A kind of preparation method of di-tertiary peroxide

A technology of di-tert-butyl peroxide and di-tert-butyl peroxide, which is applied in the field of preparation of di-tert-based peroxide, can solve problems such as high safety risk, long reaction time, and strict requirements on feeding temperature, and achieve safety The effect of high stability, short reaction time and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

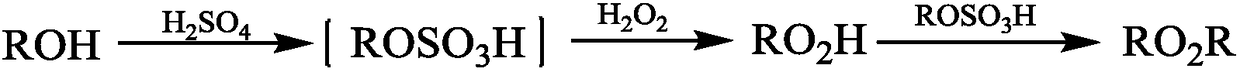

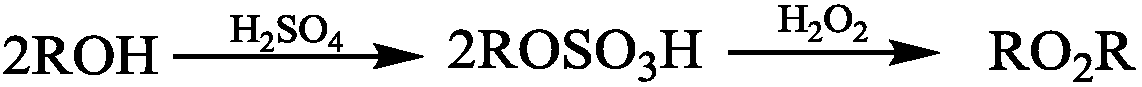

[0025] A kind of preparation method of di-tertiary base peroxide, tert-butanol, hydrogen peroxide, catalyzer are introduced in the micro-reaction device in continuous mode, and the total flow velocity that tert-butanol, hydrogen peroxide and catalyzer enters micro-reaction device is 5 ~30mL / min, that is, the sum of the flow rates of tert-butanol, hydrogen peroxide and catalyst is 5~30mL / min, so that tert-butanol and hydrogen peroxide undergo peroxidation reaction, the reaction temperature is 30~60℃, and the time is 26 ~218s, make the stream that comprises di-tert-butyl peroxide, then draw the stream that comprises di-tert-butyl peroxide from the micro-reaction device, separate, wash with water, dry to obtain di-tert-butyl peroxide, Wherein catalyzer is the sulfuric acid that mass concentration is 98%;

[0026] Wherein the molar ratio of tert-butanol to peroxide is 1:2~1:2.2, and the catalyst consumption accounts for 10~20% of the total mass of tert-butanol, hydrogen peroxide a...

Embodiment 1

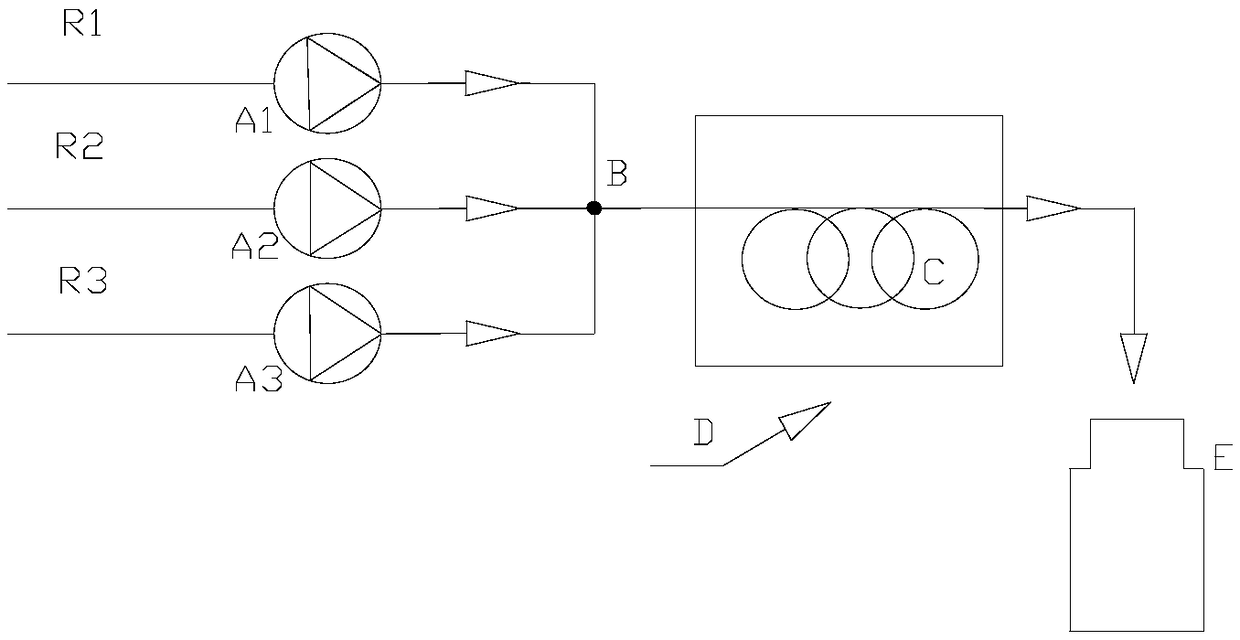

[0029] Such as figure 1 As shown, tert-butanol, hydrogen peroxide, and sulfuric acid are transported into the micro-mixer B by the first micro-advection pump A1, the second micro-advection pump A2, and the third micro-advection pump A3 (T-shaped stainless steel tee, inner diameter 0.5 mm), uniform mixing reaction, the total feed rate is 5mL / min, the mol ratio of tert-butanol to hydrogen peroxide is 1:2, and the sulfuric acid consumption is 10% of the overall material quality. The length of microreactor C is 10m, placed in thermostat D (30°C), and the reaction residence time is 26s. The material enters the product collector E after fully reacting in the microreactor. After the crude product was separated, washed with water and dried, the peroxide components were analyzed by gas chromatography. The content of di-tert-butyl peroxide was 89.7%, and the content of mono-tert-butyl peroxide was 10.2%. The conversion rate of tert-butanol is 98.1%.

Embodiment 2

[0031] Such as figure 1 As shown, tert-butanol, hydrogen peroxide, and sulfuric acid are transported into the micro-mixer B by the first micro-advection pump A1, the second micro-advection pump A2, and the third micro-advection pump A3 (T-shaped stainless steel tee, inner diameter 0.5 mm), uniform mixing reaction, the total feed rate is 5mL / min, the mol ratio of tert-butanol to hydrogen peroxide is 1:2.02, and the sulfuric acid consumption is 10% of the overall material quality. The length of microreactor C is 10m, placed in thermostat D (30°C), and the reaction residence time is 26s. The material enters the product collector E after fully reacting in the microreactor. After the crude product was separated, washed with water and dried, the peroxide components were analyzed by gas chromatography. The content of di-tert-butyl peroxide was 91.6%, and the content of mono-tert-butyl peroxide was 8.2%. The conversion rate of tert-butanol is 99.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com