Eccentric flow guiding valve controlled speed adjusting type hydrokinetic coupoler

A hydraulic coupling and diversion valve technology, which is applied to fluid transmission devices, belts/chains/gears, mechanical equipment, etc., to reduce weight, reduce oil filling, and enhance safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

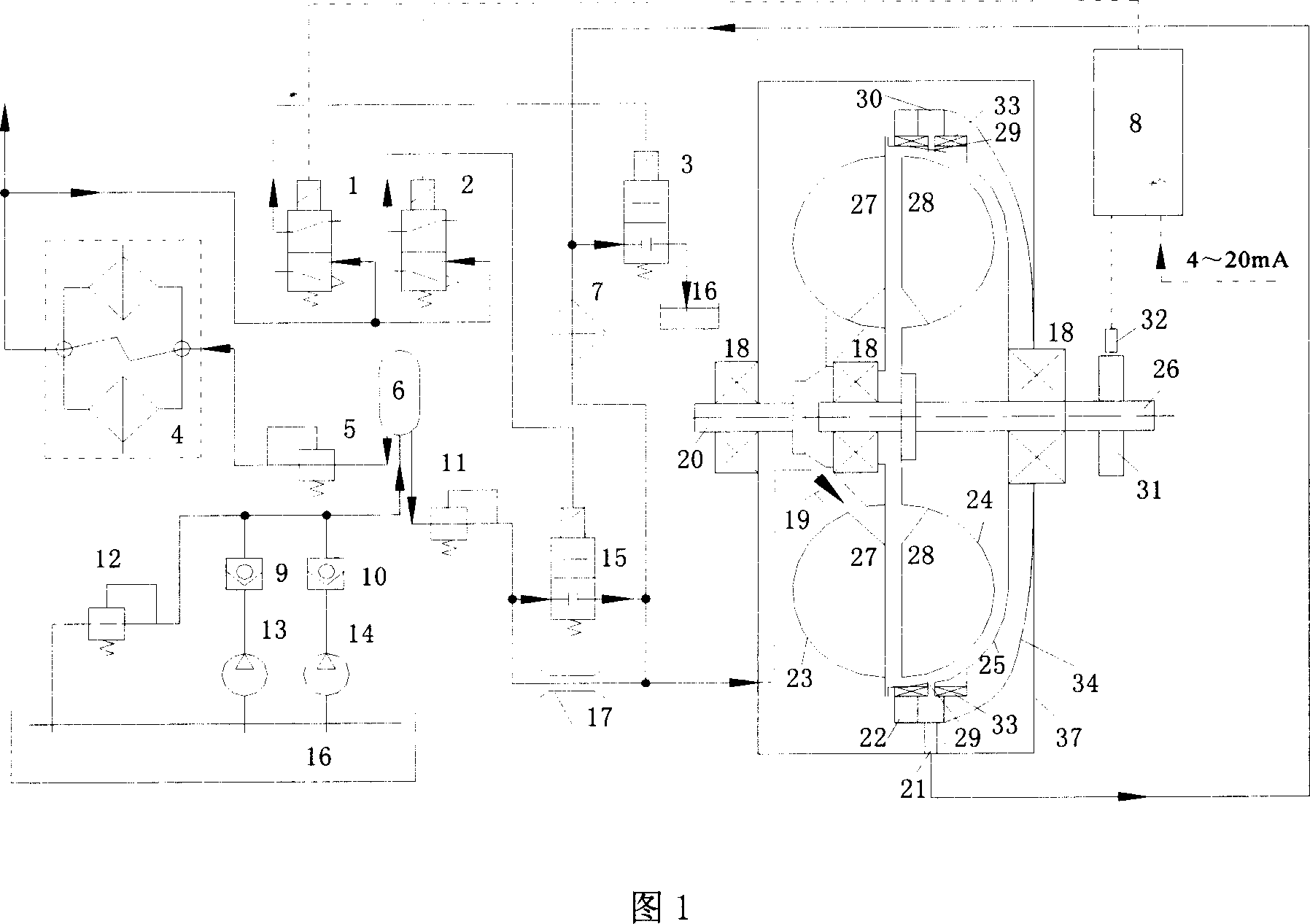

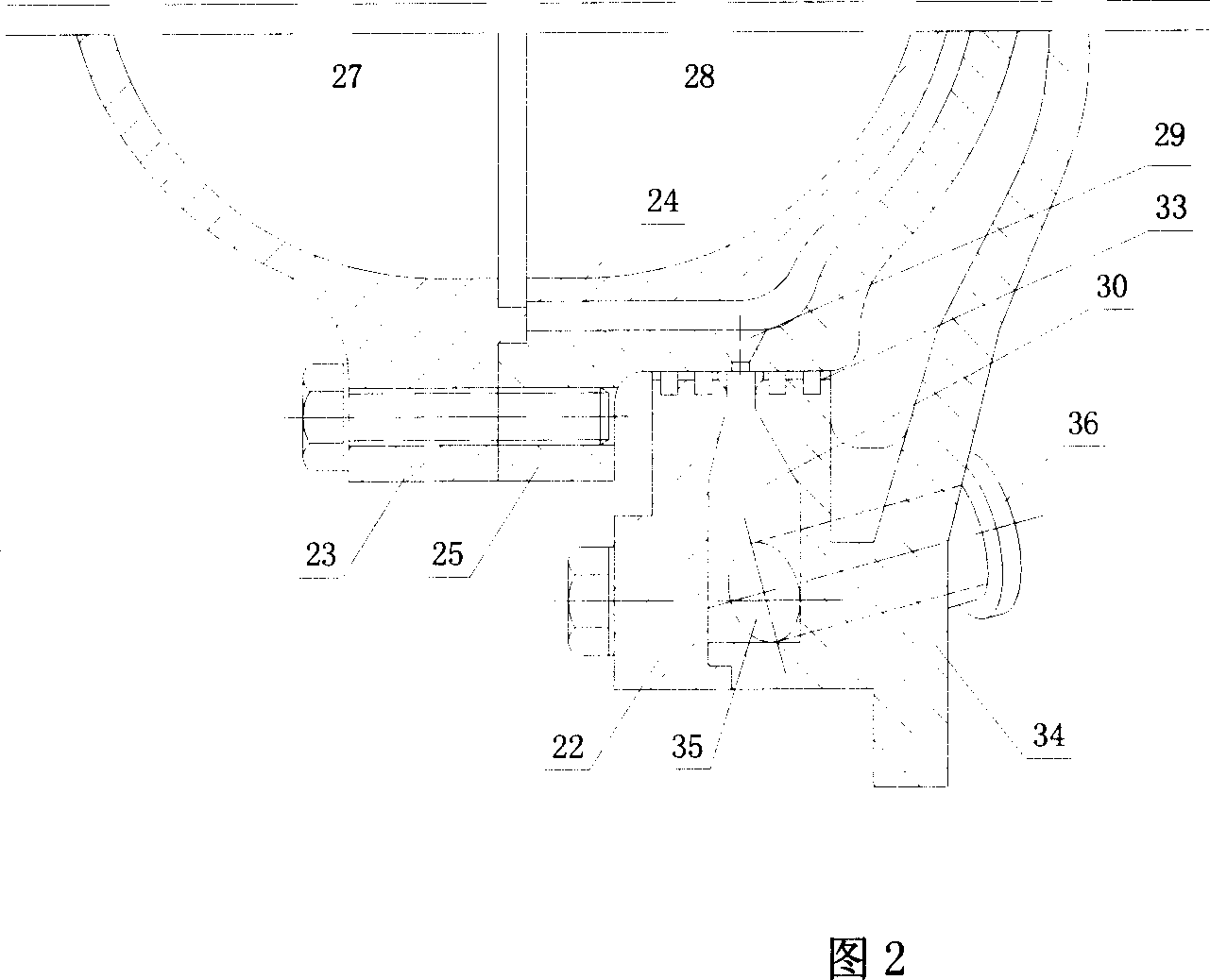

[0021] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] As shown in Figure 1 and Figure 2: the present invention includes A pilot valve 1, B pilot valve 2, A hydraulic control valve 3, duplex filter 4, A pressure reducing valve 5, pressure accumulator 6, cooler 7, control Device 8, A one-way valve 9, B one-way valve 10, B pressure reducing valve 11, overflow valve 12, A electric pump 13, B electric pump 14, B hydraulic control valve 15, oil pool 16, throttle orifice 17. Bearing 18, oil inlet connecting pipe 19, drive shaft 20, oil outlet connecting pipe 21, centrifugal shroud 22, pump wheel 23, turbine wheel 24, back wheel 25, driven shaft 26, pump wheel cavity 27, Turbine cavity 28, centrifugal diversion hole 29, centrifugal diversion groove 30, speed measuring gear 31, speed sensor 32, oil seal 33, end cover 34, passage hole 35, flange 36, box body 37.

[0023]The pump wheel 23 is fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com