Crankshaft and inverter compressor

A frequency conversion compressor and crankshaft technology, applied in the field of compressors, can solve problems affecting the normal operation of compressors, oil leakage accidents, and low strength of the main shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

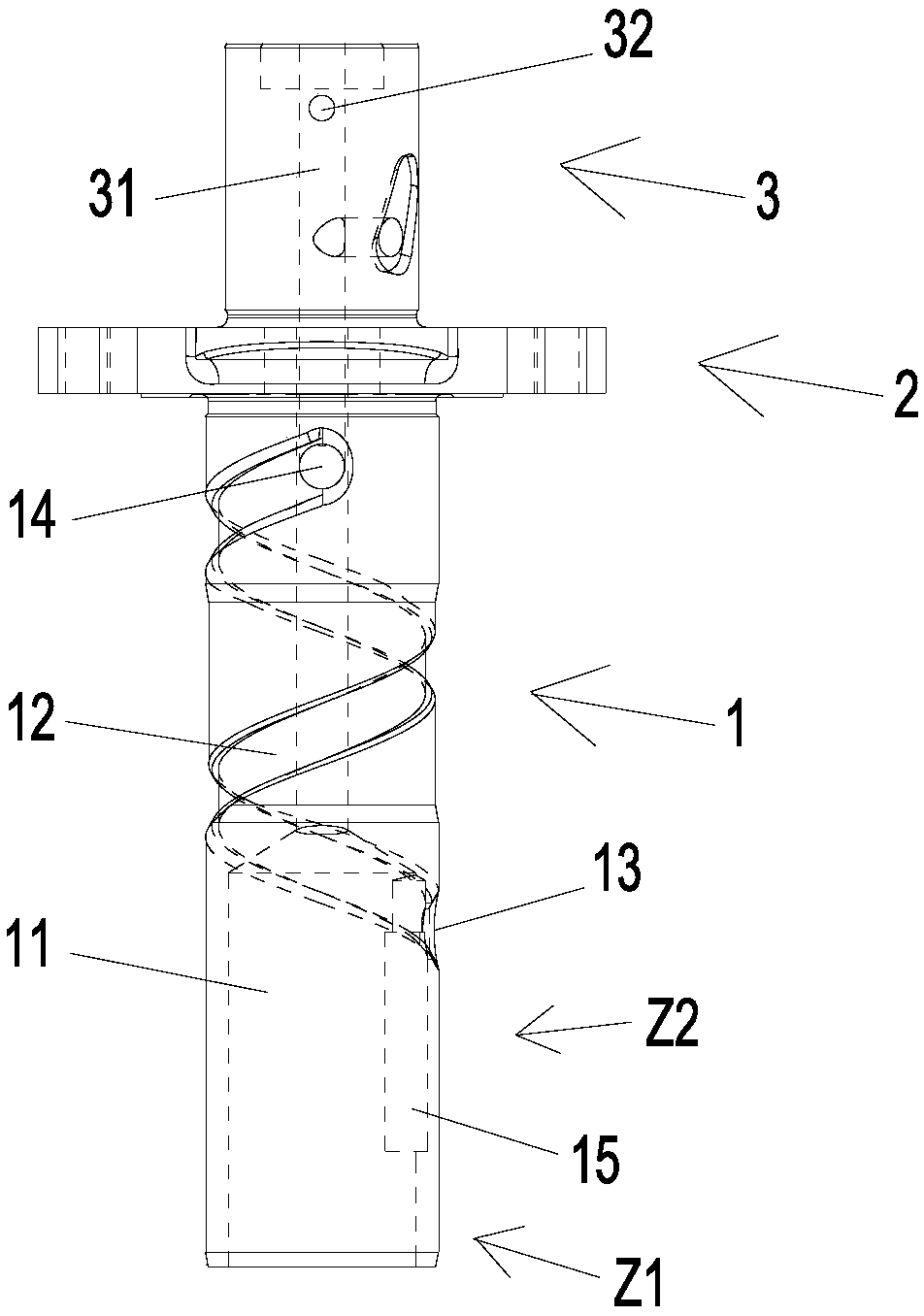

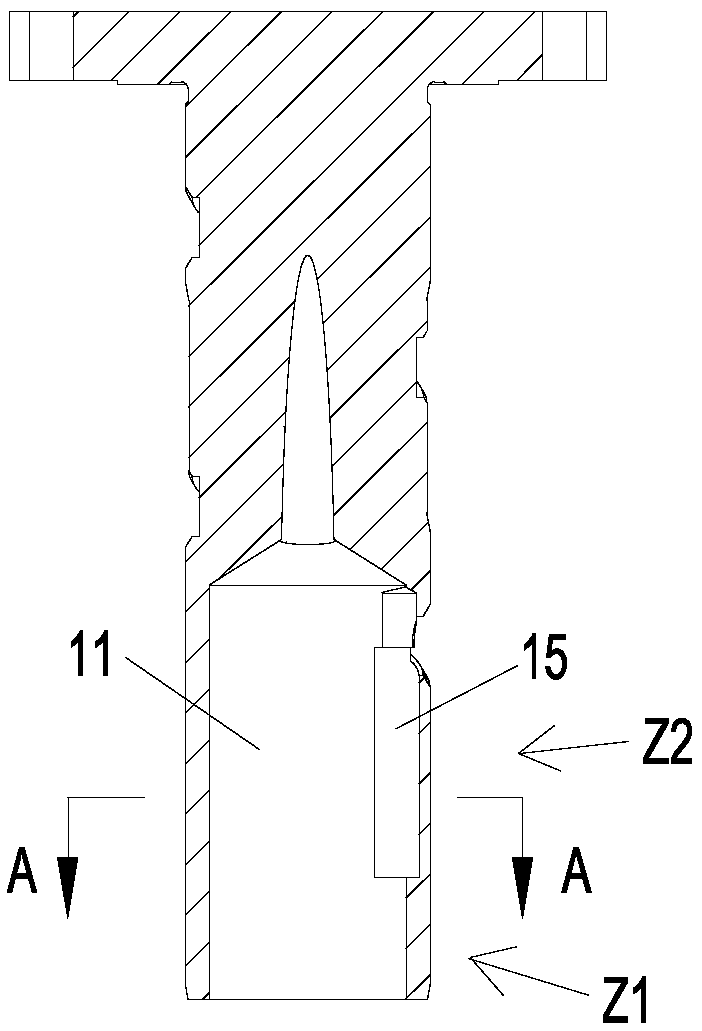

[0040] first implementation

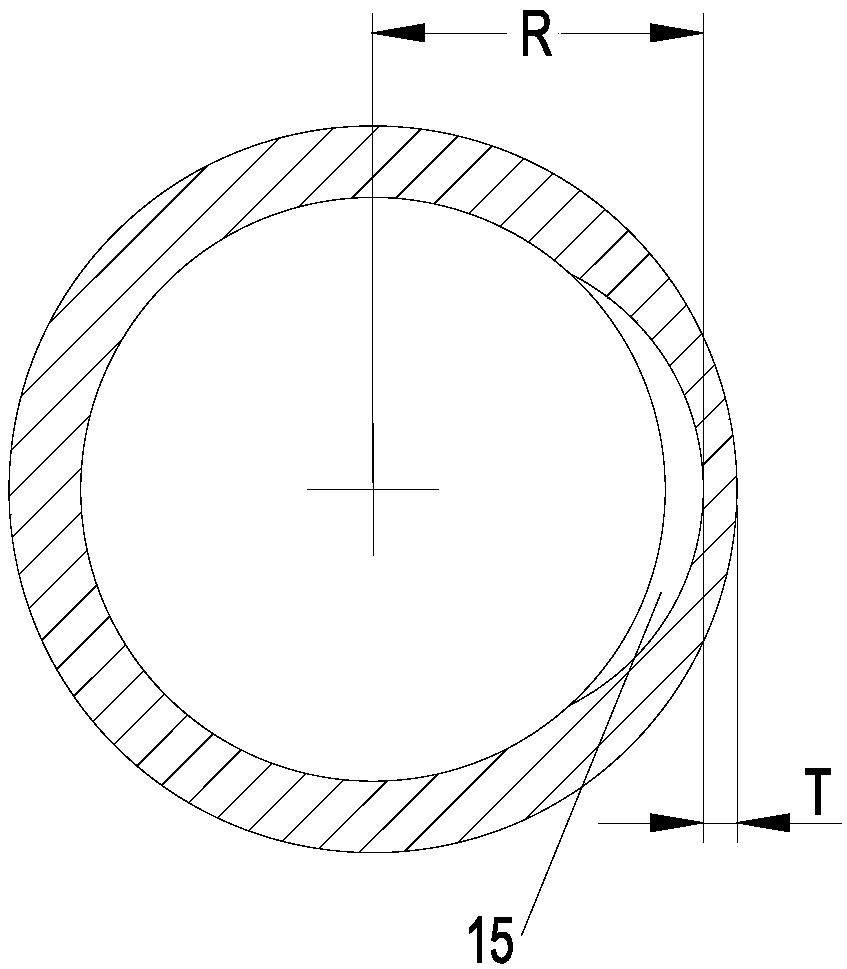

[0041] like image 3 As shown, the cross-section of the second shaft section Z2 is circular, and the cross-section of the recess 15 has a depth in the radial direction from the center (of the cross-section) to two sides (of the cross-section) in the circumferential direction. An arc-shaped structure with gradually smaller sides. Here, the "radial direction" refers to the radial direction of the main shaft 1, and the "circumferential direction" refers to the circumferential direction of the main shaft 1. Further preferably, the cross section of the recessed portion 15 can be an arc-shaped structure formed on the inner wall of the main shaft 1 after the inner circle of the circular ring is moved a set distance in the radial direction toward the first oil through hole 13 . Moreover, the deepest middle position of the arc structure can be aligned and connected with the first oil through hole 13, so that the pump oil lift at the first oil through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com