Kerosene-hydrogenation production process and system

A production process and jet fuel technology, which is applied in the production process field of jet fuel hydrogenation, can solve the problems of high energy consumption, low energy recovery and utilization rate of the device, etc. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

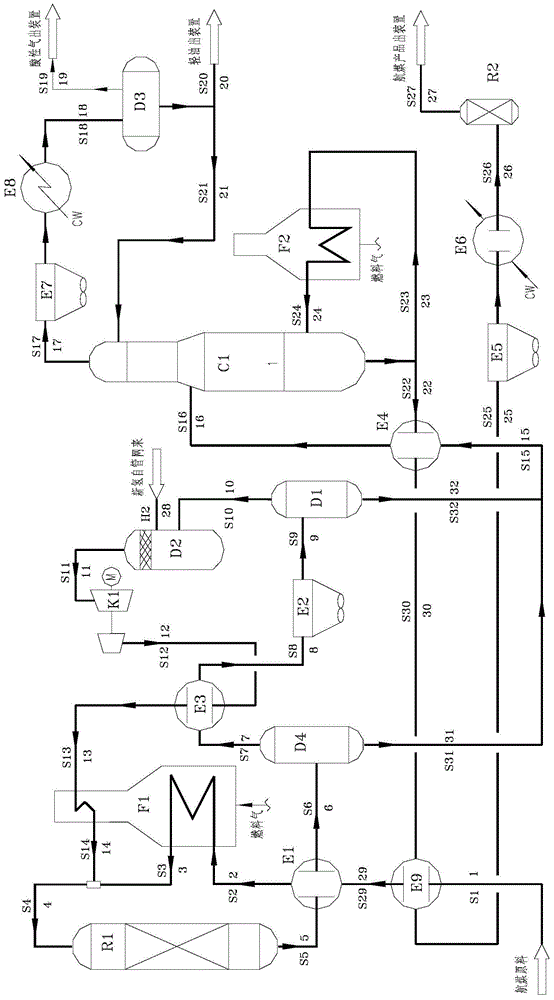

[0096] This embodiment adopts the hydrogen mixing heat high-pressure separator process in front of the furnace, and the process flow is shown in the attached figure 2 .

[0097] (1) Reaction part

[0098]The pressurized aviation kerosene raw material S1 (40°C, 166 tons / hour) is first exchanged in the heat exchanger E9 with the jet kerosene product S30 from the hot side outlet of the heat exchanger E4 to about 138°C, and then with the circulating hydrogen S14 is mixed via pipeline 29. The vapor-liquid mixture is heated to 245°C through the heat exchanger E1 and the reaction product S5, then enters the raw material heating furnace F1 through the pipeline 3 and is heated to 260°C, and then enters the jet fuel sweetening reactor R1 through the pipeline 4.

[0099] The operating condition of jet fuel sweetening reactor R1 is 2.0MPa, 260°C. Hydrogenation reaction occurs in jet coal sweetening reactor R1, and non-hydrocarbon compounds such as sulfur, oxygen, and nitrogen in fuel o...

