Comprehensive utilization method of sweet sorghum straw and juice thereof

A technology of sweet sorghum stalks and sweet sorghum, which is applied in the field of comprehensive utilization of sweet sorghum stalks and their juices, can solve the problems of restricting the extension and development of the sweet sorghum industry chain, low comprehensive utilization rate, and low comprehensive utilization degree, and improve the comprehensive utilization rate. Utilization value, water saving, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

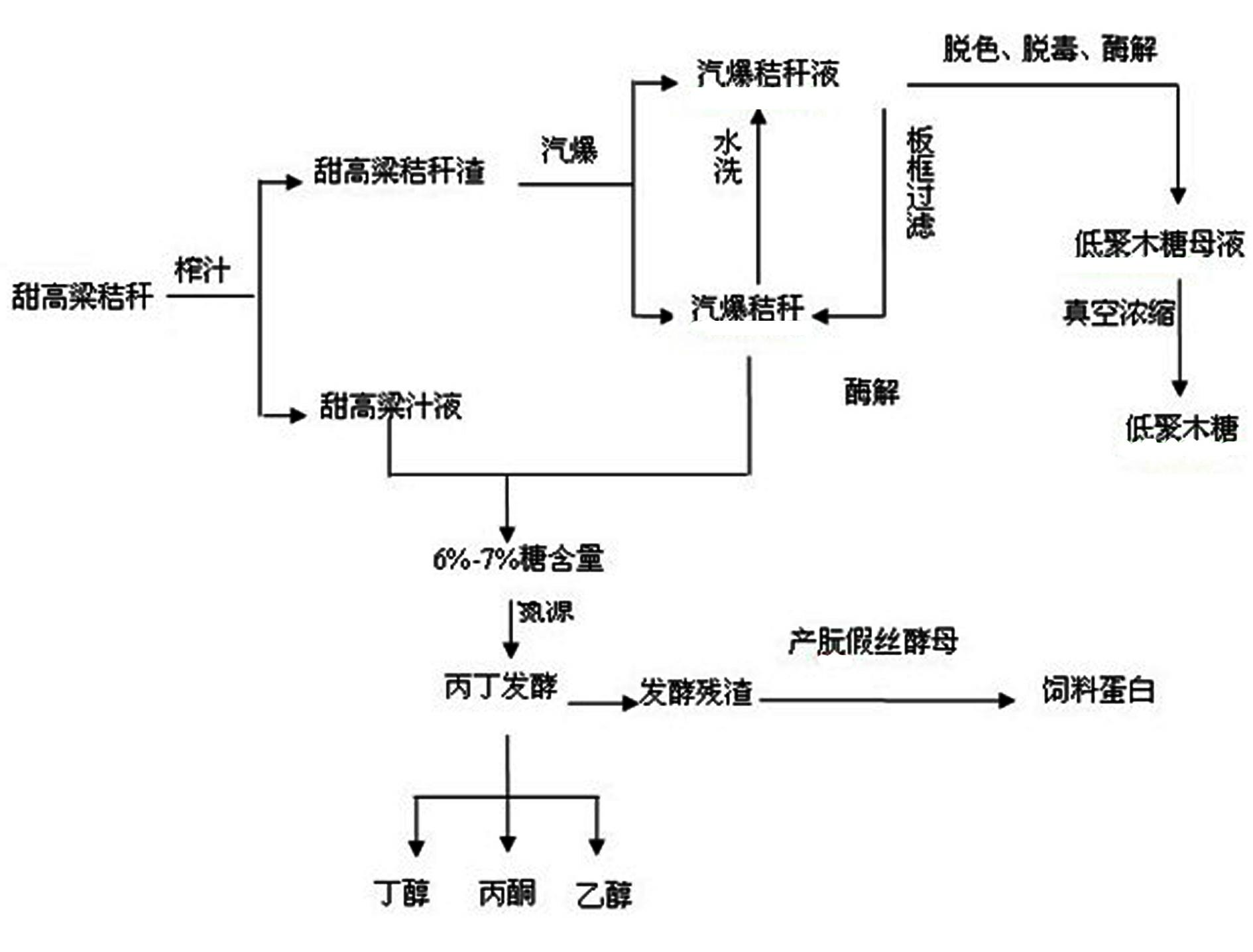

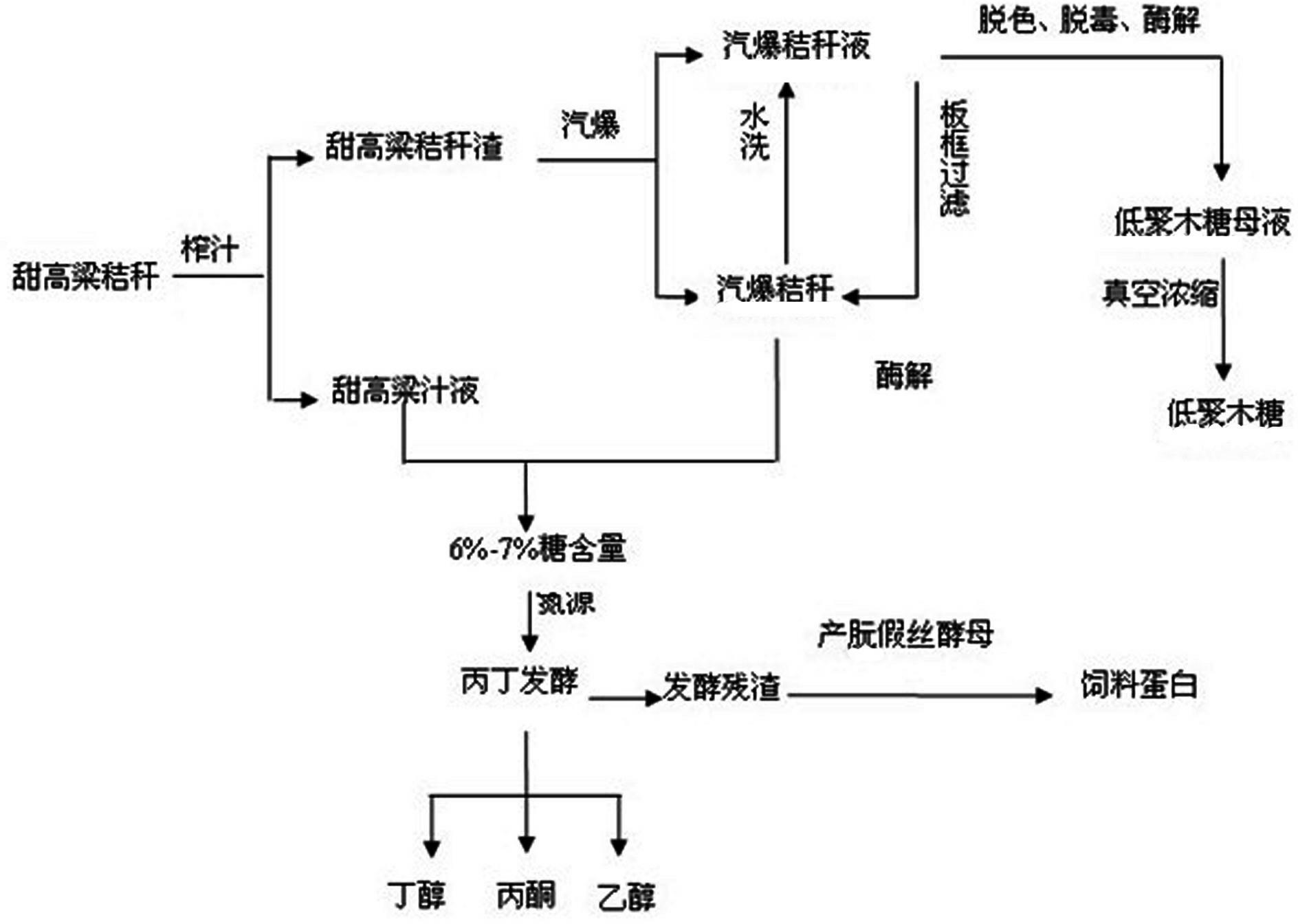

[0023] Such as figure 1 As shown, a method for comprehensive utilization of sweet sorghum stalks and their juices in the present invention comprises the following steps: first, take 5000 g of sweet sorghum stalks and use a three-roller juice extractor to squeeze the juice to obtain sweet sorghum stalk residue and sweet sorghum juice , the sweet sorghum straw slag was steam-exploded under the condition of 1.0MPa for 10 minutes to obtain steam-exploded straw liquid and steam-exploded straw; The straw liquid is combined, and then the steam-exploded straw liquid is filtered through an 80-mesh plate frame, and the filter residue is incorporated into the steam-exploded straw.

[0024] Enzymatically hydrolyze steam-exploded straw slag, the dosage of cellulase is 5FIU / g straw, carry out enzymatic hydrolysis at pH 4.8, temperature 50°C for 24 hours, and then carry out solid-liquid separation after enzymatic hydrolysis, the obtained enzymatic hydrolyzate and sweet sorghum juice Mix, th...

Embodiment 2

