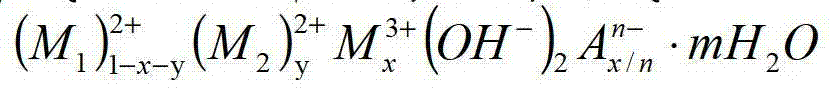

Lithium base grease and preparation method thereof

A lithium-based grease, lithium soap technology, applied in the field of grease, can solve the problems of difficult mixing with other greases, poor equipment lubrication, low temperature flow performance, etc. Colloidal stability properties, the effect of good colloidal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

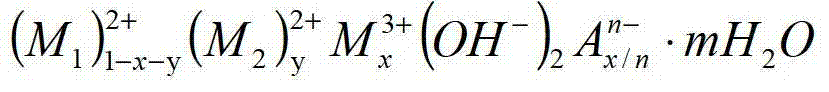

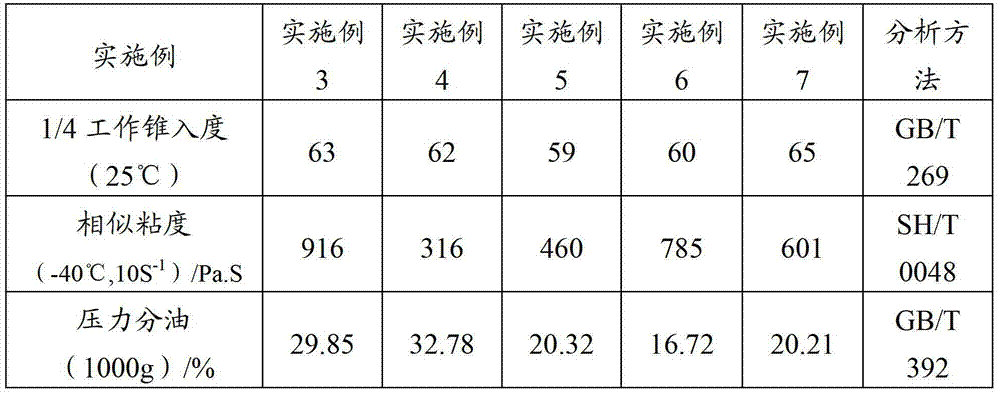

Examples

preparation example Construction

[0054] The present invention also provides a preparation method of lithium-based grease, comprising:

[0055]A) mixing fatty acid or hydroxy fatty acid with layered bishydroxy complex metal oxide and the first mass part of base oil to obtain a mixture;

[0056] B) Add LiOH aqueous solution to the obtained mixture, react and remove water, and refine at high temperature to obtain a lithium-based grease intermediate;

[0057] C) adding a second mass part of base oil, an antioxidant and a corrosion inhibitor to the obtained lithium-based grease intermediate, and grinding to obtain lithium-based grease;

[0058] First, the fatty acid or hydroxy fatty acid is fully mixed with the layered double hydroxy composite metal oxide and the first mass part of base oil to obtain a mixture; the fatty acid is selected from any one or several of C2~C30 fatty acids, and more It is preferably stearic acid; the hydroxy fatty acid is selected from any one or several of C2-C30 hydroxy fatty acids, m...

Embodiment 1

[0080] 5.13g Mg(NO 3 ) 2 ·6H 2 O and 3.75g Al(NO 3 ) 3 ·9H 2 O was mixed with 60mL deionized water in the first constant pressure dropping funnel, and 1.92g NaOH and 2.12g NaOH were mixed at the same time 2 CO 3 Mix with 15mL deionized water in the second constant pressure dropping funnel, install the two constant pressure dropping funnels in a 100mL three-necked flask, and control the dropping speed of the first constant pressure dropping funnel and the second constant pressure dropping funnel The ratio is 4:1, the dropwise addition is completed in 1 hour, and at the same time, the stirring device is turned on, and the reflux crystallization is performed at 100°C for 3 hours. After the reaction is completed, the reaction system is naturally cooled to room temperature (25°C), and the crude magnesium-aluminum binary hydrotalcite is obtained by filtration; then Wash the obtained solid with deionized water, collect the solid by centrifugation, repeat 3 times, and finally dr...

Embodiment 2

[0082] 2.57g Mg(NO 3 ) 2 ·6H 2 O, 2.97g Zn(NO 3 ) 2 ·6H 2 O and 3.75g Al(NO 3 ) 3 ·9H 2 O was mixed with 60mL deionized water in the first constant pressure dropping funnel, and 1.92g NaOH and 2.12gNa 2 CO 3 Mix with 15mL deionized water in the second constant pressure dropping funnel, install the two constant pressure dropping funnels in a 100mL three-necked flask, and control the dropping speed of the first constant pressure dropping funnel and the second constant pressure dropping funnel The ratio is 4:1, the dropwise addition is completed in 1 hour, and the stirring device is turned on at the same time, and the crystallization is carried out at 100°C for 3 hours. After the reaction is completed, the reaction system is naturally cooled to room temperature (25°C), and the crude zinc-magnesium-aluminum ternary hydrotalcite is obtained by filtration; Then the obtained solid was washed with deionized water, centrifuged to collect the solid, and repeated three times, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com