Building low-toxicity epoxy resin grouting material and preparation method thereof

A technology of epoxy resin grouting and epoxy resin, which is applied in the field of grouting materials, can solve the problems that affect the bonding performance of grouting materials and the effect of filling and reinforcement, many hidden dangers brought about by the production and use process, and large shrinkage, etc., to achieve good results. Mechanical properties and medium corrosion resistance, easy to control, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

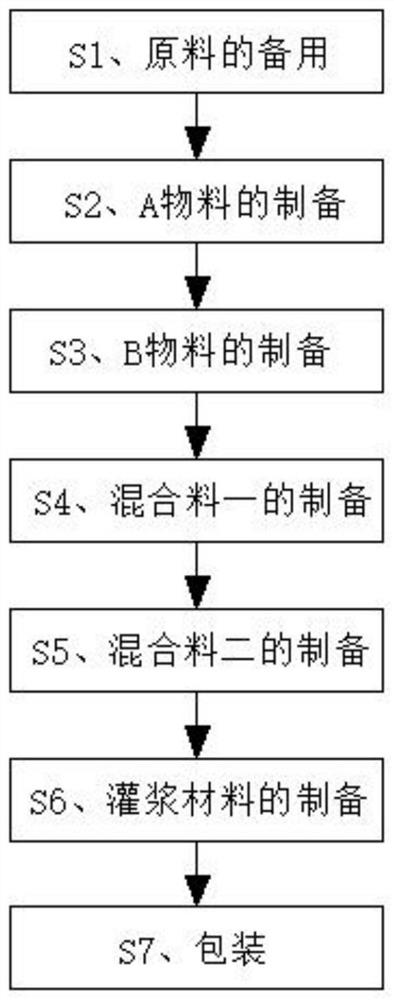

[0026] Example 1: Please refer to figure 1 , a low-toxic epoxy resin grouting material for construction, comprising the following parts by weight: 50 parts of bisphenol A epoxy resin, 30 parts of curing agent, 10 parts of diluent, 3 parts of coupling agent, 7 parts of defoamer, 60 parts of quartz sand, 50 parts of slag, 60 parts of cement, 10 parts of expansion agent and 80 parts of water.

[0027] A preparation method for building low-toxic epoxy resin grouting material, comprising the following steps:

[0028] S1, standby of raw materials: take bisphenol A type epoxy resin, curing agent, diluent, coupling agent, defoamer, quartz sand, slag, cement, expansion agent and water successively by weight, standby;

[0029] S2, preparation of material A: add the quartz sand and slag weighed in step S1 into the pulverizer in sequence, and then pulverize, then add cement to the pulverizer and pulverize again, the cement is fast hardening sulfoaluminate cement, Get the required A mate...

Embodiment 2

[0035] Example 2: Please refer to figure 1 , a low-toxic epoxy resin grouting material for construction, comprising the following parts by weight: 55 parts of bisphenol A epoxy resin, 40 parts of curing agent, 15 parts of diluent, 4 parts of coupling agent, 8 parts of defoamer, 70 parts of quartz sand, 70 parts of slag, 70 parts of cement, 13 parts of expansion agent and 90 parts of water.

[0036] A preparation method for building low-toxic epoxy resin grouting material, comprising the following steps:

[0037] S1, standby of raw materials: take bisphenol A type epoxy resin, curing agent, diluent, coupling agent, defoamer, quartz sand, slag, cement, expansion agent and water successively by weight, standby;

[0038] S2, preparation of material A: Add the quartz sand and slag weighed in step S1 into the pulverizer in sequence, and then pulverize, then add cement to the pulverizer and pulverize again, the cement is Portland cement, and the required Material A;

[0039] S3, p...

Embodiment 3

[0044] Example 3: Please refer to figure 1 , a low-toxic epoxy resin grouting material for construction, comprising the following parts by weight: 60 parts of bisphenol A epoxy resin, 50 parts of curing agent, 20 parts of diluent, 5 parts of coupling agent, 10 parts of defoamer, 80 parts of quartz sand, 80 parts of slag, 80 parts of cement, 15 parts of expansion agent and 100 parts of water.

[0045] A preparation method for building low-toxic epoxy resin grouting material, comprising the following steps:

[0046] S1, standby of raw materials: take bisphenol A type epoxy resin, curing agent, diluent, coupling agent, defoamer, quartz sand, slag, cement, expansion agent and water successively by weight, standby;

[0047] S2, preparation of material A: add the quartz sand and slag weighed in step S1 into the pulverizer in sequence, and then pulverize, then add cement to the pulverizer and pulverize again, the cement is fast hardening sulfoaluminate cement, Get the required A ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com