Prestressed expanded-head anti-floating anchor rod and construction method

A technology of anti-floating anchor rod and enlarged head, which is used in infrastructure engineering, wine cellars, buildings, etc., can solve the problems of unconsidered corrosion of metal anchor rods, complicated expansion of reinforcement cages, and unconsidered corrosion of tendons. Reduce the possibility of shear damage, simple and fast construction, and enhance the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

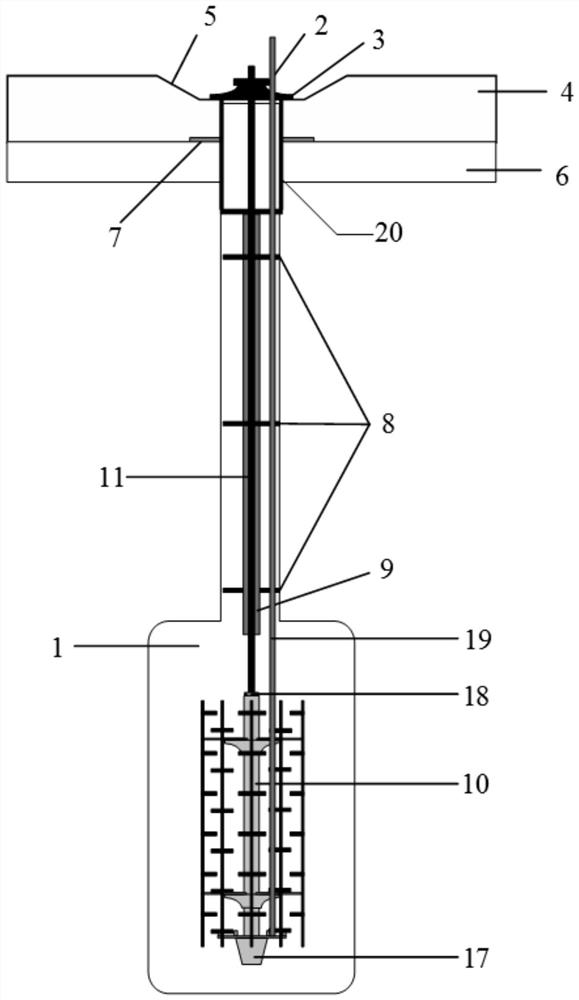

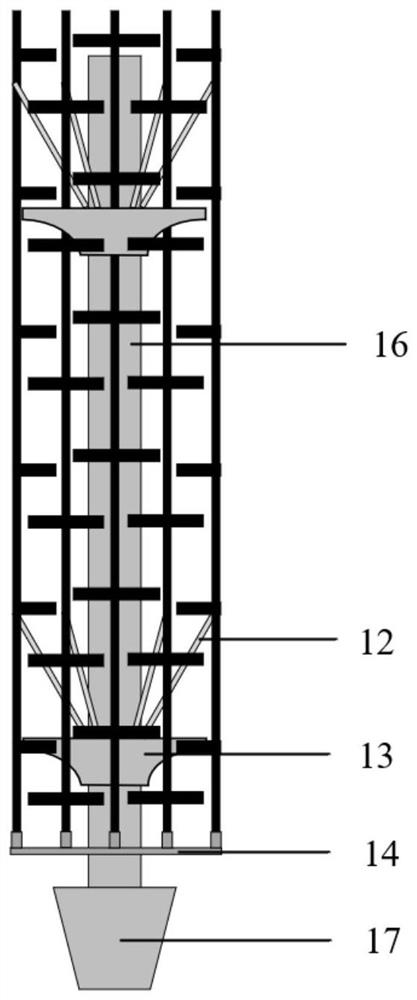

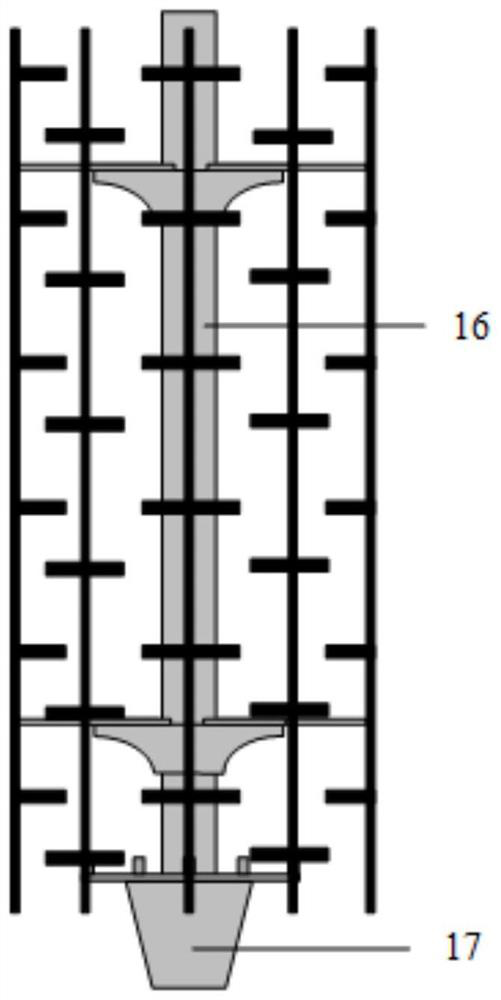

Embodiment 1

[0049] The structure of the prestressed anti-floating anchor with variable diameter expansion head described in this embodiment includes anchor drilling 1, fastening nut 2, stress diffusion anchor plate 3, building foundation bottom plate 4, anchor pit 5, foundation waterproof layer 6, anchor Bar anti-seepage layer 7, anchor centering device 8, anti-corrosion collar 9, variable diameter reinforcement cage 10, anchor bar body 11, grouting pipe 19 and second steel sleeve 20; anchor bore 1 is upper narrow The lower width structure, the anchor rod body 11 is placed in the anchor rod borehole 1, the anchoring section of the anchor rod body 11 is equipped with a variable diameter reinforcement cage 10, and the variable diameter reinforcement cage 10 is composed of a connecting steel rod 12, a stress diffusion tray 13, The steel cage fixer 14, the hoop stirrup 15, the first steel sleeve 16, the inverted tapered expanding head 17 and the steel sleeve fixer 18 are connected, and the bot...

Embodiment 2

[0067] In this embodiment, the specific process of constructing the anti-floating anchor rod of the prestressed enlarged head is as follows:

[0068] (1) Anchor hole positioning: Use a total station to measure the elevation of the construction site to determine the depth of the borehole, and at the same time carry out setting-out measurement. According to the elevation and horizontal distance required by the design, use a level and a steel ruler to determine the hole position, and do a good job. Marking, according to the anti-floating anchor technical specification (YB / T 4659-2018) and the relevant requirements of the design drawings, the error of the hole position setting out should not be greater than 20mm, and the mechanical positioning error should not be greater than 50mm;

[0069] (2) Drilling: Move the drilling rig according to the on-site setting-out line, so that the drill bit of the drilling rig moves to the center of the anchor hole, and then correct the drilling rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com