Centrifugal separation device for aero-engine

An aero-engine and centrifugal separation technology, applied in the directions of engine components, engine lubrication, centrifuges, etc., can solve the problems of large oil consumption, unsuitable for aero-engine use, etc., to achieve high oil and gas separation efficiency, low processing and maintenance costs, The effect of improving the reuse rate of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

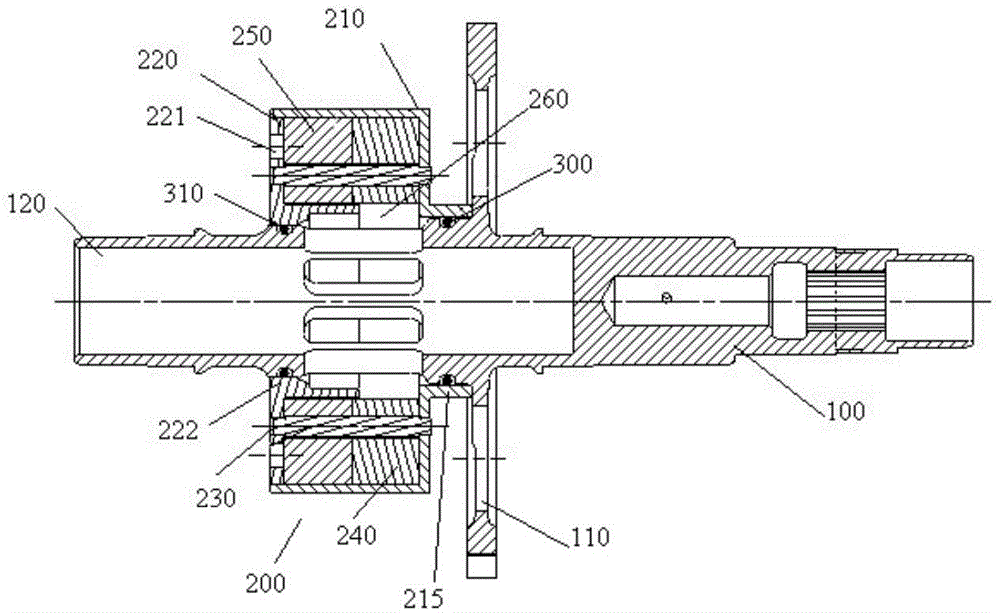

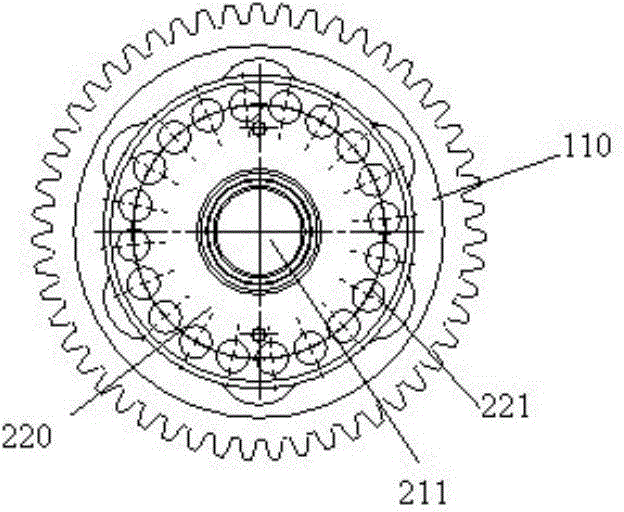

[0030] See figure 1 , The present invention provides a centrifugal separation device for an aeroengine, which includes a rotating shaft 100 and a centrifugal separator 200 sleeved on the outer wall of the rotating shaft 100. The second end of the rotating shaft 100 is provided with a transmission gear 110 close to the housing. The rotating shaft 100 is rotated by the transmission gear 110. The rotation of the rotating shaft 100 drives the centrifugal separator 200 to rotate, and a centrifugal force field is formed inside the centrifugal separator 200.

[0031] See figure 1 with figure 2 , The centrifugal separator 200 includes a first housing 210, a second housing 220, oil and gas separation materials and pins 230. One end of the first housing 210 is closed. One end of the first housing 210 is open. A cavity is formed inside the first housing 210. A first mounting hole 211 is provided in the center of the first housing 210 along its axial direction. One end of the second ho...

Embodiment 2

[0044] The difference from the first embodiment is that the housing is mounted on the outer wall of the transmission gear 110. It is fixed by three screws evenly distributed along the circumference of the rotating shaft 100. The housing is integrated with the rotating shaft 100. The relative reduction in the consumption of lubricating oil of the web type centrifugal ventilator is the same as in Example 1.

Embodiment 3

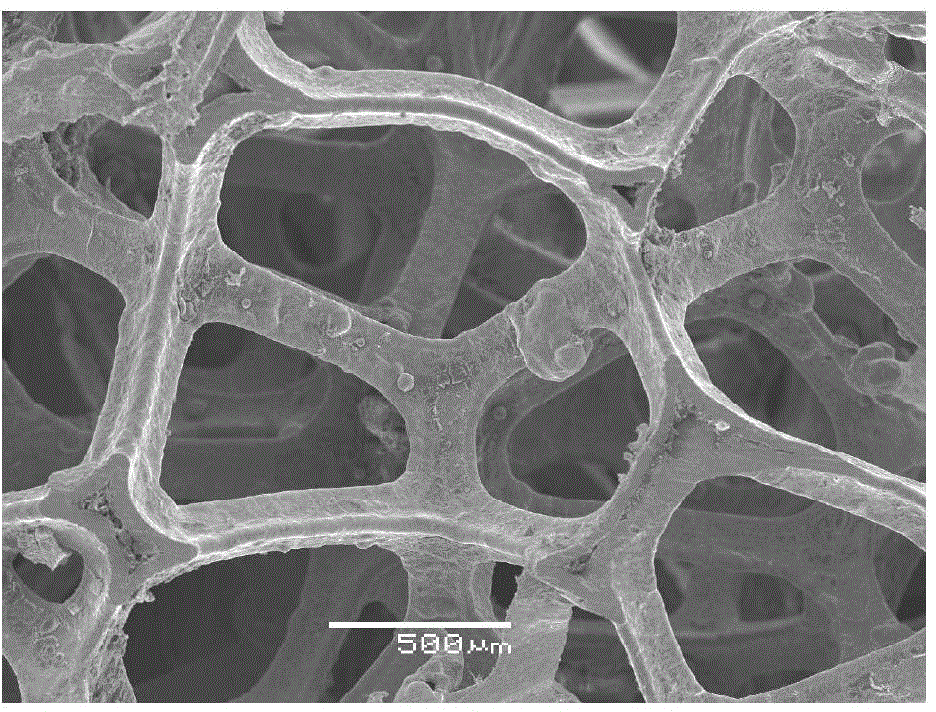

[0046] The difference from Embodiment 1 is that only one piece of porous metal is provided, and the thickness of the porous metal is 32.4 mm. The hole metal used has an outer diameter of 87mm and an inner diameter of 47mm. The relative reduction in the consumption of lubricating oil of the web type centrifugal ventilator is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com