Patents

Literature

31results about How to "Reduce the amount of oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bearing chamber axle center ventilating structure and gas turbine engine with same

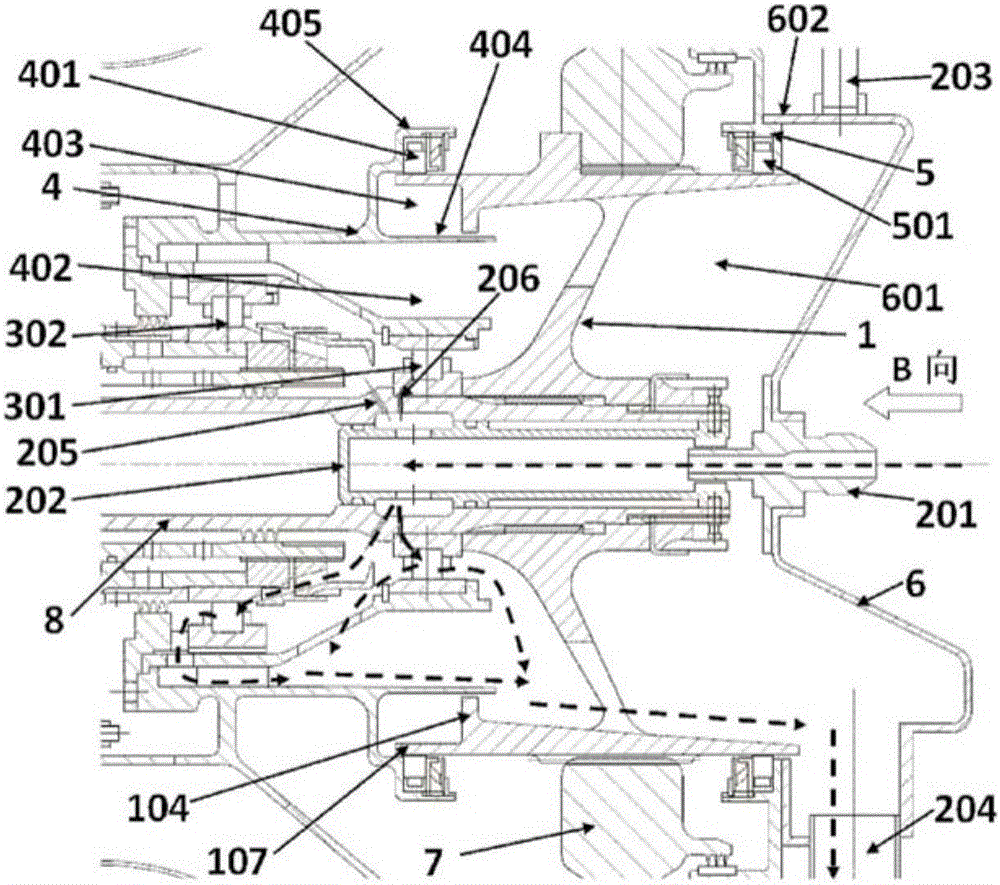

The invention relates to an axle center ventilating structure and a gas turbine engine. A bearing chamber of a cold end component of the engine communicates with a bearing chamber of a hot end component of the engine, a ventilating system is used for maintaining the pressure of the bearing chamber of the cold end component of the engine to be the same with that of the bearing chamber of the hot end component of the engine basically, the bearing chamber of the cold end component communicates with an engine nozzle through a centrifugal oil-gas separator, an oil-gas mixture in the bearing chamber of the hot end component enters the bearing chamber of the cold end component of the engine via an axle center ventilating cavity, then the oil-gas mixture in the bearing chamber of the hot end component and an oil-gas mixture of the bearing chamber of the cold end component are subjected to oil-gas separation together by the centrifugal oil-gas separator, and the unseparated oil-gas mixture is discharged via the engine nozzle. The bearing chamber axle center ventilating structure of the engine is simple and is convenient to design and adjust, the bearing chamber of the cold end component communicates with the bearing chamber of the hot end component, the pressure of the bearing chamber of the cold end component and the pressure of the bearing chamber of the hot end component can be ensured to be almost the same, design and adjustment of a secondary air system are facilitated, faults of the engine due to leakage of lubricating oil and unsmooth circulation are reduced, the reliability of the engine is improved, meanwhile, heat transmission from the bearing chamber of the hot end component to the bearing chamber of the cold end component can be improved, and therefore, the quantity of lubricating oil required for cooling a bearing of the hot end component is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

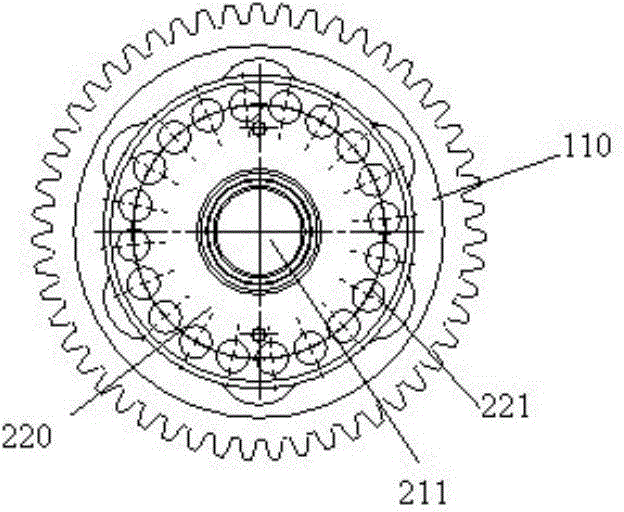

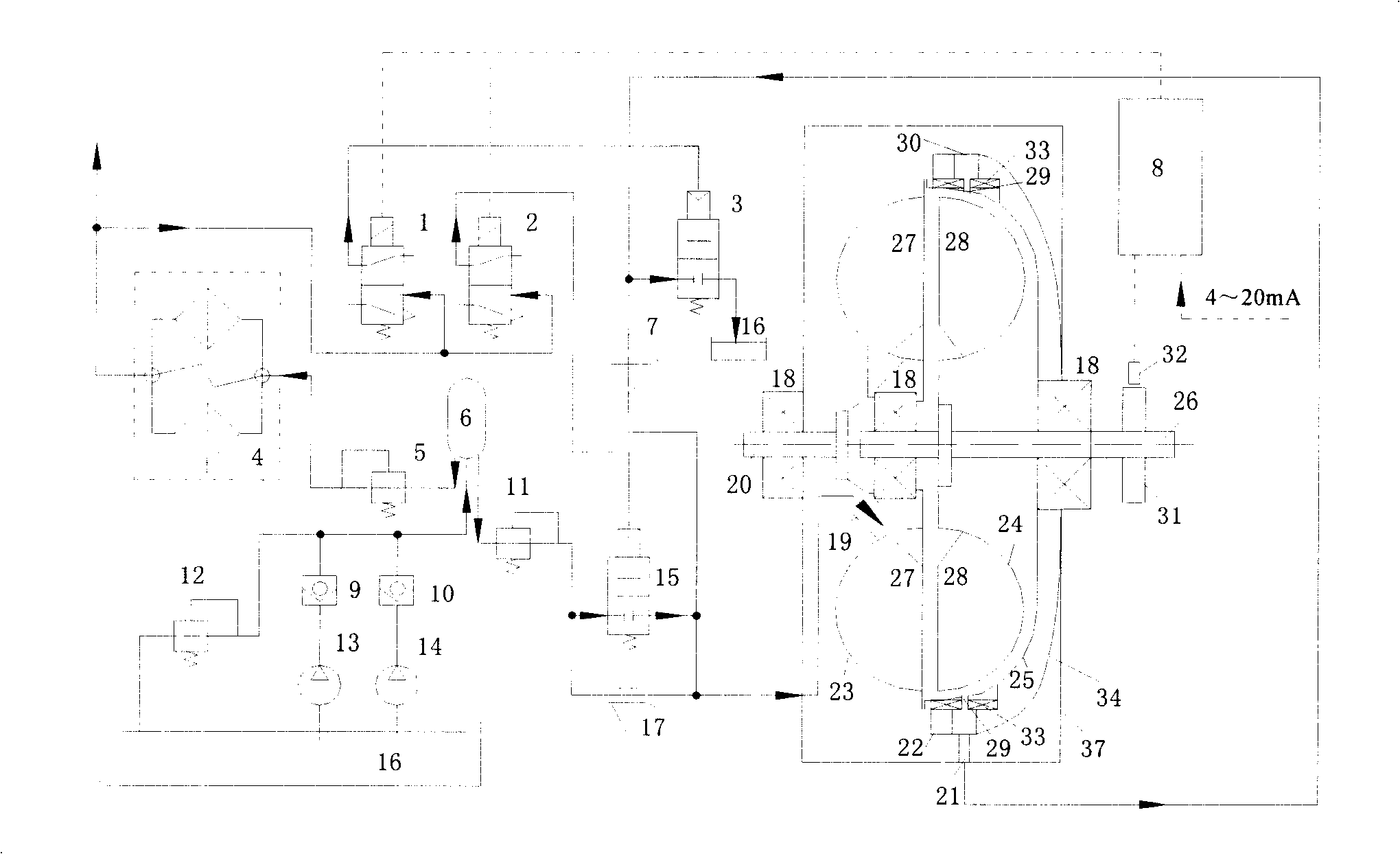

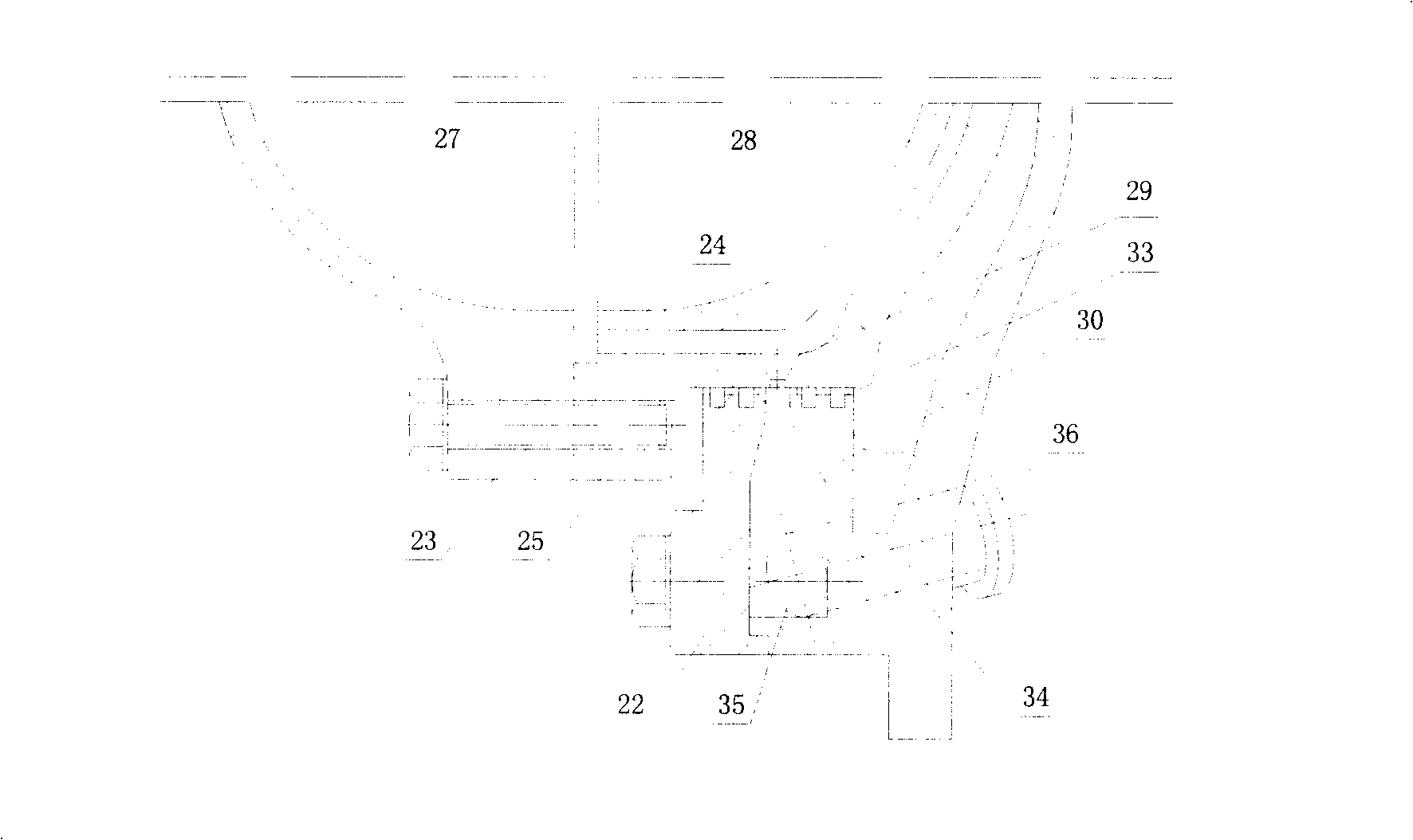

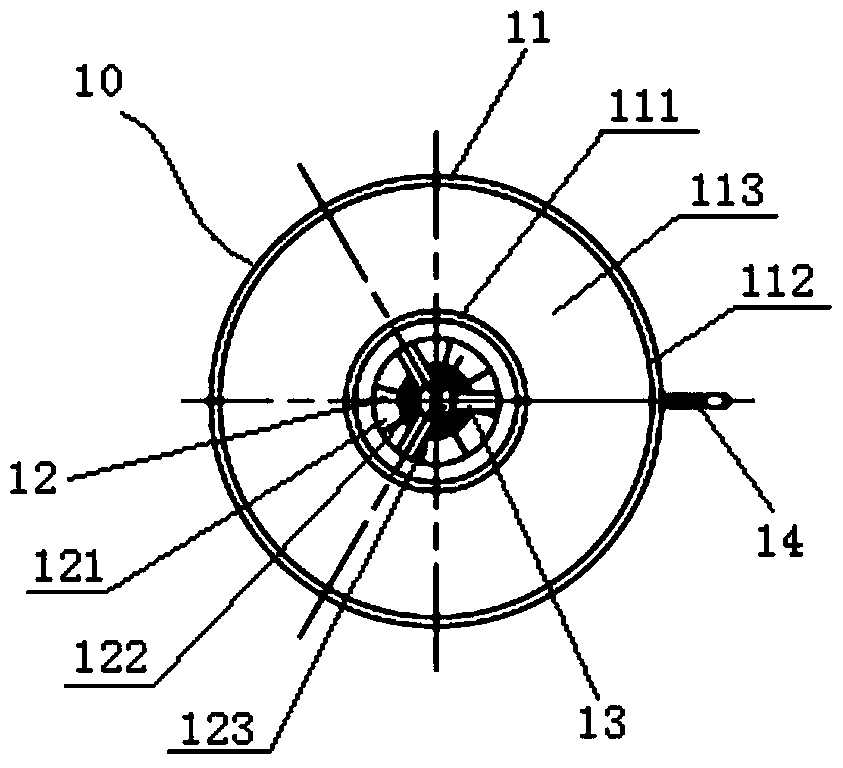

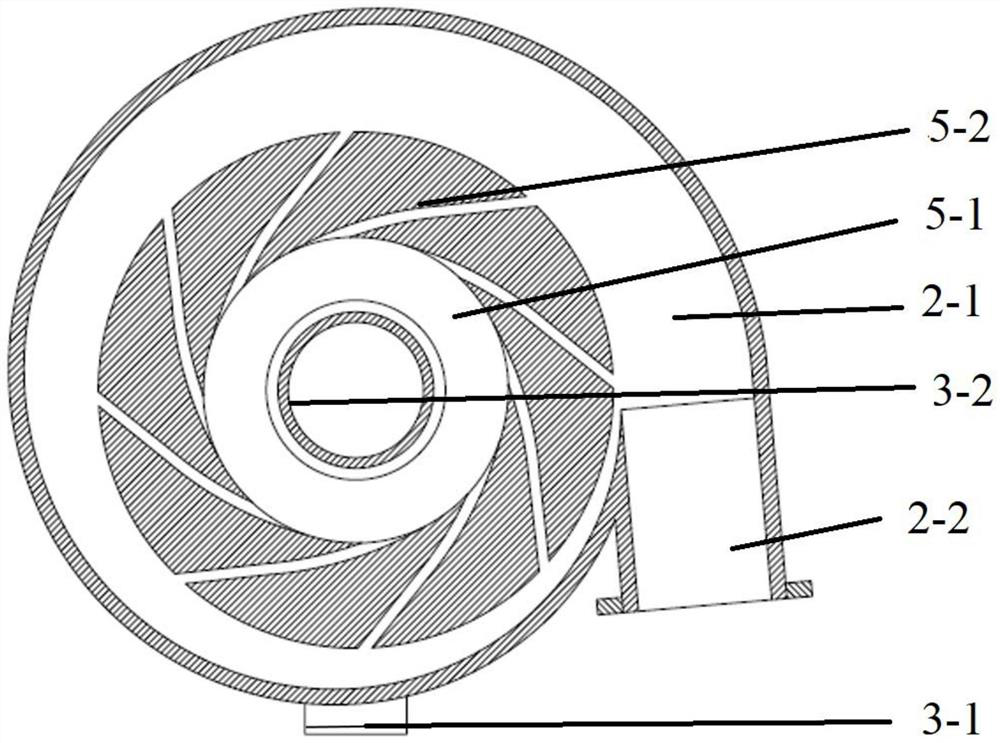

Centrifugal flow guiding intelligent speed governing hydraulic coupler body structure

A main body structure of a hydrodynamic coupler with centrifugal diversion and intelligent speed adjustment belongs to the technical field of energy-saving and hydrodynamic transmission. The structure comprises a pump wheel, a pump wheel flange, a turbine, a driving shaft, a driven shaft, a case body, oil inlet / outlet connecting tubes, a rotation speed sensor, a speed-measuring gear, a rotating shell, a rotating shell flange, nozzles, left and right sealed end surfaces and an oil seal ring. Based on the principle of centrifugal diversion, the working oil is led out of the nozzles arranged on the rotating shell and cooled under the centrifugal action, and the quantity and aperture of the nozzles are determined by the type and the load characteristics of the coupler, so as to improve the load adaptability of the coupler. The labyrinth oil seal in axial arrangement can greatly reduce the leakage at the seals, and help the coupler reduce energy loss and improve the controllability of rotation speed and stability of operation. The coupler is externally supported to prevent the case body from bearing the self-weight of the coupler and the case body is only used for storing oil. The invention also has the advantages of small wall thickness and size, compact overall structure, reduced material consumption and good social and economic benefits.

Owner:SHANGHAI JIAO TONG UNIV

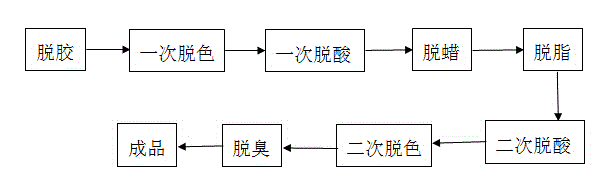

Refining method of rice oil

InactiveCN104312721APlay the role of adsorbing some pigmentsReduce colorFatty-oils/fats refiningEdible oils/fatsOil and greasePhosphoric acid

The invention discloses a refining method of rice oil. The refining method comprises the following steps: degumming; primarily decoloring; primarily deacidifying; dewaxing; degreasing; secondarily deacidifying; secondarily decoloring and deodorizing, wherein the degumming step specifically comprises the following steps: carrying out reaction on heated crude oil and phosphoric acid in an acid reaction tank, then, adding alkaline liquor to mix for centrifugal separation, then, adding water to mix for washing centrifugal separation, and finally vacuum-drying; the primarily deacidifying step is physical deacidifying; the secondarily deacidifying step specifically comprises the following steps: quickly mixing heated oil with alkaline liquor for centrifugal separation, then, adding water for washing centrifugal separation, and finally vacuum-drying. According to the method, in the degumming and secondarily deacidifying steps, alkaline liquor is added to remove part of free fatty acids in grease, thus, not only is oryzanol remained, but also part of pigments can be adsorbed. In the degumming, primarily deacidifying and secondarily deacidifying steps, physical refining and chemical refining are organically combined, so that not only is oryzanol remained and the color reduced, but also the product yield is effectively improved.

