A Three-Stage Anchor Combined Hollow Grouting Anchor

A grouting bolt, three-stage technology, used in the installation of bolts, sheet pile walls, mining equipment, etc., can solve the problem of uniform stress on the backing plate and the wall and buffer rock vibration, can not be anchored in the center, and will leak air Even problems such as leakage of mortar can be achieved to reliably stabilize the anchoring strength, improve the pull-out strength, and prevent the mortar from overflowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

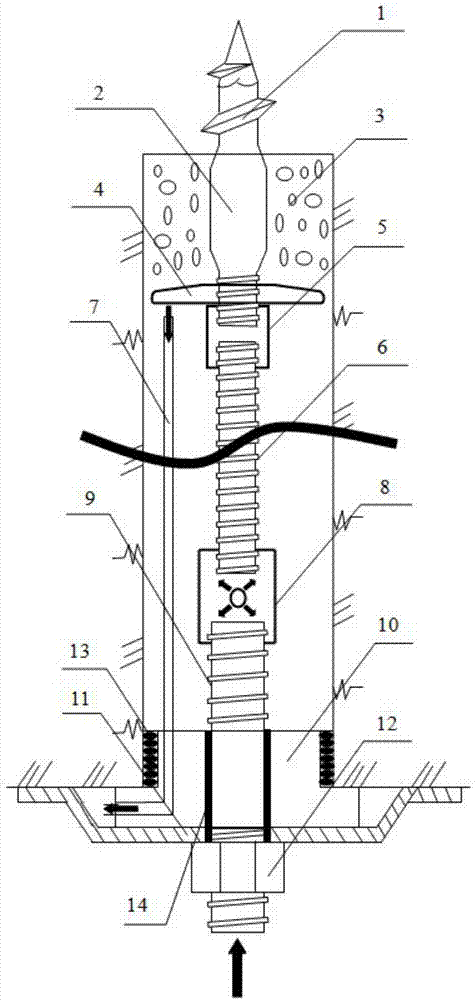

[0027] like figure 1 As shown, the new three-stage anchoring hollow bolt mainly includes: a new anchor head (the main anchor head 1 with the helical blade whose diameter gradually increases, the secondary anchor head 2 with equidistant threads at the rear end), and the inner side with equidistant threads Metal pressure ring 4, threaded front connector 5 on the inner side of the front and rear ends, solid threaded steel bar body 6, rear connector 8 with threads on the inner side of the front and rear ends, hollow grouting anchor body 9 (the bottom end is coated with a silicone protective layer ), a grout stopper 10 with an exhaust hole, a threaded backing plate 11 on the inner side of the middle, a nut 12 for fixing, and an exhaust hose 7 that can be connected with the grout stopper vent hole.

[0028] The inner side of the upper and lower ends of the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com