Preparation technique of sealing material

A preparation process and sealing material technology, which is applied in the field of circular preparation process of oil-resistant sealing materials, can solve the problems of large oil input and low recovery rate, and achieve the effect of reducing oil input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

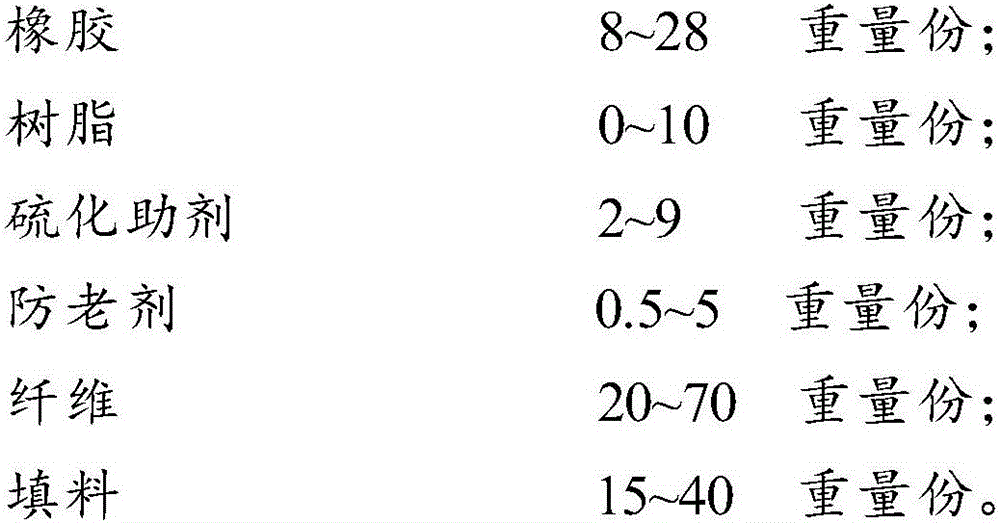

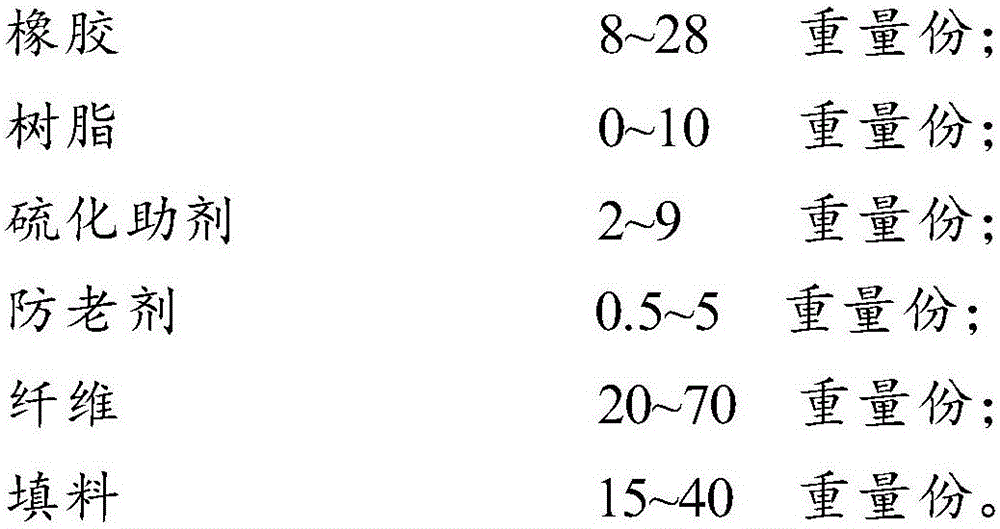

[0041] The invention provides a preparation process of a sealing material, comprising the following steps:

[0042] 1) After mixing the raw materials including rubber with the mixed solvent, the mixed raw materials are obtained, and then rolled into sheets to obtain semi-finished products;

[0043] After the waste solvent produced in the mixing step and the rolling step is absorbed, analyzed and separated, the recovered solvent is obtained;

[0044] 2) After the semi-finished product obtained in the above steps is vulcanized, the sealing material is obtained;

[0045] The recovered solvent obtained in the above steps is sent to step 1) for recycling.

[0046] In the invention, firstly, the raw material including rubber is mixed with a mixed solvent to obtain the mixed raw material, and then rolled into a sheet to obtain a semi-finished product.

[0047] The present invention has no special restrictions on the mixed solvent, and those skilled in the art can select and adjust ...

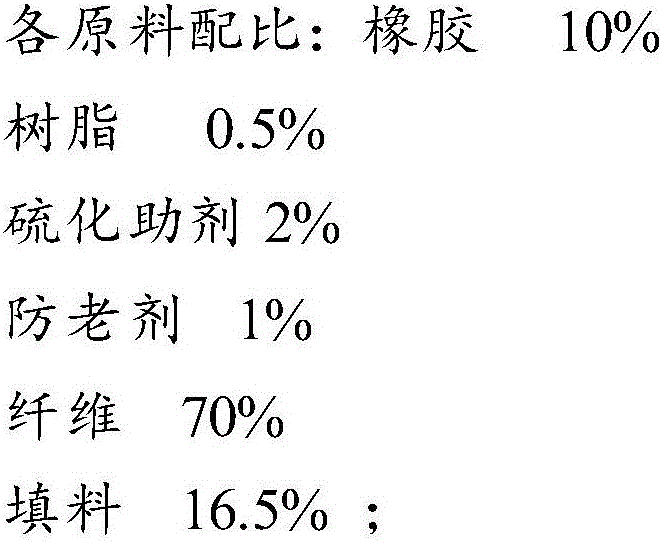

Embodiment 1

[0079] Production of sealing material NY300 sealing liner board

[0080]

[0081] Take toluene and 120 solvent oil from the oil depot according to the volume ratio of 6:1 to the oil storage tank in the production workshop;

[0082] Mix 200Kg of the above raw materials in proportion, put them into the mixer, add 140Kg of mixed solvent twice and stir to completely dissolve the rubber, and mix evenly with fibers, fillers, vulcanization aids, anti-aging agents, etc.

[0083] Weigh the mixed material according to the planned product thickness, and put it into the two rolls of the hot roll temperature 110°C sheeting machine. The material is wound on the hot roll during the opposite rotation of the two rolls, and the solvent is sprayed on the material at the same time. (about 20Kg / 200Kg material), turn the material between the two rollers to reduce the resistance when the two rollers rotate, keep the surface of the small roller smooth, and achieve the expected product thickness by a...

Embodiment 2

[0089] Production of sealing material MT250 sealing liner plate

[0090]

[0091] Take toluene and 120 solvent oil from the oil depot according to the volume ratio of 6:1 to the oil storage tank in the production workshop;

[0092] Mix 200Kg of the above raw materials in proportion, put them into the mixer, add 130Kg of mixed solvent twice and stir to completely dissolve the rubber, and mix evenly with fibers, fillers, vulcanization aids, anti-aging agents, etc.

[0093] Weigh the mixed material according to the planned product thickness, and put it into the two rolls of the hot roll temperature 110°C sheeting machine. The material is wound on the hot roll during the opposite rotation of the two rolls, and the solvent is sprayed on the material at the same time. (about 20Kg / 200Kg material), turn the material between the two rollers to reduce the resistance when the two rollers rotate, keep the surface of the small roller smooth, and achieve the expected product thickness by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com