DMF (N,N-Dimethyl Formamide) rectification dehydration purification method

A purification method and rectification technology, applied in the field of separation and purification of substances, can solve the problem of DMF toxicity, and achieve the effects of reducing equipment investment, increasing feed temperature, and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

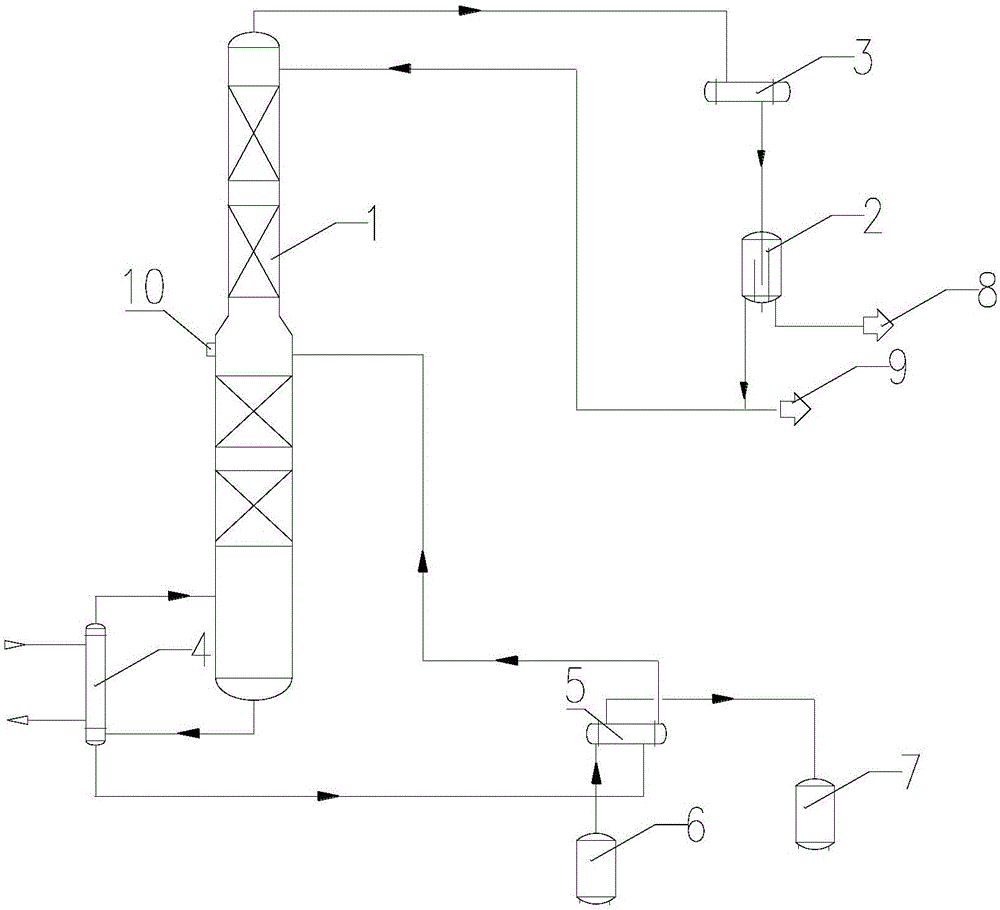

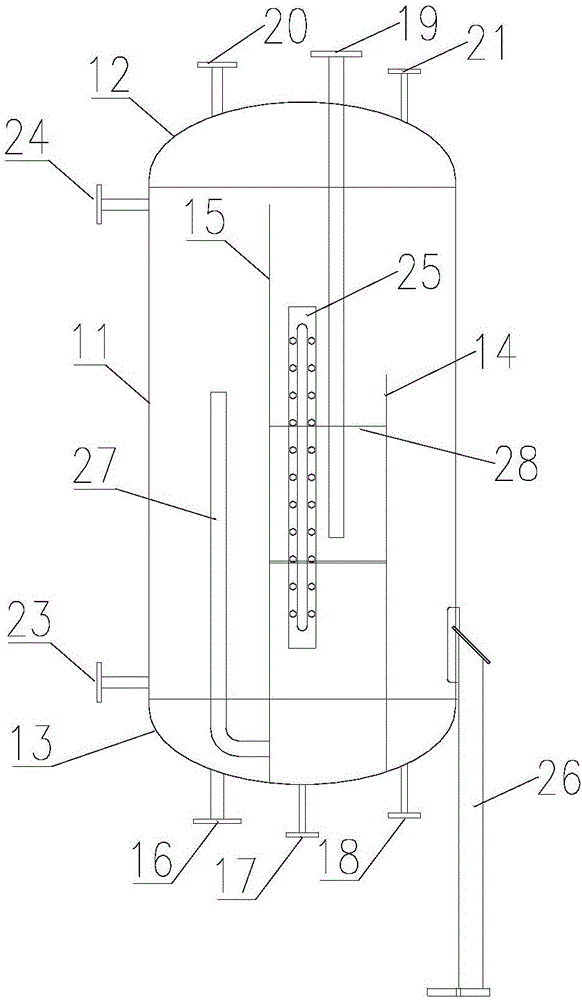

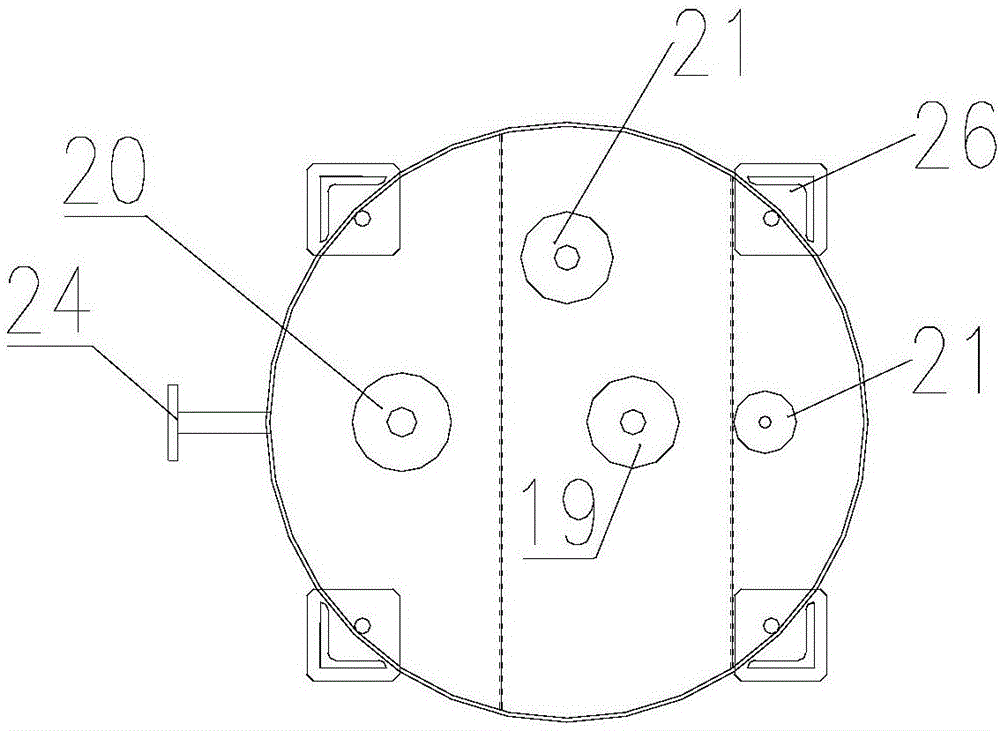

[0033] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention and not used to limit the scope of the present invention.

[0034] A DMF distillation dehydration purification method, the method includes the following steps:

[0035] (1) Blow nitrogen to replace air into the rectification tower 1, and then the raw materials enter the heat exchanger 5, exchange heat with the solvent extracted from the bottom of the rectification tower 1, and then feed from the middle of the rectification tower 1;

[0036] (2) The material falling into the bottom of the rectification tower 1 is heated by the reboiler 4 and rises to the top of the tower. The vapor at the top of the tower is condensed into liquid by the condenser 3 connected to the vacuuming device and enters the multifunctional tank 2;

[0037] (3) After passing through the phase separation in the multifunction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com