Semi-closed refrigerating compressor

A refrigeration compressor, semi-hermetic technology, applied in the field of compressors, can solve the problems such as the overall structure is not compact, and achieve the effect of small vibration, small resistance and high cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

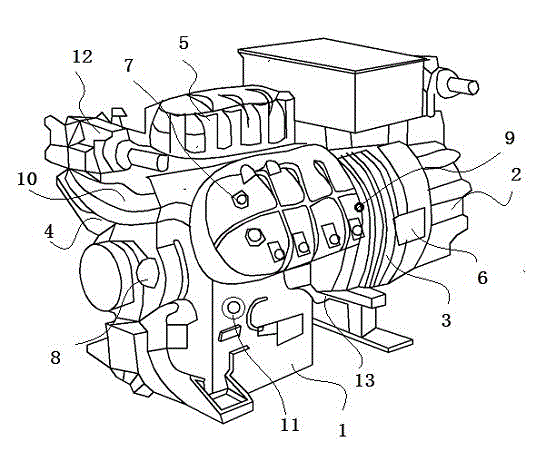

[0009] like figure 1 As shown, a semi-hermetic refrigeration compressor is composed of a body 1, an insulated motor 2 and a cooling system. The body 1 is provided with a crankshaft connecting rod piston 3, and the body 1 is provided with a steel valve plate 4. The crankshaft is connected One side of the rod piston 3 is provided with an oil pump pressure lubrication system 4, the oil pump pressure lubrication system 4 is provided with an oil return system, the oil pump pressure lubrication system 4 is provided with a deep oil groove 10, and the body 1 is also provided with a six-cylinder W type structure of the cylinder body 5, a PTC thermistor sensor 6 is provided on one side of the insulated motor 2, an exhaust temperature temperature sensing probe 7 is provided at the upper end of the body 1, a safety pressure relief valve 8 is built in the body 1, and a pressure relief valve 8 is built in the body 1. One section is provided with a crankcase heater 9, and the cooling system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com