Owner:唐山圣昊农科发展有限公司

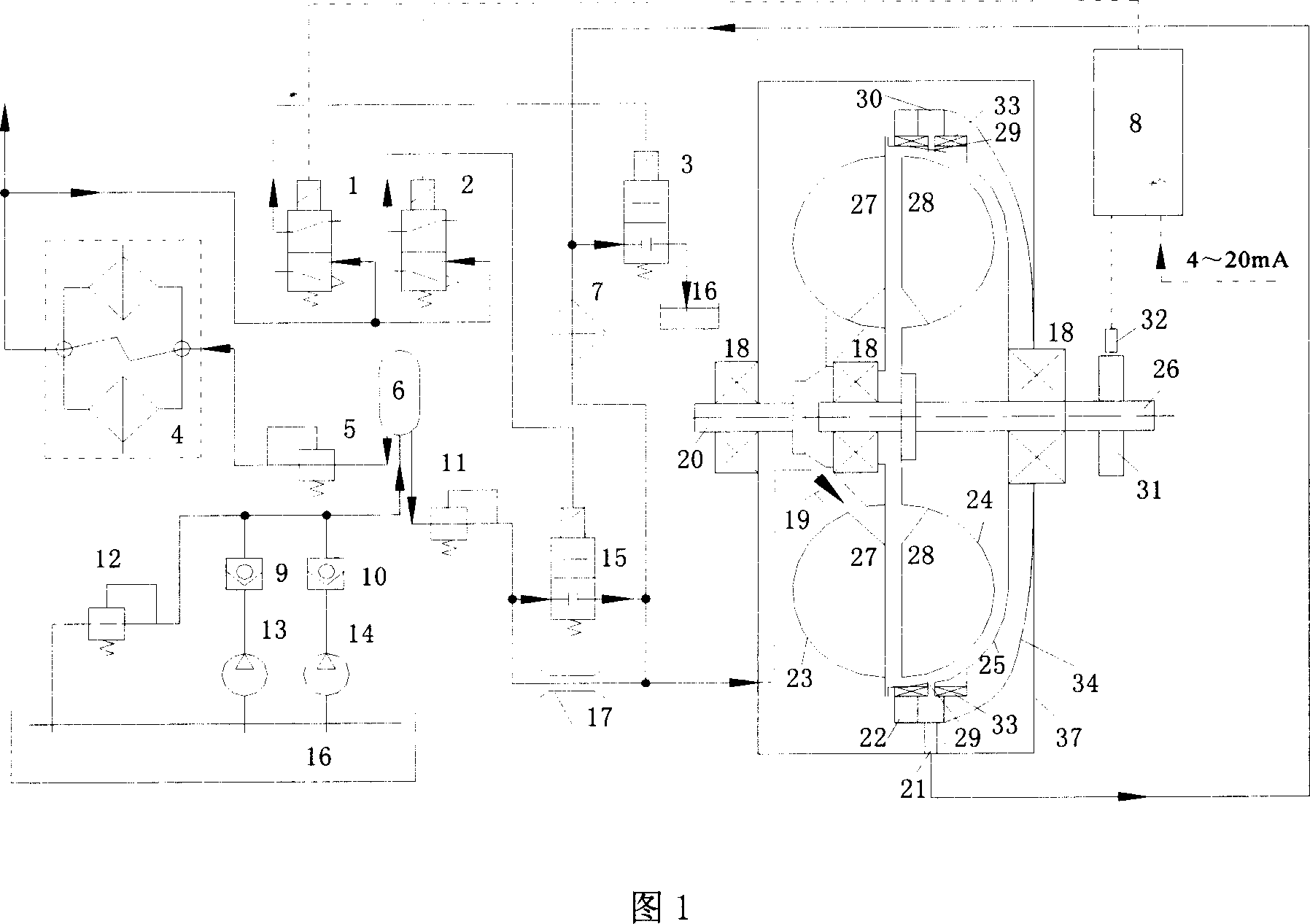

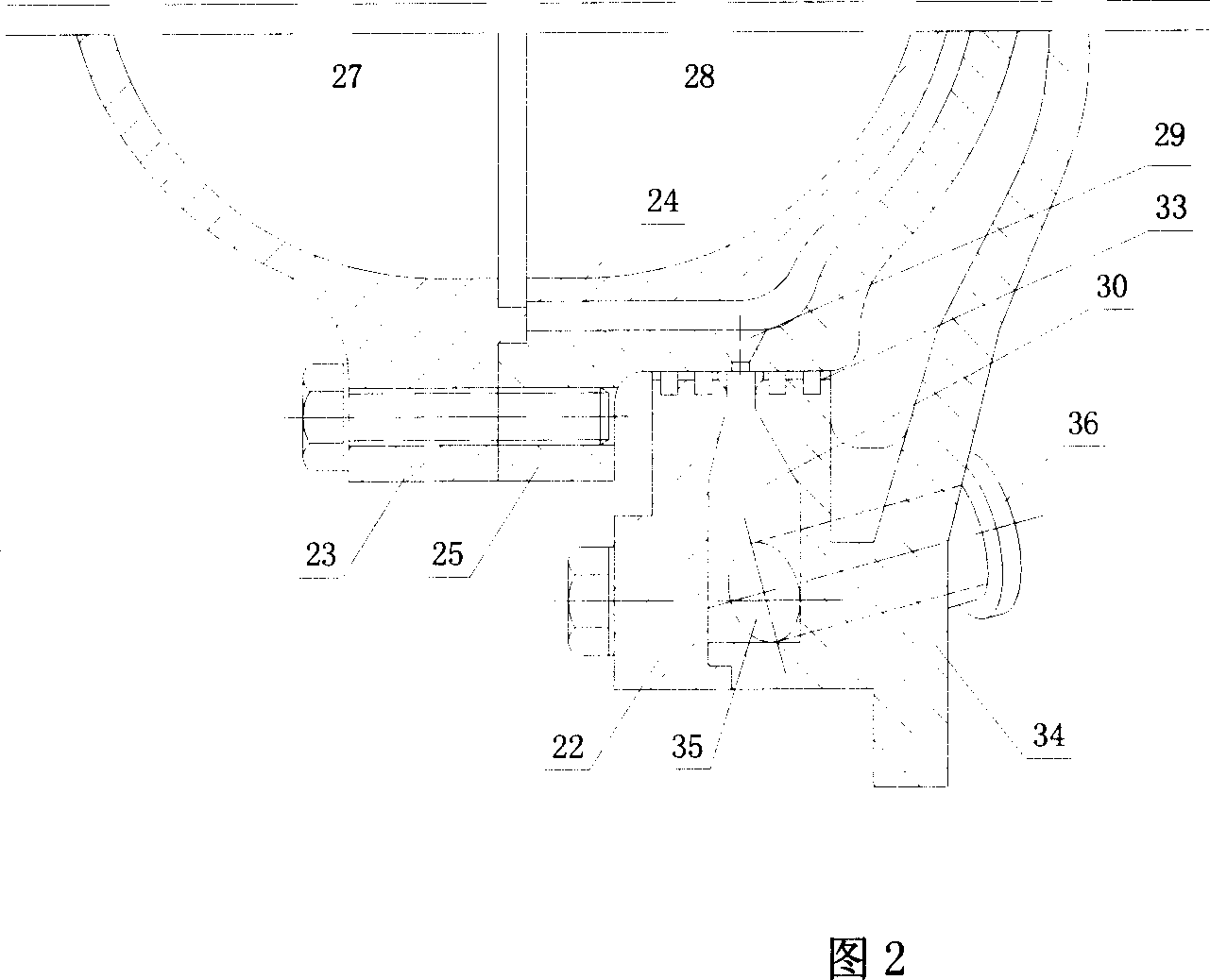

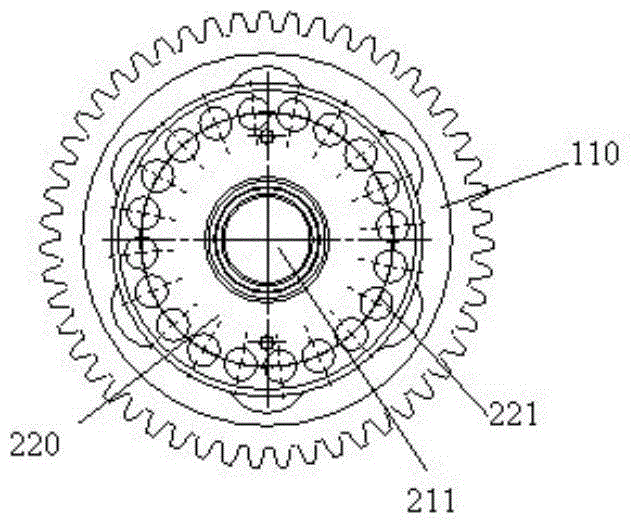

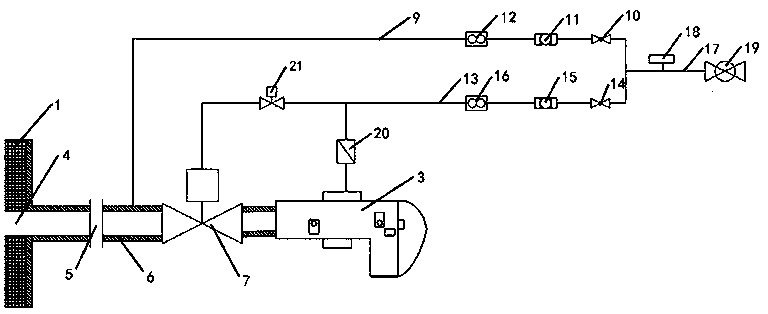

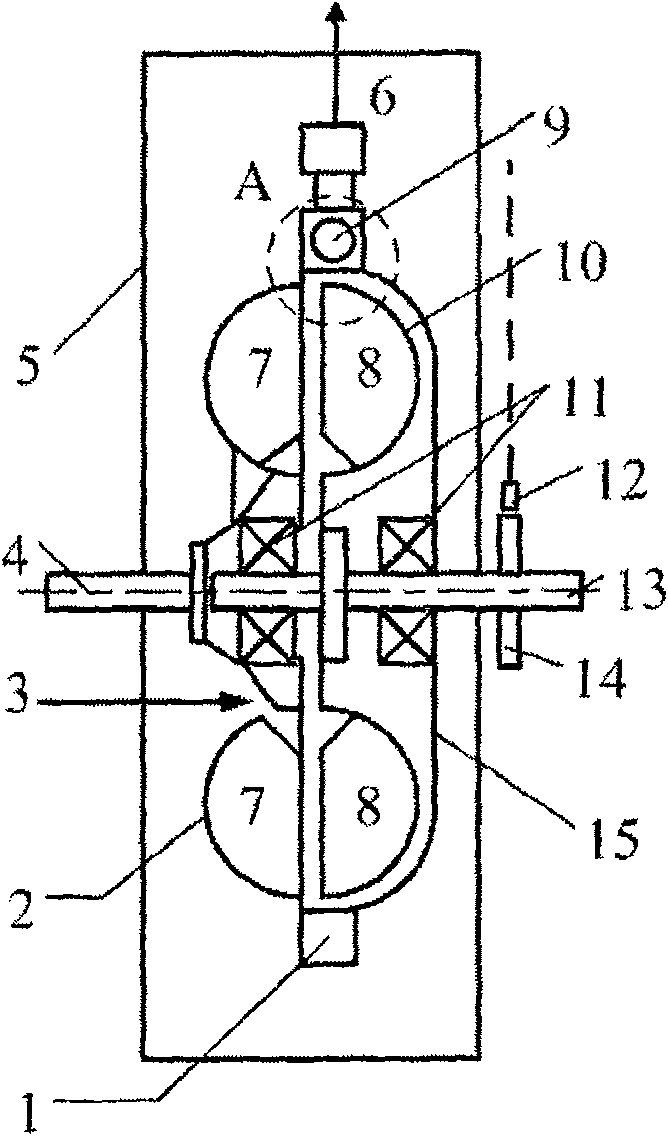

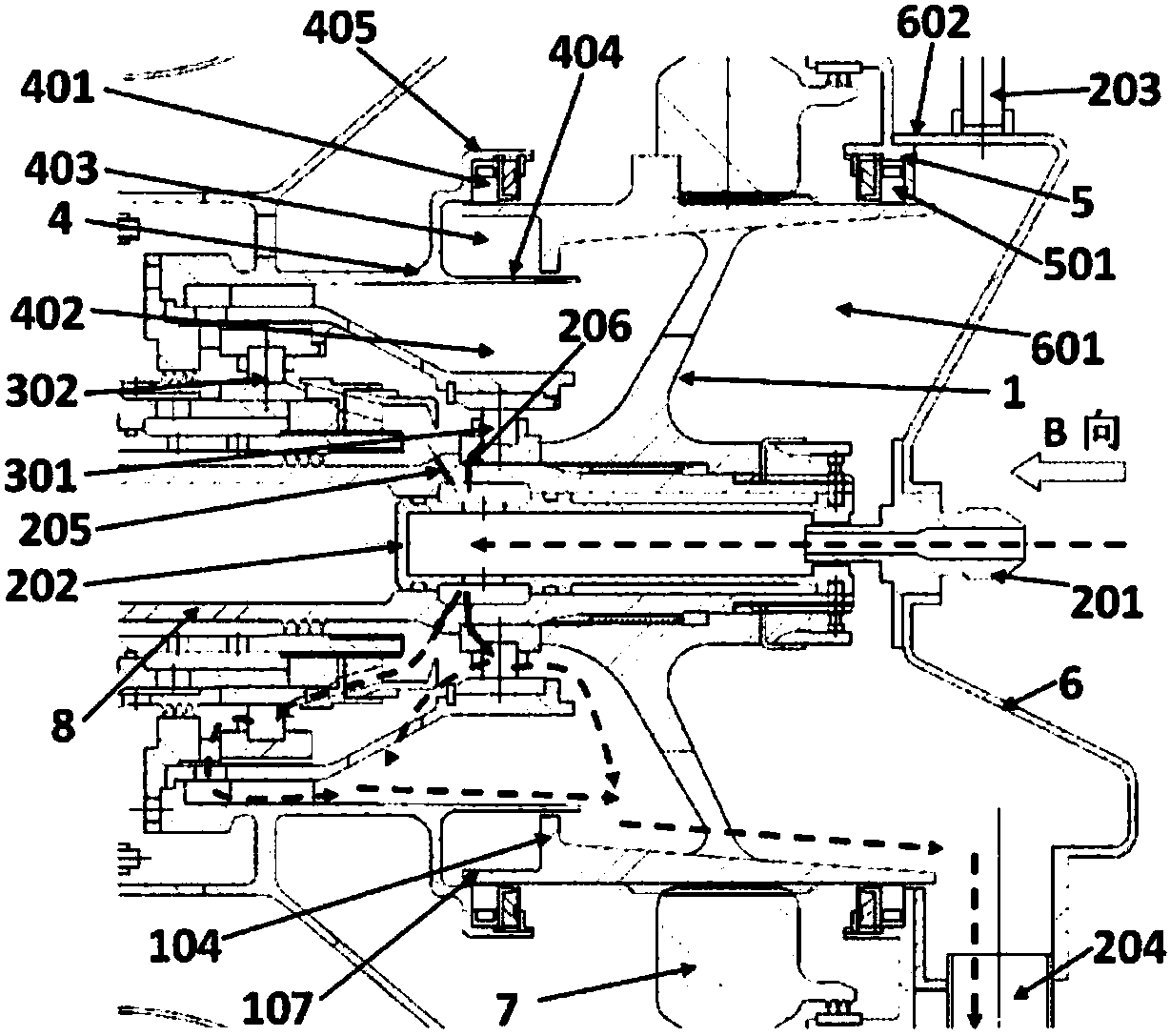

Eccentric flow guiding valve controlled speed adjusting type hydrokinetic coupoler

InactiveCN1924403AReduce the amount of oilShorten the axial lengthFluid gearingsGear wheelSpeed test

This invention relates to eccentric flow guide valve control speed adjusting hydraulic coupler, which comprises the following parts: two guide valves, two hydraulic control valve, two release valves, two electrical pumps, filter, storage device, cooling device, controller, two single valves, overflow valve, oil pool, flow saving hole board, eccentric guide cover, eccentric hole guide, eccentric guide tank, speed test gear, speed sensor, oil sealing, top cover and channel hole.

