Large-gradient sloping roof tile fixing structure

A technology for fixing structures and roof tiles, which is applied to roofs, roof coverings, and roofs using tiles/slate tiles, etc. It can solve the problem of low strength of metal wires connecting perforated tiles and hanging tile strips, and it is difficult to guarantee perforated tiles. Paving stability, swaying and deflection of shingles, etc., to ensure the connection strength and positional stability, improve positional stability, and reduce the effect of swaying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

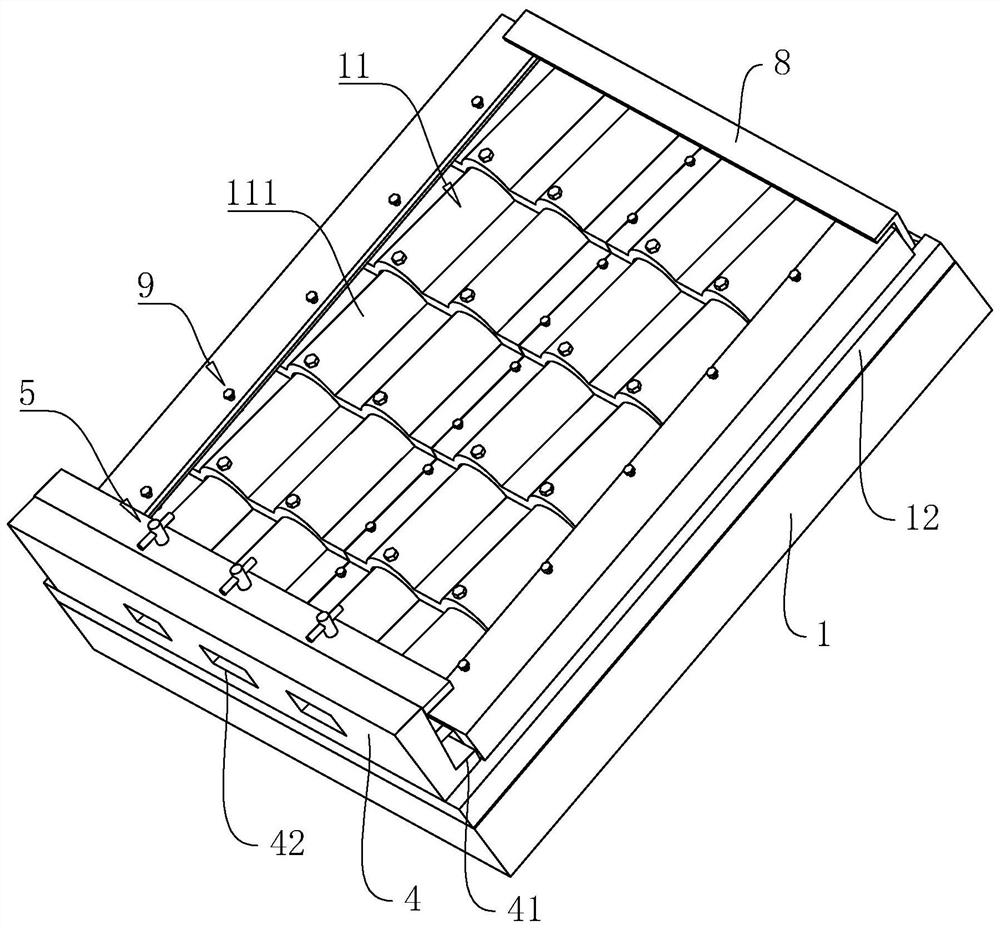

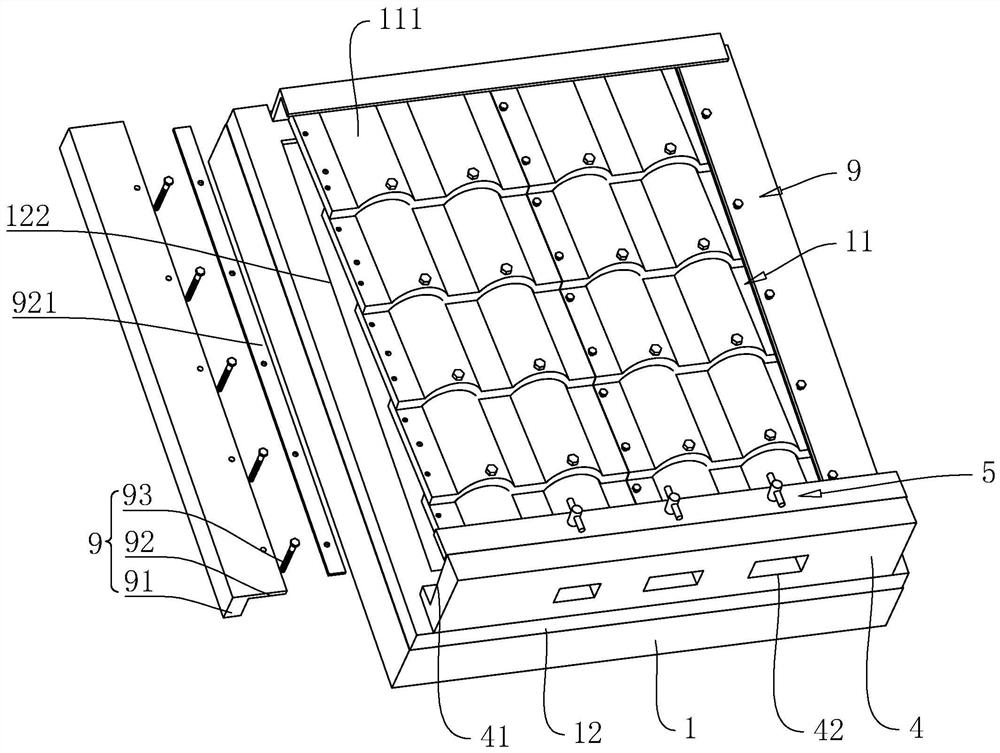

[0036] The following is attached Figure 1-6 The application is described in further detail.

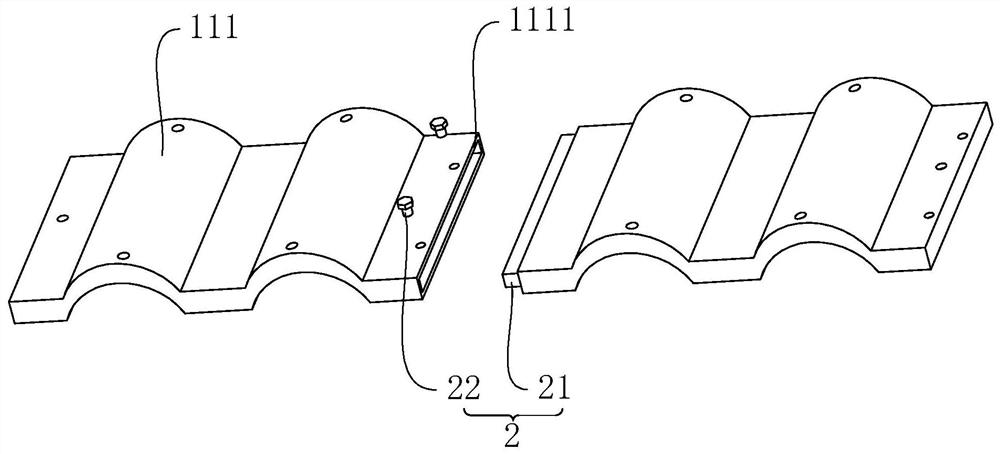

[0037] The embodiment of the present application discloses a large-slope inclined roof tile fixing structure. refer to figure 1 and figure 2 , a large-slope inclined roof tile fixing structure includes roof tiles 111 . In this embodiment, the roof tile 111 is an asphalt tile. Two adjacent roof tiles 111 are fixedly connected to form a tile assembly 11 through the receiving assembly 2. The receiving assembly 2 includes an abutment plate 21 and a connecting piece 22. In this embodiment, the connecting piece 22 is a bolt.

[0038] refer to figure 2 , the abutment plate 21 is integrally formed on the outer wall of one of the roof tiles 111 along the horizontal direction, and the other roof tile 111 is provided with a side groove 1111 facing the side wall of the abutment plate 21. The inner diameter of the side groove 1111 is the same as that of the abutment plate 21 to match the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com