Horizontal push-flow anaerobic dry fermentation device and process for organic waste

A technology of organic waste and dry fermentation device, applied in biochemical cleaning device, enzymology/microbiology device, bioreactor/fermenter combination, etc., can solve the problem of affecting gas production, low volume gas production rate and waste of resources and other problems, to ensure the retention period, improve the yield, and improve the gas production rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

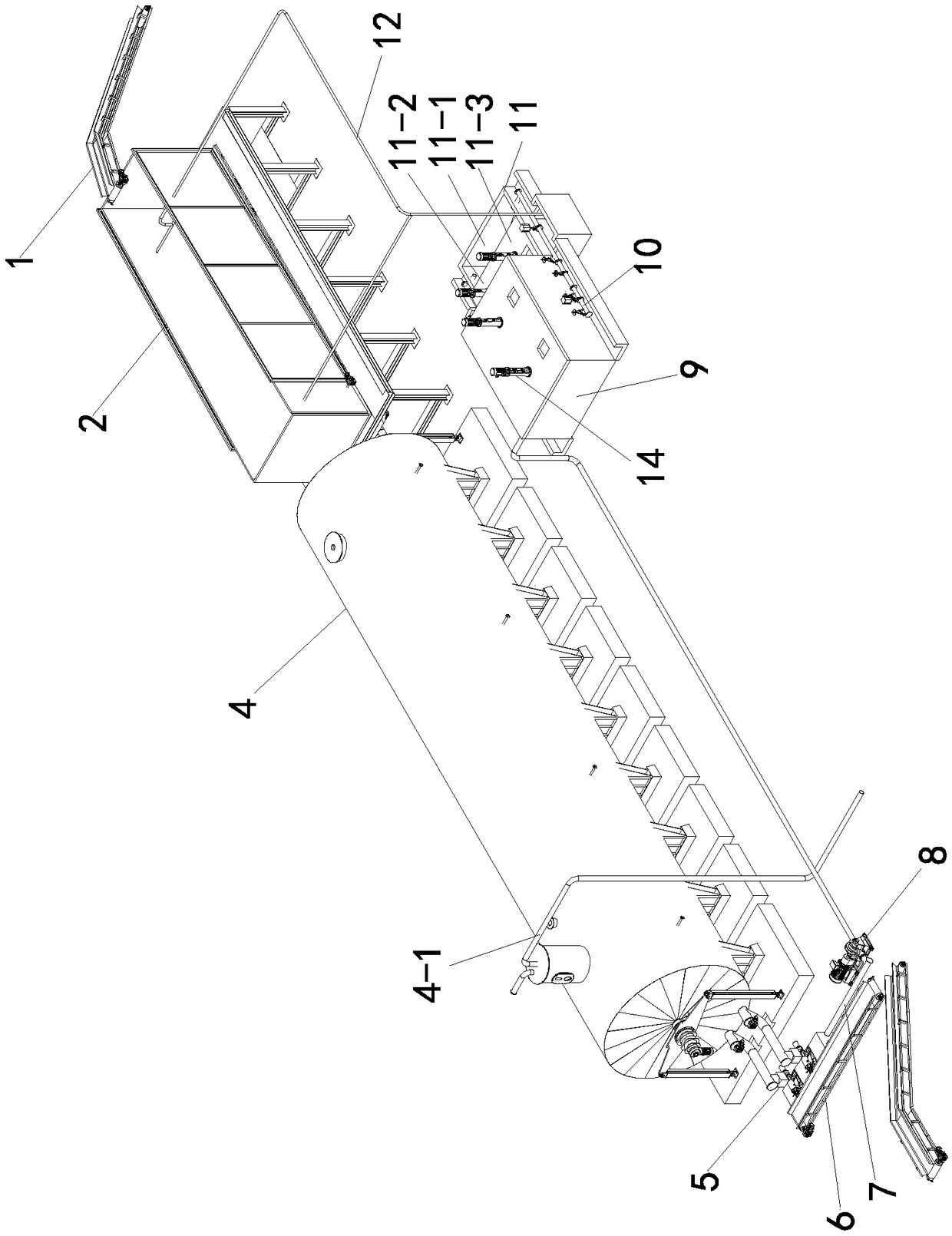

