Underwater solvent-free epoxy anchoring adhesive and preparation method thereof

A solvent-free, rebar-planting adhesive technology, which is applied in the field of underwater solvent-free epoxy rebar-planting adhesive and its preparation, can solve the problem that the safety and reliability cannot be guaranteed, and the pull-out strength, shear strength, and positive tensile bond strength decrease. and other problems, to achieve the effects of safety and reliability guarantee, positive tensile bond strength improvement, good wettability and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

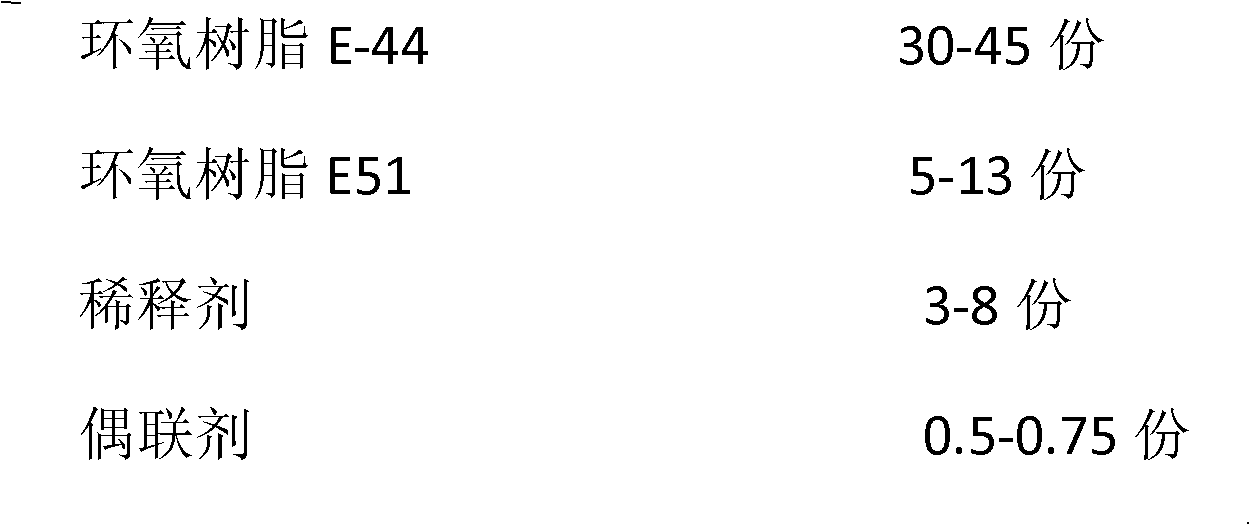

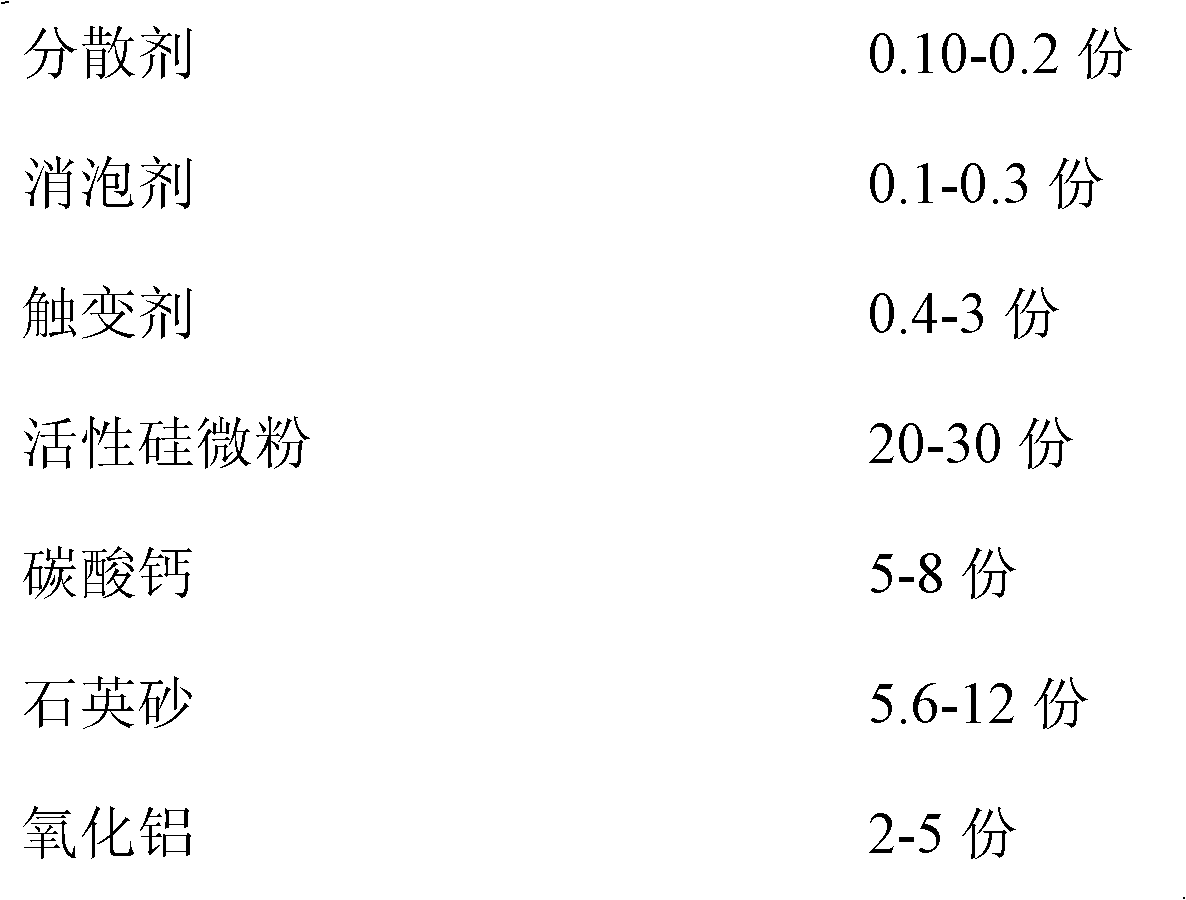

[0023] A component, calculated in parts by weight:

[0024]

[0025] B component, calculated in parts by weight:

[0026] 1085A curing agent 52 parts

[0027] Active silica powder 47.6 parts

[0028] 0.4 parts of organic bentonite,

[0029] The first step, the preparation of component A:

