Method for making biomass waste carbonization environmental-friendly briquette coal

A technology of biomass and biomass pyrolysis, which is applied in the field of preparation of environmentally friendly briquettes from biomass waste carbonization, can solve problems such as low energy density, environmental pollution, energy waste, etc., achieve high energy recovery rate and reduce production costs , Good combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

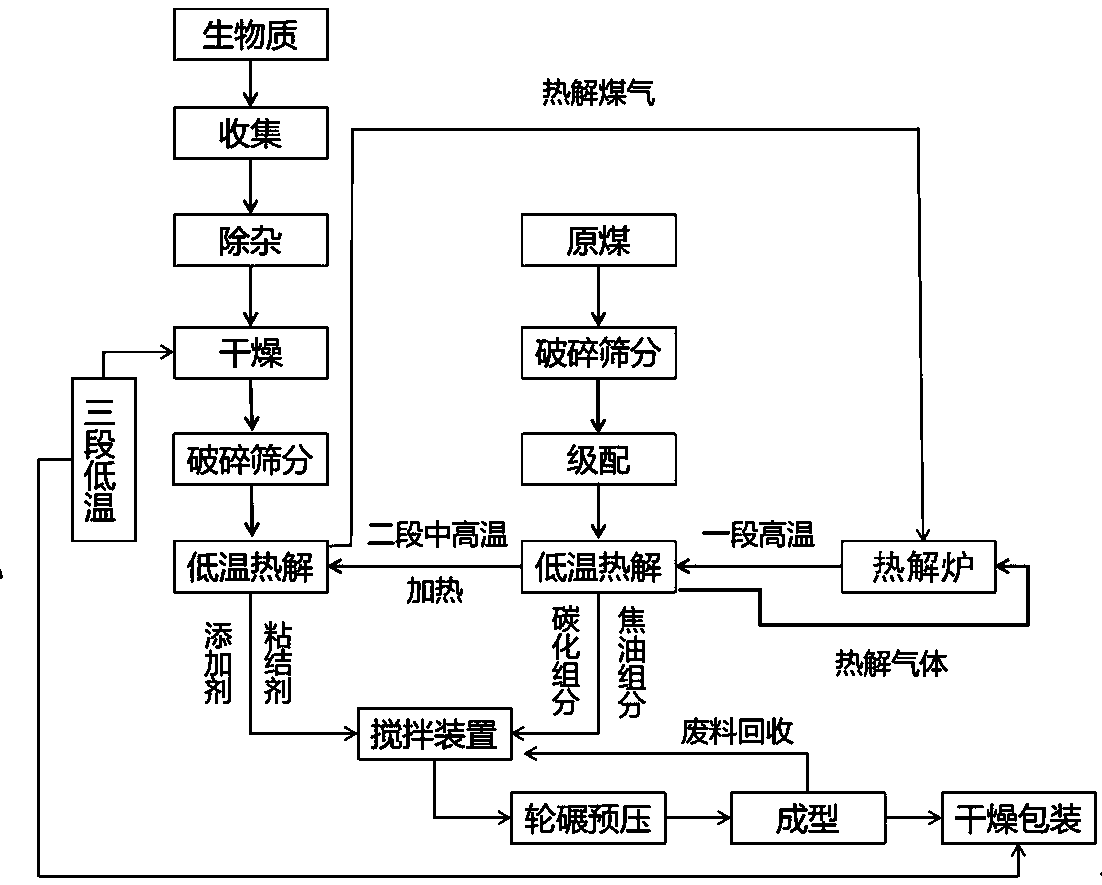

[0025] Such as figure 1 Shown, the preparation method of biomass carbonization system environment-friendly briquette of the present invention, its steps are:

[0026] a. The raw coal is crushed, screened and graded appropriately. According to the needs, the raw coal used includes low-rank coal, coal slime or high ash coal or mixed with each other. The reversible impact hammer crusher is used to crush and grind at both ends. The process crushes the raw coal to obtain raw coal particles with a particle size of less than 5 mm;

[0027] b. Feed the collected raw coal particles with a diameter of less than 5mm into the raw coal pyrolysis furnace and fill it with inert gas. The raw coal pyrolysis furnace generates a section of heat energy for low-temperature pyrolysis of the raw coal particles. The first section of heat energy is 400-600°C, Raw coal particles are thermally decomposed and converted into volatile gas components, carbonized components and tar components, the volatile ...

example 1

[0035] Example 1: After the crops are harvested, the crop stalks in the field are collected by a baler, and the collected stalks are separated by gravity and magnetic force to remove impurities such as iron and stones. After drying to a suitable moisture content at ℃, it is broken to less than 7mm. The crushed biomass that meets the particle size requirements is pyrolyzed in a nitrogen atmosphere at a temperature of 250-280°C, and the residence time is 20-30min. The low-rank coal is crushed by a reversible hammer crusher and then sieved by a vibrating screen and moderately graded. The graded raw coal is pyrolyzed in a nitrogen atmosphere at 420-540°C with a residence time of 30-40min. The volatile substances produced in the pyrolysis carbonization are collected as raw materials, and the oil can be used for forming and bonding. The carbonized coal and biomass are added to the mixing material stirring device at a mass ratio of 7:3-9:1, and mixed with the material The proportion...

example 2

[0036]Example 2: Remove impurities such as iron and stones by gravity and magnetic separation of wood scraps, and the straw after removal is dried to a suitable moisture content in three stages of low-temperature airflow at 100-120°C and then crushed to less than 5mm . The crushed biomass that meets the particle size requirements is pyrolyzed by heating the second-stage airflow after the pyrolysis coal to a temperature of 280-320°C in a nitrogen atmosphere, and the residence time is 20-30min. The low-rank coal is crushed by a reversible hammer crusher and screened by a vibrating screen. The raw coal is crushed by a reversible hammer crusher and screened by a vibrating screen with 2mm, 1mm, 0.5mm sieve plates and collected -0.5mm, 0.5- Coal with three particle sizes of 1mm and 1-2mm completes the gradation. The graded low-rank coal is pyrolyzed in a nitrogen atmosphere at 400-500°C, with a residence time of 30-40min. The volatile substances produced in the pyrolysis carboniza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com