Wind-resistant and overturn-preventing external expansion pole foundation for electric power

A pole foundation and anti-overturning technology, which is applied in infrastructure engineering, building types, buildings, etc., can solve problems such as damage, waste of investment, and windproof reinforcement of poles, and achieve the effect of avoiding land acquisition and improving pullout resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

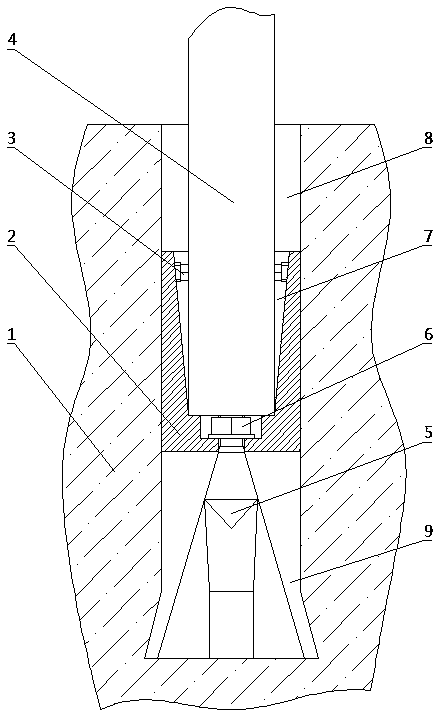

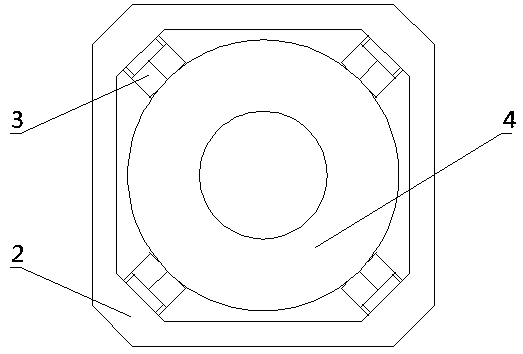

[0023] As shown in the figure, the foundation 2 is placed on the ground 1. After the foundation 2 is straightened, it can be directly driven or pressed into the ground with a beating or pressing machine. Connected to eliminate shipping and pressing difficulties. The base 2 bottom may have expansion plates in four directions, which can be increased or decreased depending on the actual situation. When the expansion plates in each direction are closed, they are internally provided with a tapered hole 9 that matches the two-way conical screw rod 5; The conical screw rod 5 can rise along the wall of the tapered hole all the time to reduce frictional resistance; after hitting or pressing into the ground, tighten the nut 6 to make the bidirectional conical screw rod 5 rise, and the expansion plate is opened in all directions, The lower part is claw-shaped to strengthen the stability and pull-out resistance of the foundation 2; the foundation 2 may be in a rectangular shape, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com