Owner:上海交大南洋机电科技有限公司

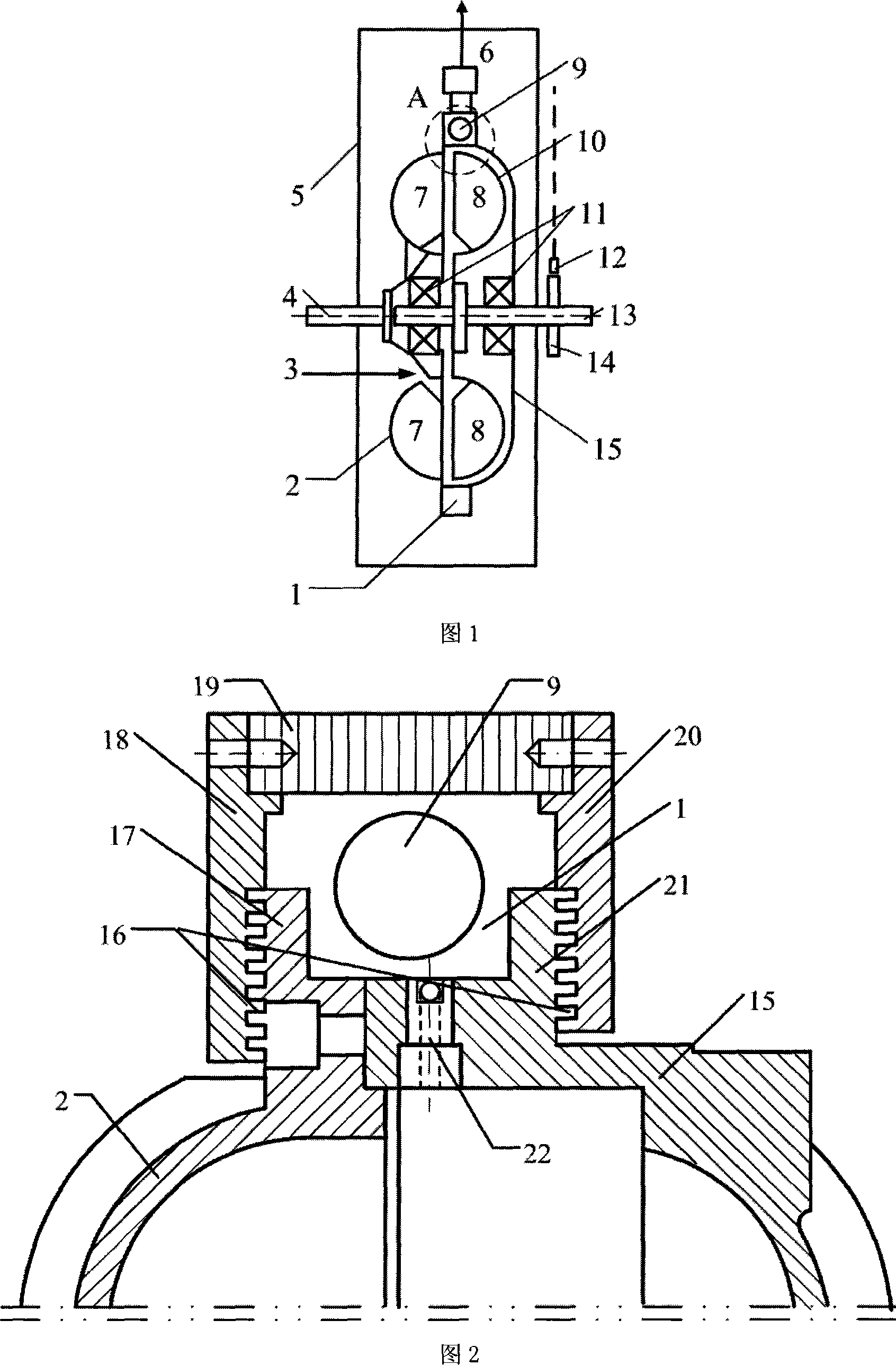

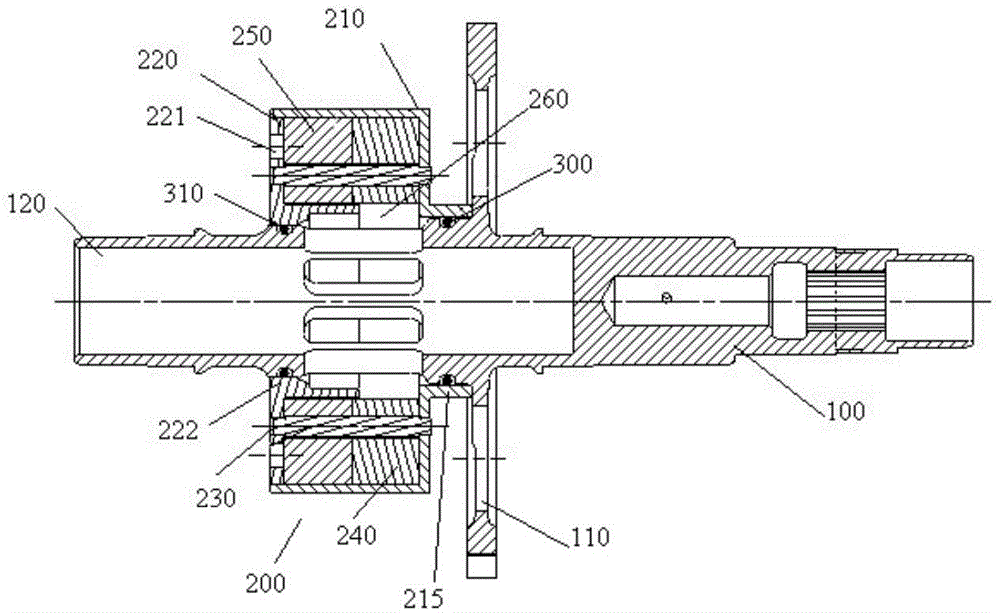

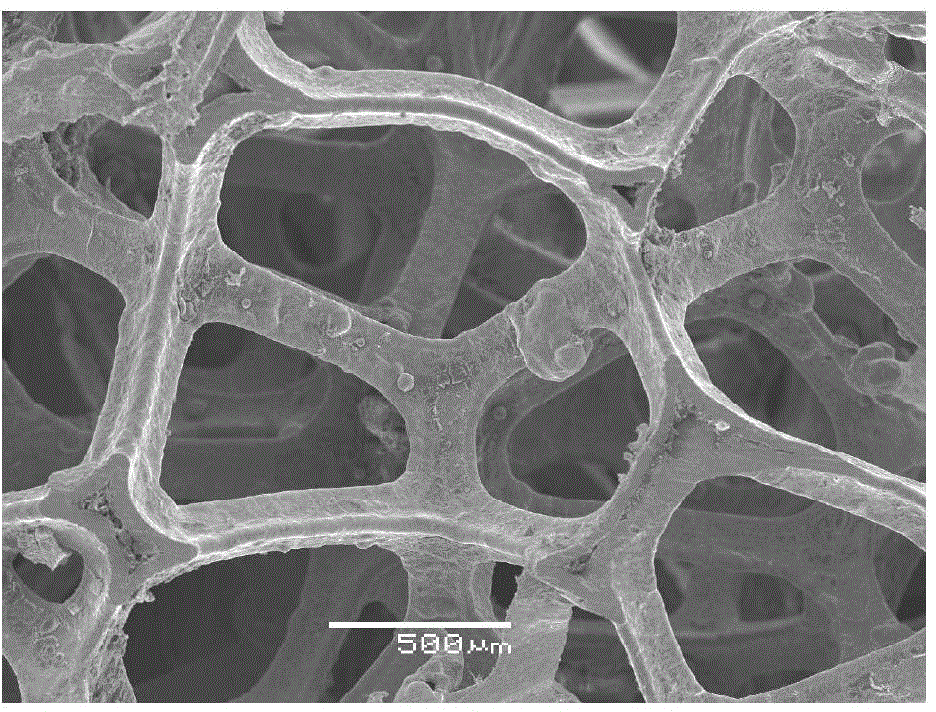

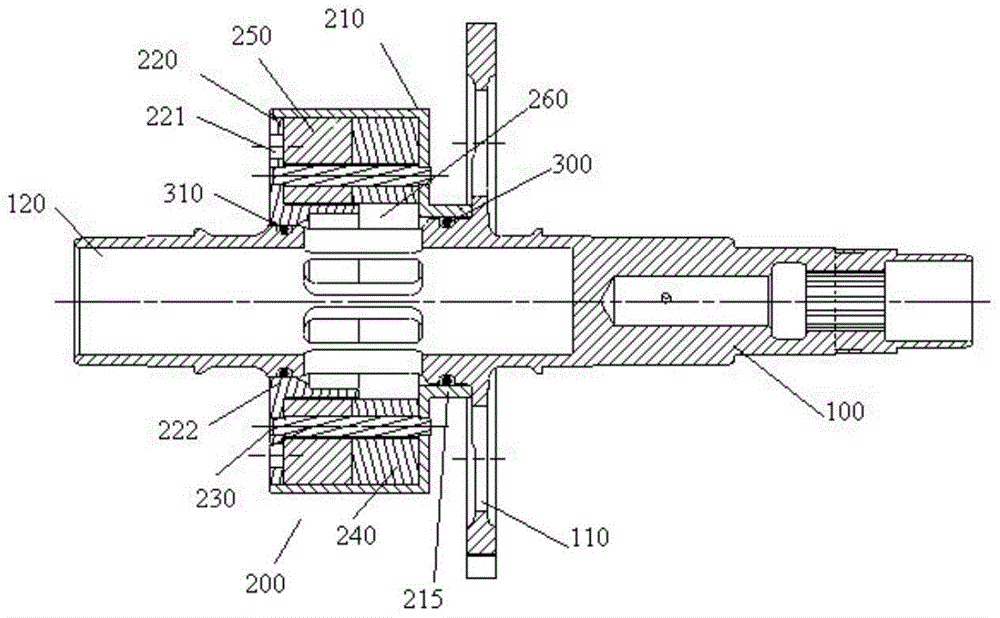

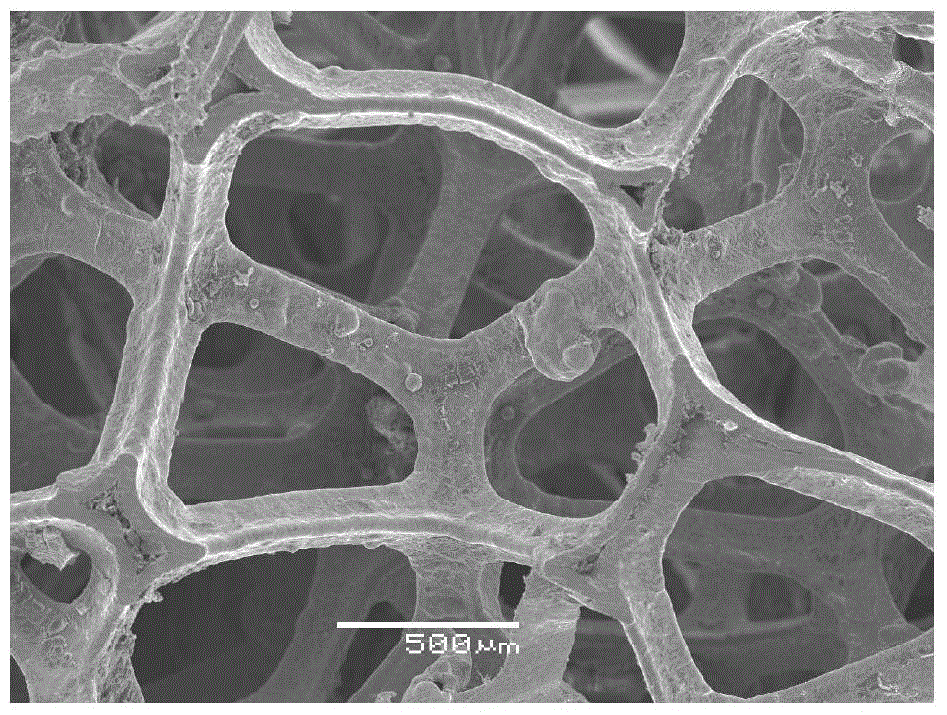

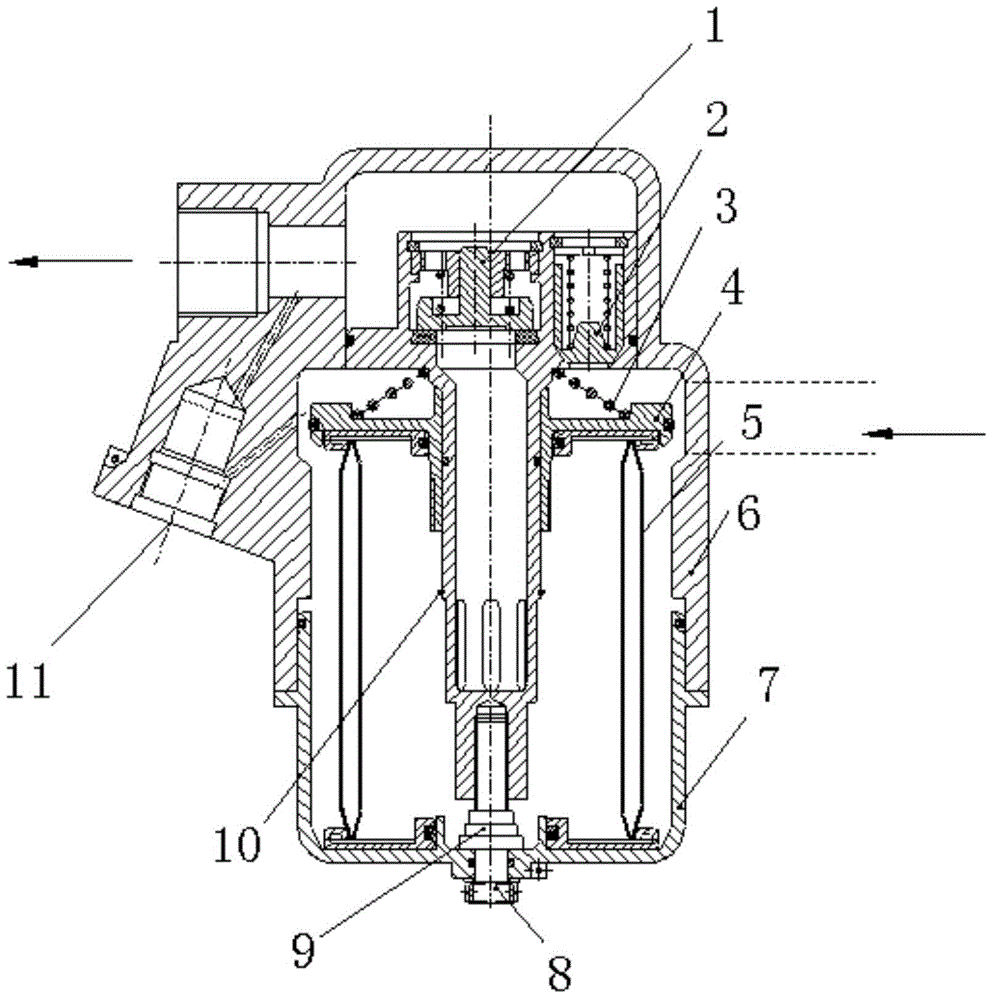

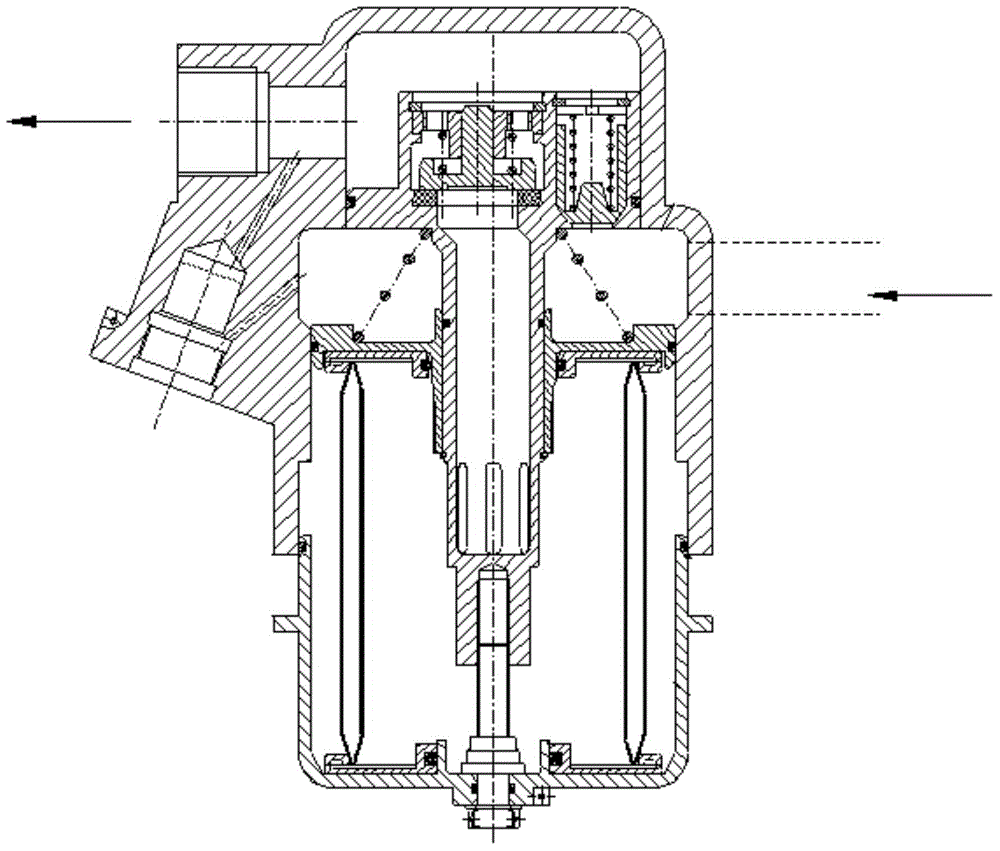

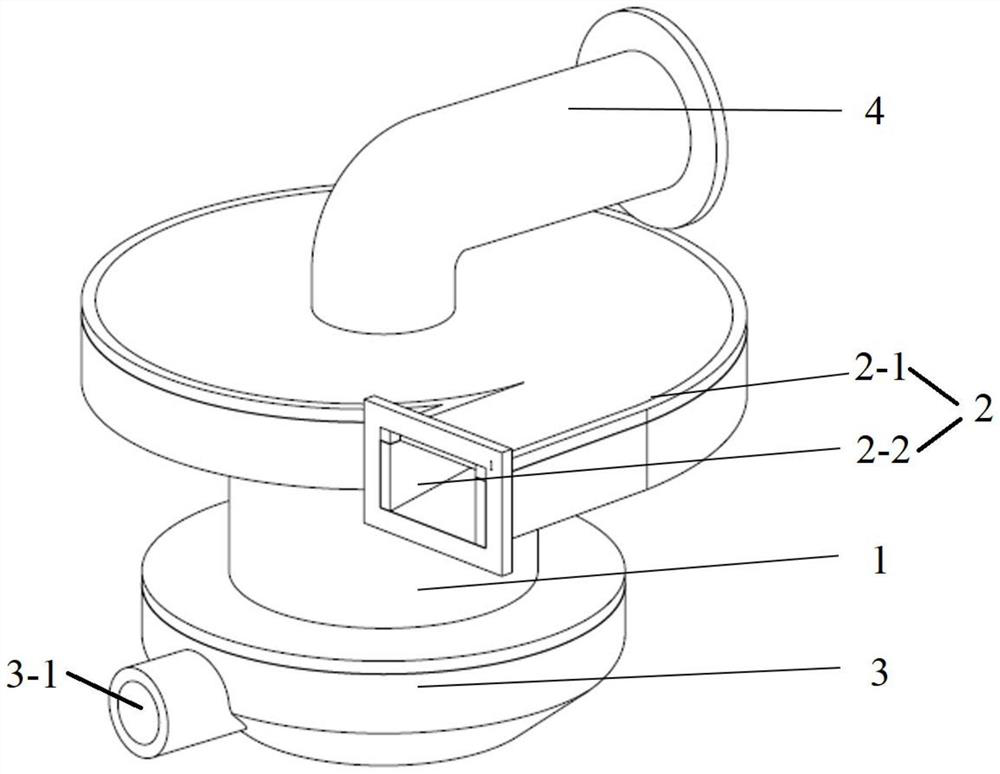

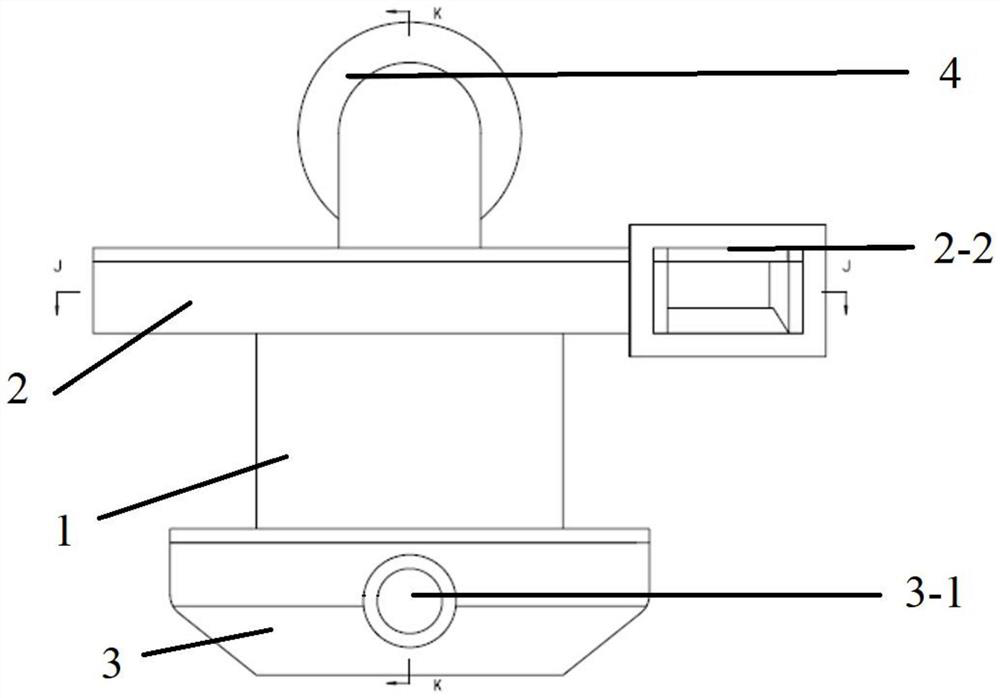

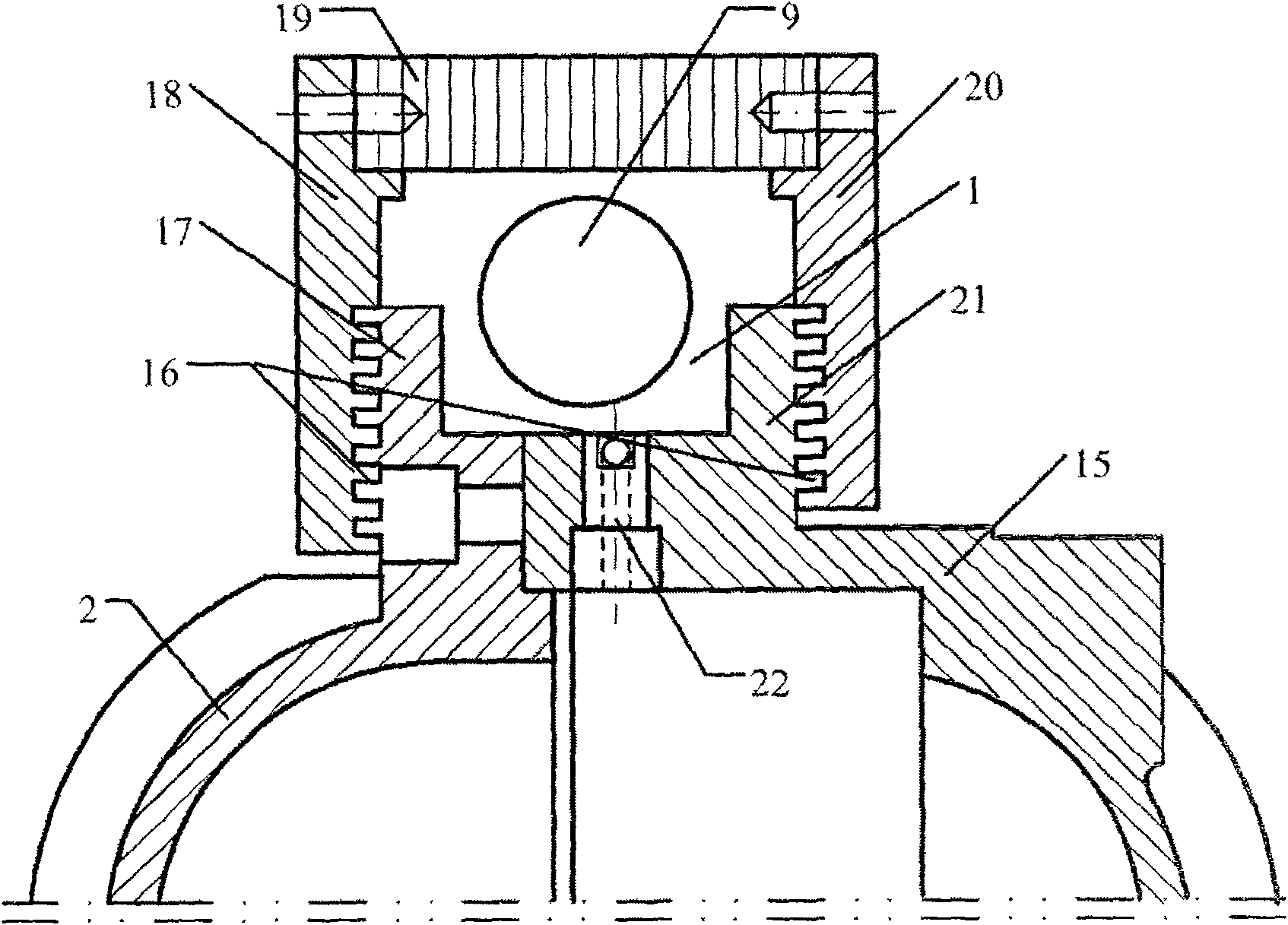

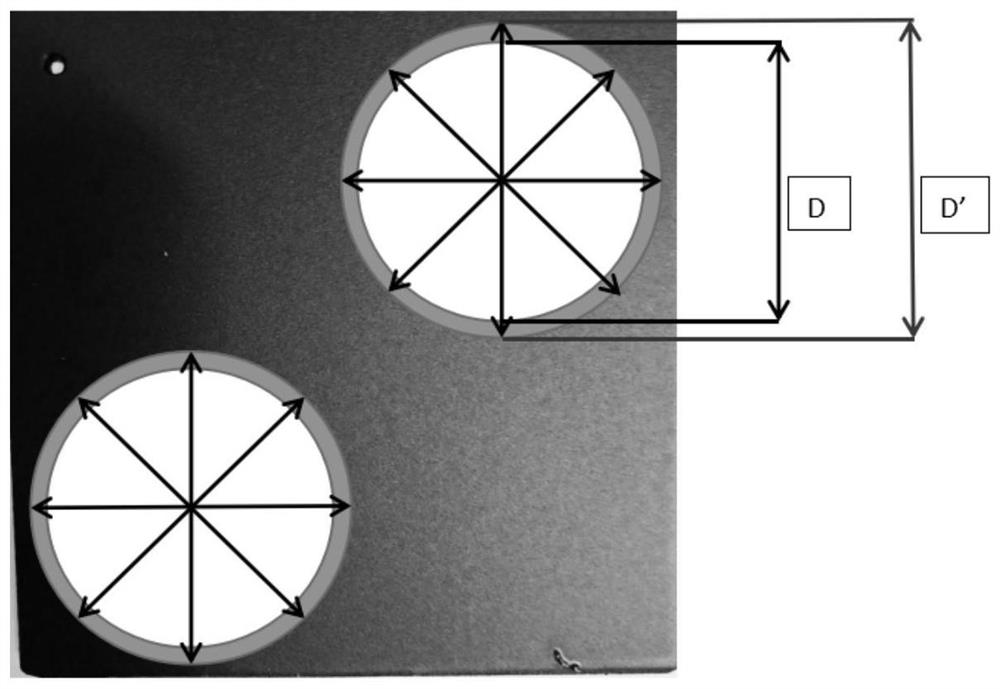

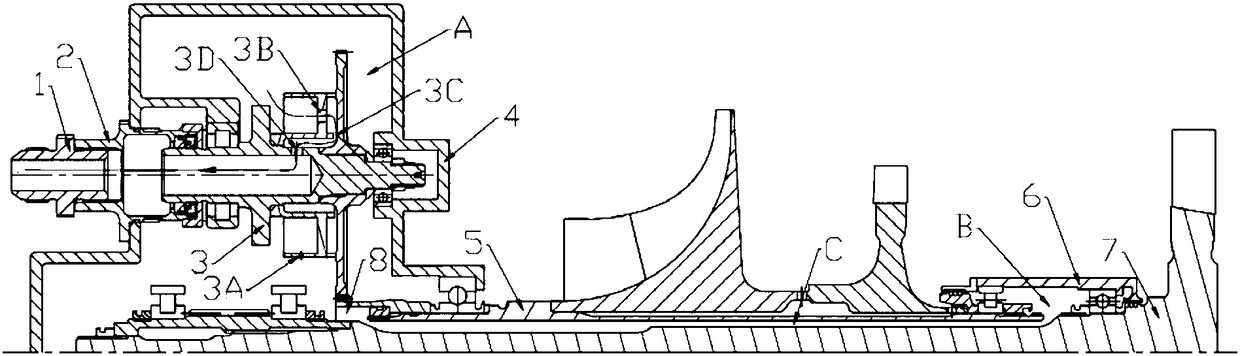

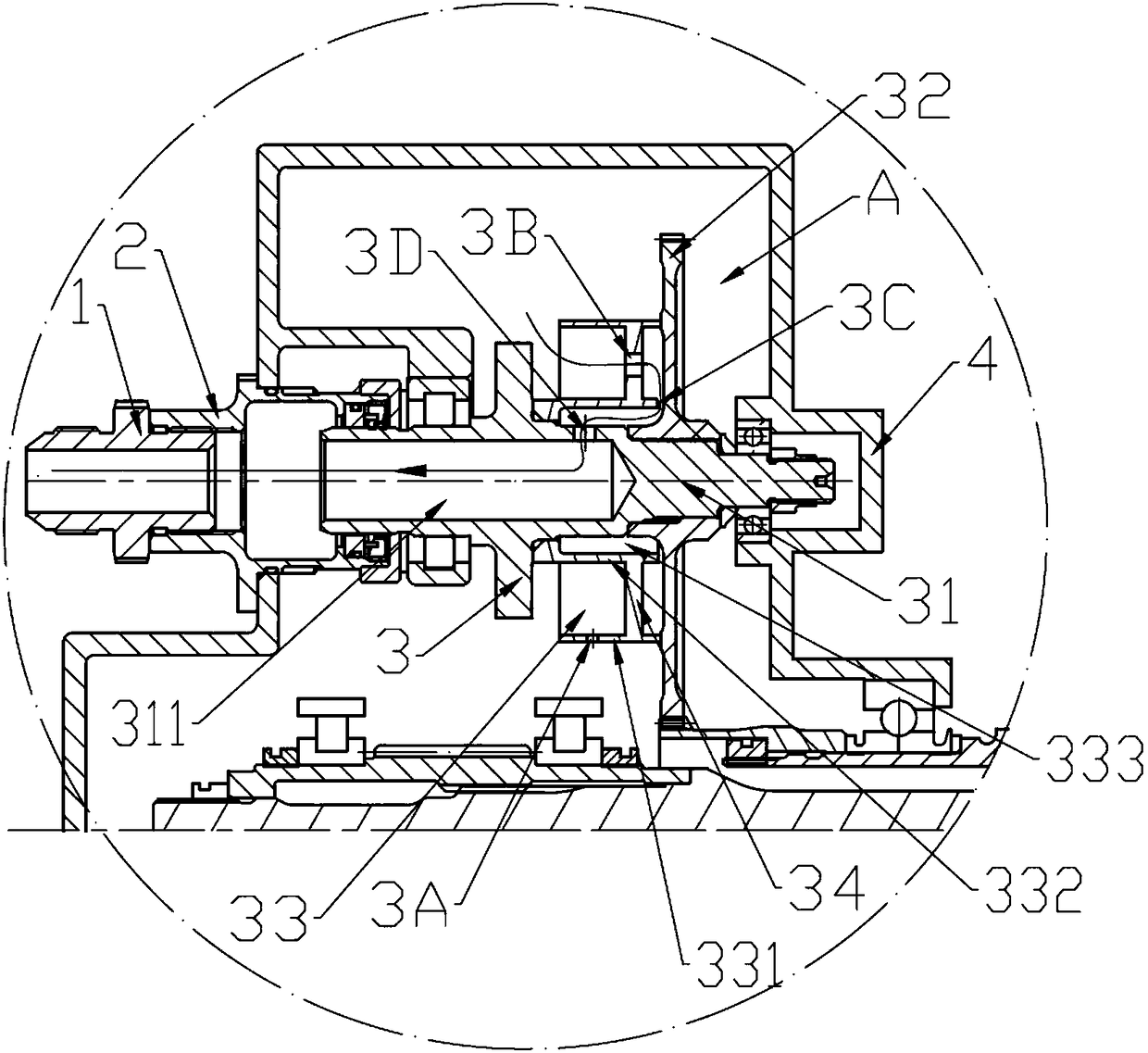

Centrifugal separation device for aero-engine

ActiveCN103982300AReduce the amount of oilLose weightCentrifugesTurbine/propulsion lubricationAero enginePetroleum engineering

The invention provides a centrifugal separation device for an aero-engine. The centrifugal separation device comprises a rotating shaft and a centrifugal separator sleeving the outer wall of the rotating shaft, wherein the centrifugal separator comprises a shell sleeving the rotating shaft and multiporous metal; the multiporous metal fills the shell; a plurality of oil return holes are formed in one end face of the shell along the circumferential direction. Compared with an amplitude-plate blade type centrifugal separation device, the centrifugal separation device disclosed by the invention is simple and compact in structure, convenient to assemble and disassemble, light in weight, low in processing and maintenance cost and high in oil-gas separation efficiency.

