Novel high-overload differential pressure sensor

A differential pressure sensor, high overload technology, applied in the field of measuring instruments, can solve the problems of unsatisfactory temperature compensation data of the sensor, unequal oil volume at both ends, sensor measurement error, etc., to achieve stable accuracy, reduction of oil filling, and removal of effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

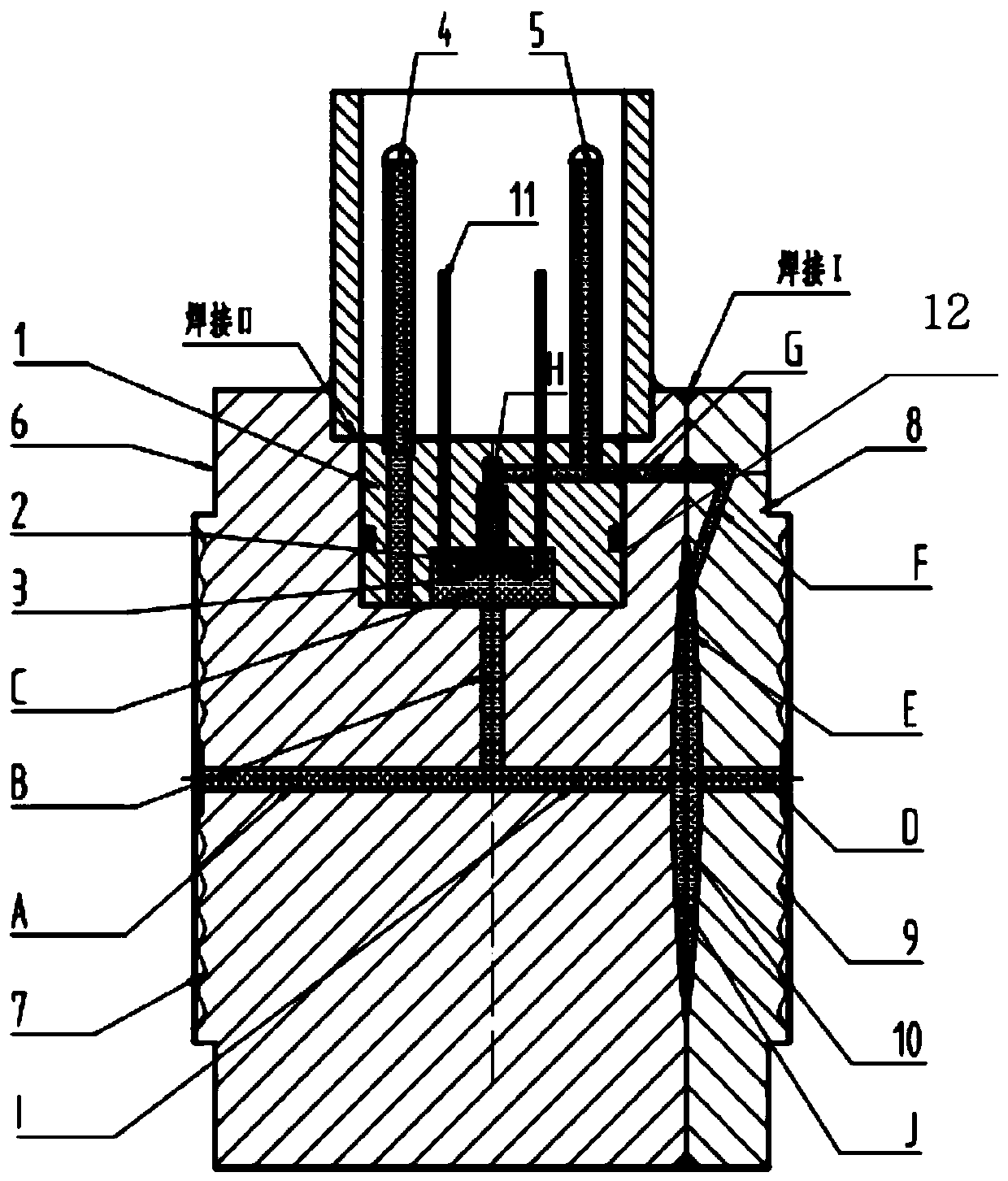

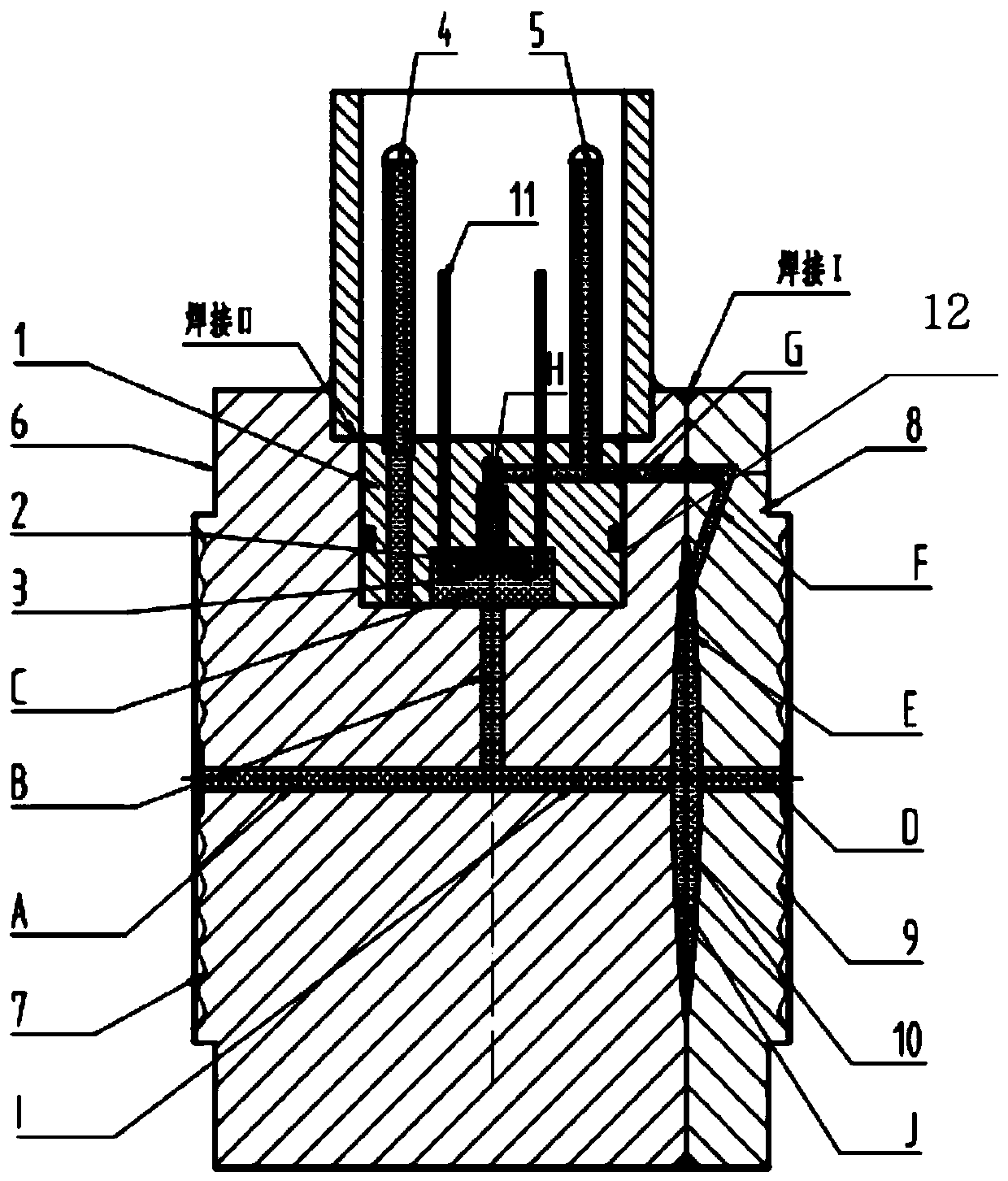

[0024] A new type of high overload differential pressure sensor provided by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0025] Such as figure 1 As shown, a new type of high overload differential pressure sensor provided by the present invention includes a chip base 1, a single crystal silicon differential pressure chip 2, a gold wire 3, a positive pressure end oil filling tube 4, a negative pressure end oil filling tube 5, a positive pressure Base 6, positive pressure isolation diaphragm 7, negative pressure base 8, negative pressure isolation diaphragm 9, center overload diaphragm 10, pin 11, fluorine rubber ring 12;

[0026] The chip base 1 is sintered, and the single crystal silicon differential pressure chip 2 is glued inside. The single crystal silicon differential pressure chip 2 is connected to the pin 11 on the chip base 1 through the gold wire 3, thereby realizing the chip base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com