Method and equipment for improving selectivity of low-carbon olefins

A low-carbon olefin and selectivity technology, which is applied in the field of olefin preparation, can solve the problem of low selectivity of low-carbon olefins, and achieve the effects of improving the selectivity of low-carbon olefins, wide application range, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

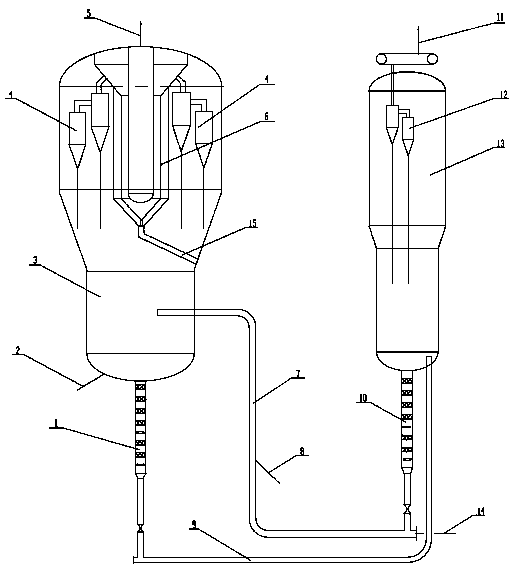

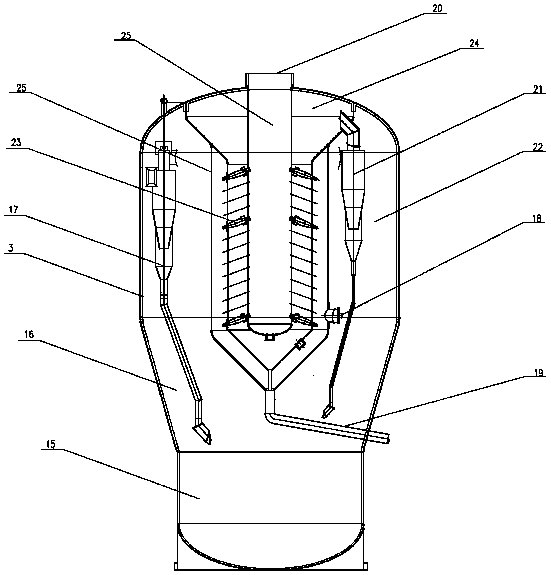

[0050] Such as figure 1 As shown, the raw material oxygen-containing compound 2 (mainly including methanol, dimethyl ether, C4-C10 alcohol compound or its mixture) enters the reactor 3 after preheating, and the oxygen-containing compound 2 in the reactor 3 is mixed with the 7, the high-temperature regenerated catalyst is in direct contact, and the exothermic reaction is carried out rapidly on the surface of the catalyst. The reaction oil gas 5 generated by the reaction is removed by the two-stage cyclone separator 4 of the reactor to remove most of the catalyst carried, and then removed by the built-in separation facility 6. After the catalyst is removed, it is drawn from the top of the reactor 3 and sent to the rear quenching water washing system after heat exchange. The catalyst recovered by the built-in separation facility 6 is discharged out of the reactor 3 through the spent catalyst delivery pipe 19 . After the reaction, the coke-deposited catalyst enters the standby st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com