An integrated lubricating oil filter

An oil filter and lubricating oil technology, applied in the installation/connection of lubricating parts, pressure lubricants, lubricant purification devices, etc., can solve the problem of increased maintenance time, easy pollution of the engine room, and the disassembly direction of the filter element is not completely vertical. Inferior problems, to achieve the effect of improving maintenance efficiency, improving system maintenance efficiency, and reducing the number of refills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

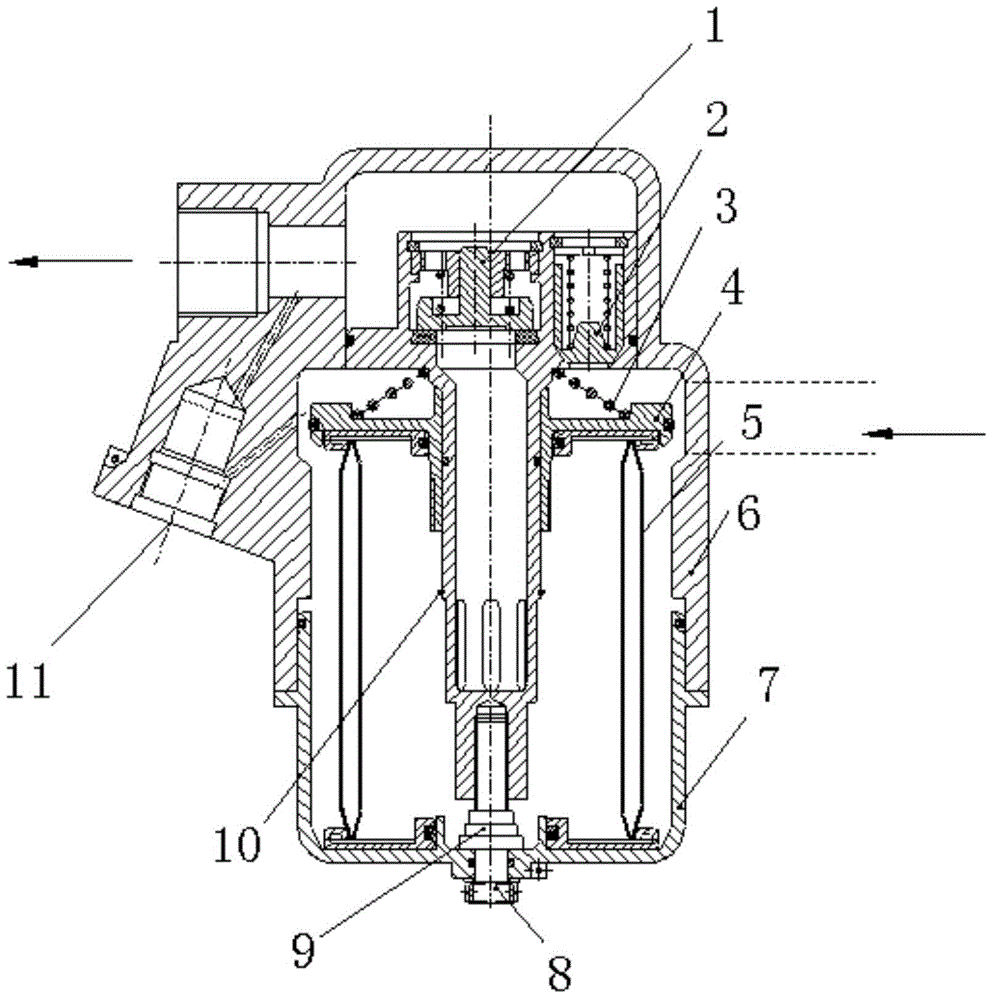

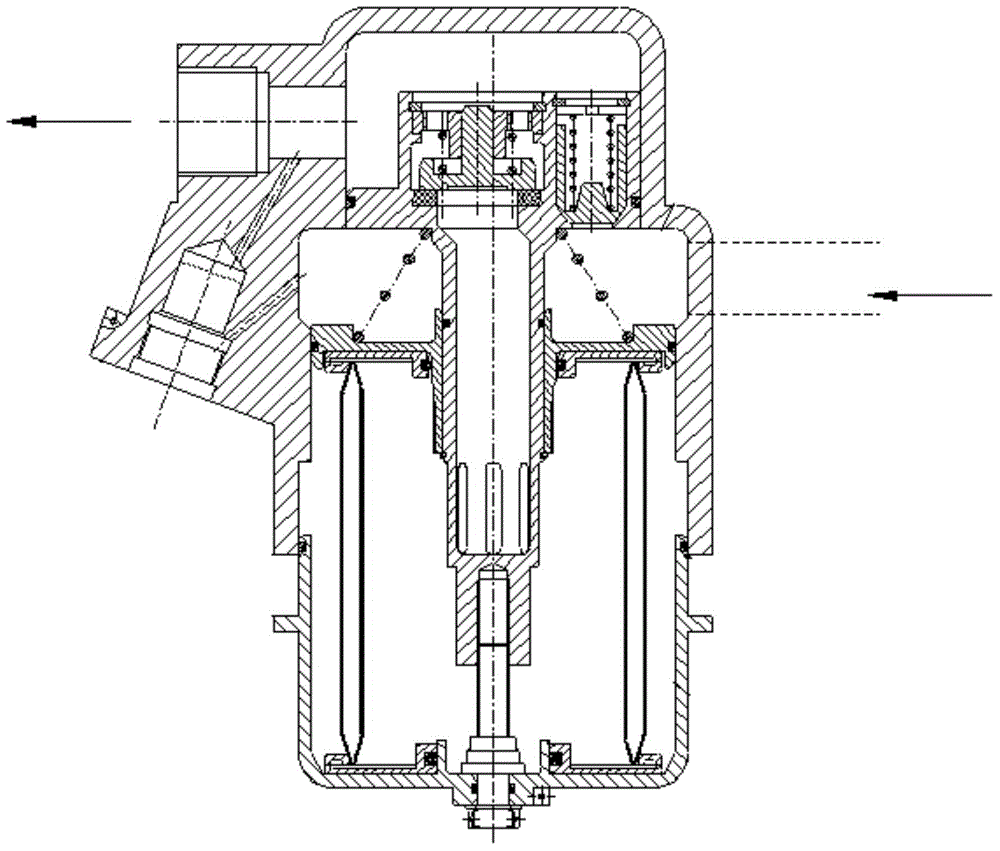

[0021] This embodiment provides an integrated structure lubricating oil filter, which is characterized in that: the integrated structure lubricating oil filter includes a one-way valve 1, a bypass valve 2, a coil spring 3, a self-sealing valve 4, an oil filter element 5, an oil Filter housing 6, oil filter cover 7, long screw 8, self-locking nut 9, shaft circlip 10, oil filter differential pressure sensor mounting seat 11;

[0022] Among them: the oil filter cover 7 is installed on the lower part of the shaft circlip 10 through the long screw 8 and the self-locking nut 9, and is socketed together with the oil filter housing 6; the oil filter element 5 is installed inside the oil filter housing 6, and the oil One end of the filter element 5 is pressed against the inner wall of the oil filter cover 7, and the other end is pressed against one side of the self-sealing valve 4; the self-sealing valve 4 is installed on the shaft elastic retaining ring 10 through the coil spring 3; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com