Owner:CHINA AVIATION POWER MACHINE INST

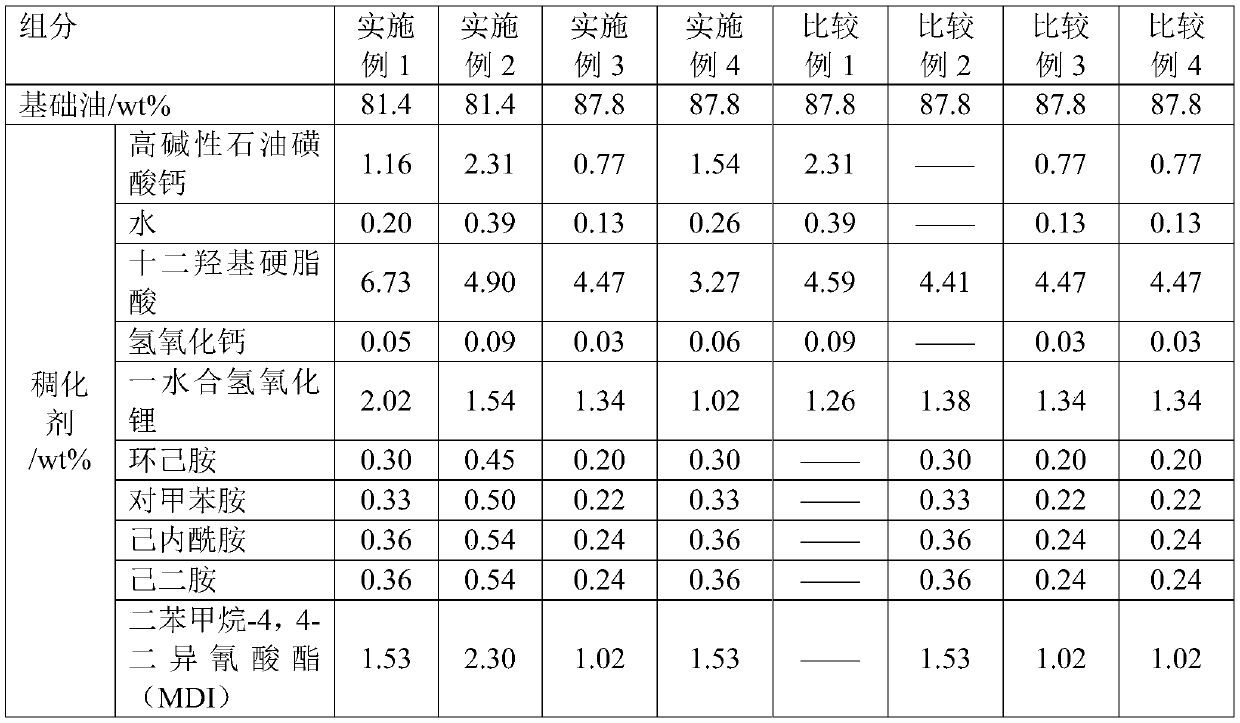

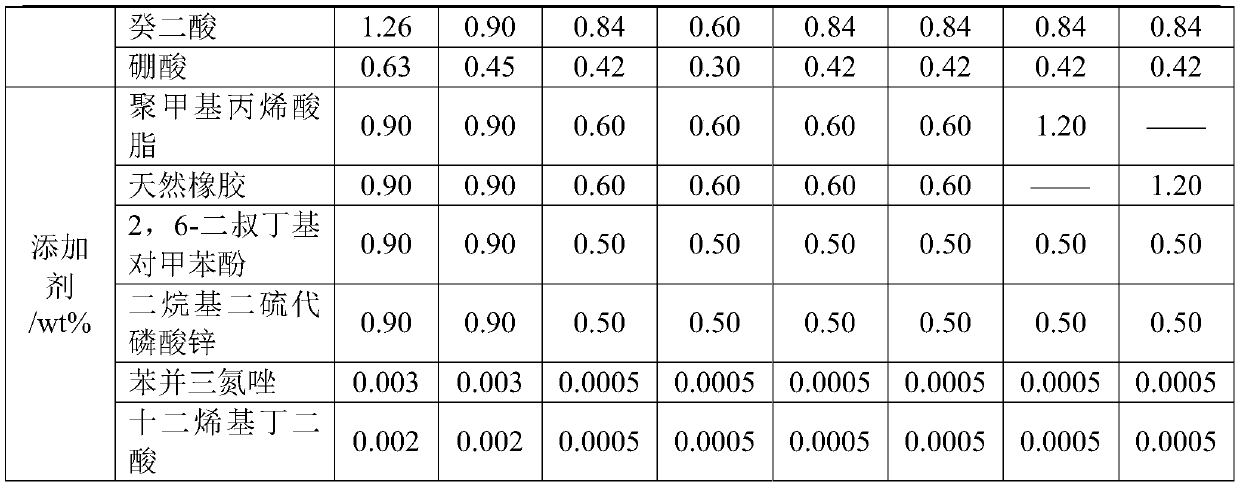

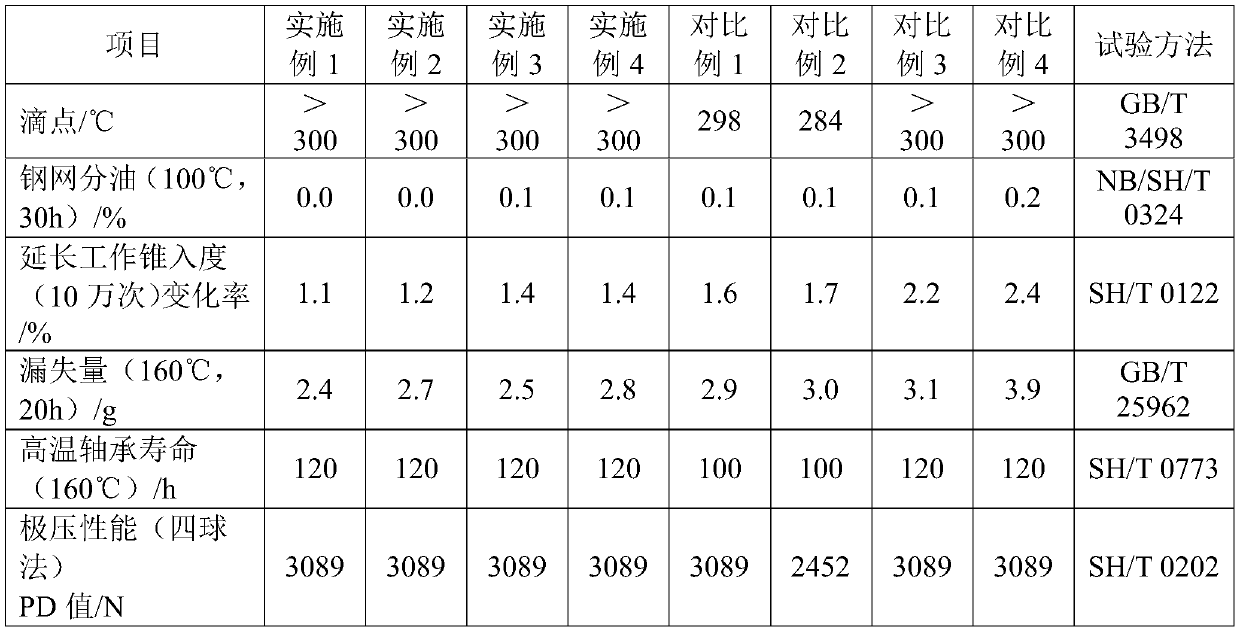

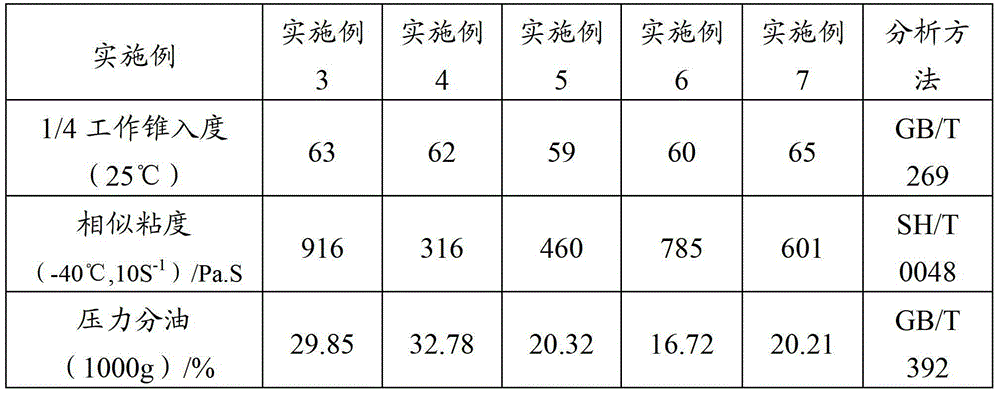

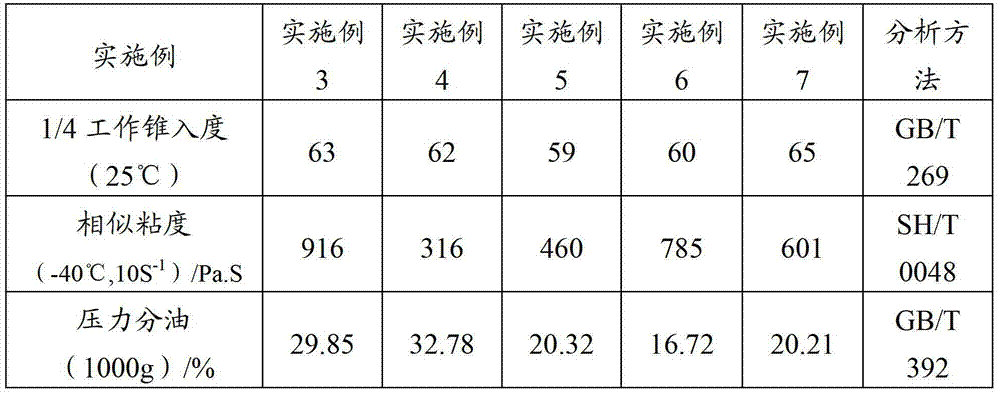

Commercial vehicle hub bearing lubricating grease and preparation method thereof

ActiveCN110616103APlay a synergistic roleImprove shear stabilityThickenersRolling resistance optimizationLithiumSynthesis methods

The invention discloses commercial vehicle hub bearing lubricating grease and a preparation method thereof. The invention belongs to the technical field of commercial vehicle hub bearing lubricating grease. The invention aims to improve the high-temperature stability and colloid stability of the lubricating grease, to reduce the grease separation amount of the lubricating grease, to improve the extreme pressure property and the shearing resistance of the lubricating grease, and to reduce consistence changes and grease-water separation of the lubricating grease. A composite polyurea thickeningagent, a composite calcium sulfonate thickening agent and a composite lithium thickening agent are compounded through an integrated synthesis method, so that the high-temperature stability and colloidstability of the lubricating grease are obviously improved, the oil separation amount of the lubricating grease is reduced, the service lifetime of a high-temperature bearing is prolonged, the oil leakage risk of the lubricating grease is reduced, the extreme pressure property and shearing resistance of the lubricating grease are improved, the consistency change of the lubricating grease is reduced and the grease-water separation risk is reduced. A composition of a synthetic adhesive and a natural adhesive has a synergistic effect, the shear stability of the lubricating grease is obviously improved, the consistency change of the lubricating grease is reduced, the lubricating grease is well adhered to the surface of a friction pair, and the grease-water separation risk of the lubricating grease is reduced.

Owner:FAW JIEFANG AUTOMOTIVE CO

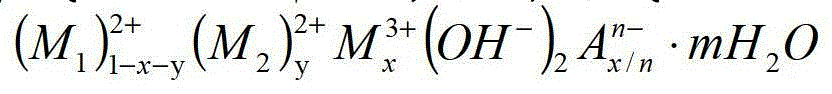

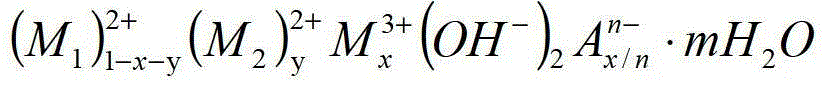

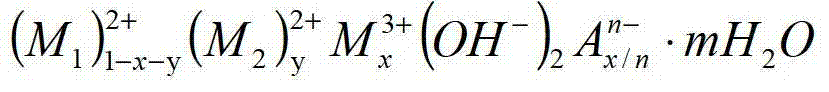

Lithium base grease and preparation method thereof

The invention provides lithium base grease. The lithium base grease comprises the following components in parts by mass: 75-95 parts of base oil, 5-20 parts of lithium soap, 2-15 parts of laminated dihydroxy composite metal oxide, 0.1-2.0 parts of antioxidant, and 0.1-2.0 parts of corrosion inhibitor. The laminated dihydroxy composite metal oxide is introduced in the lithium base grease, and organic modified treatment is performed on the lithium base grease by adopting the lithium soap, so that the lithium soap, the laminated dihydroxy composite metal oxide and the base oil achieve highly scattered states; and therefore, the colloid stability of the lithium base grease is obviously improved under the precondition that the low-temperature flow property of the grease is not influenced, and the application of the lithium base grease under a low-temperature environment is expanded.

Owner:CHINA PETROLEUM & CHEM CORP

Annealing method of cast-rolling aluminum foil used for air conditioner radiation fin

The invention provides a method for annealing a rolling-casting aluminum foil used for an air conditioner radiating plate, which is characterized by comprising the following steps: 1) raising the furnace gas temperature of an annealing furnace to between 200 and 230 DEG C and keeping the temperature for 1 to 3 hours; 2) raising the furnace gas temperature of the annealing furnace to between 316 and 375 DEG C and keeping the temperature for 80 to 200 minutes; and 3) reducing the furnace gas temperature of the annealing furnace to between 266 and 300 DEG C and keeping the temperature for 3 to 5hours. The method adopts a differential temperature annealing process to raise the furnace gas temperature of the annealing furnace so that the speed of temperature rise is increased, the nucleating rate of the internal grain structure of the aluminum foil is larger than the growth rate to achieve recrystallization, and the crystallizing structure is tiny and uniform to achieve the optimal mechanical property; besides, belt oil on the material surface is volatilized to effectively prevent the defects of oil spot and the like on the surface of the aluminum foil, ensure that the quality of the surface of the aluminum foil is good, shorten the total time for annealing the aluminum foil, and improve the production efficiency.

Owner:包头常铝北方铝业有限责任公司

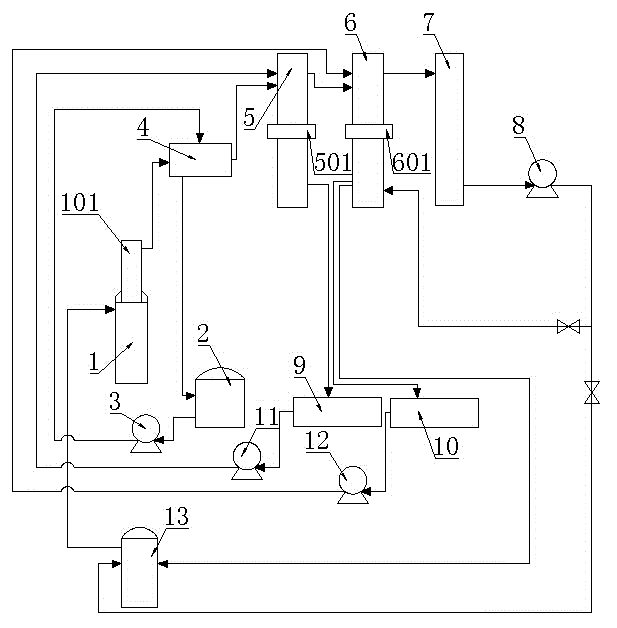

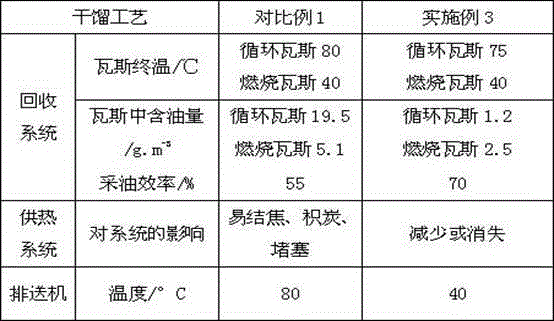

Full-negative-pressure recovery process of dry distillation furnace generation gas in oil shale dry distillation oil refining and system thereof

InactiveCN104531196AReduce the amount of oilImprove oil production efficiencyDirect heating destructive distillationLiquid hydrocarbon mixture productionHeat carrierHeating furnace

Provided are a full-negative-pressure recovery process of dry distillation furnace generation gas in oil shale dry distillation oil refining and a system thereof. The recovery system comprises a dry distillation furnace, a mud collecting tank, a mud collecting pump, a collecting pipe, washing saturation towers, an indirect cooling tower, a gas exhaust-feeding machine, a washing pool, a washing pump and a heating furnace. According to the recovery process, generation gas generated by the dry distillation furnace in oil shale dry distillation oil refining is pumped to the collecting pipe, a washing saturation tower I and a washing saturation tower II for spraying washing through the gas exhaust-feeding machine, the gas is conveyed into the indirect cooling tower, after heat exchanging in the direct cooling tower, one part of the gas is conveyed into the heating furnace by the gas exhaust-feeding machine for heating the heating furnace, the other part of the gas is used as circulation gas to be conveyed to the bottom of the washing saturation tower II, and after heat exchanging, the gas enters the heat storage type heating furnace for continuous heat exchanging and is used as a heat carrier to be conveyed to the dry distillation furnace. The process and the system have the advantages that the process is simple, whole system heat is fully used, energy loss is low, water using amount is small, and oil productivity can be improved.