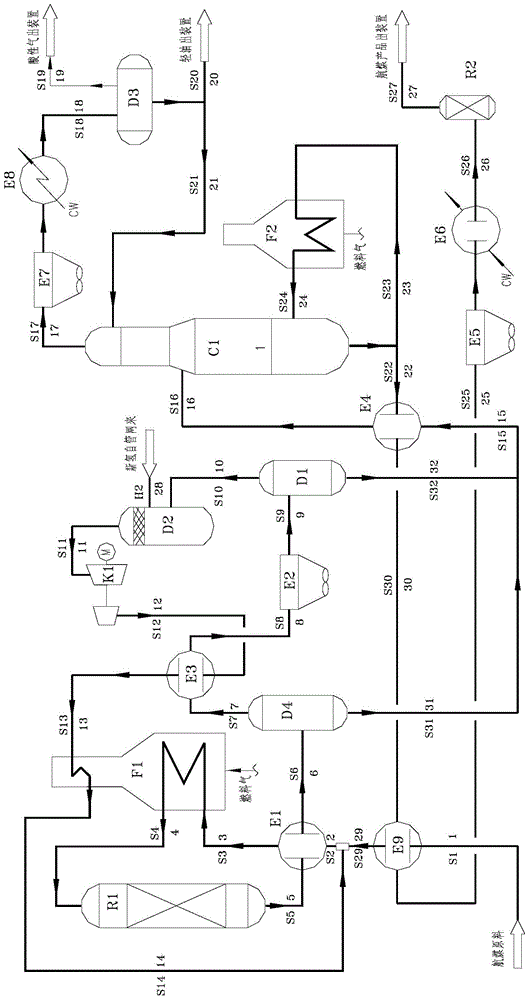

Embodiment 3

[0111] When the hydrogen mixing process after the furnace is adopted, the following procedures are included (see attached image 3 )

[0112] (1) Reaction part

[0113] After the jet fuel raw material is pressurized, it first passes through the heat exchanger E1 to exchange heat with the reaction product, then enters the raw material heating furnace F1 to be heated, and then mixes with circulating hydrogen, and then enters the jet fuel sweetening reactor R1.

[0114] The hydrogenation reaction takes place in the jet fuel sweetening reactor R1, the sulfur, oxygen, nitrogen and other non-hydrocarbon compounds in the fuel oil are effectively removed, and at the same time, some olefins and aromatics are hydrogenated and saturated.

[0115] The reaction product comes out from the bottom of the aviation coal sweetening reactor R1, first passes through the heat exchanger E1 to exchange heat with the raw material, and then enters the hot high-pressure separator D4, and the hydrogen-r...

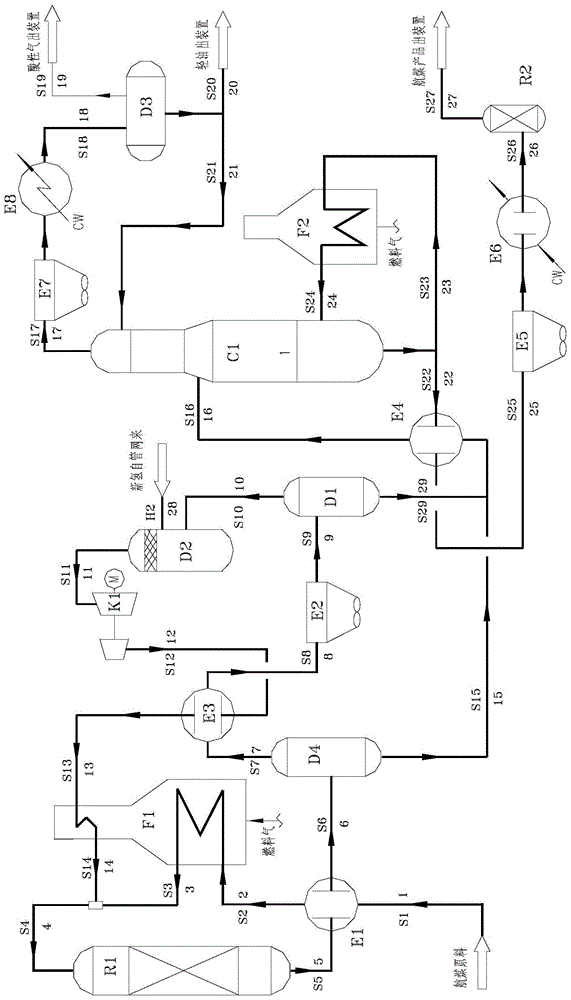

Embodiment 4

[0123] When using the hydrogen mixing process in front of the furnace, the following procedures are included (see attached Figure 4 )

[0124] (1) Reaction part

[0125] The raw material of jet fuel is pressurized and mixed with circulating hydrogen, first passes through the heat exchanger E1 to exchange heat with the reaction product, then enters the raw material heating furnace F1 for heating, and then enters the jet fuel sweetening reactor R1.

[0126] The hydrogenation reaction takes place in the jet fuel sweetening reactor R1, the sulfur, oxygen, nitrogen and other non-hydrocarbon compounds in the fuel oil are effectively removed, and at the same time, some olefins and aromatics are hydrogenated and saturated.

[0127] The reaction product comes out from the bottom of the aviation coal sweetening reactor R1, first passes through the heat exchanger E1 to exchange heat with the raw material, and then enters the hot high-pressure separator D4, and the hydrogen-rich vapor p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com