Transmission and method for adjusting the circumferential backlash of the transmission

A technology of transmission mechanism and adjustment components, which is applied in the direction of anti-centrifugal rotating parts, transmission devices, gear transmission devices, etc., and can solve the problems of maintaining theoretical presets, sinking, and no longer maintaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

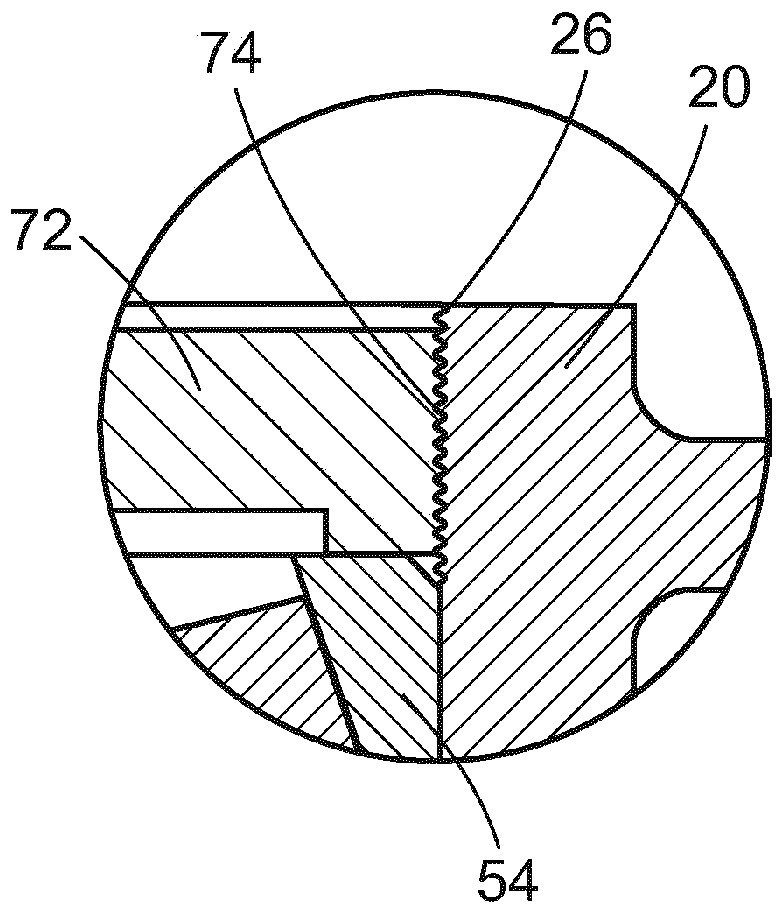

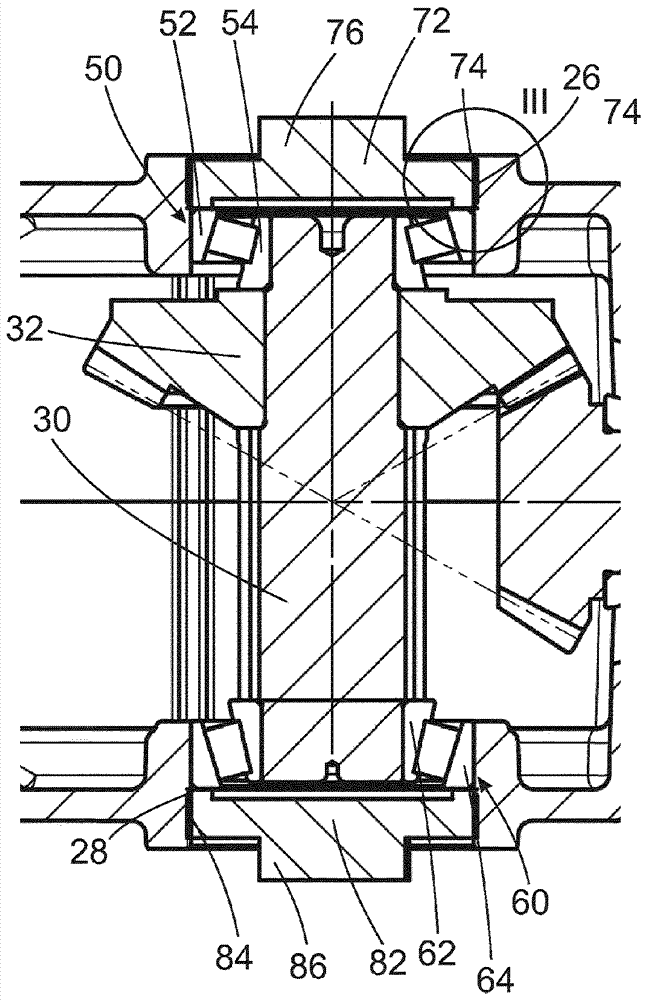

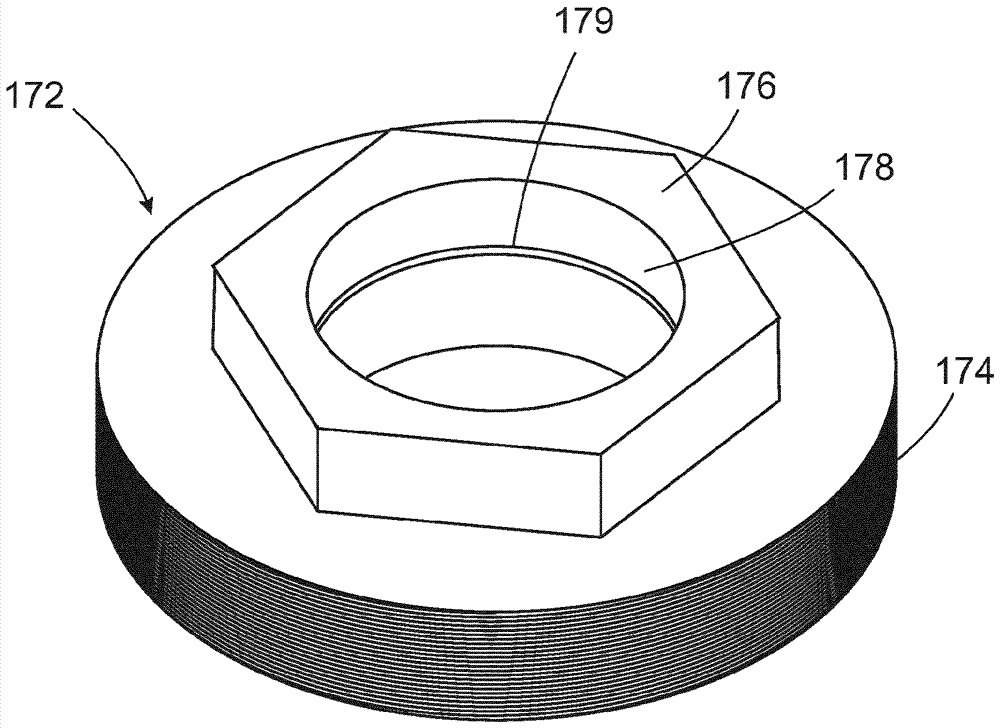

[0032] figure 1 The transmission 10 according to the invention is shown, which is distinguished by two bevel gears 32 , 42 meshing with each other. figure 2 and 3 Details of the transmission are shown in an enlarged view.

[0033] The transmission 10 has a housing 20 , wherein the housing is considered to be all sections of the transmission 10 that are stationary relative to one another after assembly. The housing 20 delimits a housing interior in which two mutually non-parallel shafts 30 , 40 are mounted. Two bevel gears 32 , 42 meshing with each other are fixed on said shaft 30 , 40 .

[0034] In order to be able to adjust the rotational play of the bevel gears 32 , 42 according to the field of application, the first shaft 30 is axially displaceable by means of an adjusting device 70 , 80 . The mode of operation of the adjusting device 70 , 80 is explained below.

[0035] The first shaft 30 is supported by means of two rolling bearings 50 , 60 which are each designed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com