Owner:BEIPIAO BEITA OIL SHALE INTEGRATED DEV UTILIZATION CO LTD

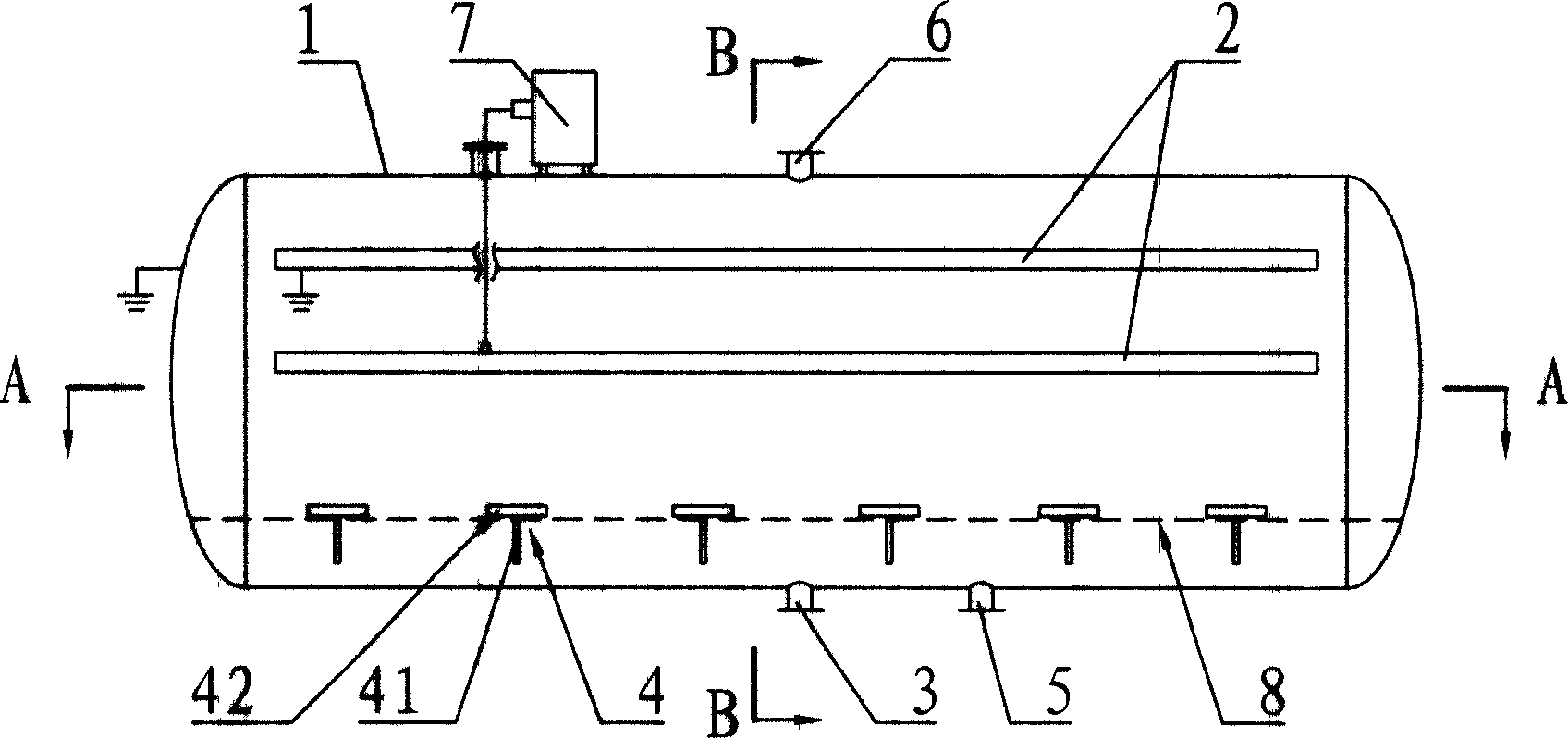

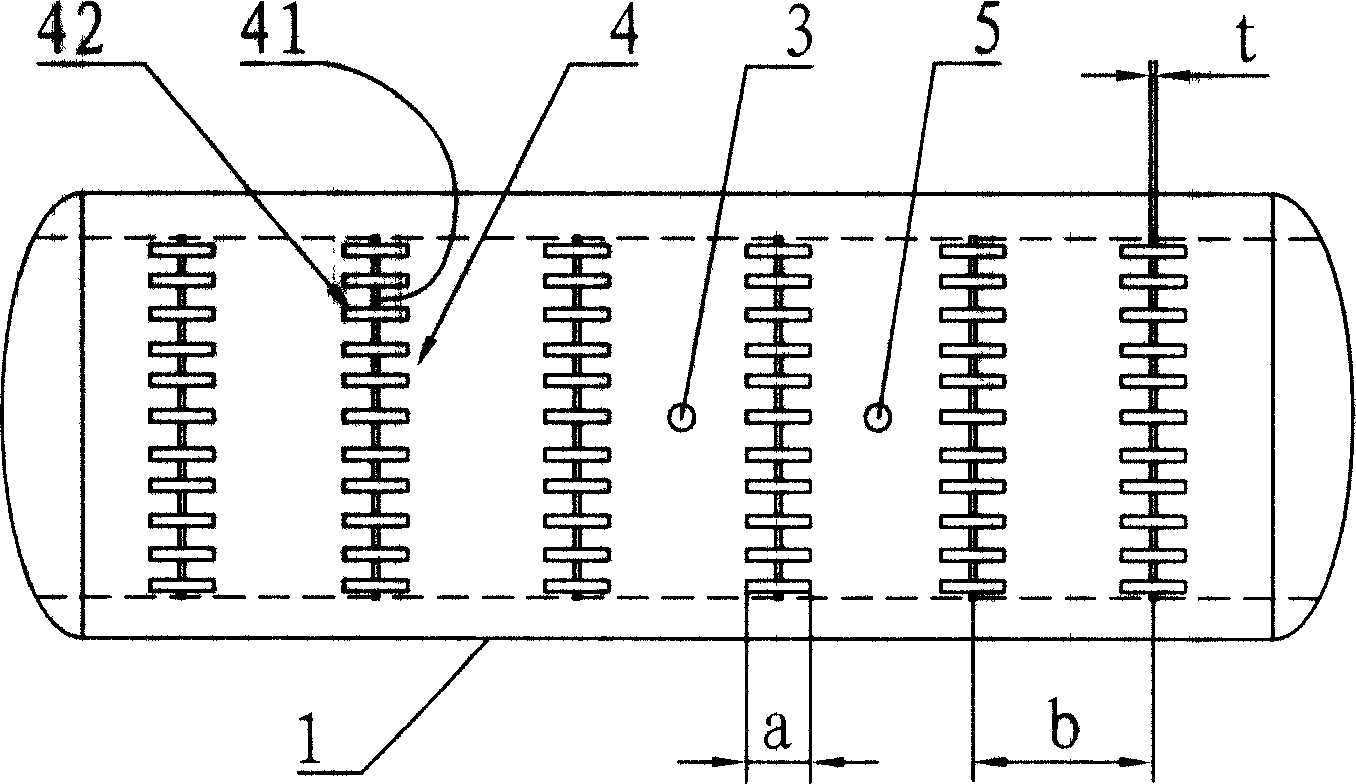

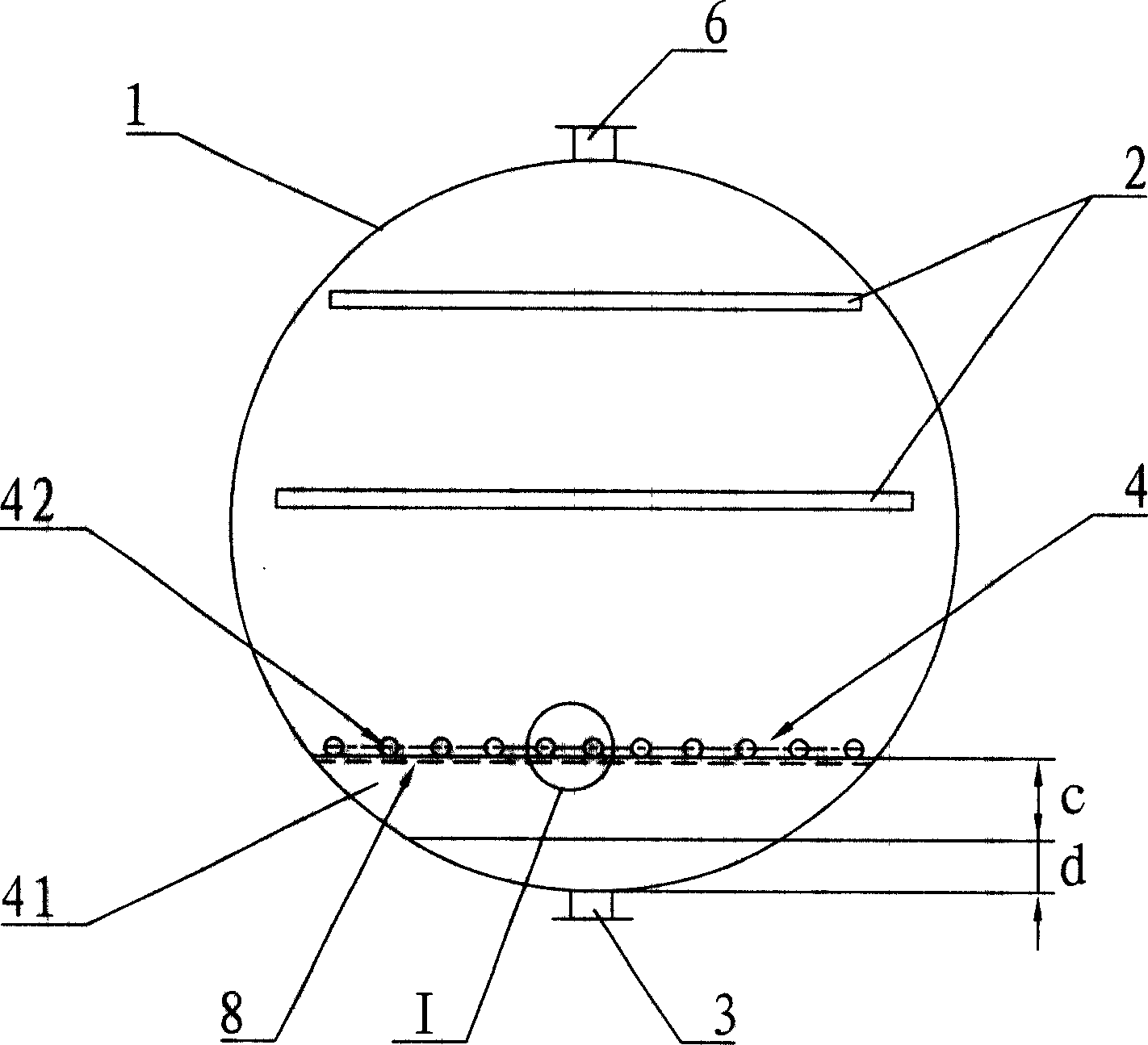

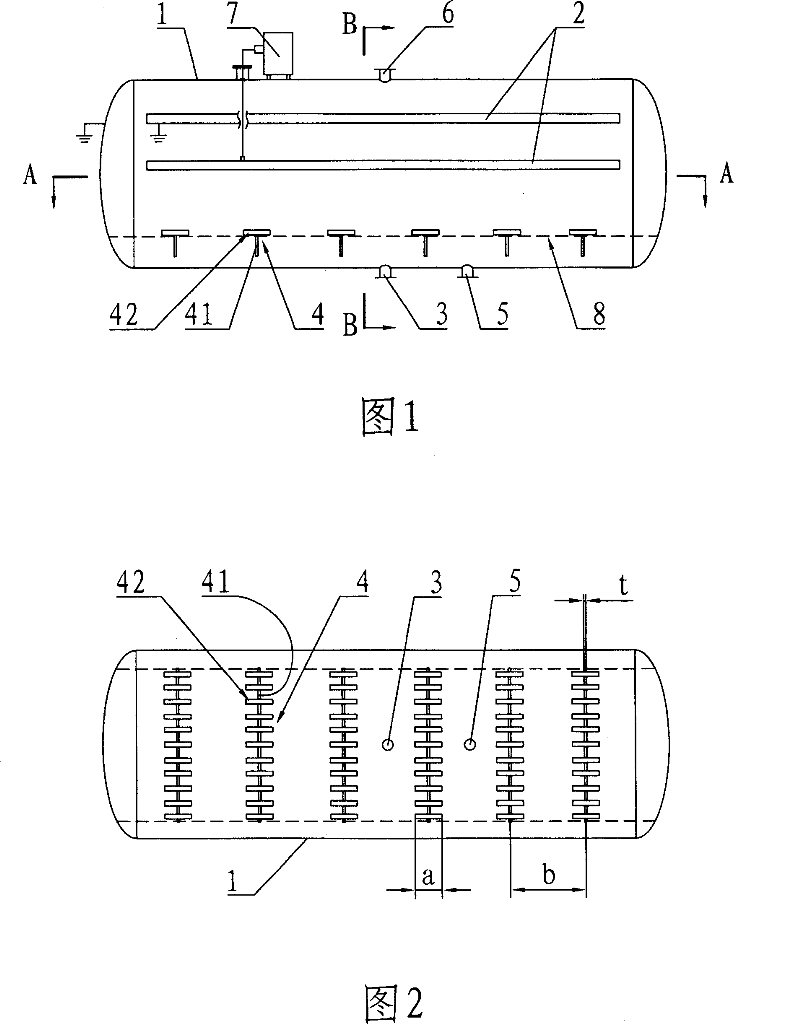

Electric desalting and dewatering tank

InactiveCN1900229AReduce the amount of oilReduce up and down fluctuationsDewatering/demulsification with electric/magnetic meansMetal stripsOil field

The present invention discloses a kind of electric desalting and dewatering tank for use in oil field and oil refinery, and aims at reducing oil in exhausted water of electric desalting and dewatering tank. The electric desalting and dewatering tank has inside the tank at least three axial water exhaust stabilizing devices in the bottom, and each of the water exhaust stabilizing devices consists of metal plate and lattice. The metal plate is perpendicular to the tank axis and has two ends connected to the inner wall of the tank, and there is gap between the plate and the tank wall for deposited water to flow through. The lattice set in the top of the metal plate consists of metal strips perpendicular to the metal plate. The present invention is used mainly for desalting and dewatering raw oil.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

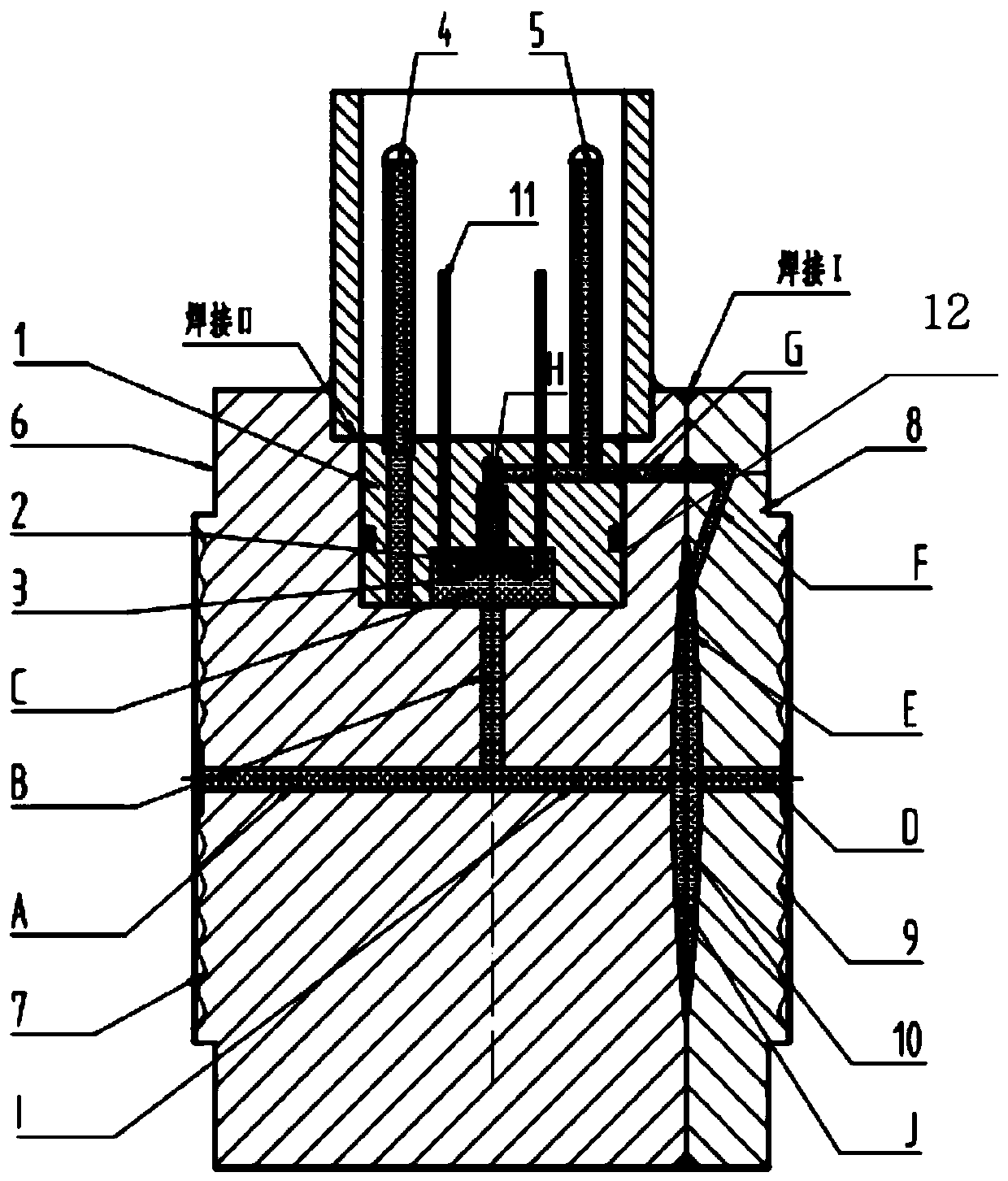

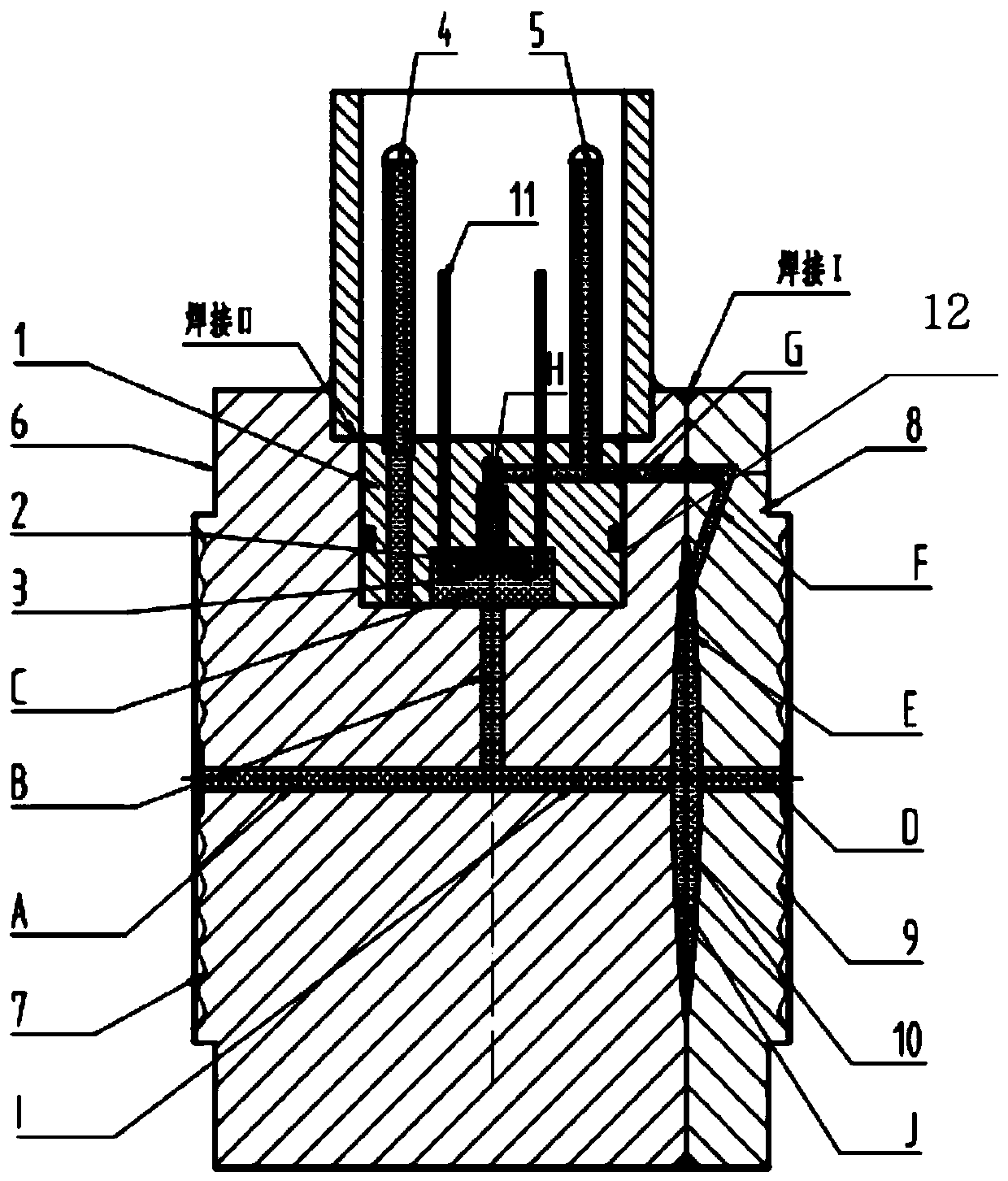

Novel high-overload differential pressure sensor

PendingCN111157171AImprove stabilityOil circuit is simplePressure difference measurement between multiple valvesMeasuring instrumentSilicone oil

The invention belongs to the technical field of measuring instruments, and particularly relates to a novel high-overload differential pressure sensor. A chip base is installed in a groove in the center of the top of a positive pressure base, and a monocrystalline silicon differential pressure chip is bonded to the interior of the chip base; two oil filling pipes are sintered on the chip base and are divided into a positive pressure end oil filling pipe and a negative pressure end oil filling pipe; oil ways are formed in the positive pressure base and the negative pressure base, a central overload membrane is installed between the negative pressure base and the positive pressure base, the oil ways in the positive pressure base and the negative pressure base are divided into the positive pressure oil way and the negative pressure oil way, and the volume of the positive pressure oil way is equal to that of the negative pressure oil way. The positive pressure oil way cavity is filled withsilicone oil through the positive pressure end oil filling pipe, the negative pressure oil way cavity is filled with silicone oil through the negative pressure end oil filling pipe, and after oil filling is completed, the positive pressure end oil filling pipe and the negative pressure end oil filling pipe are blocked and sealed through argon arc welding. The volumes of the positive pressure end and the negative pressure end are ensured to be equal so that the precision of the monocrystalline silicon differential pressure chip is stable and the stability of the sensor is improved.

Owner:盛雪梅

Centrifugal separation device for aircraft engine

ActiveCN103982300BReduce the amount of oilLose weightCentrifugesTurbine/propulsion lubricationAero enginePetroleum engineering

The invention provides a centrifugal separation device for an aero-engine. The centrifugal separation device comprises a rotating shaft and a centrifugal separator sleeving the outer wall of the rotating shaft, wherein the centrifugal separator comprises a shell sleeving the rotating shaft and multiporous metal; the multiporous metal fills the shell; a plurality of oil return holes are formed in one end face of the shell along the circumferential direction. Compared with an amplitude-plate blade type centrifugal separation device, the centrifugal separation device disclosed by the invention is simple and compact in structure, convenient to assemble and disassemble, light in weight, low in processing and maintenance cost and high in oil-gas separation efficiency.

Owner:CHINA AVIATION POWER MACHINE INST

Eccentric flow guiding valve controlled speed adjusting type hydrokinetic coupoler

InactiveCN100445601CReduce the amount of oilShorten the axial lengthFluid gearingsGear wheelSpeed test

This invention relates to eccentric flow guide valve control speed adjusting hydraulic coupler, which comprises the following parts: two guide valves, two hydraulic control valve, two release valves, two electrical pumps, filter, storage device, cooling device, controller, two single valves, overflow valve, oil pool, flow saving hole board, eccentric guide cover, eccentric hole guide, eccentric guide tank, speed test gear, speed sensor, oil sealing, top cover and channel hole.

