A pre-embedded component of wall tie bars and its construction method

A technology of tie bars and tie pieces, which is applied in the directions of buildings and building structures, can solve the problems such as the failure to fully guarantee the qualified strength of the pull test, the low connection strength between the tie bars and the structural adhesive, and the influence of the curing effect of the structural adhesive. , to achieve the effect of improving connection stability, improving pull-out strength and reducing looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

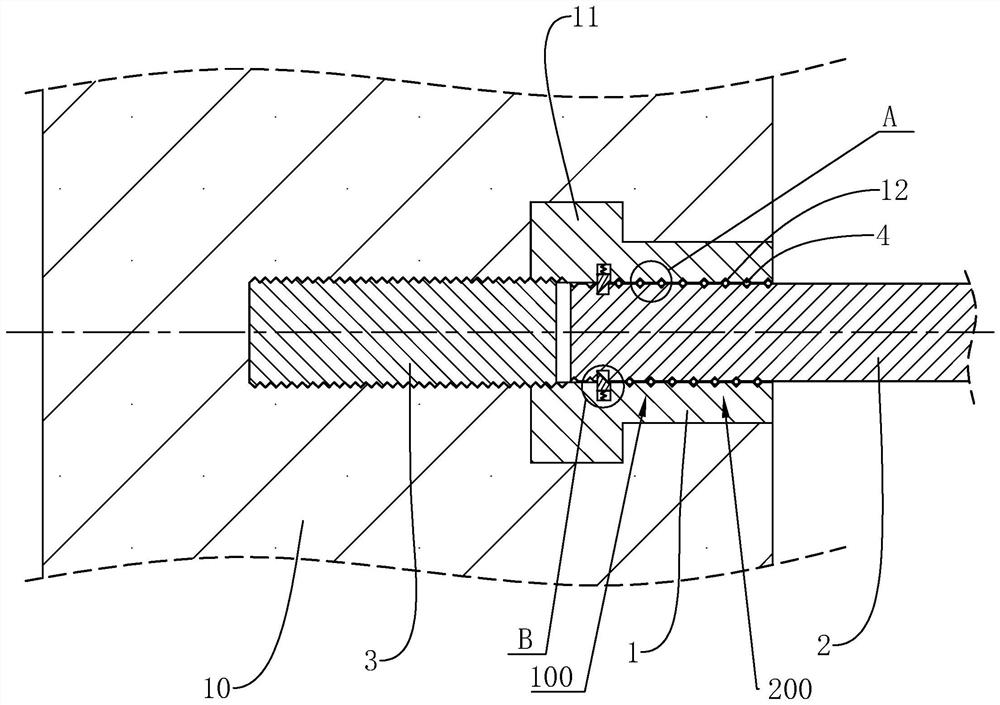

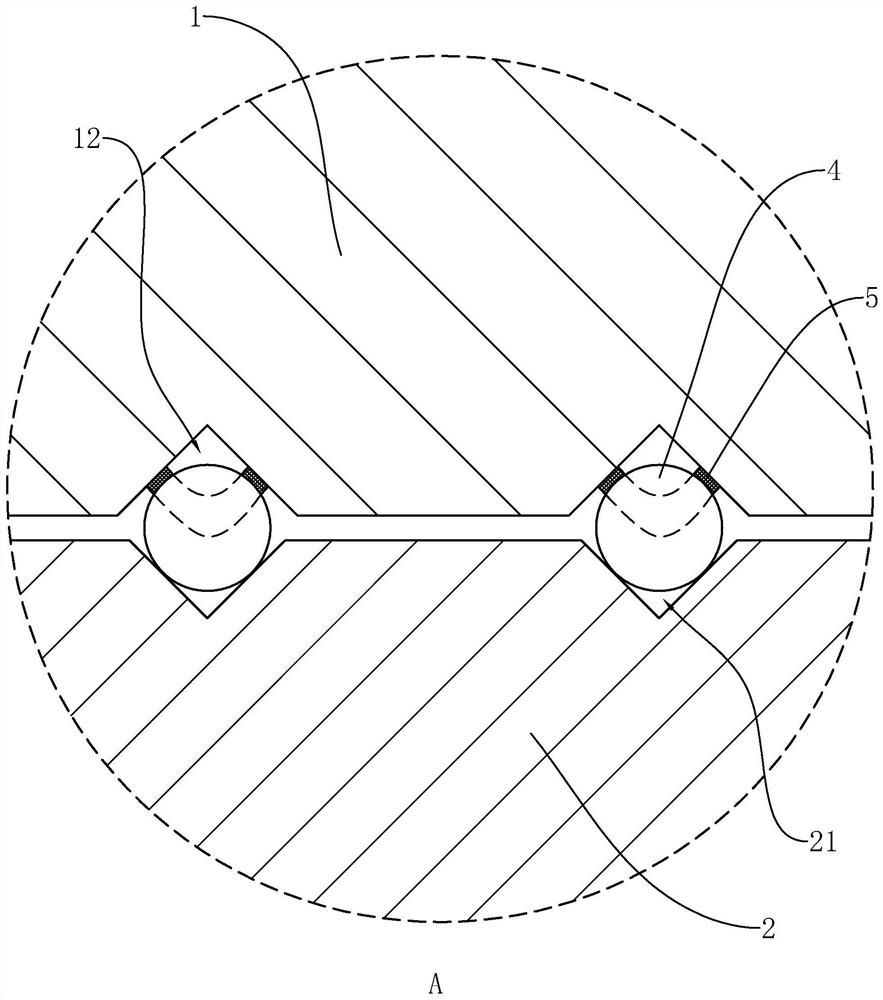

[0038] The following is attached Figure 1-5 The application is described in further detail.