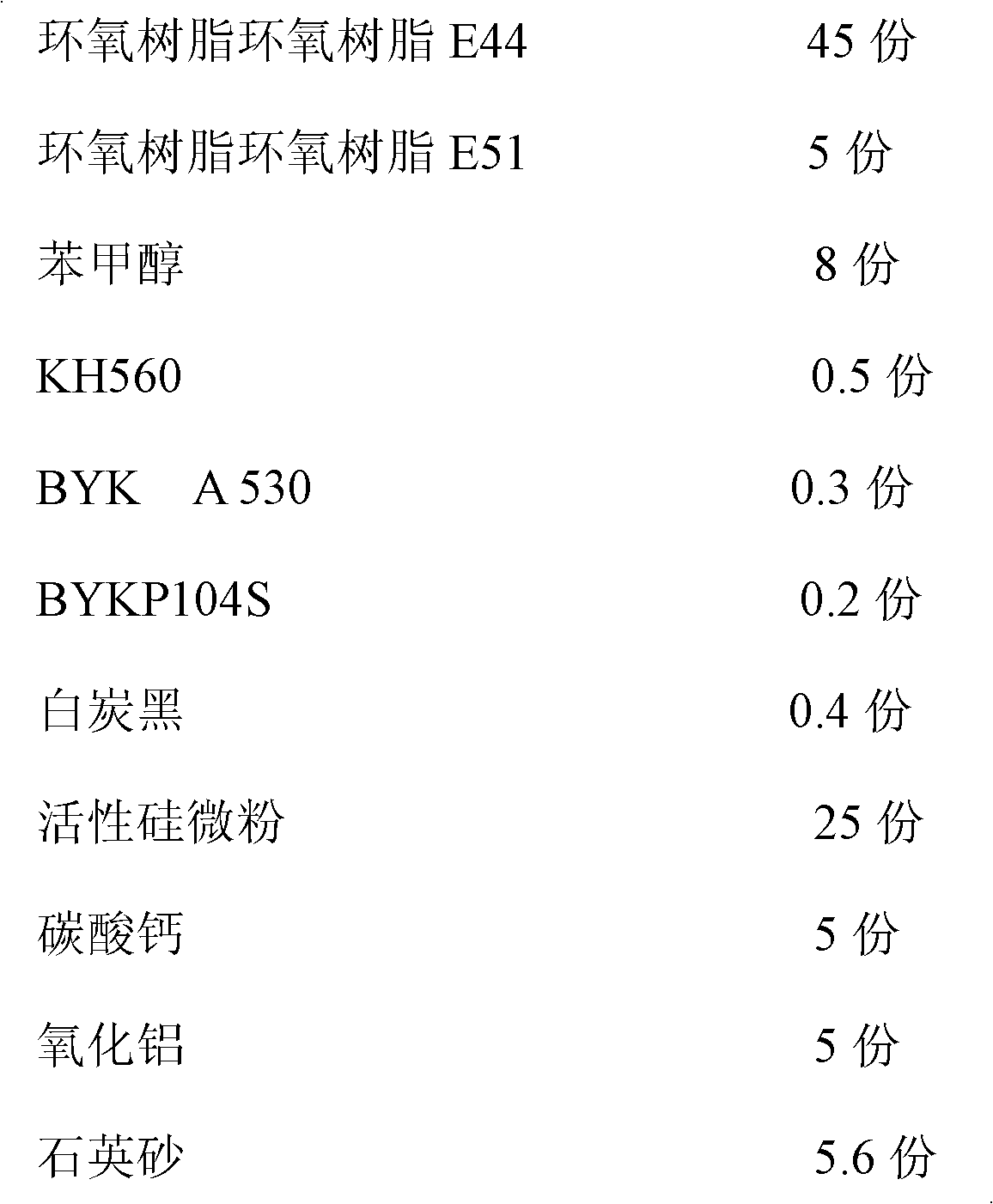

[0030] Mix 45 parts of epoxy resin E44, 5 parts of epoxy resin E51, 8 parts of benzyl alcohol, 0.5 parts of KH560, 0.3 parts of BYKA 530, 0.2 parts of BYKP104S, stir well and then add 0.4 parts in sequence 5 parts of white carbon black, 5 parts of aluminum oxide, 5.6 parts of quartz sand, 25 parts of active silicon micropowder, 5 parts of calcium carbonate, then stir, stir evenly and pack after grinding and defoaming;

[0031] The second step, the preparation of component B:

[0032] Pour 52 parts by weight of 1085A curing agent into an airtight container, then pour 0.4 parts of organic bentonite and 47.6 parts of active silicon micropowder in sequence, stir evenly, grind and defoam,...

Embodiment 2

[0041] A component, calculated by weight percentage:

[0042]

[0043]

[0044] B component, calculated in parts by weight:

[0045] 1085A curing agent 48 parts

[0046] Active silica powder 50 parts

[0047] 0.2 parts of organic bentonite,

[0048] The first step, the preparation of component A:

[0049] Pour 30 parts by weight of epoxy resin E44, 13 parts of epoxy resin E51, 5 parts of benzyl alcohol, 0.75 parts of KH560, 0.1 parts of BYKA 530, and 0.1 parts of BYKP104S into the stirring and dispersing tank in sequence , Stir, stir evenly and then pour 0.4 parts of white carbon black, 12 parts of quartz sand, 2 parts of alumina, 6.5 parts of calcium carbonate, 30 parts of active silica powder, and then stir, stir evenly, Packaging after grinding and defoaming;

[0050] The second step, the preparation of component B:

[0051] Pour 48 parts by weight of 1085A curing agent into an airtight container, then pour in 0.2 parts of organic bentonite and 50 parts of activ...

Embodiment 3

[0060] A component, calculated in parts by weight:

[0061]

[0062] B component, calculated in parts by weight:

[0063] 1085A curing agent 54 parts

[0064] Active silica powder 44 parts

[0065] Organic bentonite 0.2 parts

[0066] The first step, the preparation of component A:

[0067] Pour 40 parts by weight of epoxy resin E44, 10 parts of epoxy resin E51, 3 parts of benzyl alcohol, 0.6 parts of KH560, 0.2 parts of BYKA530, and 0.20 parts of BYK P104S into the stirring and dispersing tank in sequence , Stir, stir evenly and then pour 3 parts of organic bentonite, 20 parts of active silica powder, 8 parts of calcium carbonate, 12 parts of quartz sand, 3 parts of alumina, and then stir, stir evenly and grind to eliminate Packaging after blistering;

[0068] The second step, the preparation of component B:

[0069] Pour 54 parts by weight of 1085A curing agent into an airtight container, then pour 0.2 parts of organic bentonite and 44 parts of active silica powder in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com