Concrete member plug connector and connection structure

A plug-in joint, concrete technology, applied in the direction of building structure, construction, etc., can solve problems such as plug-in failure, achieve the effect of convenient plug-in, large friction, and prevent poor or failure of plug-in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

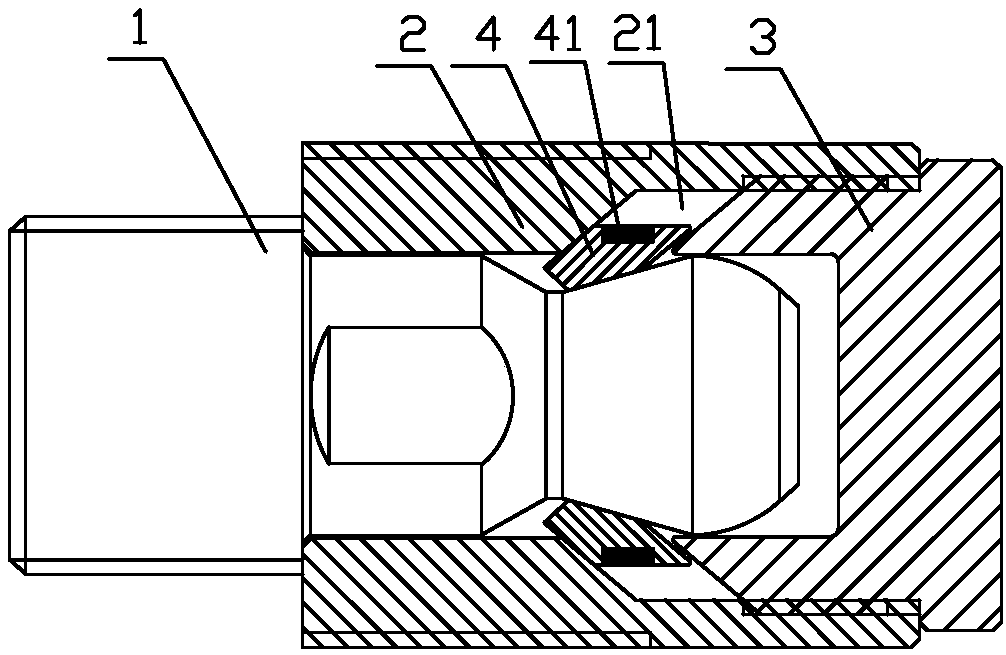

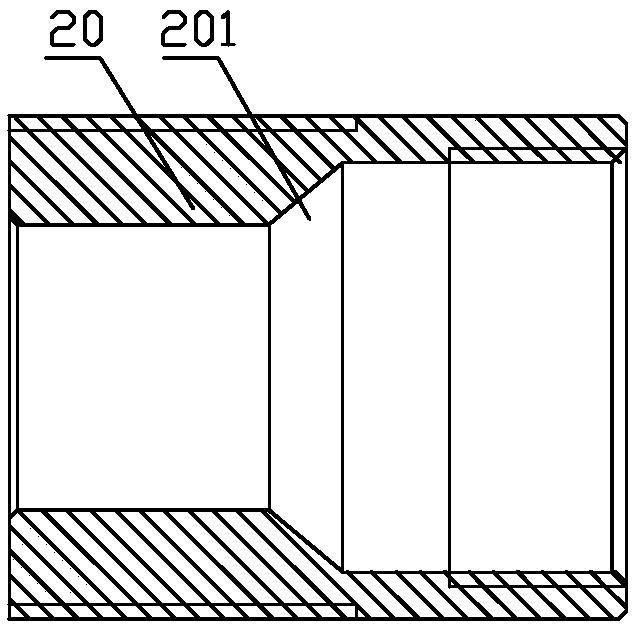

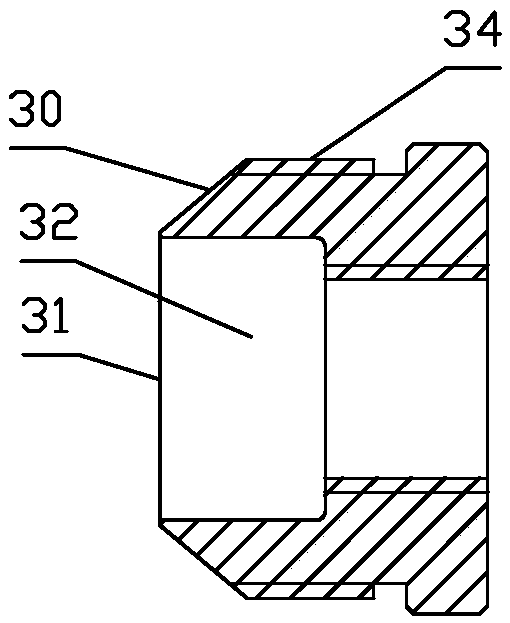

[0030] Such as figure 1 As shown, a plug joint for concrete components includes a plug 1 , a connecting sleeve 2 , a guide 3 and a split snap ring 4 . Such as figure 2 As shown, the inner side of one end of the connecting sleeve 2 is provided with a radially inwardly protruding card platform 20, and the other end is fixed with the guide 3. In this embodiment, the guide 3 is fixed on the connection by a thread 34. In the sleeve 2, the clamping table 20 is provided with a frusto-conical clamping surface 201 at one end facing the guide member 3, such as Figure 3a and Figure 3b As shown, the end of the guide member 3 facing the card table 20 is a guide end 31, and the guide end 31 is provided with a frustum-conical guide surface 30, so that the guide end 31 is in a frustum-shaped structure. The surface 201 and the guide surface 30 are opposite to form a guide groove 21 for accommodating the split snap ring. The guide end 31 is provided with a correction cavity 32 capable of ...

Embodiment 2

[0038] Such as Figure 7 and Figure 8 As shown, a concrete component connection structure includes the concrete component plug joint disclosed in the present invention, and also includes a first end plate 50 and a second end plate 51, and the plug 1 is fixed on the first end plate 50, the connecting sleeve 2 is fixed on the second end plate 51, and the first end plate 50 and the second end plate 51 are fixed to each other by bonding or welding, specifically by sticking steel glue or The edges are fully welded for fixation.

[0039] In this embodiment, the first end plate 50 and the second end plate 51 have the same structure, such as Figure 9 As shown, the first end plate is provided with a first fixing hole 500, and the second end plate is provided with a second fixing hole 510. In this embodiment, since the first end plate and the second The end plates have the same structure, so the labels of the first fixing hole and the second fixing hole are marked in the same figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com