[0039] The embodiment of the present application discloses a pre-embedded assembly of wall tie bars. refer to figure 1 , including pre-embedded steel bar 3, pre-embedded sleeve 1 and tie piece 2, wherein one end of pre-embedded sleeve 1 is fixedly connected with pre-embedded steel bar 3, and its connection form can be integrally formed, welded or threaded. In this embodiment Threaded connection is selected; the rod-shaped tie piece 2 is connected with the embedded sleeve 1 .

[0040] The tie piece 2 is used as a tie structure for connecting the wall body 10 with the rear masonry, so as to ensure reliable connection between the rear masonry and the concrete member, and to enhance the overall stability of the rear masonry.

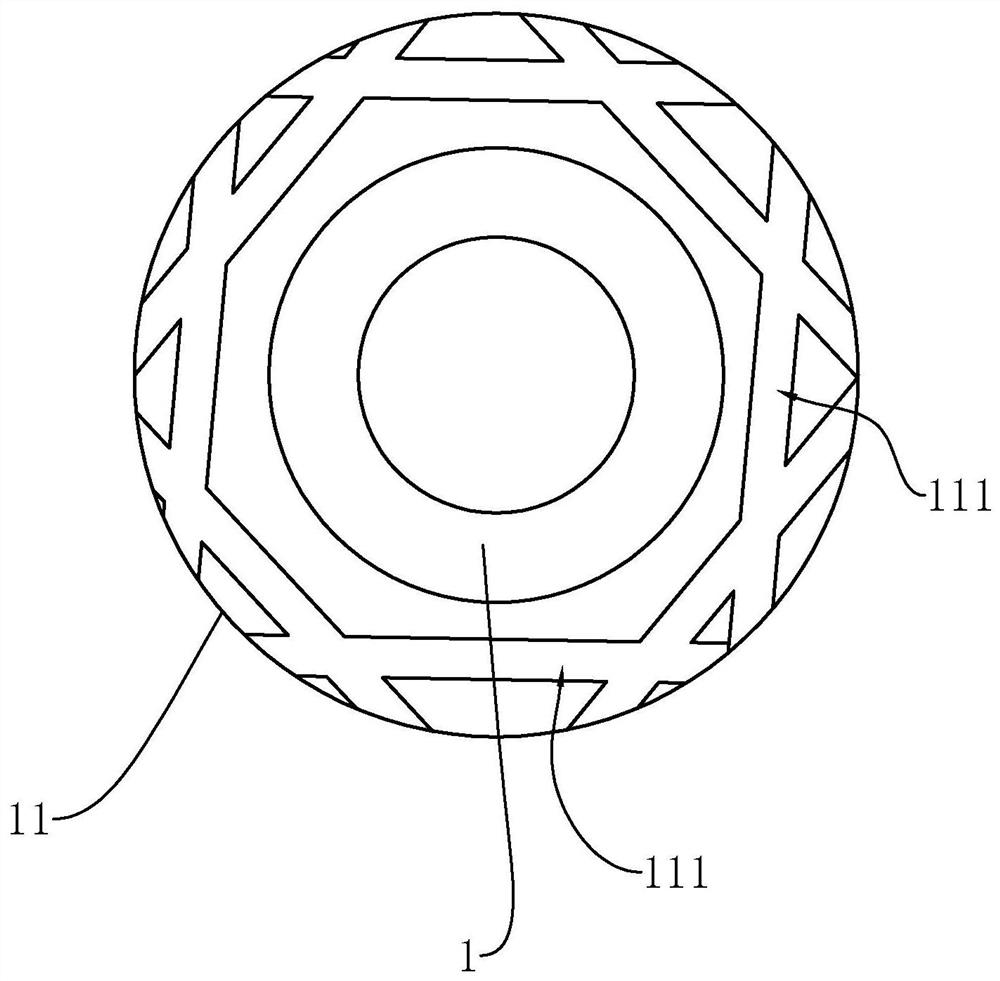

[0041] Such as figure 1 , figure 2As shown, the outer peripheral surface of the end of the embedded sleeve 1 away from the anchor 2 is protrudingly configure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com