Oil atmospheric vacuum distillation technology

A technology of atmospheric and vacuum distillation and petroleum, which is only applied in the direction of multi-stage series refining process treatment, etc. It can solve the problems of affecting the vacuuming effect of the vacuum tower, affecting the vacuum extraction rate, and low energy utilization efficiency, and achieves the goal of equipment The possibility of burning through is reduced, the effect of environmental protection is good, and the effect of energy saving is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

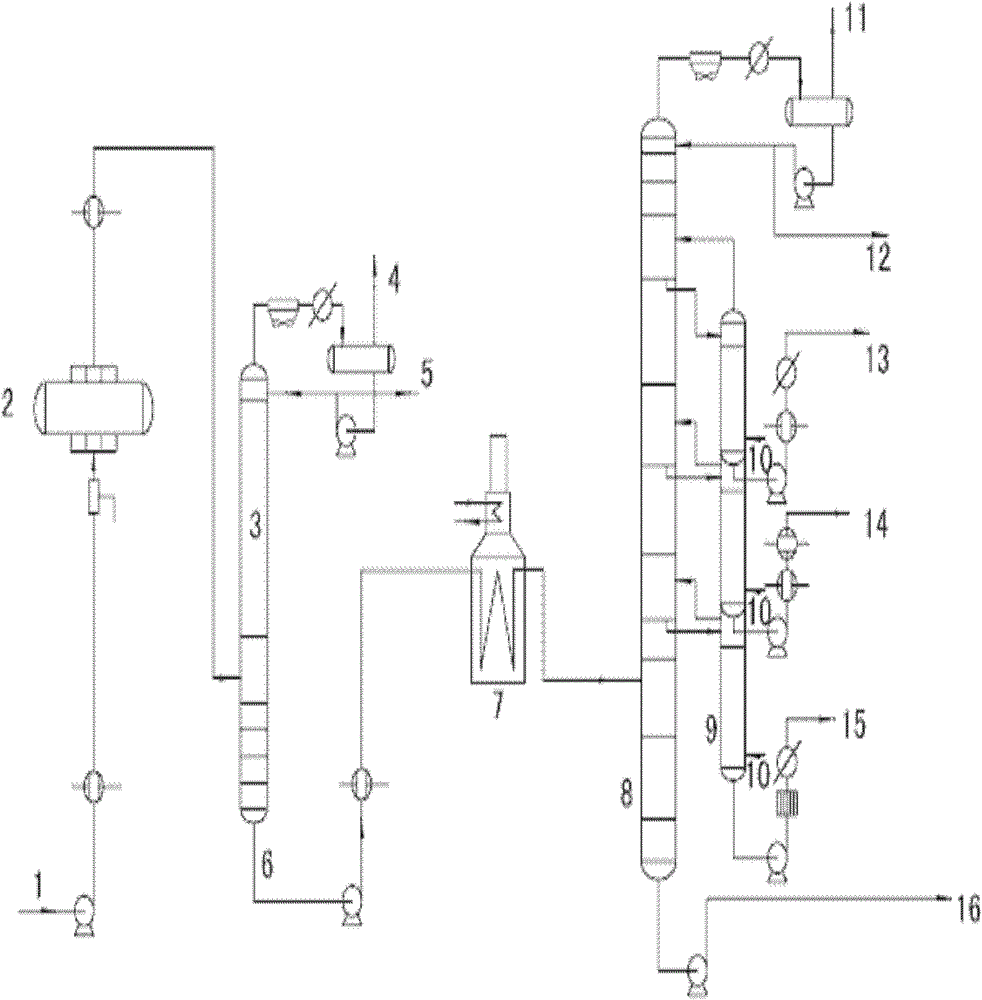

[0018] Such as figure 1 As shown, the oil 1 is heated to 100°C-150°C, and then enters the electric desalination tank 2 for desalination and dehydration. The temperature is 80°C-160°C, the temperature at the bottom of the tower is 180°C-245°C, the top of the tower is equipped with a reflux at the top of the tower to extract the initial distillation tower top gas 4 and the initial distillation tower top oil 5, and the initial distillation tower bottom oil 6 enters the atmospheric furnace after heat exchange 7 After heating to 320°C-370°C, enter the atmospheric tower 8, the operating conditions of the atmospheric tower 8 are: tower top temperature 110°C-150°C, tower top gauge pressure 0.04MPa-0.10MPa, tower bottom temperature 305°C-365°C . The atmospheric pressure tower top gas 11 and the atmospheric pressure tower top oil 12 are extracted from the top of the tower, and the atmospheric pressure tower bottom oil 16 is extracted from the bottom of the atmospheric pressure tower. T...

