Refining method of rice oil

A technology for rice oil and crude oil, which is applied in the direction of oil/fat refining, edible oil/fat, and fat production, etc., can solve the problems of difficult removal of benzopyrene content in oil products, easy generation of trans fatty acids, and high equipment investment costs. , to achieve the effect of eliminating benzopyrene, reducing color and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

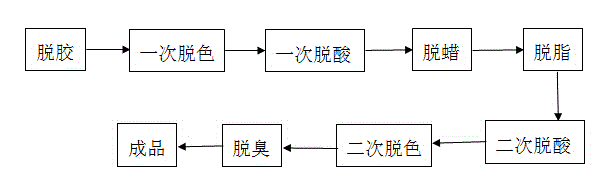

[0020] figure 1 As shown in the refining method of the rice oil, the crude oil of the rice oil enters the steps of degumming, primary decolorization, primary deacidification, dewaxing, degreasing, secondary deacidification, secondary decolorization and deodorization successively, and finally obtains refined rice oil; The specific process of each process is as follows.

[0021] 1. Degumming process:

[0022] After the crude oil is heated to 65°C, add phosphoric acid with a crude oil quality of 0.7-1‰ and a concentration of 85wt% for mixing, and then transport it to the acid reaction tank. After the phosphoric acid-added oil stays in the acid reaction tank for 35-40 minutes, Add water and lye of 10 degrees Baume to quickly mix and send to the centrifuge for centrifugal separation. After the centrifuged oil is heated in sequence, add water and quickly mix and send to the second and third centrifuges for water washing and centrifugation. After two The oil washed and centrifuged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com