Owner:上海交大南洋机电科技有限公司

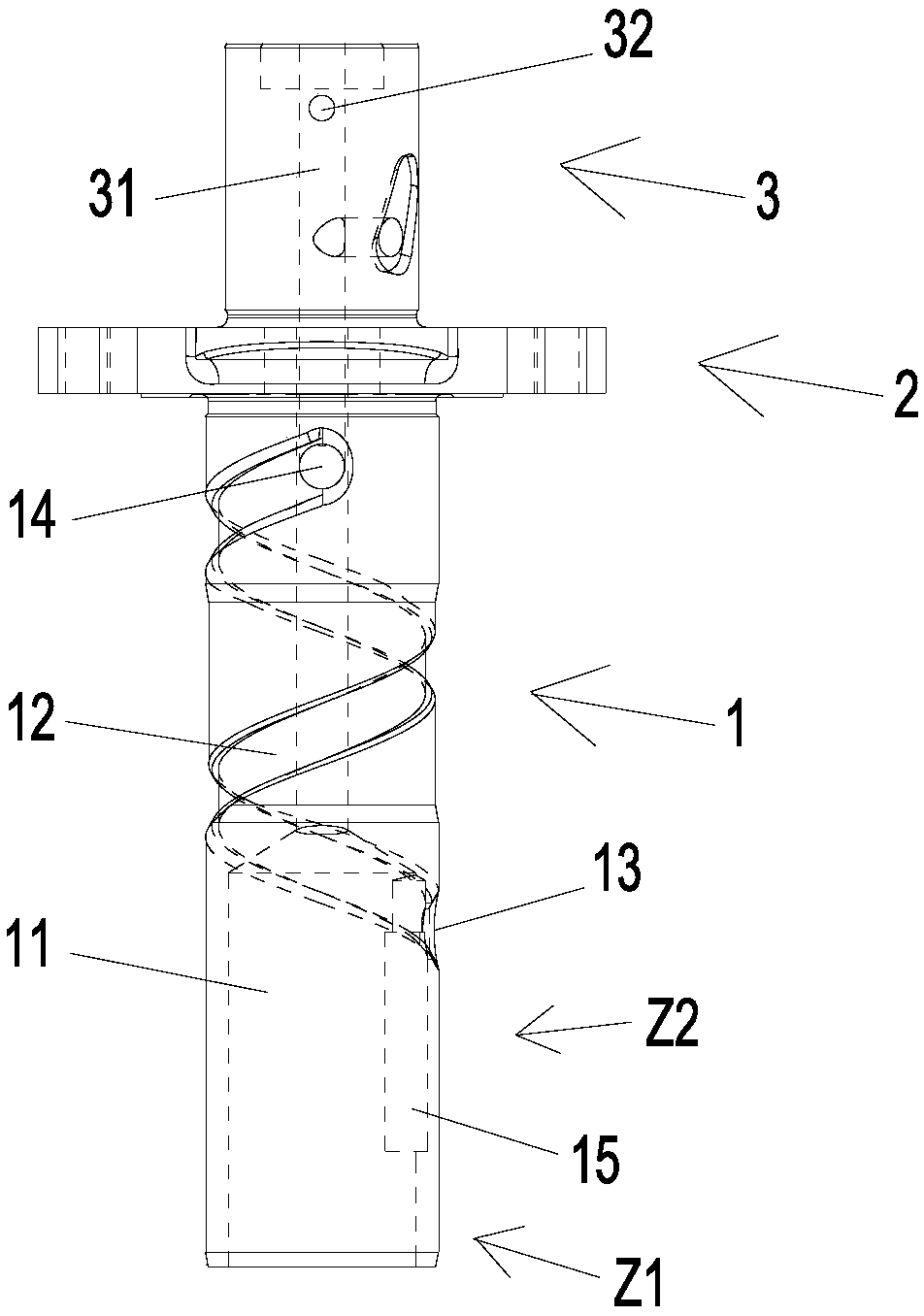

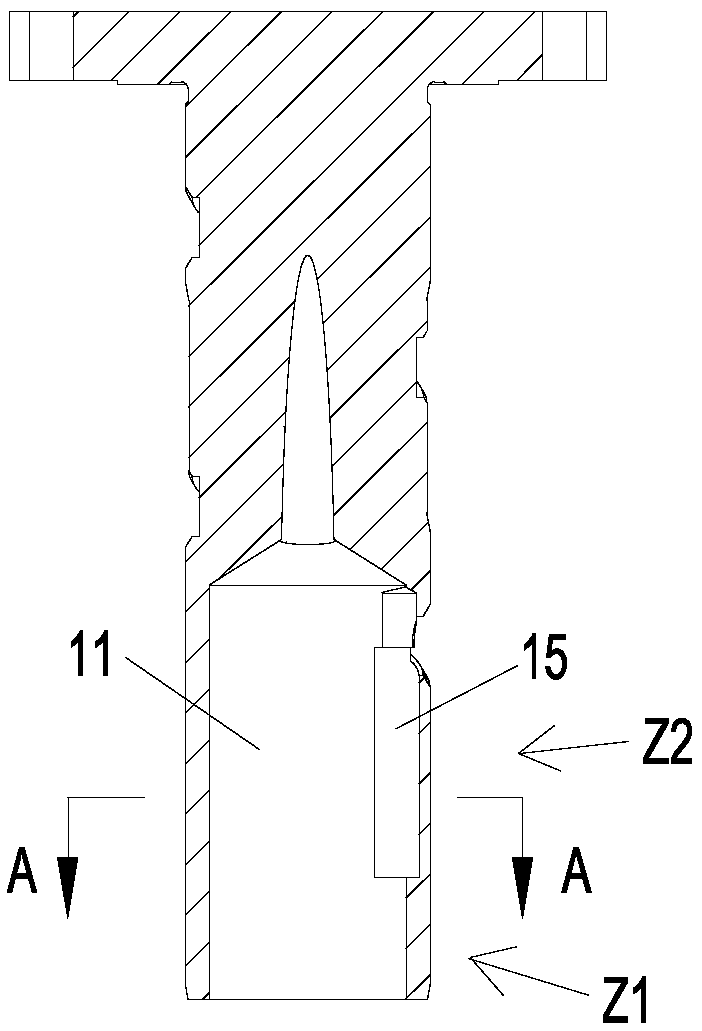

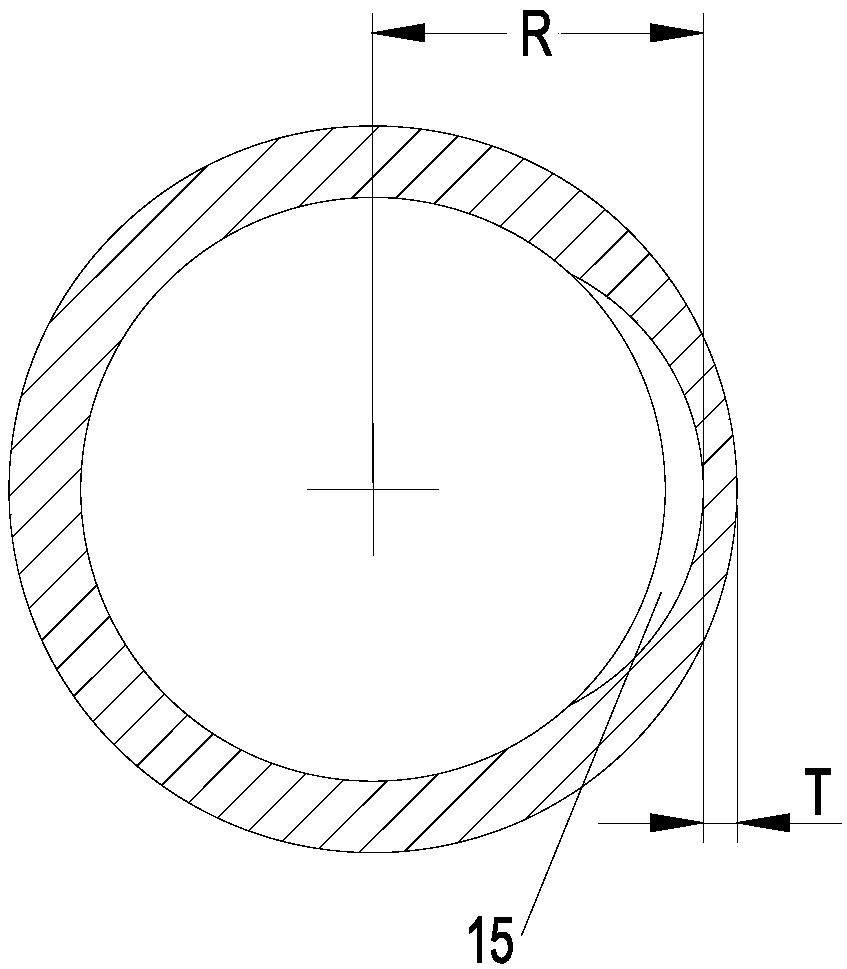

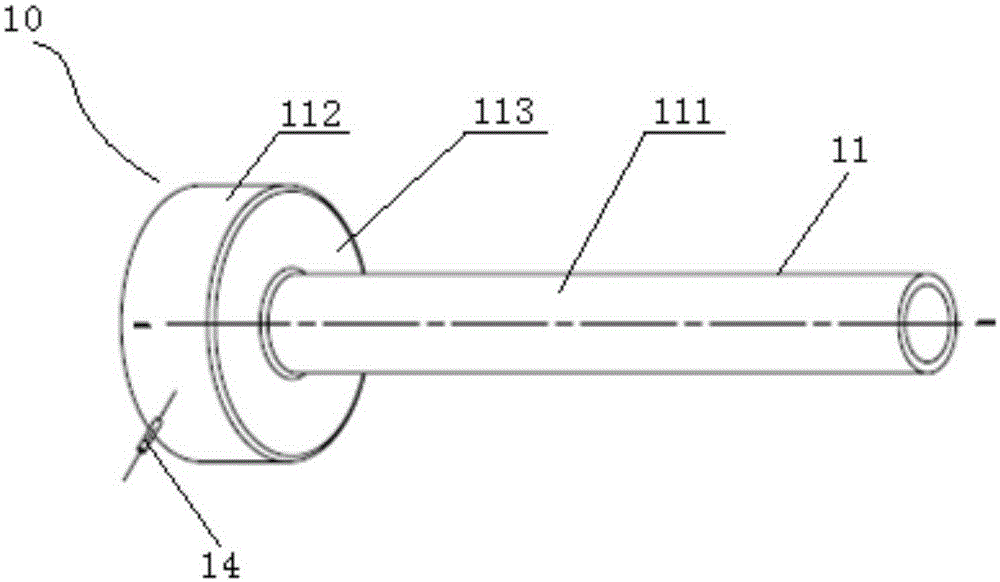

Crankshaft and inverter compressor

PendingCN110873032AGuaranteed StrengthReduce intensityPositive displacement pump componentsPositive-displacement liquid enginesCrankEngineering

The invention relates to the field of compressors, and discloses a crankshaft and an inverter compressor. The crankshaft comprises a main shaft, a crank arm and an auxiliary shaft which are connectedin sequence; and the auxiliary shaft is eccentrically arranged relative to the center line of the main shaft, the main shaft is internally provided with a main shaft oil passage extending in the axialdirection, the center line of the main shaft oil passage coincides with the center line of the main shaft, the outer wall of the main shaft is provided with a groove extending helically in the axialdirection, a first oil passing hole and a second oil passing hole, wherein the two ends of the groove communicate with the main shaft oil passage respectively through the first oil passing hole and the second oil passing hole, the first oil passing hole is arranged away from the crank arm relative to the second oil passing hole, the main shaft comprises a first shaft section used for installing oil pump components, and a second shaft section located between the first shaft section and the first oil passing hole in the axial direction in sequence from the end portion away from the crank arm, and the inner wall of the second shaft section is provided with a concave part communicating with the first oil passing hole and extending in the axial direction. According to the crankshaft and the inverter compressor, on the premise of ensuring the strength of the crankshaft, the wall thickness of the main shaft can be minimized to increase the amount of feeding oil.

Owner:ANHUI MEIZHI COMPRESSOR

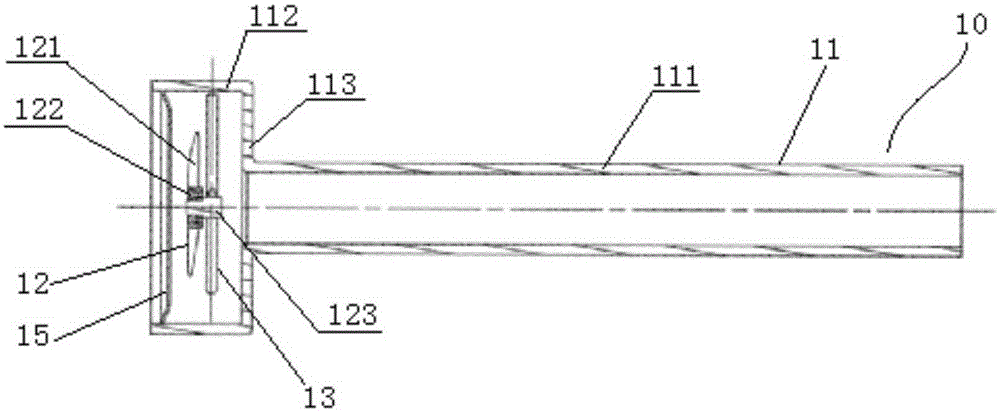

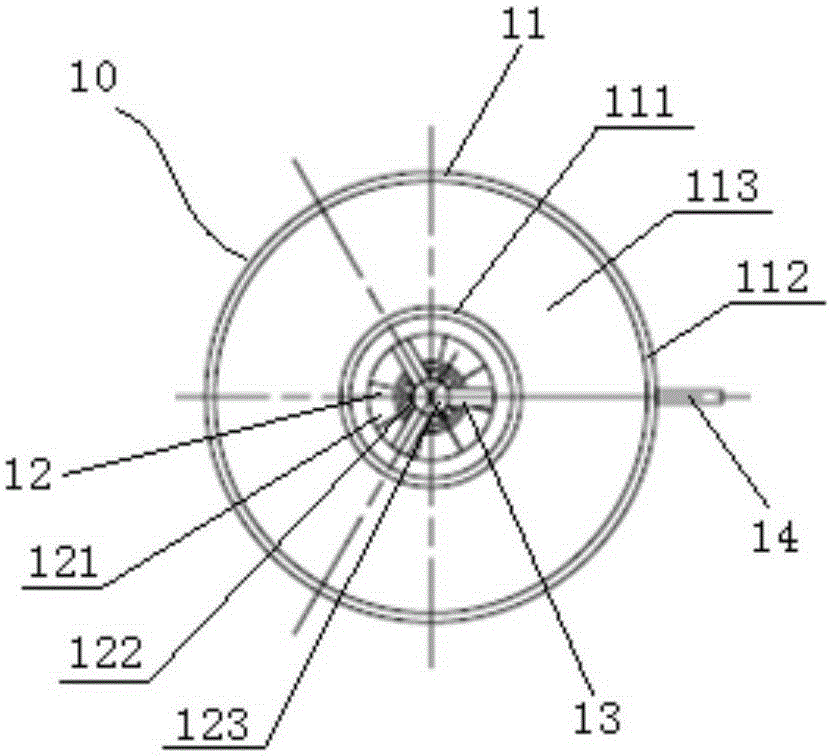

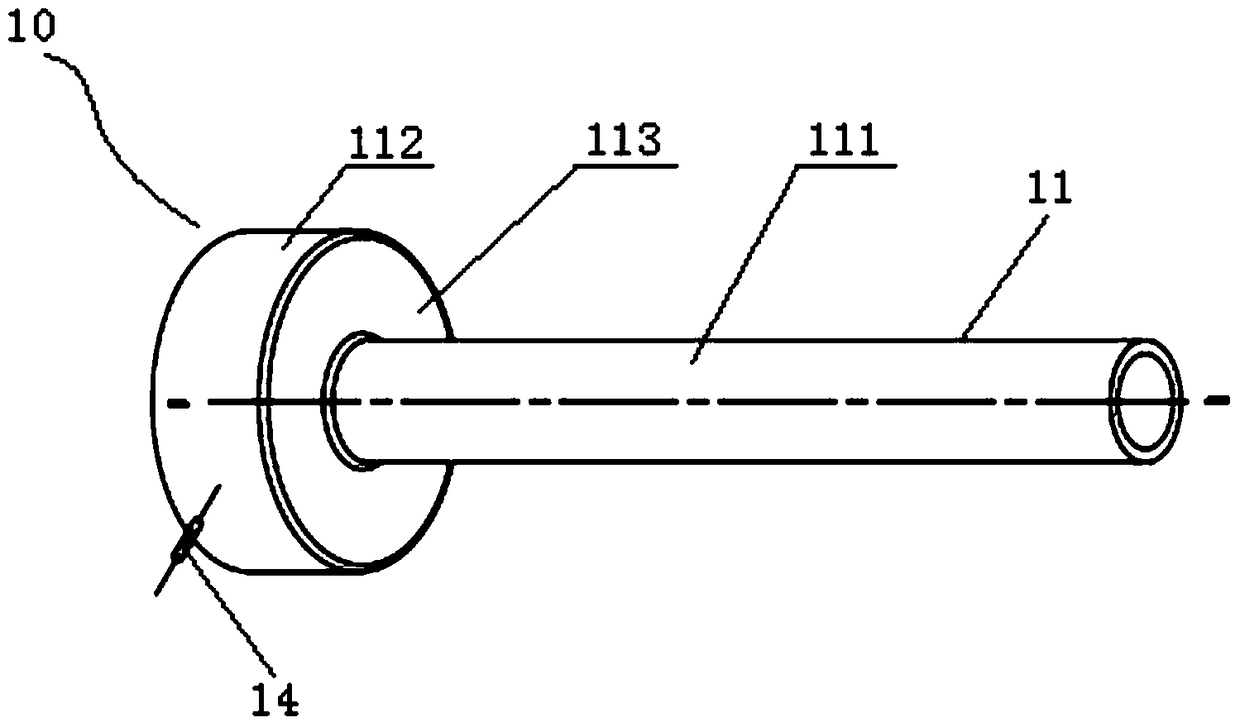

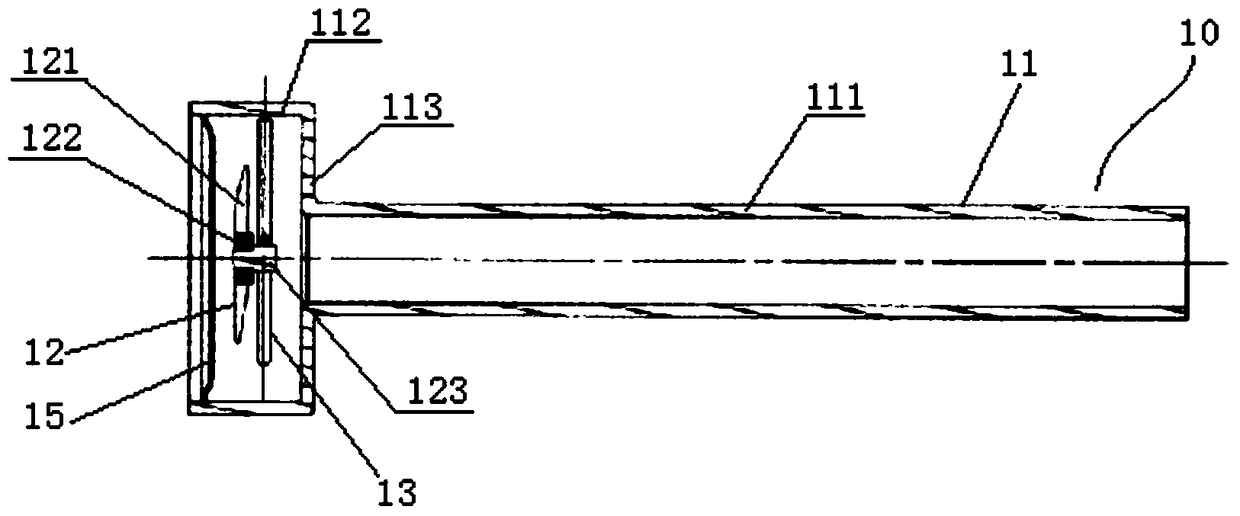

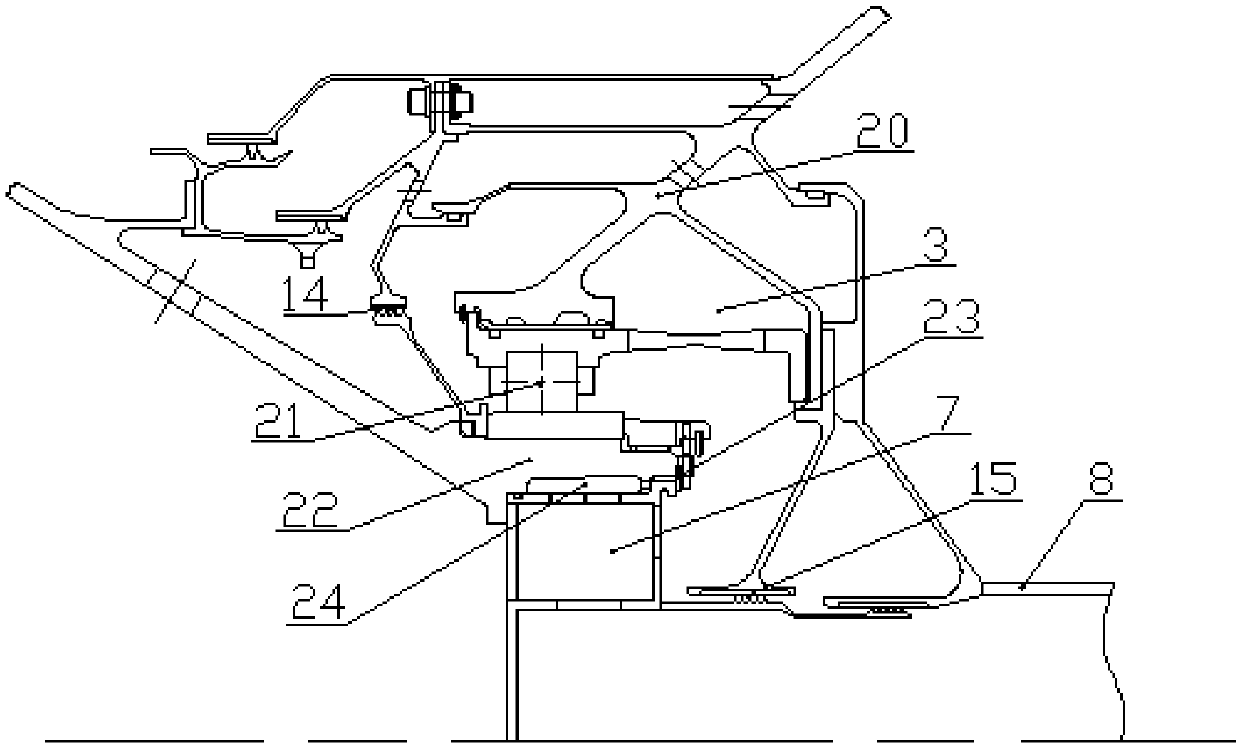

Axis vent pipe structure of turbine engine and turbine engine

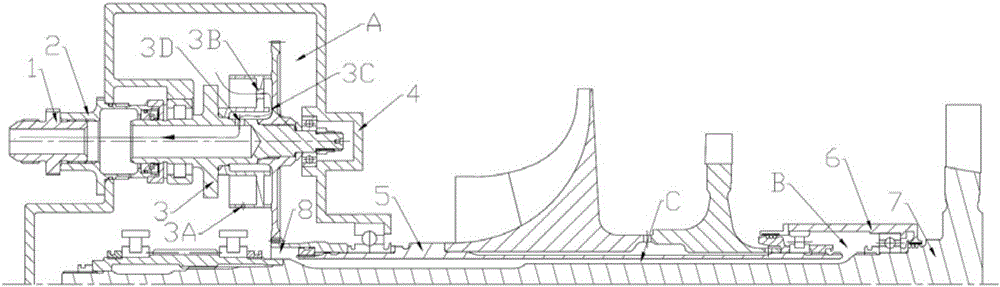

ActiveCN106555622AReduce oil consumptionAvoid enteringMachines/enginesEngine componentsImpellerTurbine

The invention discloses an axis vent pipe structure of a turbine engine and the turbine engine. The axis vent pipe structure comprises an axis vent pipe, a wind wheel assembly and an oil outlet structure, the axis vent pipe comprises a main pipe section, a wind wheel assembly installation pipe section and a back hollow baffle with a first through hole, the wind wheel assembly installation pipe section is arranged on the front side of the main pipe section in the axial direction of the axis vent pipe, the back hollow baffle is located between the wind wheel assembly installation pipe section and the main pipe section, and the wind wheel assembly installation pipe section and the main pipe section are communicated through the first through hole; the wind wheel assembly comprises an impeller which is arranged in the wind wheel assembly installation pipe section and can conduct centrifugal separation on oil drops in oil-gas mixing air flow entering the axis vent pipe, and the back hollow baffle prevents the oil drops obtained through centrifugal separation from entering the main pipe section; and the oil outlet structure comprises an oil outlet for guiding the oil drops obtained through centrifugal separation out of the axis vent pipe. According to the technical scheme, the lubricating oil consumption amount of the turbine engine can be reduced, and the maintaining cost can be reduced.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Axial vent pipe structure of turbine engine and turbine engine

ActiveCN106555622BReduce oil consumptionAvoid enteringMachines/enginesEngine componentsImpellerTurbine

The invention discloses an axis vent pipe structure of a turbine engine and the turbine engine. The axis vent pipe structure comprises an axis vent pipe, a wind wheel assembly and an oil outlet structure, the axis vent pipe comprises a main pipe section, a wind wheel assembly installation pipe section and a back hollow baffle with a first through hole, the wind wheel assembly installation pipe section is arranged on the front side of the main pipe section in the axial direction of the axis vent pipe, the back hollow baffle is located between the wind wheel assembly installation pipe section and the main pipe section, and the wind wheel assembly installation pipe section and the main pipe section are communicated through the first through hole; the wind wheel assembly comprises an impeller which is arranged in the wind wheel assembly installation pipe section and can conduct centrifugal separation on oil drops in oil-gas mixing air flow entering the axis vent pipe, and the back hollow baffle prevents the oil drops obtained through centrifugal separation from entering the main pipe section; and the oil outlet structure comprises an oil outlet for guiding the oil drops obtained through centrifugal separation out of the axis vent pipe. According to the technical scheme, the lubricating oil consumption amount of the turbine engine can be reduced, and the maintaining cost can be reduced.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

An integrated lubricating oil filter

ActiveCN103470339BReduce the amount of oilReduce the number of reraisesLubricant mounting/connectionPressure lubricationDifferential pressureDecomposition

An integrated oil filter comprises a one-way valve, a bypass valve, a spiral spring, a self-seal valve, an oil filter element, an ail filter shell, an oil filter cover, a long screw, a self-locking nut, a shaft elastic retaining ring and an oil filter differential pressure transducer. The oil filter cover is mounted on the lower portion of the shaft elastic retaining ring through the self-locking nut and sleeved with the oil filter shell. The self-seal valve is mounted on the shaft elastic retaining ring through the spiral spring. The one-way valve is mounted on the upper portion of the shaft elastic retaining ring. The bypass valve is mounted on the side of the one-way valve and between an oil outlet and an oil inlet and separated by a partition on the upper portion of the shaft elastic retaining ring. The integrated oil filter has the advantages the oil filter connecting pipes are simplified, self-sealing of internal passages of the oil filer during decomposition oil filtering, oil discharge amount during oil filter decomposition is reduced effectively, oil refilling times are reduced, and system maintenance efficiency is increased.