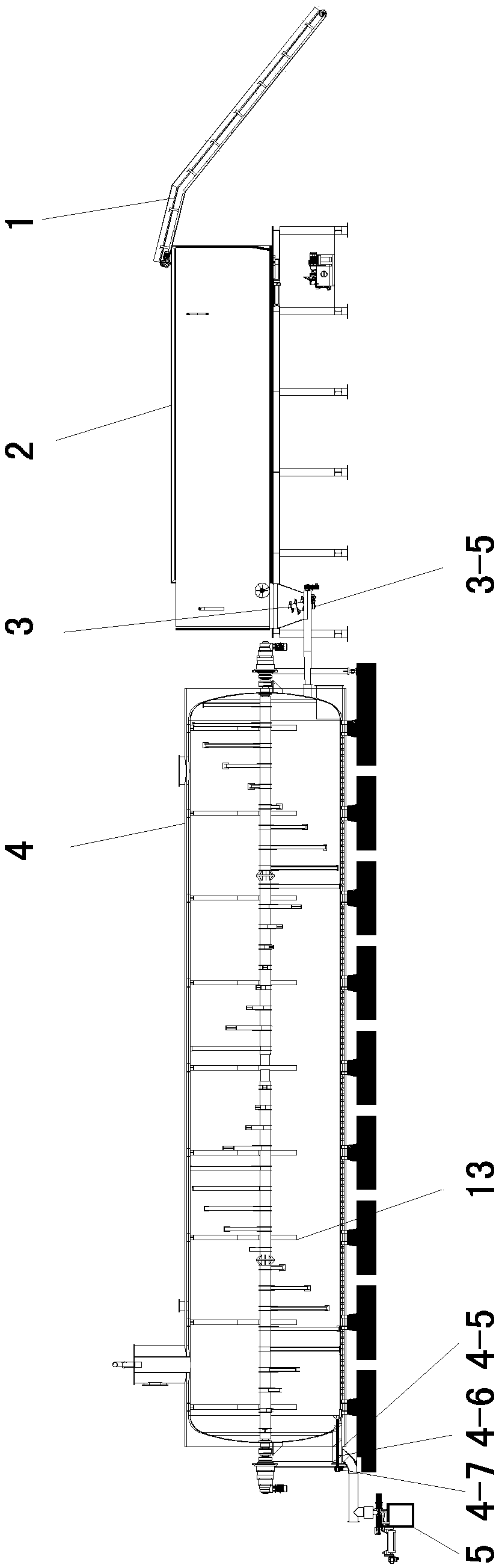

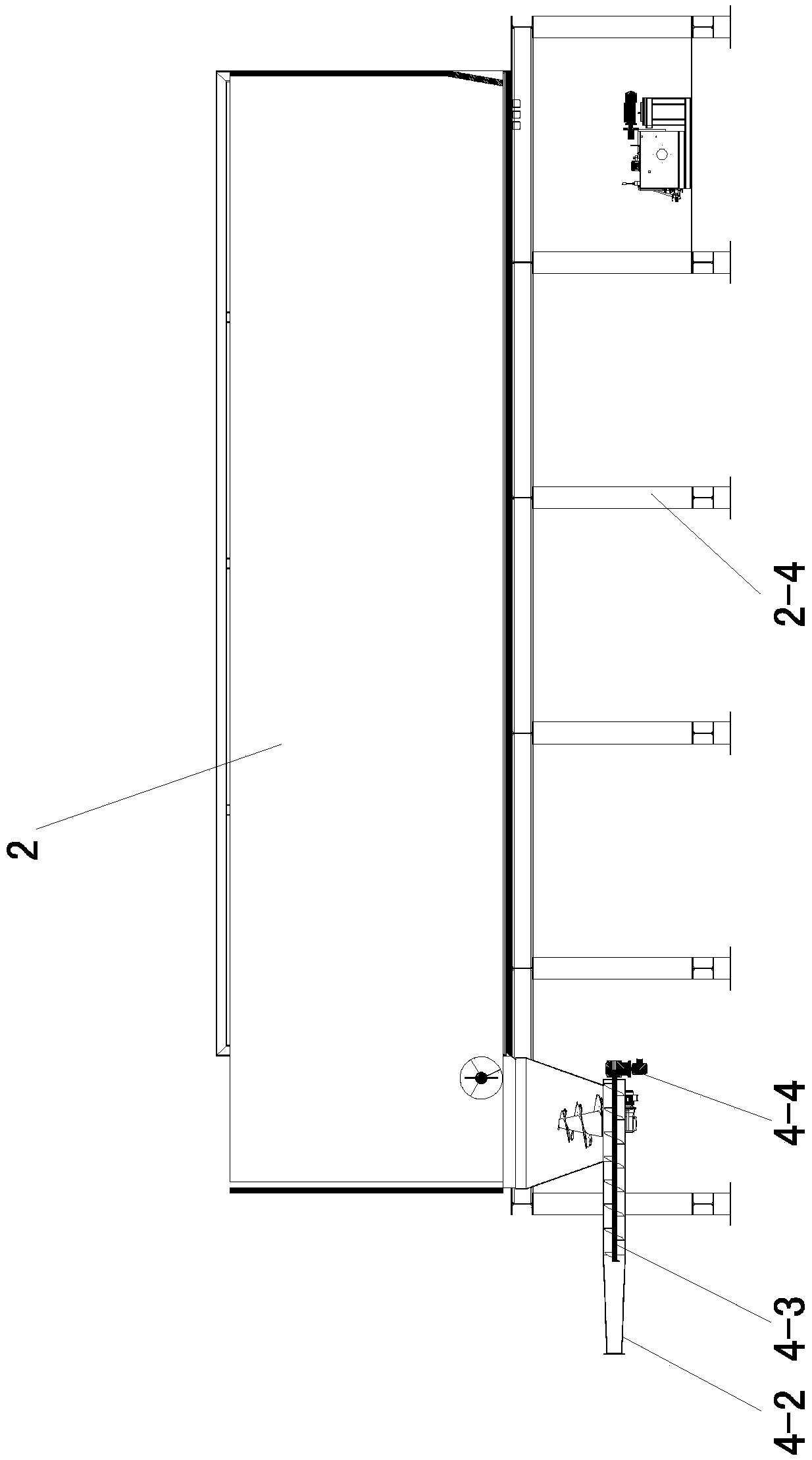

[0038] Such as Figure 1 to Figure 16As shown, a horizontal plug-flow anaerobic dry fermentation device for organic waste, including conveyor belt 1, pretreatment tank 2, feeder 3, anaerobic fermentation tank 4, press 5, conveyor belt 2 6, biogas liquid conduit 7, biogas slurry tank 9, delivery pipe 10, cow dung tank 11, water spraying pipeline 12 and plug-flow stirring shaft 13; the conveyor belt 1 transports the organic waste to the pretreatment tank 2 for stacking and retting, The feed end of described pretreatment pool 2 and the discharge end are all provided with drenching pipeline 12, and the discharge end of pretreatment pool 2 is provided with feeder 3, and described feeder 3 and anaerobic fermentation tank 4 The feed port is connected and the organic waste is transported to the anaerobic fermentation tank 4 for fermentation, and the biogas output pipe 4-1 provided with the anaerobic fermentation tank 4 is connected to an external gas transmission line to output the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com