Gradient utilization device for heat energy in methanol rectifying process and utilization method of gradient utilization device

A technology of methanol rectification and thermal energy, which is applied in chemical instruments and methods, fractionation, preparation of organic compounds, etc., can solve problems such as high temperature of soft water tank, equipment corrosion, large heat loss, etc., and achieve reduced steam consumption and low operating costs , the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

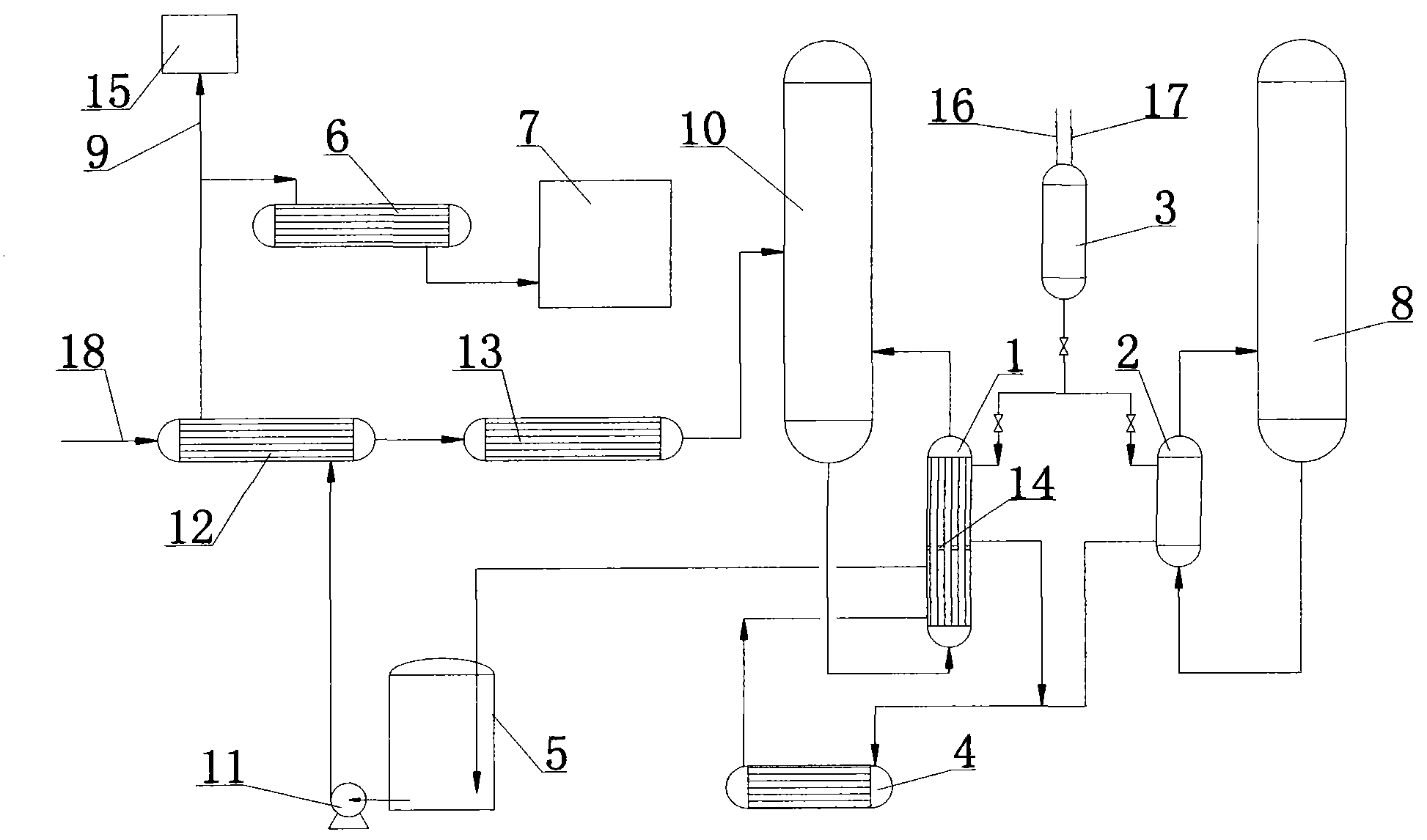

[0029] A method for utilizing a thermal energy cascade utilization device in a methanol rectification process, comprising the following steps:

[0030] 1. The low-pressure steam and the medium-pressure steam respectively enter the steam buffer tank 3 through the low-pressure steam pipeline 16 and the medium-pressure steam pipeline 17 for mixing to form mixed steam;

[0031] Two, the mixed steam described in step 1 enters the shell side of the upper part of the pre-column reboiler 1 and the shell side of the pressurized column reboiler 2 respectively for heat exchange, and after the heat exchange, in the tube side of the pre-column reboiler 1 The temperature of the methanol is 70°C, and the temperature of the methanol in the tube side of the pressurized column reboiler 2 is 125°C. After heat exchange, the mixed steam becomes condensate, and the temperature of the condensate at the shell side outlet of the upper part of the pre-column reboiler 1 is 72°C. ℃, the condensate temper...

Embodiment 2

[0039] A method for utilizing a thermal energy cascade utilization device in a methanol rectification process, comprising the following steps:

[0040] 1. The low-pressure steam and the medium-pressure steam respectively enter the steam buffer tank 3 through the low-pressure steam pipeline 16 and the medium-pressure steam pipeline 17 for mixing to form mixed steam;

[0041] Two, the mixed steam described in step 1 enters the shell side of the upper part of the pre-column reboiler 1 and the shell side of the pressurized column reboiler 2 respectively for heat exchange, and after the heat exchange, in the tube side of the pre-column reboiler 1 The temperature of methanol in the pressure column reboiler 2 is 127.5°C. After heat exchange, the mixed steam becomes condensate. ℃, the condensate temperature of the shell-side outlet of the pressurized column reboiler 2 is 125 ℃;

[0042] Three, the condensate of the shell-side outlet of the pre-tower reboiler 1 upper section described...

Embodiment 3

[0049] A method for utilizing a thermal energy cascade utilization device in a methanol rectification process, comprising the following steps:

[0050] 1. The low-pressure steam and the medium-pressure steam respectively enter the steam buffer tank 3 through the low-pressure steam pipeline 16 and the medium-pressure steam pipeline 17 for mixing to form mixed steam;

[0051] Two, the mixed steam described in step 1 enters the shell side of the upper part of the pre-column reboiler 1 and the shell side of the pressurized column reboiler 2 respectively for heat exchange, and after the heat exchange, in the tube side of the pre-column reboiler 1 The temperature of methanol is 75°C, and the temperature of methanol in the tube side of the pressurized column reboiler 2 is 130°C. After heat exchange, the mixed steam becomes condensate. ℃, the condensate temperature of the shell-side outlet of the pressurized column reboiler 2 is 125 ℃;

[0052] Three, the condensate of the shell-side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com