Phase change microcapsule and preparation method thereof

A phase change microcapsule and phase change material technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of large particle size of phase change microcapsules, long production cycle, complex production process, etc., and achieve easy industrialization. The effect of production, reduction of production cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention also discloses a preparation method of phase change microcapsules, comprising the following steps:

[0028] First, the oil phase component is mixed with the water phase component, and at a temperature of 20°C-50°C and a stirring speed of 10000r / min-20000r / min, the oil phase component The mixed liquid is emulsified for 10-30 minutes to obtain a stable and uniform emulsion.

[0029] Then, reduce the stirring speed to 200r / min-600r / min, heat the temperature to 60°C-90°C, start emulsion polymerization, react for 1-6 hours, and complete the polymerization of the phase change microcapsule shell.

[0030] Stop heating, keep the stirring speed at 200r / min-600r / min and stir until it cools down naturally to obtain a white liquid.

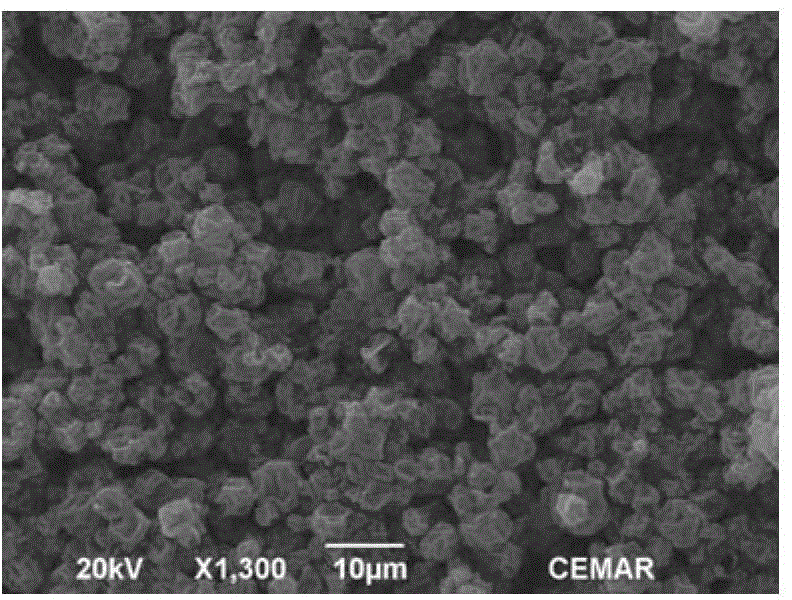

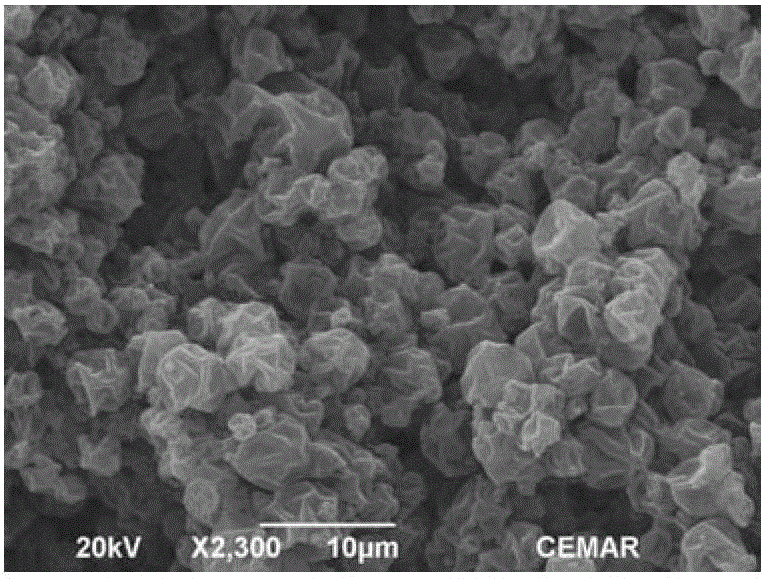

[0031] centrifuging and filtering the white liquid to obtain a white filter cake, washing the white filter cake with hot ethanol, and centrifuging and drying to obtain white phase-change microcapsule powder. The particle size of the whi...

Embodiment 1

[0046] Water phase component solution configuration: Add 0.2g of sodium dodecylbenzenesulfonate and 1.5g of 5% polyvinyl alcohol AH-26 (PVA) solution (dissolved and left overnight) to 100ml in distilled water. After mixing, place in a 35°C water bath and stir until the solution is clear and the temperature of the solution is constant.

[0047] Oil phase component solution configuration: 3.5g of n-octadecane, 2.5ml of styrene, 2.5ml of methyl methacrylate, 2ml of acrylic acid, 1ml of divinylbenzene, and (di)benzoyl peroxide (alias peroxide Add 0.05g of benzoyl peroxide (BPO for short) into a 50ml beaker and stir until (di)benzoyl peroxide (BPO) is fully dissolved and the solution is clear.

[0048] Add the oil-phase component solution to the water-phase component solution, keep the water bath at 35°C, use a high-speed shear mixer at a stirring speed of 12000r / min, emulsify for 20min, and transfer the emulsion to a 4-necked flask. At a water bath temperature of 35°C and a stir...

Embodiment 2

[0050] Water phase component solution configuration: Add 0.2g of sodium lauryl sulfate and 1.5g of 5% polyvinyl alcohol AH-26 (PVA) solution (dissolved overnight) into 100ml of distilled water. After mixing, place in a 35°C water bath and stir until the solution is clear and the temperature of the solution is constant.

[0051] Oil phase component solution configuration: 3.5g of n-octadecane, 2.5ml of styrene, 2.5ml of propyl acrylate, 2ml of acrylic acid, 1ml of diethylmethacrylate, and 0.1g of azobisisobutyronitrile (AIBN) Add it to a 50ml beaker and stir until the azobisisobutyronitrile (AIBN) is fully dissolved and the solution is clear.

[0052] Add the oil phase component solution to the water phase component solution, keep the water bath at 35°C, use a high-speed shear mixer at a stirring speed of 12000r / min, emulsify for 20 minutes, and transfer the emulsion to a 4-necked flask. At a water bath temperature of 35°C and a stirring speed of 400r / min, after passing nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com