Embodiment 2

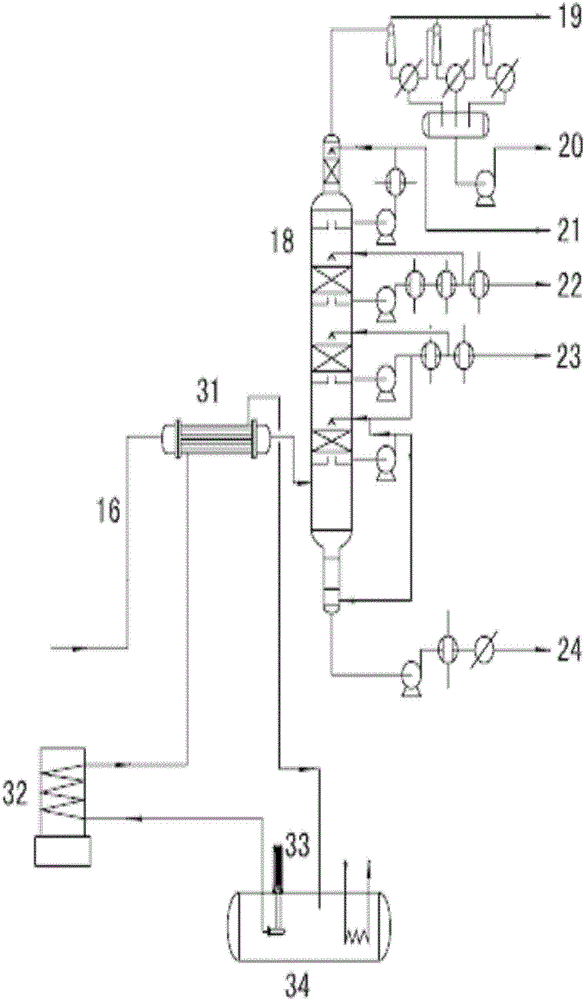

[0020] figure 2 Single-stage distillation is used for the vacuum distillation part, and the heating furnace before the vacuum tower is changed to a partition wall heat exchanger for heat exchange between molten molten salt and petroleum feed. As shown in the figure, the atmospheric tower bottom oil 16 enters the molten salt heat exchanger 31 to be heated to 360°C-440°C and then enters the decompression tower 18. Operate at a pressure of 5-100mmHg and a tower bottom temperature of 345°C to 425°C; the decompression tower 18 and the top pipe 19 are connected to the vacuum facility to extract the top gas and maintain the vacuum at the top of the tower, and draw out the decompression diesel oil 20 from the top reflux. The decompression tower 18 can be equipped with 3 to 4 side lines according to the needs. The figure shows the situation of setting up 3 side lines. 24 is also extracted from the device after heat exchange.

Embodiment 3

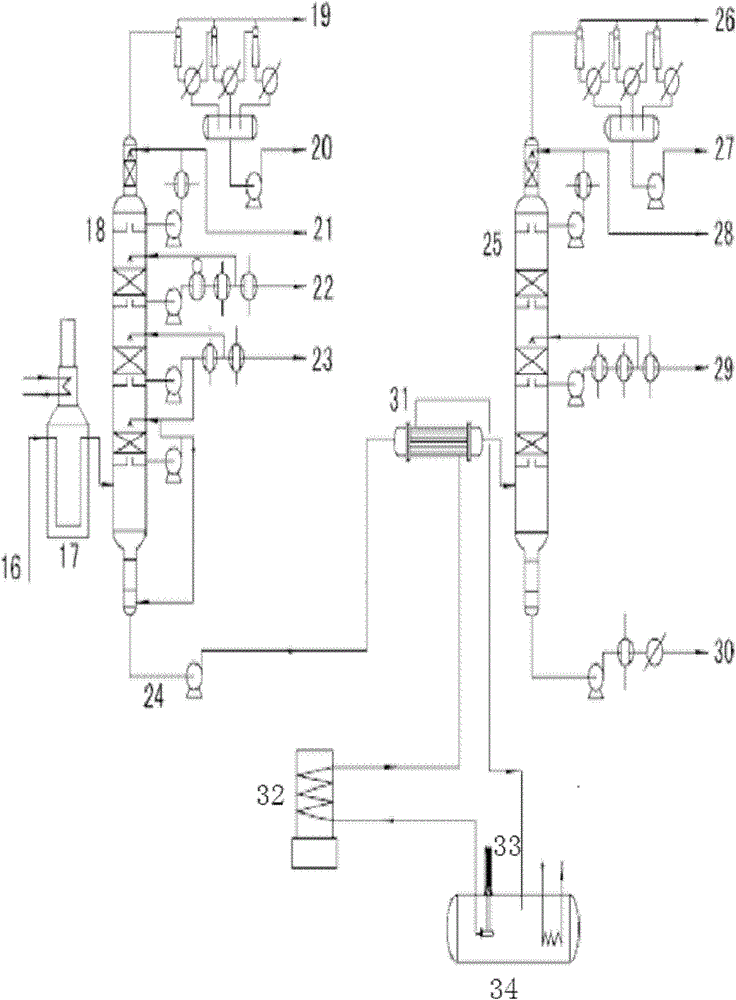

[0022] image 3 For the vacuum distillation part, two-stage distillation is adopted, and the heating furnace in front of the second-stage vacuum tower is changed to a partition wall heat exchanger for heat exchange between molten molten salt and petroleum feedstock, and the heating furnace in front of the first-stage vacuum tower remains unchanged. As shown in the figure, the atmospheric pressure tower bottom oil 16 enters the heating furnace 17 to be heated to 350°C-400°C and then enters the first-stage decompression tower 18. The absolute pressure is 10-100mmHg, and the temperature at the bottom of the tower is 345°C-390°C; the first-stage decompression tower 18 and the top pipe 19 are connected to the vacuuming facilities to extract the top gas and maintain the vacuum at the top of the tower. Diesel oil 20, first-stage decompression tower 18 can be provided with 3 to 4 side lines according to needs, the figure shows the situation of setting up 3 side lines, minus first-line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com