Trichlorosilane rectification process

A technology of trichlorosilane and process, which is applied in the field of rectification of trichlorosilane, can solve the problems of increasing the energy consumption of a rectifying tower due to the feed temperature, and achieve the advantages of reducing steam consumption, increasing the feed temperature and saving electric energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

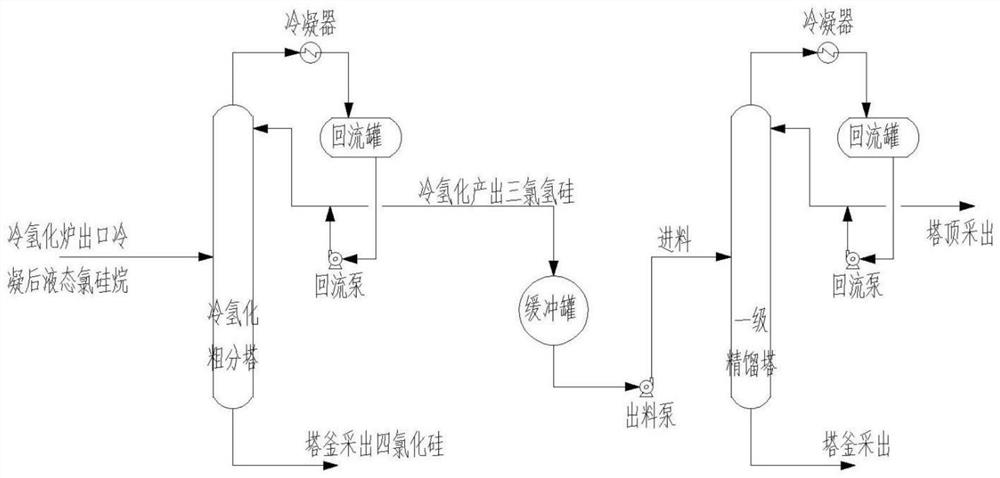

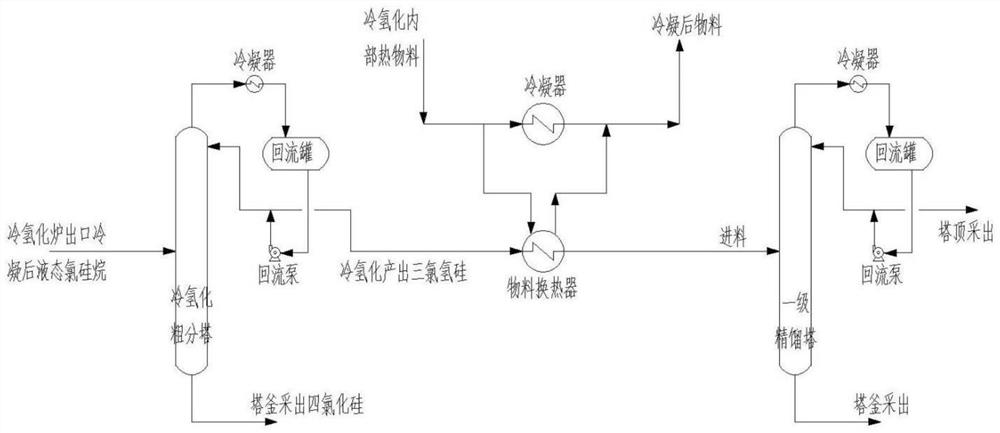

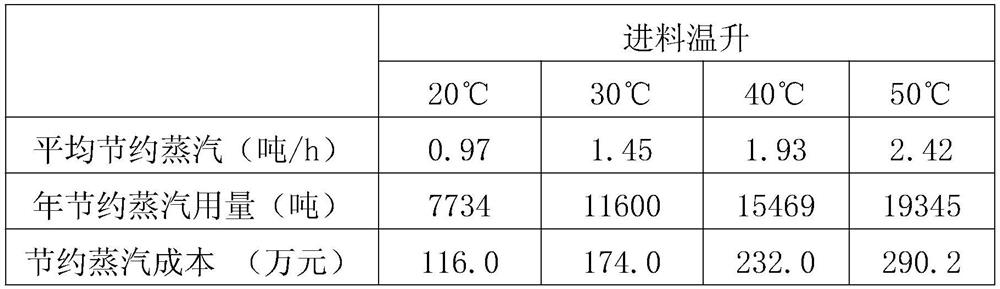

[0029] The reaction furnace outlet was discharged from the liquid mixture obtained by cold-bonded separation, and the liquid mixture of silicon tetrachloride was required, and it is necessary to pass through a rectification column (referred to as a cold hydrogenated coarse tower) to combine trichloride and tetrachloride. Departure. The impurity content in the isolated trichloride is too high as the requirements of the production of polysilicon, and is required to be sent to the rectification system for multi-stage rectification purification. Due to the multifestine silicon in the top of the coarse column, the cooling medium of air cooling, water cooling or even lower temperature is cooled, and the temperature of the top elimination of trichloride is between 20-50 ° C, and the rectification system first-stage tower The material plate temperature is more than 70-90 ° C, and the feed temperature is obviously low.

[0030] The use of a partial material having a cold hydrogenation furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com