Method for isomerization of light hydrocarbon

A technology of isomerization and light hydrocarbons, which is applied in the field of isomerization of light hydrocarbons, can solve the problem of octane number limitation of isomerized gasoline products, and achieve the effect of improving single-pass conversion rate, high octane number, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

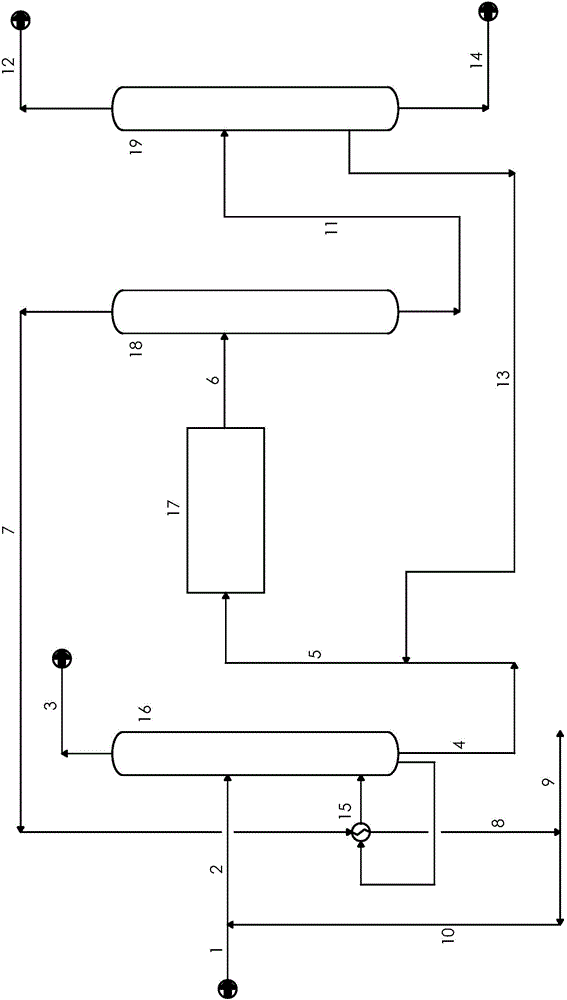

[0034] Embodiment 1 adopts attached figure 1 In the process scheme shown, the processing scale of the isomerization unit is 300,000 tons / year. The raw material for isomerization is light hydrocarbons that have undergone hydrotreating. In addition to C5 and C6 alkanes, it also contains a small amount of other components. The specific composition data is shown in Table 1. It can be seen from Table 1 that: The molar content of alkanes is 47.94%, of which isopentane accounts for 42.49% of the content of C5 paraffins; the molar content of C6 paraffins is 39.93%, of which dimethylbutane accounts for 7.29% of the content of C6 paraffins. The research octane number of the raw material is 67.5. The composition and properties of the isomerized gasoline product are also listed in Table 1, as can be seen from Table 1: isopentane in the isomerized gasoline product accounts for 95.15% of the C5 paraffin content, and dimethylbutane accounts for The content of C6 paraffins was increased to ...

Embodiment 2

[0038] Embodiment 2 also adopts the attached figure 1 The difference in the process flow scheme shown is that the gas phase stream drawn from the top of the depentanizer adopts a conventional condensation cooling method.

[0039] The isomerization raw material of Example 2 is the same as the raw material of Example 1, the process conditions of the isomerization reaction part of the two are also the same, and the separation precision of the deisopentanizer, depentanizer and deisohexane tower is also the same .

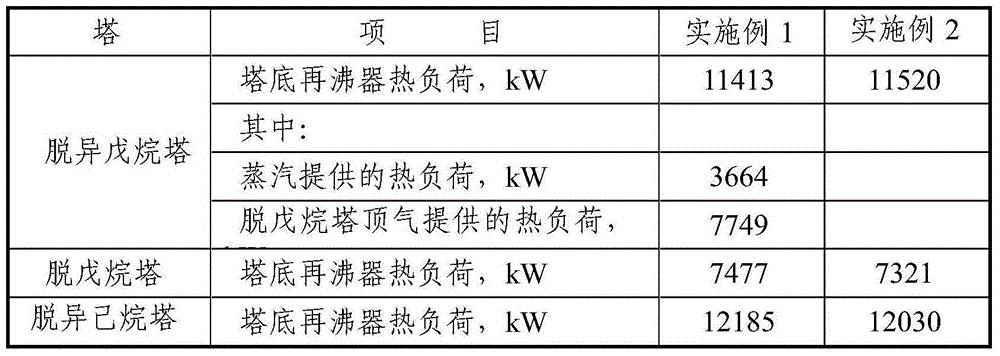

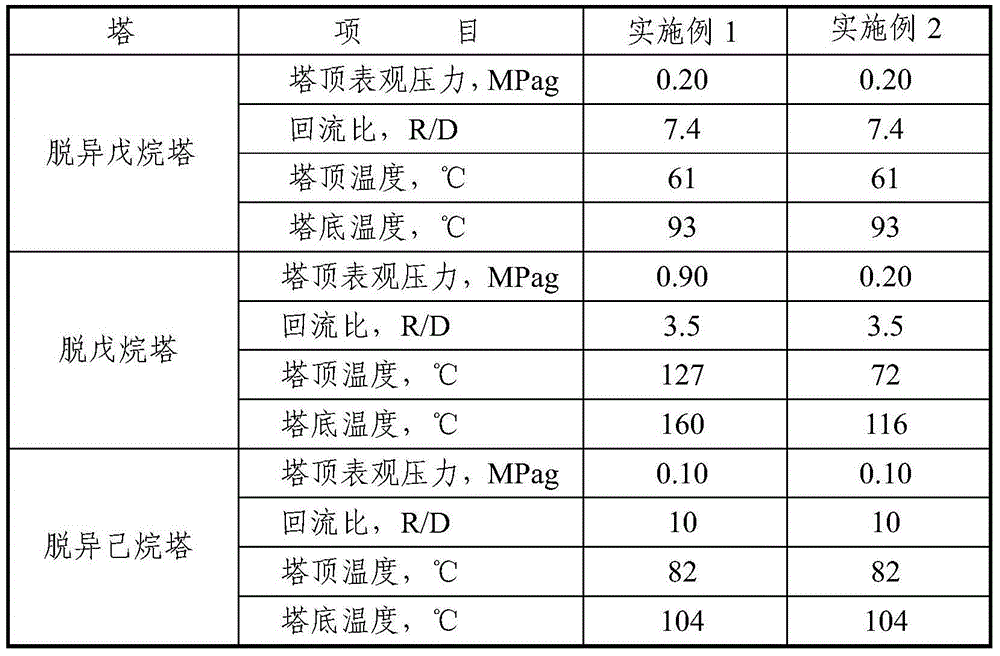

[0040] The operating conditions of the deisopentanizer, depentanizer and deisohexane tower in Example 2 are shown in Table 2, and the heat loads of the reboilers of the three towers are shown in Table 3. Since there is no need to consider the temperature of the gas phase at the top of the depentanizer, the depentanizer can be operated at a lower pressure.

[0041] The total heat load provided by the external heat source for the deisopentanizer, depentanizer and deisoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com