Owner:AECC SHENYANG ENGINE RES INST

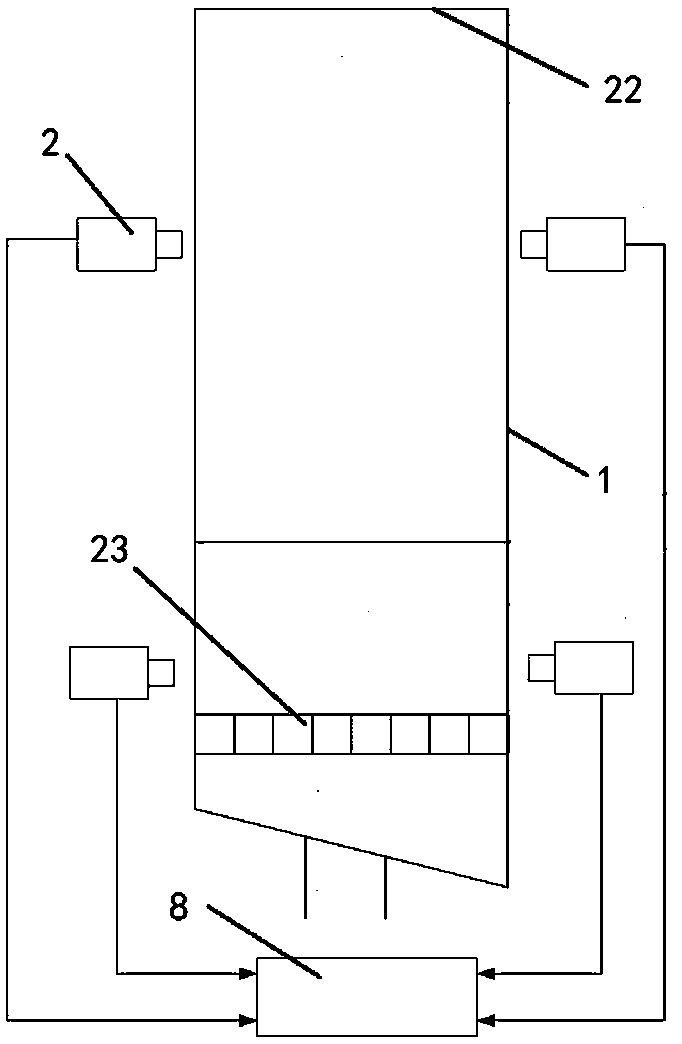

A circulating fluidized bed boiler

ActiveCN109028048BExtended service lifeReduce wear rateFluidized bed combustionApparatus for fluidised bed combustionControl systemFluidized bed

The invention discloses a circulating fluidized bed-boiler, and belongs to the technical field of electricity generating. The circulating fluidized bed-boiler comprises a control system, a boiler walland a soot blowing hole, wherein the soot blowing hole is formed in the boiler wall. The circulating fluidized bed-boiler further comprises infrared temperature measurement systems, the infrared temperature measurement systems comprises infrared temperature measurement probes, peep pipes and flanges, one ends of the peep pipes are fixed to the boiler wall through the flanges, the other ends of the peep pipes are connected with the infrared temperature measurement probes, the infrared temperature measurement probes directly face the center of the soot blowing hole through the peep pipes, and measurement values of the infrared temperature measurement probes are fed back to the control system. The circulating fluidized bed-boiler has a long service life, reduces the abrasion speed of temperature measurement elements, reduces daily maintenance quantities, has high temperature measurement response speed, shortens the starting time, saves the fuel cost and prevents a furnace bottom from coking, and the reliability of bed temperature measurement is guaranteed.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

Efficient attachment plastic spraying process method with orange lines

InactiveCN113102201AResidue reductionPrevent shrinkagePretreated surfacesCoatingsNickel saltWater soluble

The invention discloses an efficient attachment plastic spraying process method with orange lines. The efficient attachment plastic spraying process method comprises the following steps of S1, pretreatment of an iron product to be subjected to plastic spraying, wherein the iron product to be subjected to plastic spraying is subjected to oil removal, rust removal and acid-base neutralization treatment; S2, surface pretreatment of the iron product to be subjected to plastic spraying, wherein the iron product to be subjected to plastic spraying is subjected to grinding, puttying and re-grinding treatment, it is guaranteed that the surface of the iron product to be subjected to plastic spraying is smooth and level, the cleaned iron product to be subjected to plastic spraying is integrally put into a plating solution to be plated for 2-4 h, and the plating solution comprises water-soluble nickel salt and a reducing agent; and S3, plastic spraying treatment of the iron product to be subjected to plastic spraying, wherein after passivation treatment, the iron product to be subjected to plastic spraying is firstly heated to 40-50 DEG C, then plastic spraying powder is subjected to electrostatic spraying to the surface of the iron product to be subjected to plastic spraying by 2-4 times, heating and curing are conducted after electrostatic spraying, the heating and curing temperature is 180-230 DEG C, and the heating and curing time is 8-25 min. According to the method, the phenomenon that shrinkage cavities happen to a coating is avoided, the orange-line-shaped coating is automatically presented, and the surface defects of a substrate are better covered.

Owner:黄石恒辉智能装备有限公司

Electric desalting and dewatering tank

InactiveCN100355864CReduce the amount of oilReduce up and down fluctuationsDewatering/demulsification with electric/magnetic meansMetal stripsOil field

The present invention discloses a kind of electric desalting and dewatering tank for use in oil field and oil refinery, and aims at reducing oil in exhausted water of electric desalting and dewatering tank. The electric desalting and dewatering tank has inside the tank at least three axial water exhaust stabilizing devices in the bottom, and each of the water exhaust stabilizing devices consists of metal plate and lattice. The metal plate is perpendicular to the tank axis and has two ends connected to the inner wall of the tank, and there is gap between the plate and the tank wall for deposited water to flow through. The lattice set in the top of the metal plate consists of metal strips perpendicular to the metal plate. The present invention is used mainly for desalting and dewatering raw oil.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

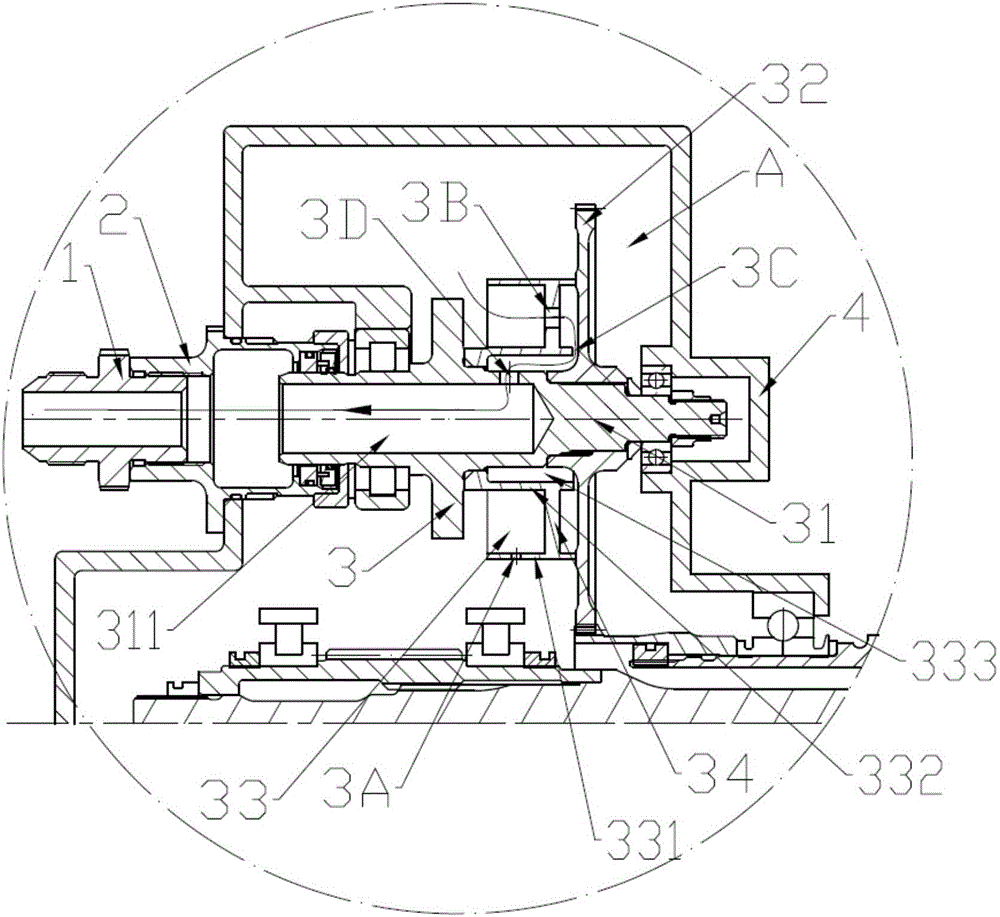

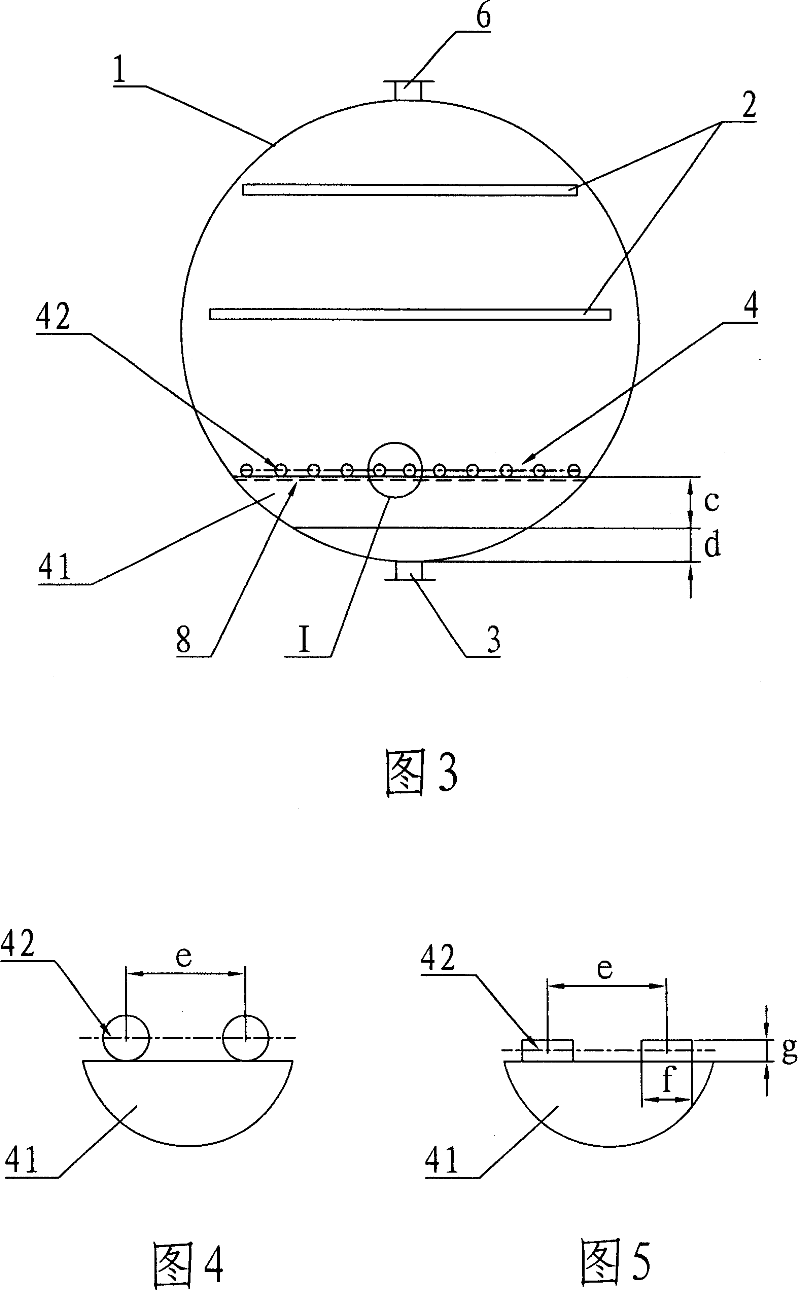

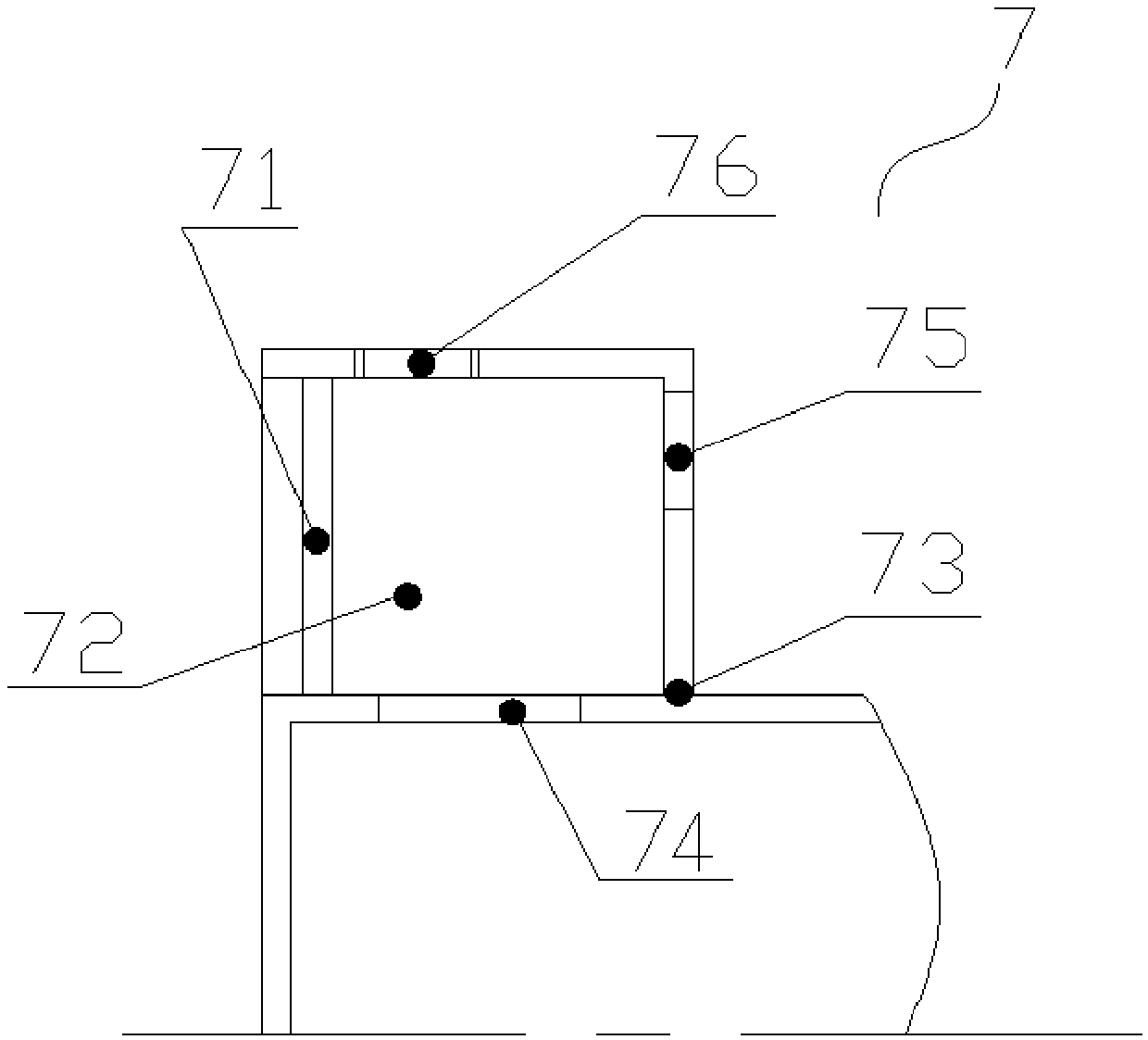

Oil Ventilators, Ventilation Systems and Gas Turbine Engines

ActiveCN107762631BReduce consumptionIncrease resistanceGas turbine plantsTurbine/propulsion lubricationEngineeringCell separation

The invention relates to a lubricating oil ventilator, a ventilating system and a gas turbine engine. The lubricating oil ventilator (7) comprises a housing (73) in which a gas-oil separating chamberis arranged, wherein the gas-oil separating chamber is used for gas-oil separation of a gas-oil mixture entering the gas-oil separating chamber; a core body (72) with variable density is arranged in the gas-oil separating chamber and is capable of changing the flowing resistance of the gas-oil separating chamber. According to the lubricating oil ventilator, the flowing resistance of the gas-oil separating chamber can be changed as the demand or as the change of outside conditions; in case of high flow rate of the gas-oil mixture, the core body can be compressed to increase the resistance of the gas-oil separating chamber, thus the time of performing gas-oil separation on the gas-oil mixture in the lubricating oil ventilator can be prolonged, and as a result, the separating performance canbe improved; meanwhile, the volume of lubricating oil drained along with fluid is decreased, and thus the consumption of the lubricating oil is reduced; in case of low flow rate of the gas-oil mixture, the core body can be released to reduce the resistance of the gas-oil separating chamber, and thus the separated gas can flow out normally.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Oil-gas separator with spiral line type inlet runner

ActiveCN114458419AImprove separation efficiencySame flowInternal combustion piston enginesCrankcase ventillationEngineeringExhaust pipe

The oil-gas separator comprises a separation cavity barrel, an oil-gas mixture inlet section and an oil storage cavity, the oil-gas mixture inlet section and the oil storage cavity are connected to the two ends of the separation cavity barrel, an exhaust pipe is further connected to the oil-gas mixture inlet section, and the oil-gas mixture inlet section comprises a pre-swirling flow channel and an inlet flow channel communicated with the pre-swirling flow channel; the pre-swirling flow channel is in a cylinder shape on the whole, an inlet flow channel is arranged in the tangential direction, and the outer side wall of the pre-swirling flow channel is in an Archimedes spiral line shape. According to the dynamic pressure type oil-gas separator, the Archimedes spiral is introduced into the dynamic pressure type oil-gas separator of the aero-engine lubricating oil system, the pre-rotation section above the oil-gas separator is arranged to be of the Archimedes spiral type, and it is guaranteed that the flow of oil-gas mixtures entering all branches is roughly the same; the stability of a flow field in the separator is improved, the lubricating oil amount of a central backflow area of the separator is reduced, and the separation efficiency of the separator is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Centrifugal flow guiding intelligent speed governing hydraulic coupler body structure

