Reforming heat recycling technology and device

A technology of heat recovery and process, which is applied in the field of refining and chemical production, can solve the problems of optimal design of unproduct fractionation unit, unexplained heating load of fractionation part, etc., and achieve the effect of reducing steam consumption, reducing fuel consumption and reducing heating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

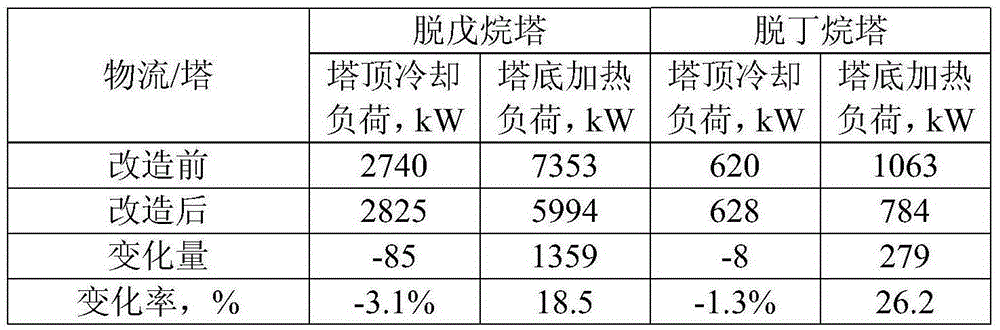

[0027] Taking the 1.2 million tons / year reforming unit of a certain oil refinery as an example, the reforming heat recovery and utilization method of the present invention is illustrated.

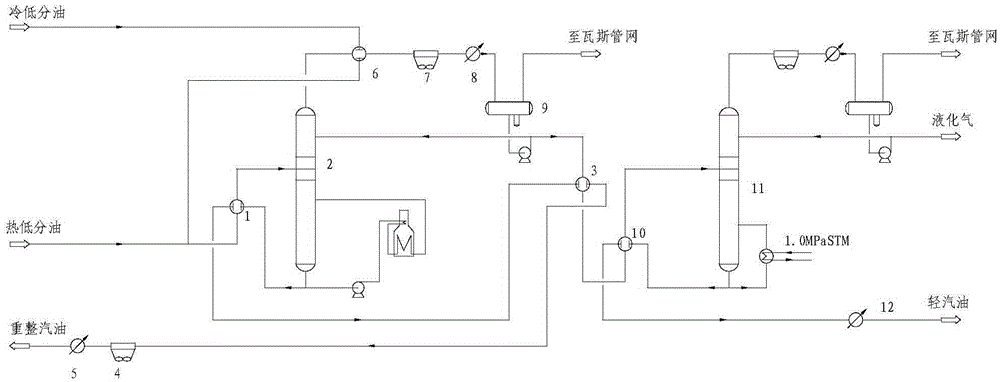

[0028] The technological process in the prior art is:

[0029] Feed to the depentanizer from the oil-gas separation unit of the reforming reaction (40°C, mainly C 5 -C 10 Component) enters the depentanizer feed-column bottom heat exchanger 1, exchanges heat with the depentanizer bottom oil to 165°C, and enters the depentanizer 2. Depentanizer overhead oil gas (110°C, C 5 The following components) enter the air cooler 7 and water cooler 8, cool to 40°C, enter the reflux tank 9 for gas-liquid separation, the gas phase enters the gas pipe network, the liquid phase is partially refluxed after pressurization, and partly enters the debutanizer for feeding - The tower bottom heat exchanger 10, exchanges heat with the debutanizer bottom oil to 75°C, enters the debutanizer 11, and separates light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com