System and method for recovering alcohol ketone by using thermal energy of wastewater

A heat recovery and waste water technology, which is applied in the field of cyclohexanone refining, can solve the problems of waste of resources such as alcohol and ketone, waste of energy, increase of waste water treatment cost, etc., and achieve the effect of saving the use of external energy and increasing the feed temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The solution of the present invention will be further described below in combination with specific embodiments and accompanying drawings.

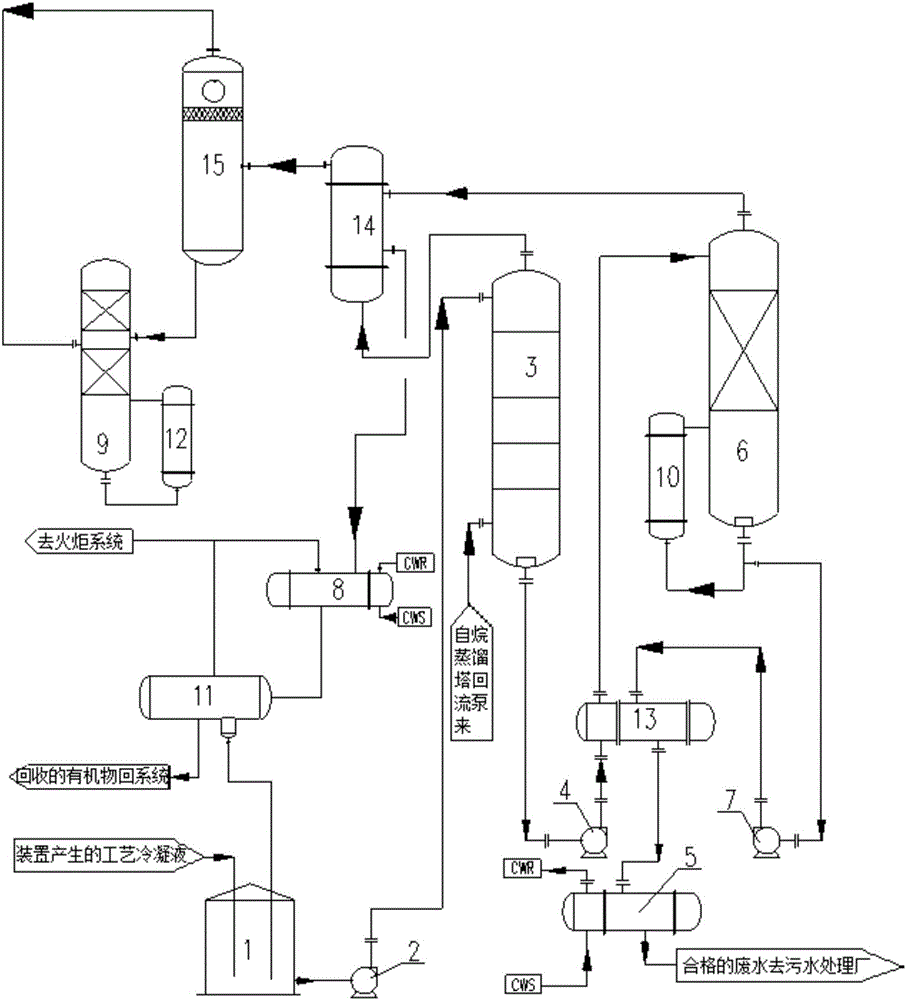

[0038] Such as figure 1 Shown, a kind of system that utilizes waste water heat energy to reclaim ketone alcohol, the tower top inlet of extraction tower 3 is communicated with the water inlet pipeline of the process condensed water that contains ketone alcohol, the tower top outlet of waste water stripping tower 6 is fed with alkane distillation tower The heat medium passage inlet of preheater 14 is connected, and the heat medium passage outlet of alkane distillation column feed preheater 14 is communicated with the heat medium passage entrance of waste water condenser 8; The cold medium inlet of alkane distillation tower feed preheater 14 It is communicated with the tower top outlet of extraction tower 3, and the cold medium outlet of alkane distillation tower feed preheater 14 is communicated with the inlet of alkane distillation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com