Sand filling instrument for detecting large-thickness and wide-width water-stable layer and construction method of sand filling instrument

A water-stable layer and large-thickness technology, which is applied in the field of sand filling instrument, can solve the problems of reduced position stability, loose and swaying of the base plate of the sand storage tank, deviation, and affecting the detection accuracy of the sand filling instrument, so as to improve the connection strength and improve the The effect of positional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

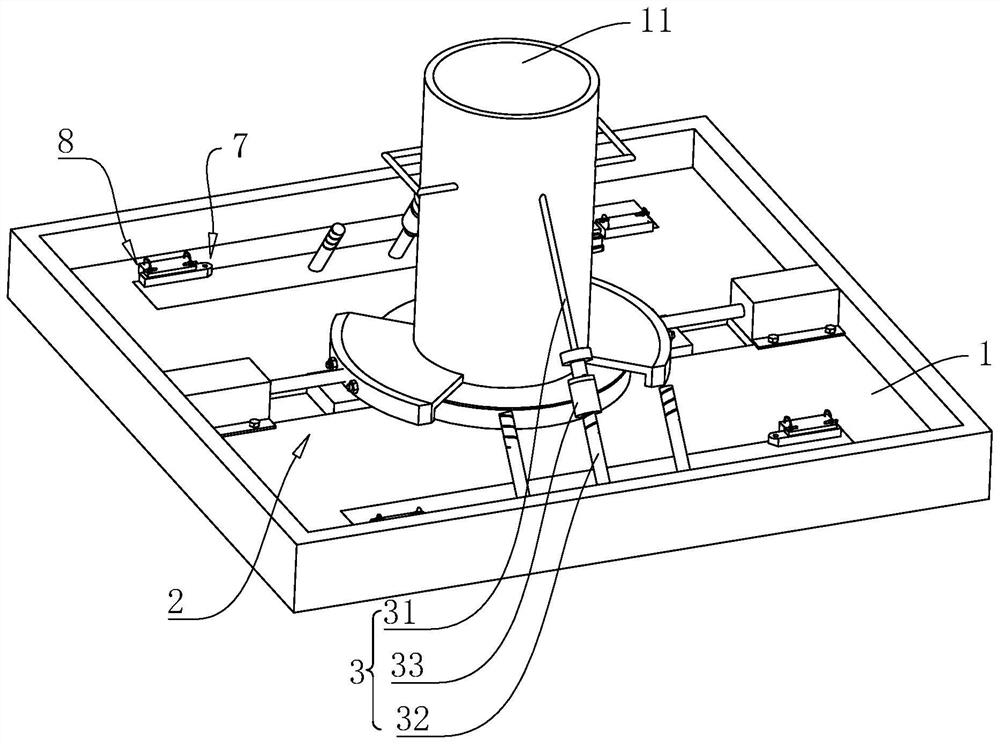

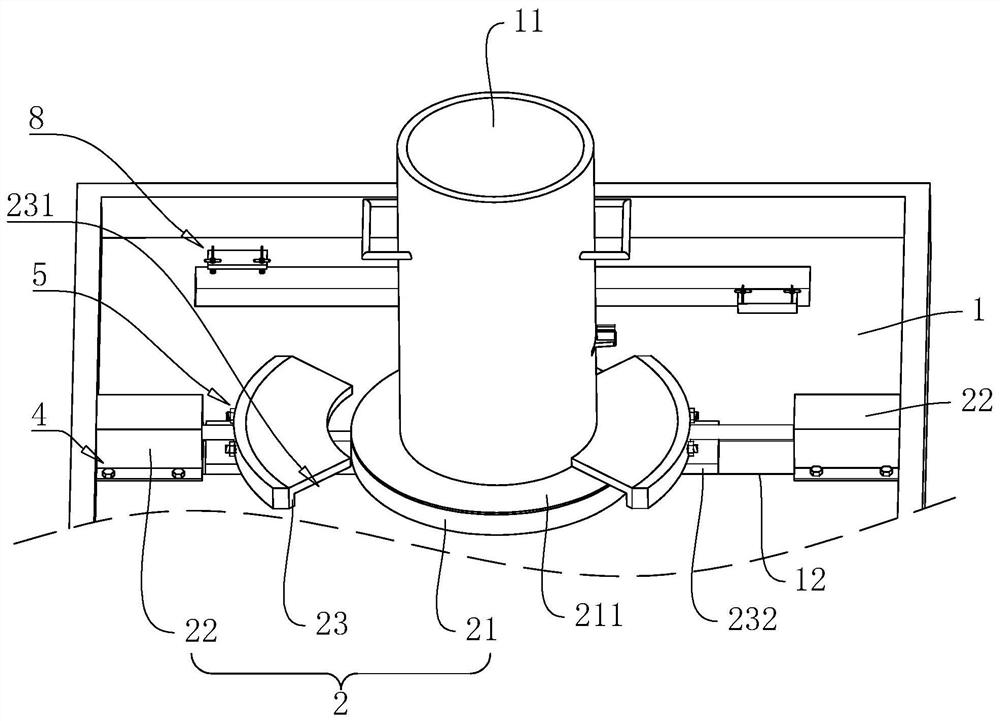

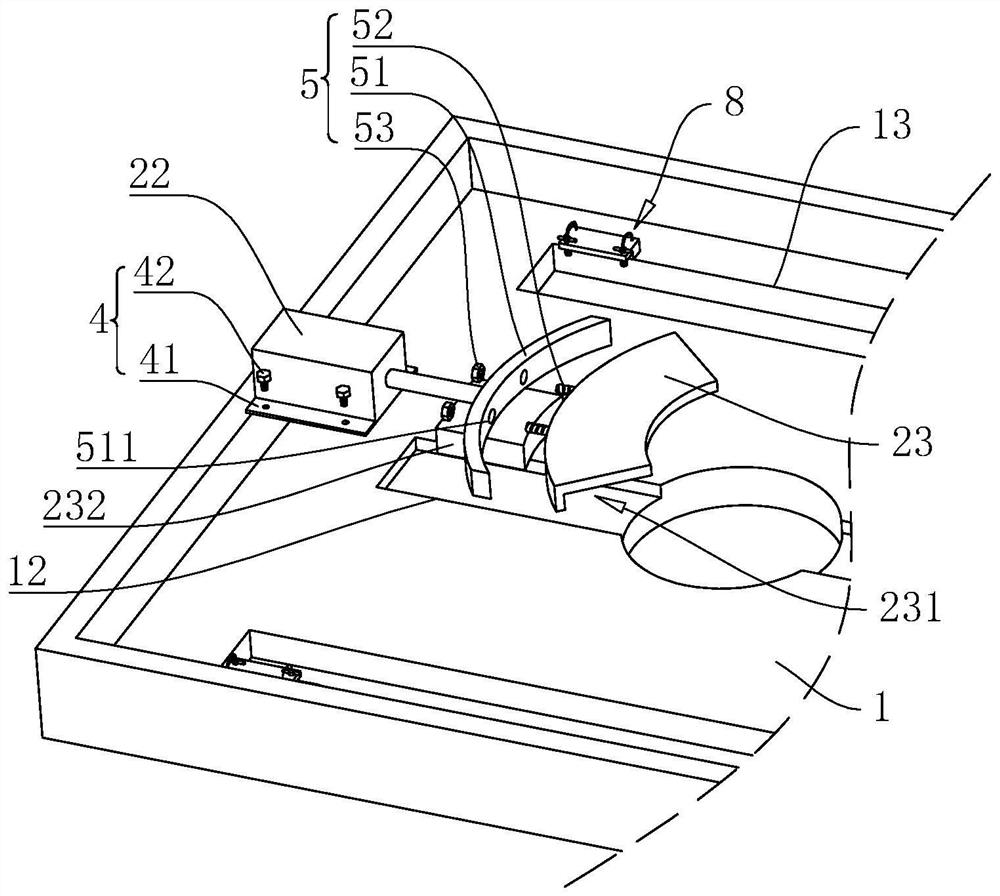

[0040] The following is attached Figure 1-7 The application is described in further detail.

[0041] The embodiment of the present application discloses a sand filling instrument for detecting a large-thickness and wide-width water stability layer. refer to figure 1 , a large-thickness and wide-width water-stable layer detection sand filling instrument includes a sand storage tank 11 and a base plate 1 . The base plate 1 is a plate body with a through hole on the upper surface. The inner cavity of the sand storage cylinder 11 is used to contain the sand used for testing. The sand storage cylinder 11 is placed at the through hole of the base plate 1 along the longitudinal direction.

[0042] refer to figure 1 and figure 2 The base plate 1 and the sand storage cylinder 11 are jointly provided with a pressing assembly 2 and an anti-deflection assembly 3. The pressing assembly 2 includes a bottom support ring plate 21, a limit cylinder 22 and an abutment plate 23. The limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com