Owner:SHANGHAI JIAOTONG UNIV

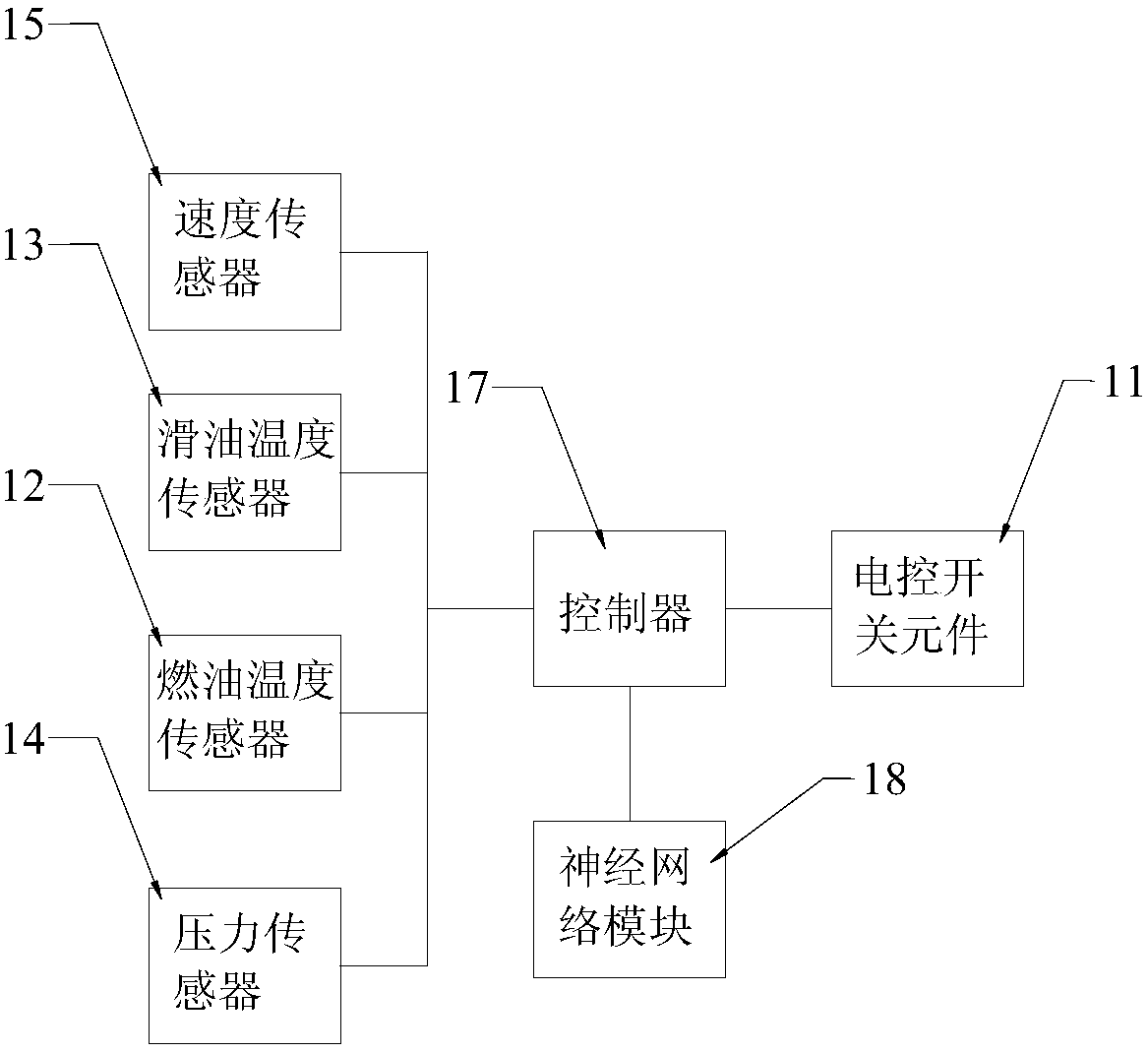

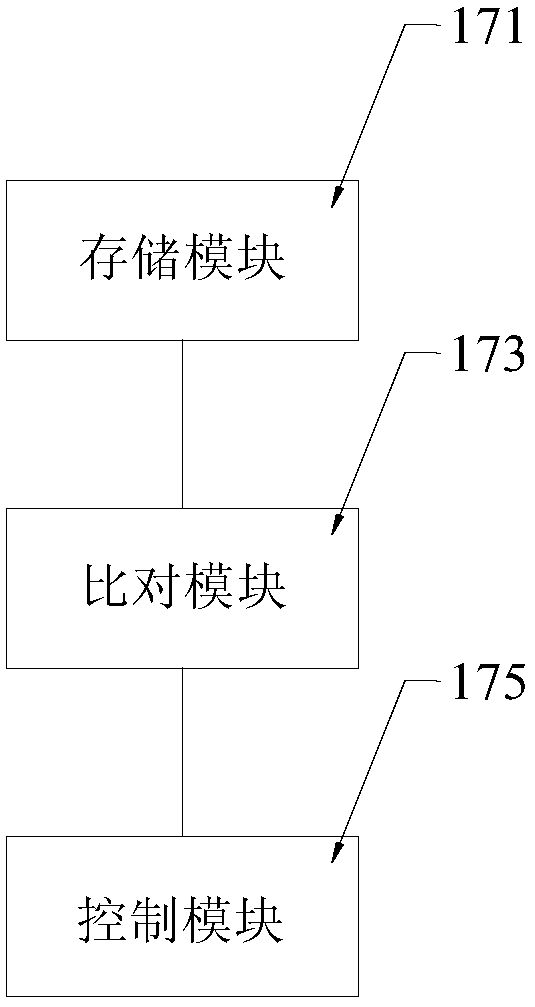

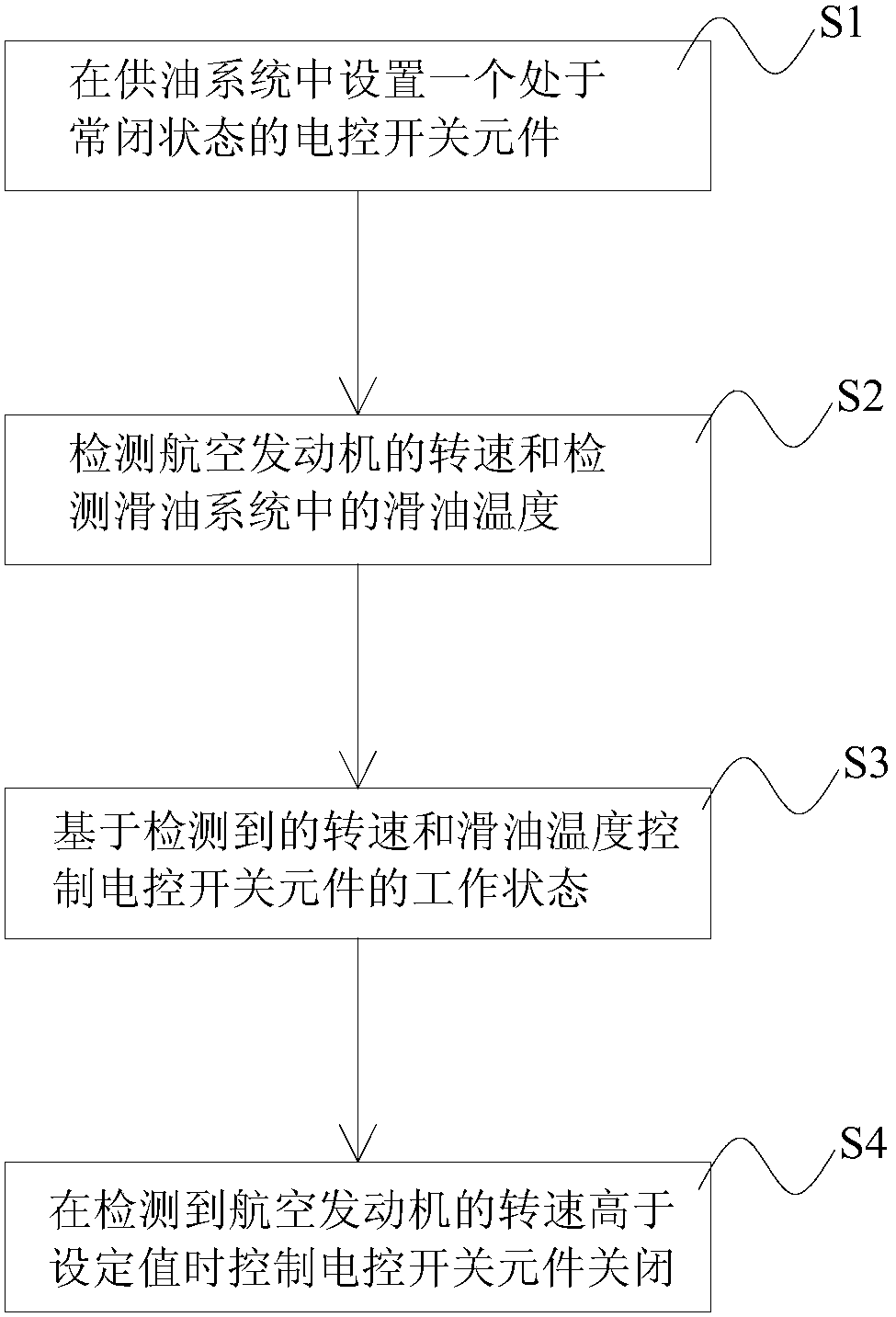

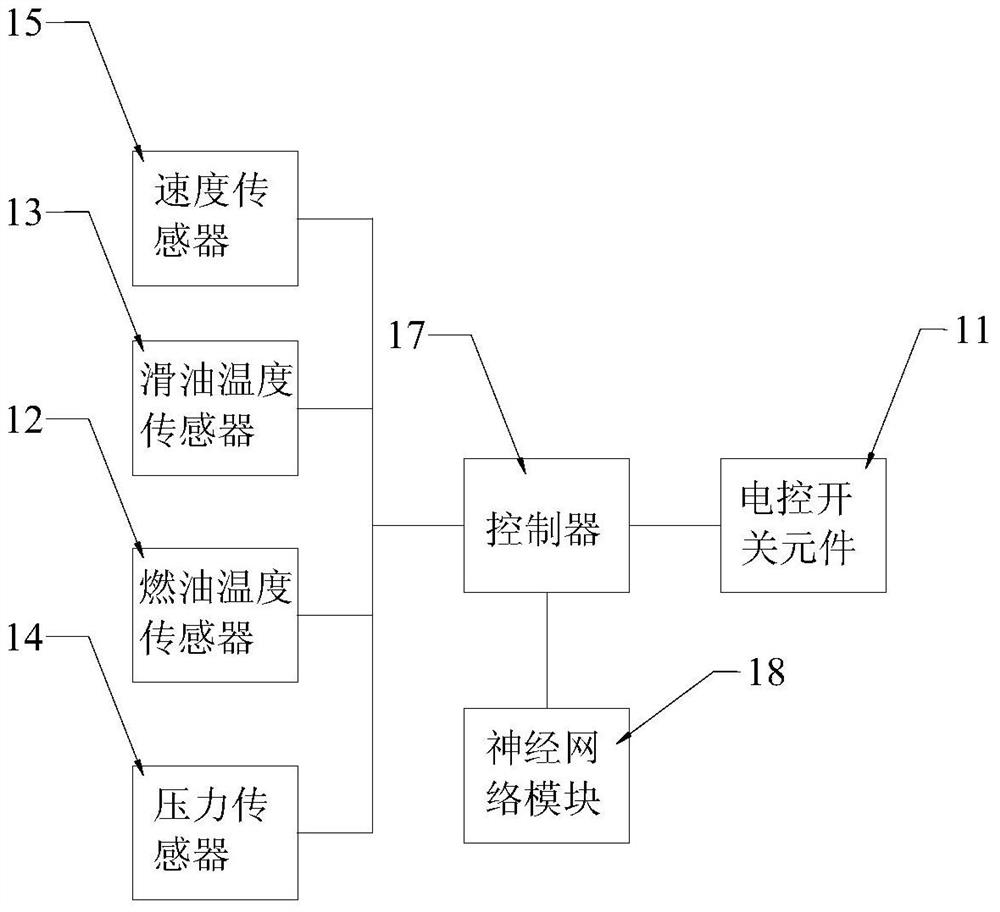

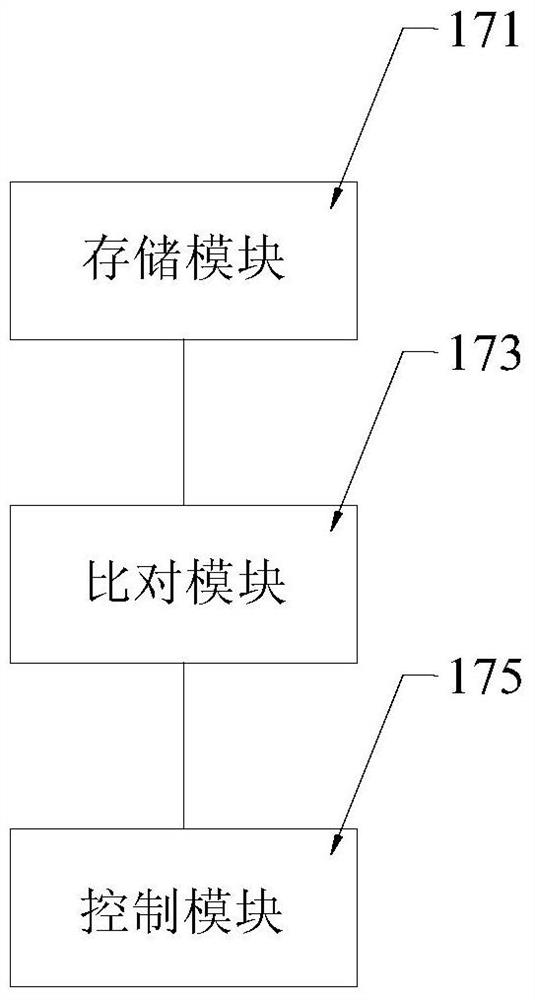

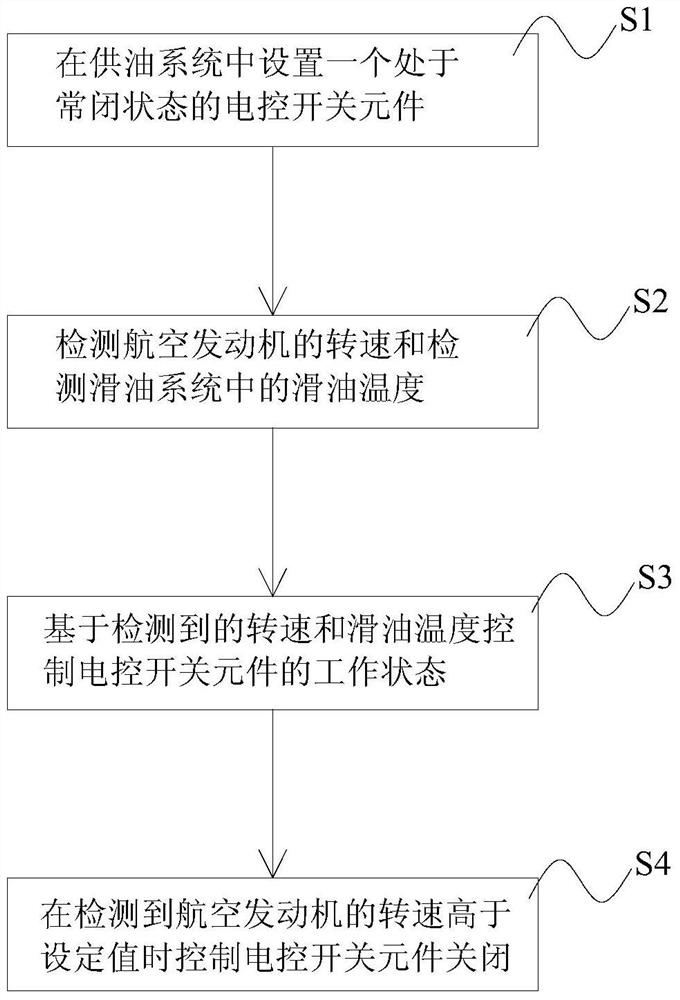

Control system and method for reducing low-temperature starting load of aero-engine

ActiveCN109488461AIncrease success rateShorten the timeTurbine/propulsion lubricationFlight heightControl system

The invention discloses a control system for reducing the low-temperature starting load of an aero-engine. The aero-engine comprises a fuel system, a lubricating oil system and an oil supply system used for supplying lubricating oil to the lubricating oil system, and the control system comprises an electric control switch element which is arranged in the oil supply system and is in a normally closed state, a lubricating oil temperature sensor used for detecting the lubricating oil temperature, a fuel temperature sensor used for detecting the fuel temperature, a pressure sensor used for detecting the flight height of an aircraft, and a controller used for controlling a working state of the electric control switch element according to the detecting result of at least one of the lubricating oil temperature sensor, the fuel temperature sensor and the pressure sensor; and the electric control switch element, the lubricating oil temperature sensor, the fuel temperature sensor and the pressure sensor are all connected with the controller. According to the control system and method for reducing the low-temperature starting load of the aero-engine, the success rate of low-temperature starting of the aero-engine is increased, and meanwhile the time of low-temperature starting of the aero-engine is shortened.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Control system and method for reducing aeroengine low-temperature start-up load

ActiveCN109488461BIncrease success rateShorten the timeTurbine/propulsion lubricationAviationThermodynamics

The invention discloses a control system for reducing the low-temperature starting load of an aero-engine. The aero-engine comprises a fuel system, a lubricating oil system and an oil supply system used for supplying lubricating oil to the lubricating oil system, and the control system comprises an electric control switch element which is arranged in the oil supply system and is in a normally closed state, a lubricating oil temperature sensor used for detecting the lubricating oil temperature, a fuel temperature sensor used for detecting the fuel temperature, a pressure sensor used for detecting the flight height of an aircraft, and a controller used for controlling a working state of the electric control switch element according to the detecting result of at least one of the lubricating oil temperature sensor, the fuel temperature sensor and the pressure sensor; and the electric control switch element, the lubricating oil temperature sensor, the fuel temperature sensor and the pressure sensor are all connected with the controller. According to the control system and method for reducing the low-temperature starting load of the aero-engine, the success rate of low-temperature starting of the aero-engine is increased, and meanwhile the time of low-temperature starting of the aero-engine is shortened.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

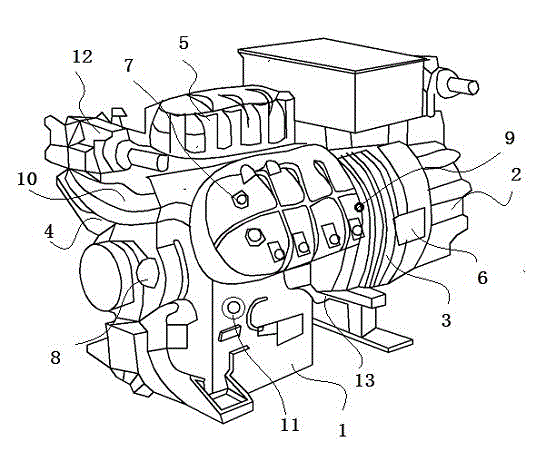

Semi-closed refrigerating compressor

InactiveCN105697291AHigh movement precisionImprove efficiencyPositive displacement pump componentsPiston pumpsRefrigeration compressorCrankcase heater

The invention relates to a semi-closed refrigerating compressor. The semi-closed refrigerating compressor consists of a machine body, an insulation motor and a cooling system, wherein a crankshaft connecting rod piston is arranged in the machine body, a steel valve plate is arranged outside the machine body, one side of the crankshaft connecting rod piston is provided with an oil pump pressure lubricating system, the oil pump pressure lubricating system is provided with an oil return system, the oil pump pressure lubricating system is provided with a deep oil tank, the machine body is also provided with a cylinder body of a six-cylinder W-shaped structure, one side of the insulation motor is provided with a PTC thermistor sensor, the upper end of the machine body is provided with an exhaust temperature sensing probe, a safety pressure relief valve is arranged in the machine body, one section of the machine body is provided with a crankshaft box heater, the cooling system includes a cylinder head cooling fan, a spraying cooling system and an oil cooler assembly, and the w compressor can be operated stably, reliably and high efficiently.

Owner:夏振宇

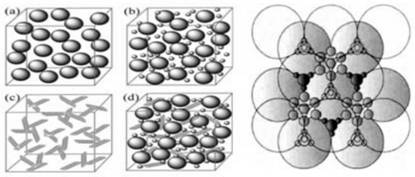

A kind of high thermal conductivity silicone grease interface material and preparation method thereof

ActiveCN108624056BImprove liquiditySimple coating processHeat-exchange elementsPolymer scienceSilicone grease

The invention discloses a high thermal conductivity silicone grease interface material and a preparation method thereof. The high thermal conductivity silicone grease interface material is characterized in that it is a paste silicone grease with low oil seepage and high thermal conductivity. In the invention, metal or inorganic powder with high thermal conductivity is used as thermal conductive filler, which is added into the organic silicone oil mixture and uniformly mixed by a three-roll grinder to obtain homogeneous gray paste silicone grease. In the paste, the mass percentage of organic silicon oil is 5%-40%, and the mass percentage of the metal or inorganic powder mixed with heat-conducting filler is 60%-95%. The average particle size of the filler is at least three kinds, the large particle size is 15-30um, the medium particle size is 5-10um, and the small particle size is 0.1-1um. The high thermal conductivity silicone grease interface material of the present invention has the characteristics of high thermal conductivity, good heat dissipation effect, small oil leakage, simple preparation process, etc., and is especially suitable for occasions where oil leakage needs to be avoided.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Axial center ventilation structure of bearing cavity and gas turbine engine with the structure

The invention relates to an axle center ventilating structure and a gas turbine engine. A bearing chamber of a cold end component of the engine communicates with a bearing chamber of a hot end component of the engine, a ventilating system is used for maintaining the pressure of the bearing chamber of the cold end component of the engine to be the same with that of the bearing chamber of the hot end component of the engine basically, the bearing chamber of the cold end component communicates with an engine nozzle through a centrifugal oil-gas separator, an oil-gas mixture in the bearing chamber of the hot end component enters the bearing chamber of the cold end component of the engine via an axle center ventilating cavity, then the oil-gas mixture in the bearing chamber of the hot end component and an oil-gas mixture of the bearing chamber of the cold end component are subjected to oil-gas separation together by the centrifugal oil-gas separator, and the unseparated oil-gas mixture is discharged via the engine nozzle. The bearing chamber axle center ventilating structure of the engine is simple and is convenient to design and adjust, the bearing chamber of the cold end component communicates with the bearing chamber of the hot end component, the pressure of the bearing chamber of the cold end component and the pressure of the bearing chamber of the hot end component can be ensured to be almost the same, design and adjustment of a secondary air system are facilitated, faults of the engine due to leakage of lubricating oil and unsmooth circulation are reduced, the reliability of the engine is improved, meanwhile, heat transmission from the bearing chamber of the hot end component to the bearing chamber of the cold end component can be improved, and therefore, the quantity of lubricating oil required for cooling a bearing of the hot end component is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

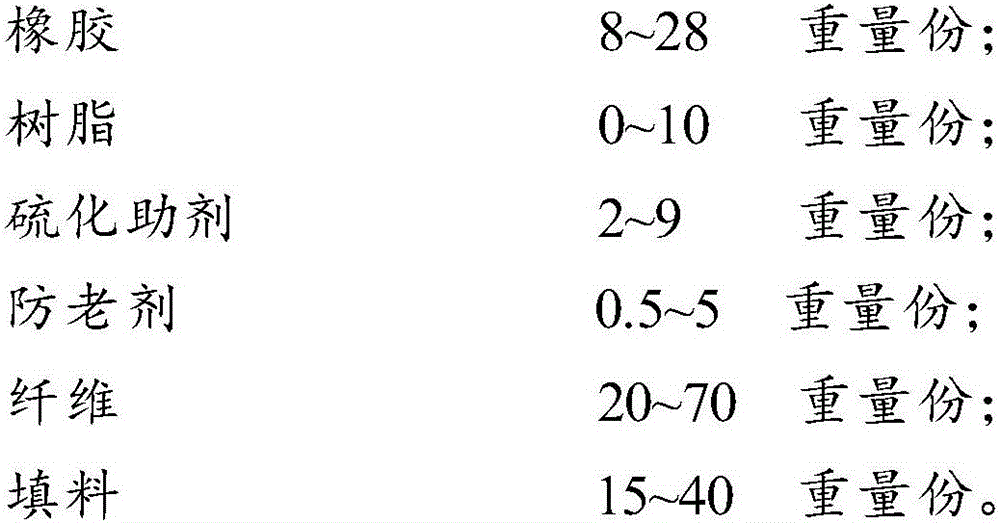

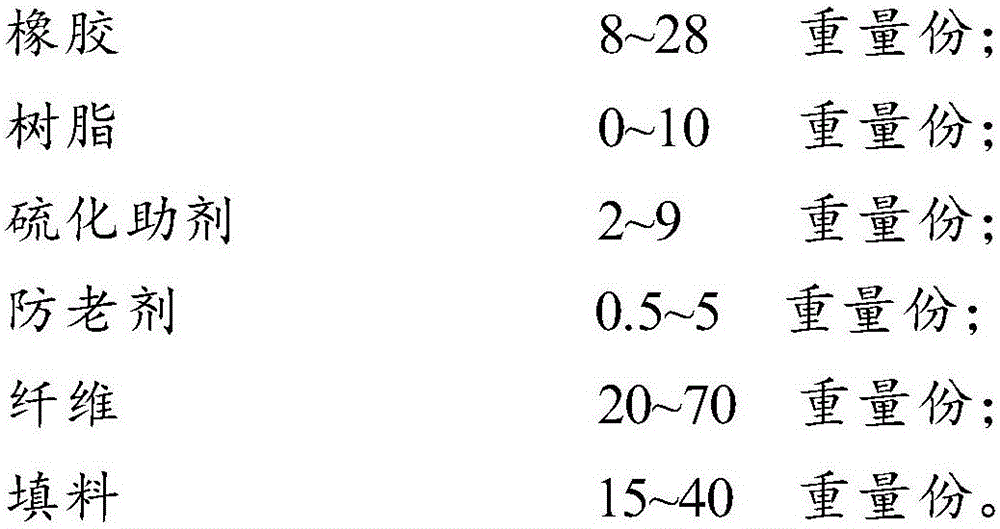

Preparation technique of sealing material

ActiveCN106750664AOvercoming technical biasReduced oil inputOther chemical processesDesorptionWork in process

The invention provides a preparation technique of a sealing material. The technique comprises the following steps: mixing a raw material comprising rubber with a mixed solvent to obtain a mixed raw material, and rolling into a sheet to obtain a semifinished product; carrying out adsorption, desorption and separation on the waste solvent generated by the mixing and rolling to obtain a recovered solvent; vulcanizing the semifinished product to obtain the sealing material; and sending the recovered solvent to the step above for cyclic utilization. Compared with the prior art, the technique aims to solve the ever-existing problems of high oil input and low recovery rate in the solvent in the existing production system and especially in the oil-resistant sealing material processing process. The mixed solvent is creatively used instead of the single solvent, thereby obtaining unexpectable technical effects, greatly lowering the oil input, obviously enhancing the solvent recovery rate in the production process, reducing the sewage treatment capacity and lowering the production cost.

Owner:长春蓝天高新技术密封材料有限责任公司

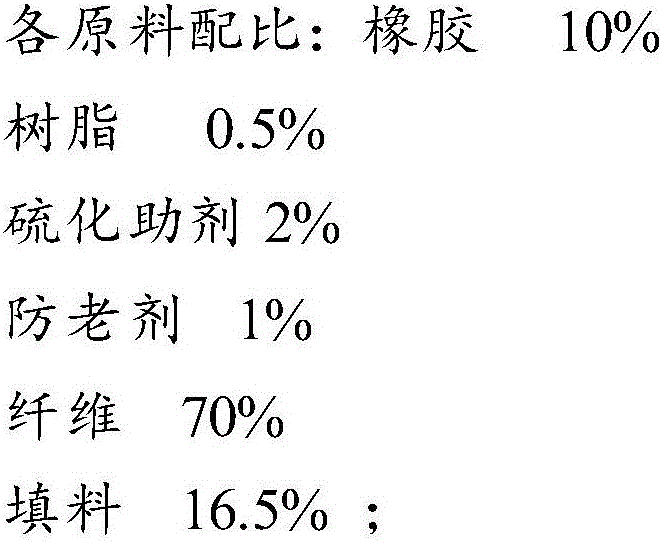

Lithium base grease and preparation method thereof

ActiveCN103333726BGood colloidal stabilityDoes not affect low temperature fluidityAdditivesLithium soapAntioxidant

The invention provides lithium base grease. The lithium base grease comprises the following components in parts by mass: 75-95 parts of base oil, 5-20 parts of lithium soap, 2-15 parts of laminated dihydroxy composite metal oxide, 0.1-2.0 parts of antioxidant, and 0.1-2.0 parts of corrosion inhibitor. The laminated dihydroxy composite metal oxide is introduced in the lithium base grease, and organic modified treatment is performed on the lithium base grease by adopting the lithium soap, so that the lithium soap, the laminated dihydroxy composite metal oxide and the base oil achieve highly scattered states; and therefore, the colloid stability of the lithium base grease is obviously improved under the precondition that the low-temperature flow property of the grease is not influenced, and the application of the lithium base grease under a low-temperature environment is expanded.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com