium sulfonate thickener: composite lithium thickener=3:2:5.

[0060] The preparation method comprises the following steps:

[0061] 1) Add 2.31wt% overbased calcium petroleum sulfonate and 0.39wt% water into the reaction kettle, stir, heat up to 90-100°C, and stir at constant temperature for 35 minutes;

[0062] 2) Add 0.18wt% lauryl hydroxystearic acid and 0.09wt% calcium hydroxide (dilute with 3 times water to form a suspension when used), raise the temperature to 140-150°C, and stir at constant temperature for 35 minutes;

[0063] 3) Cool to 90-100°C, add 30wt% base oil and 4.72wt% lauryl hydroxystearic acid, and stir at consta...

Embodiment 3

[0074] A commercial vehicle hub bearing lubricating grease, comprising the following raw material components in parts by weight: 87.8% of base oil, 10% of composite thickener, 1.2% of composite adhesive, 0.5% of antioxidant, and 0.5% of extreme pressure and antiwear agent %, antirust agent 0.001%, wherein, composite polyurea thickener: composite calcium sulfonate thickener: composite lithium thickener=2:1:7.

[0075] The preparation method comprises the following steps:

[0076] 1) Add 0.77wt% overbased calcium petroleum sulfonate and 0.13wt% water into the reaction kettle, stir, heat up to 90-100°C, and stir at constant temperature for 35 minutes;

[0077] 2) Add 0.06wt% lauryl hydroxystearic acid and 0.03wt% calcium hydroxide (dilute with 3 times water to form a suspension when used), heat up to 140-150°C, and stir at constant temperature for 35 minutes;

[0078] 3) Cool to 90-100°C, add 30wt% base oil and 4.41wt% lauryl hydroxystearic acid, and stir at constant temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com