[0028] Such as figure 1 As shown, a comprehensive utilization method of sweet sorghum stalks and their juices of the present invention comprises the following steps: taking 5000g of sweet sorghum stalks and using a three-roller juice extractor to squeeze the juice to obtain sweet sorghum stalk residue and sweet sorghum juice, Sweet sorghum straw slag was steam-exploded for 5 minutes at a pressure of 1.5 MPa to obtain steam-exploded straw liquid and steam-exploded straw; the steam-exploded straw was washed with 20,000 ml of water at a water temperature of 60°C for 20 minutes. The eluate is combined with the steam-exploded straw liquid, and then the eluate from the steam-exploded straw is filtered through an 80-mesh plate frame, and the filter residue is incorporated into the steam-exploded straw.

[0029] The steam-exploded straw residue was enzymatically hydrolyzed, the dosage of cellulase was 10FIU / g straw, and the enzymolysis was performed at pH 4.8 and temperature 50°C for ...

Embodiment 3

[0033] Such as figure 1 As shown, a comprehensive utilization method of sweet sorghum stalks and their juices of the present invention comprises the following steps: taking 5000g of sweet sorghum stalks and using a three-roller juice extractor to squeeze the juice to obtain sweet sorghum stalk residue and sweet sorghum juice, Sweet sorghum straw slag was steam-exploded for 15 minutes at a pressure of 2 MPa to obtain steam-exploded straw liquid and steam-exploded straw; the steam-exploded straw was washed with 10,000 ml of water at a temperature of 58°C for 35 minutes. The eluate is combined with the steam-exploded straw liquid, and then the eluate from the steam-exploded straw is filtered through an 80-mesh plate frame, and the filter residue is incorporated into the steam-exploded straw.

[0034] The steam-exploded straw residue was enzymatically hydrolyzed, the dosage of cellulase was 8FIU / g straw, and the enzymolysis was carried out at pH 4.8 and temperature 45°C for 40 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com