Centrifugal flow guiding intelligent speed governing hydraulic coupler body structure

A technology of hydraulic coupling and intelligent speed regulation, which is applied to fluid transmission devices, belts/chains/gears, mechanical equipment, etc., which can solve the problems of insufficient utilization of working oil energy, reduced adaptability of couplings to loads, and problems of couplings. Unstable work and other problems, achieve significant economic and social benefits, save raw materials, reduce wall thickness and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

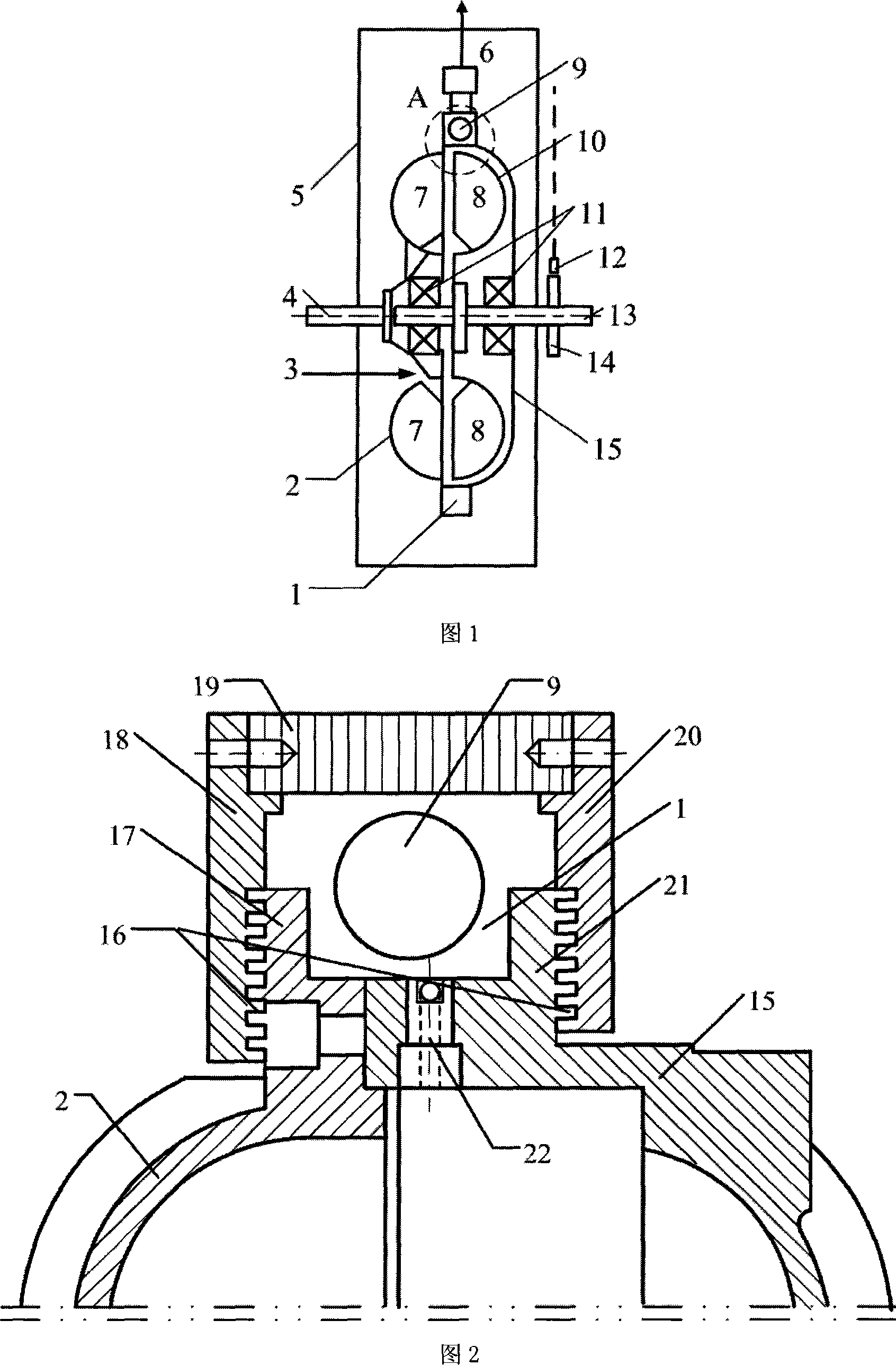

[0013] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] As shown in Figures 1 and 2: the present invention includes: a centrifugal diversion groove 1, a pump wheel 2, an oil inlet connecting pipe 3, a driving shaft 4, a box body 5, an oil outlet connecting pipe 6, a turbine 10, a bearing 11, Speed sensor 12, driven shaft 13, speed measuring gear 14, rotary casing 15, labyrinth oil seal 16, pump wheel flange 17, left sealing end face 18, oil sealing ring 19, right sealing end face 20, rotary casing flange 21, nozzle 22 .

[0015] The driving shaft 4 is connected to the output shaft of the prime mover, the driven shaft 13 is connected to the working machine, the entire coupling body is suspended on the shaft of the prime mover and the working machine, and the pump wheel flange 17 is connected to the rotary casing flange 21 by bolts. The pump wheel method The flange 17 is integrated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com